As battery size, motor power, and fast charging power increase, the protection capability of high-voltage systems in terms of covering different operating currents and short-circuit currents has become the main criterion for evaluating the excellence of a design.

From a deeper perspective, there have not been many high-voltage issues accidents in electric vehicles at present, but the situation will change in the future. On the one hand, the status of charging stations is distributed (DC charging includes old and new high-power charging stations). On the other hand, from an investment perspective, iron knots like BDU and PDU are not worth investing in. Therefore, the evolution of the protection systems inside involving DC contactors and fuses is worth our attention.

Note: the overall engineering pace and practicality require a lot of time. I understand that there are many breakthrough ideas in this field.

Eaton’s Thinking

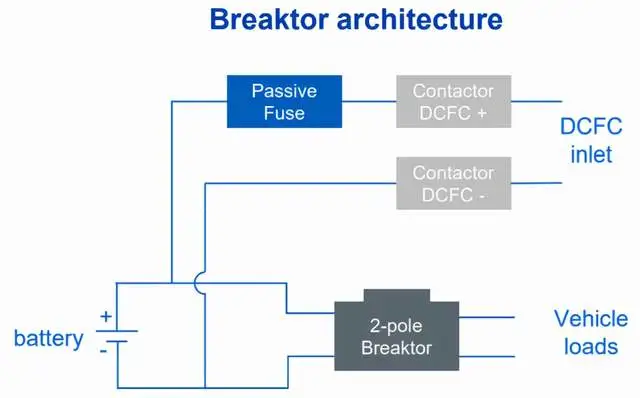

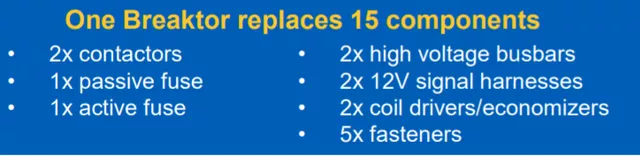

Eaton starts with a thorough transformation, as shown below, and considers the entire replacement approach.

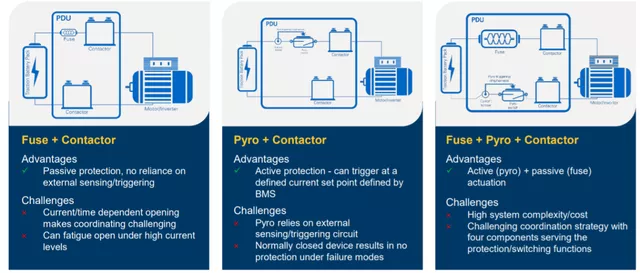

I have discussed this with many friends before, which may not be thorough. Now you can compare it by looking at this picture. There are actually several existing solutions:

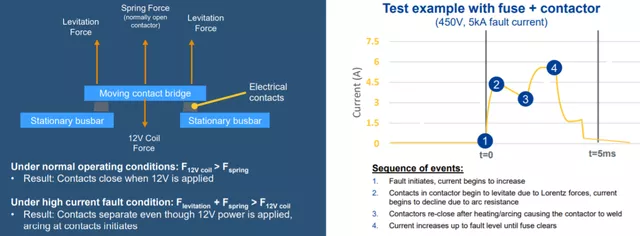

- Traditional fuse + contactor: passive protection. The biggest challenge is the difficulty in matching the current and contact action. Some high-current short-time points are corroded, which will cause the contactor to stick and make the fuse unable to operate.

- Pyro fuse + contactor: active protection. The main problem here is how to control the Pyro.

- Traditional fuse + Pyro fuse + contactor: everyone has adopted this one for active and passive safety control at 800V. The disadvantage is that the cost is relatively high, and the overall protection strategy’s action mechanism is also relatively complicated.

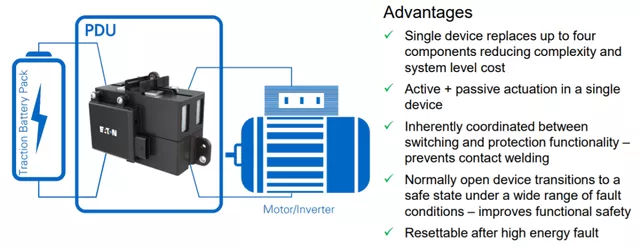

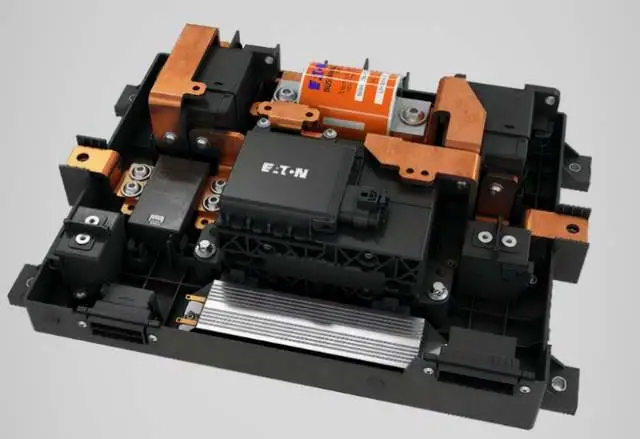

Although Eaton’s solution sounds concise, it still relies on industrial technology circuit breakers to implement the fourth solution in the design.

This approach uses a circuit breaker and traditional fuse to implement, and the advantages are as follows. The overall solution looks relatively simple.

Translate the following Chinese Markdown text into English Markdown text in a professional manner, retaining the HTML tags inside the Markdown and outputting only the result:

Translate the following Chinese Markdown text into English Markdown text in a professional manner, retaining the HTML tags inside the Markdown and outputting only the result:

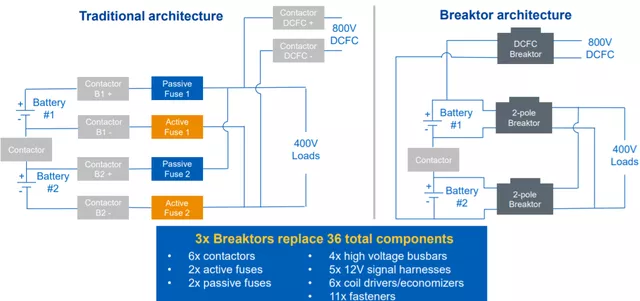

At present, there are still some overseas solutions that are connected in series with 400V and 800V (e.g. some heavy-duty trucks are designed this way), where there are cases with 800V charging and 400V driving, i.e. using two 400V batteries in parallel for driving and handling charging in the 800V area, which requires the use of three breakers.

Comment: In my personal judgment, this breaker-based design presents significant challenges in arc extinction and may not be able to disconnect.

PSM New Generation Circuit Breaker

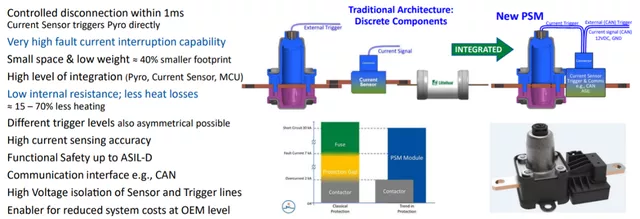

With the development of electric vehicles, companies around the world are investing in this area. Littelfuse Inc. and ASTOTEC (formerly Hirtenberger Automotive Safety) have established a joint venture called PYTIC (Pyro Technology for Intelligent Circuit Disconnection).

From Pyro’s design perspective, it mainly includes two parts of knowledge, current detection and electric drive, as well as a pyrotechnic-driven circuit breaker. The solution proposed by PYTIC is an integrated pyro safety module that combines current detection and control.

The length of this article is relatively long, so I’ll just introduce it briefly for now. In a subsequent article, I will focus on this topic. Players in this market may gradually enter and simplify the design of the BMS, and the safety protection function of the overall BMS will be gradually decomposed.

Summary: I believe that the ability to truly create value lies in engineering and technological capabilities, rather than in so-called demands. Demands need to be identified and broken down, and then fine capabilities need to be used for decomposition. In my opinion, there is still much room for improvement and development in this field.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.