UP Super Chassis: YOUPAO’s First Skateboard Chassis Product

On January 11, 2022, YOUPAO Technology released its first skateboard chassis product – UP Super Chassis.

Finally, I saw the long-awaited three words – “Metaverse” in a car industry related press conference. In my opinion, skateboard chassis is likely to be the core technology that opens the “Automotive Metaverse”.

Due to the epidemic situation, online social media has been vigorously developed. At the same time, we have deeply realized that many things do not need face-to-face communication. Online communication may be more efficient, but human beings still have a certain sentiment for “meeting” and “physical presence”. It now appears that “travel” still cannot be separated from the four basic needs of human beings: “clothing, food, shelter, and transportation”.

However, the Metaverse and transportation seem to be two opposite clues. Imagine that if one day people could completely realize face-to-face communication online through AR/VR and other technologies, or even move part of their lives into the virtual world, then it would be a disaster for the automotive industry.

Since they are two opposite things, why do I think that skateboard chassis technology can build the automotive Metaverse?

Because in the story of the skateboard chassis told by YOUPAO Technology, I found some business models that are very close to the “first stock of the Metaverse” ROBLOX. However, before starting the story of the Metaverse, we still need to understand what a skateboard chassis is.

What is a Skateboard Chassis?

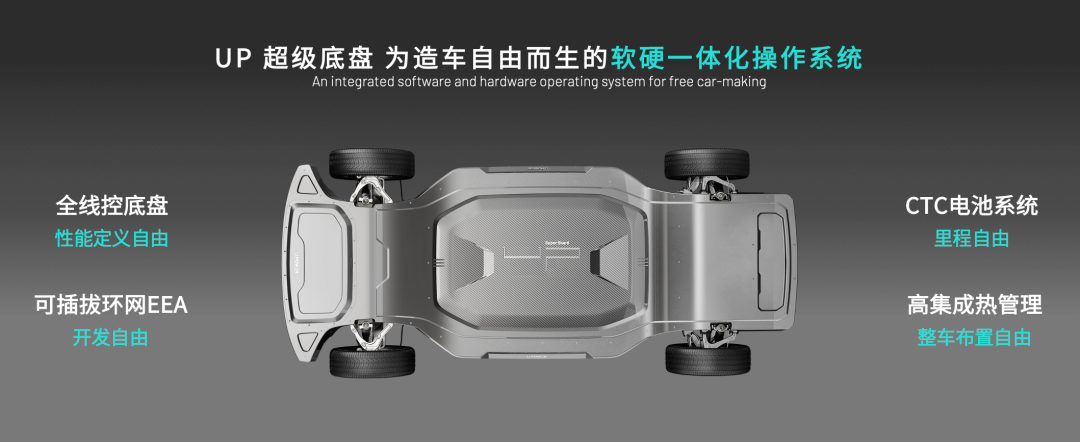

Taking YOUPAO Technology’s UP Super Chassis as an example, the four core elements of this technology are: fully controllable chassis, pluggable ring network electronic and electrical architecture, CTC battery system, and highly integrated thermal management system. The core ability of the skateboard chassis is to fully integrate all intelligent, electrical and traditional mechanical hardware and technology into the chassis structure, so that the vehicle cabin and the chassis can be completely separated and updated independently, or different types of vehicle body forms can be developed separately on the same chassis in the shortest time possible.

All-line Control Chassis: The communication mechanism between the driver and the chassis components on a car are the steering wheel, accelerator, and brake pedals. The technology of the all-line control chassis replaces the mechanical hard linkage of these two mechanisms with electrical signals, transmitting commands through wiring harnesses, similar to plugging a gaming controller into a console. This not only frees up space previously occupied by mechanical structures, but also completely severs the only connection between the cabin and chassis structure, achieving separate body and chassis development.

All-line Control Chassis: The communication mechanism between the driver and the chassis components on a car are the steering wheel, accelerator, and brake pedals. The technology of the all-line control chassis replaces the mechanical hard linkage of these two mechanisms with electrical signals, transmitting commands through wiring harnesses, similar to plugging a gaming controller into a console. This not only frees up space previously occupied by mechanical structures, but also completely severs the only connection between the cabin and chassis structure, achieving separate body and chassis development.

Plug-and-Play Ring Network Electronic Architecture: This technology is a crucial factor supporting the separate body and chassis development. Based on hardware standardization, the UP Super Chassis has standardized hardware interfaces in the VIU area to achieve software platformization, separating software and hardware and enabling asynchronous development. This allows for intelligent connection of the entire vehicle domain and ultimately provides users with a personalized experience. This makes the entire vehicle development more flexible and efficient.

CTC Battery Technology: The UP Super Chassis will adopt CTC (Cell to Chassis) technology, integrating battery cells directly into the chassis frame for highly integrated and modular designs. The battery compartment utilization rate can be increased by 10%, and compared with models of the same length, the range can also be increased by 10%, with a maximum range of 1000 kilometers. By eliminating the casing and structural components of the battery pack, the weight of the entire vehicle can also be effectively reduced. The UP Super Chassis can provide flexible and diverse combination solutions according to specific customer needs, including compatibility with mainstream CTP (Cell to Pack) and other different battery technologies, as well as the use of lithium iron phosphate and ternary lithium battery materials. Furthermore, it will also support solid-state and semi-solid-state batteries.

Highly Integrated Thermal Management System: In terms of thermal management, which is critical for range, the UP Super Chassis improves efficiency by concentrating the energy used for air conditioning and heating, saving the vehicle’s electrical power. The energy efficiency of the UP Super Chassis’ integrated energy management can be doubled, and winter heating energy consumption can be reduced by more than 70%. The modularity and integrative design can also free up more front cabin space for vehicle layout.

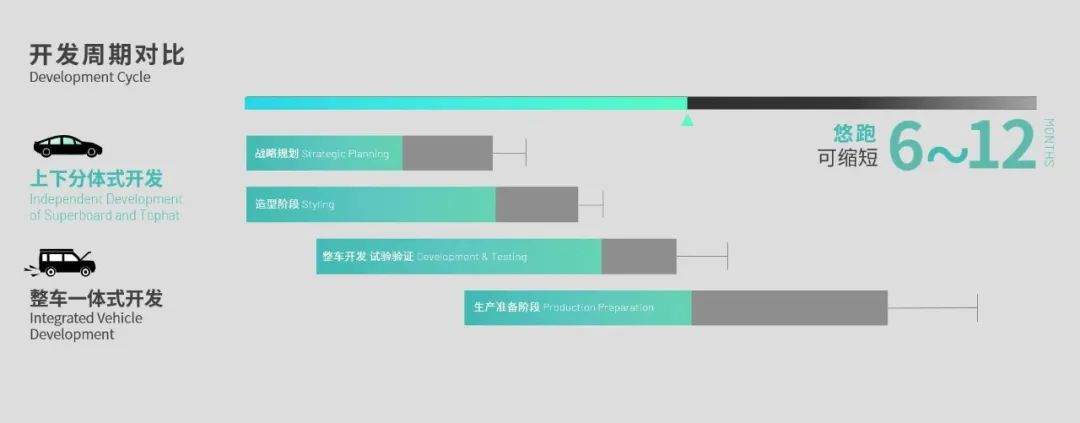

In fact, the skateboard chassis can be compared to the well-known modular platform structure, which breaks down chassis components into multiple parts, allowing the same modules to be shared across models with different wheelbases to shorten development cycles and reduce costs. The skateboard chassis not only integrates three electric systems, suspension, braking, steering, intelligent driving, and thermal management into a single entity, but also considers the advantages of modular platformization and can be packaged into a complete solution for companies with demand.

Therefore, Li Peng, the CEO of Yupao Technology, stated at the press conference that “in the future, Yupao Technology may not necessarily build cars by itself, but would like to help more car companies land their own products as soon as possible as a supplier.“

Of course, we can speculate that the car companies that Yupao may cooperate with in the future will mostly be new emerging companies, because Li Peng himself understands that the skateboard chassis is a technology that subverts the traditional whole vehicle manufacturing supply chain. There will be a lot of interests involved, and traditional car companies will find it difficult to focus on this technology in a short period of time.

Finding New Ways from ROBLOX’s Business Model

Roblox has been called the first stock of the metaverse. It was highly valued by capital in 2021 because it included the metaverse concept in its prospectus in March 2021. Currently, Roblox’s market value is $51.5 billion. In the third quarter of 2021, when the metaverse concept was the hottest, its market value once reached $70 billion, which is twice the size of “US Tencent” EA.

It is both a game, a game development tool, and a game platform similar to Steam. Its earliest positioning was educational games for young children. Later, simple development tools were implanted in the game, reducing development costs to one person or a small team.

It represents a typical UGC (User Generated Content) operating model. Players can build games with new worldviews and mechanisms by expressing their imagination on the platform. At the same time, they can directly sell them to other players through the Roblox platform and make profit through the game mall mode of purchasing props.

The essence of Roblox is to provide players with a creation platform. Their core competitiveness lies in group brainstorming, allowing a large number of users to quickly develop games based on the platform’s capabilities to express their ideas, attract more players, and profit from it.

This is very similar to Yupao Technology’s business model. Li Peng stated at the press conference that “UP Super Chassis provides car makers with a first-class smart electric vehicle “base” as a platform-type integrated software and hardware operating system, with a range of over 1,000 kilometers and computing power of over 1,000 TOPS to meet the needs of future L4 and above autonomous driving. Car-making players can focus more on the styling, space, and intelligent user experience and operations. This is also the significant value of UP Super Chassis, which achieves extreme user personalized with extreme standardization and helps industry transformation speed up.”

UP Super Chassis is a platform that makes it very easy for car manufacturers to think about how to make more innovative designs and features in the cabin space, how to create products tailored to specific driving scenarios, and how to better serve their users.

In the future, making cars may no longer require a team of thousands of people. The entry barrier for car manufacturing has been greatly lowered by the introduction of the skateboard chassis, as most of the engineering and manufacturing problems can be solved with this complete technology. Boldly imagine, it is very likely that a small team of a few hundred people could quickly develop a popular product with creative thinking relying on the capabilities of the skateboard chassis.

All is ready, except the east wind

YUPAO is the first domestic enterprise that can provide solutions for skateboard chassis, but in the international market, this technology has been applied to their own products by some companies, such as Rivian and Canoo, which are also automotive start-ups. Unlike the latter two, although YUPAO announced five conceptual products at the press conference, they only clearly stated that they would help car manufacturers as suppliers, and did not have the intention of personally manufacturing cars.

Obviously, this technology of skateboard chassis is now in a state of accumulation, but whether it is done through the supplier method or personally manufacturing cars, enterprises that focus on the skateboard technology still need a commercial order or considerable sales. Impressive technology is only one aspect, and commercial success is the east wind needed to ignite a prairie fire.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.