*This article is reproduced from the WeChat account autocarweekly

Author: Ao Ao Hu

No matter how powerful you are, if your knee is shot, you have to kneel down.

Before a broken axle, all gods are equal, and Tesla’s magic no longer works. It’s time for a recall. In China, 21,599 Model Ys were recalled, while across the ocean, 826 were recalled. This is not the first time Tesla has issued a recall due to suspension issues. Last year, imported Model S and Model X were recalled to replace the suspension link.

But this time, the scale of the recall is larger, and the defect is more specific – to the extent that the supplier (Topre Group) is directly named.

A piece of not-too-cold trivia: the so-called “broken axle” rarely involves the actual “axle.” This was mentioned by Hu in “I Once Knew Nothing About ‘Wheels’.” Nowadays, the drive shafts of passenger cars do not bear any tasks except power transmission, and it is the suspension system that is responsible for fixing the position of the wheels. Conversely, if the front or rear drive shafts are removed from an all-wheel-drive model, the side that becomes a non-drive axle will not collapse.

This time, the knee of Tesla Model Y that was shot is the steering knuckle.

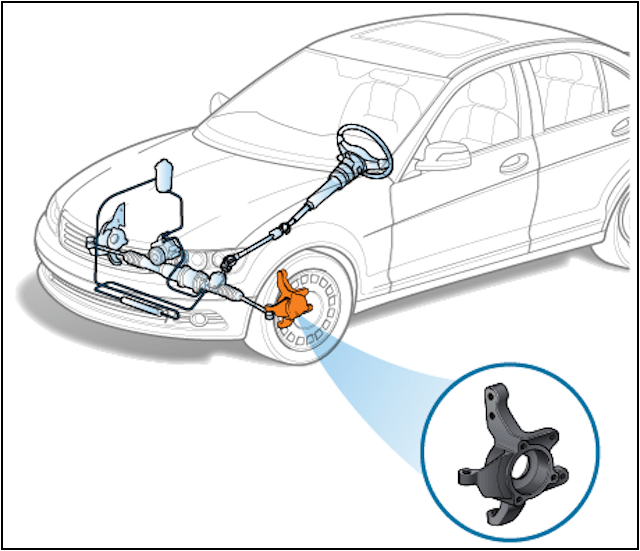

The so-called steering knuckle (Knuckle), more commonly known as the “goat horn”, gets its name from its look like goat horns when it is flailing about. Plainly speaking, the steering knuckle is the final part that connects the wheel rotation part, and its inner side is composed of non-rotating parts such as suspension links and springs, and its outer side is composed of rotating parts such as the wheel hub and brake disc.

Because the direct effect of the steering system on the front wheels is on this part: the steering tie rod pulls it to the left and right, causing the wheels above it to turn left and right, thereby achieving the vehicle’s steering function. Although the rear wheels do not have steering function, they also have this thing, which we also call the steering knuckle – the “steering” knuckle that cannot steer. However, with the rise of rear-wheel steering systems, the rear steering knuckle will soon live up to its name.

In the model above, the blue component is the steering knuckle. Note that there is no drive shaft in this model, so it can be regarded as the front axle of a rear-wheel drive car. If it is a front-wheel or all-wheel-drive model, the drive shaft will pass through the center of the steering knuckle connecting the wheels (the position that needs to move due to steering will be connected by the universal joint).The reason why the steering knuckle looks like a horn is because all the links of the suspension system need to be connected to it. In order to achieve the geometric shape designed for the suspension links, the connection points on the knuckle sometimes need to “extend out”, thus forming its complex shape. In simple terms, the knuckle is a strange-looking metal lump with a bunch of connection points on it.

According to Tesla’s recall statement, insufficient strength of the steering knuckle may cause deformation or fracture, resulting in the “suspension link coming off the steering knuckle”. This happened several times in North America, mainly due to deformation of the steering knuckle, which caused the connection between the suspension link and the knuckle to break and come loose.

However, the recent case of a broken axle on a Model Y in China is a different situation. From the photo, it can be seen that the other end of the suspension link, which is connected to the body (subframe), came off. There was no damage to any of the major components, only the fastening screws of the link sleeve (used to secure the link to the subframe) came loose from the screw holes, causing the link to separate from the subframe. It even seems that the bolts could continue to be turned after being removed (face palm).

This method of axle failure does not match Tesla’s announced steering knuckle problem. One possibility is that the link was subjected to unreasonable stress on the body (subframe) connection end for a long time due to the deformation of the steering knuckle, which eventually led to the bolt coming loose (but the intact bolt is somewhat strange). Another possibility is that this axle failure case is unrelated to the steering knuckle, and there are other potential factors that may cause the Model Y to break (such as the owner’s suspicion that the bolts were not tightened).

Tesla shifted the blame to the supplier, Ningbo Tuopu Group, a A-share listed company. According to Tuopu, during the production process of the steering knuckle, the quenching tank had insufficient water level, causing some products to not be immersed in quenching liquid, thus leading to performance issues.Translate the following Markdown text in Chinese into Markdown text in English, in a professional way, keeping the HTML tags inside Markdown and only outputting the result:

Quenching is a type of heat treatment in metal material processing. In plain language, quenching refers to heating the material to an extremely high temperature, then soaking it in water to cool it quickly. For steel, this operation changes the arrangement structure of atoms, transforming austenite into martensite, greatly improving the strength and hardness of the steel. That’s why when automakers say “hot-formed steel,” they often mean “high-strength steel,” as hot-forming is the main means of achieving high strength.

However, Tesla’s steering knuckles are not made of steel but of aluminum. The process of quenching aluminum alloys is different from that of steel. After quenching, they must also undergo aging strengthening technology, but the ultimate goal is still to increase strength and hardness. Therefore, the faster the aluminum material is quenched, the better.

If what Top Group claims is true, that the water level in the quenching tank is insufficient and the parts are not fully immersed, then the cooling speed during quenching will naturally be affected. Also, the cooling speed of each part of a single component will be different. Ultimately, this results in the finished product’s strength not meeting the requirements, and the strength of various parts of the finished product being uneven.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.