Twitter user ALEX made some design assumptions and projections based on Tesla’s Battery Day, the opening day of the Berlin factory and Tesla’s patents.

I’ve extracted some of these graphics to show you and will share my own thoughts below.

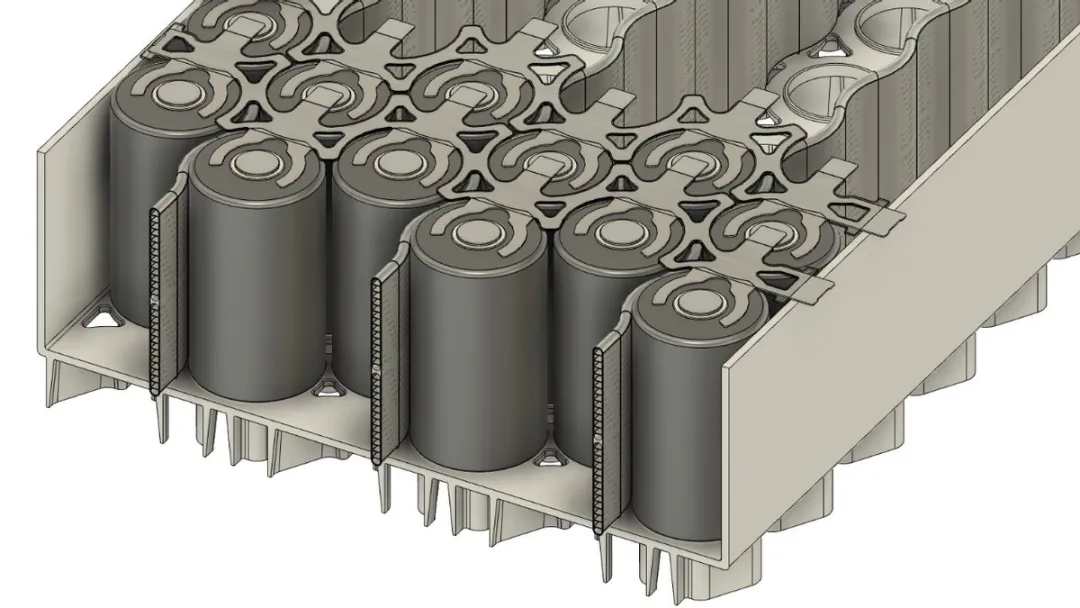

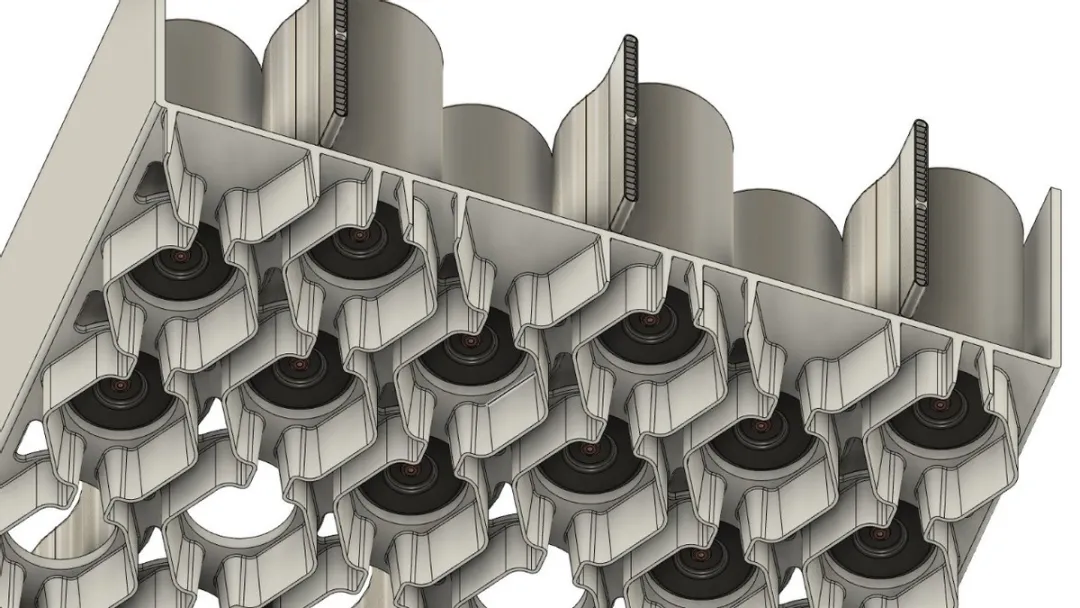

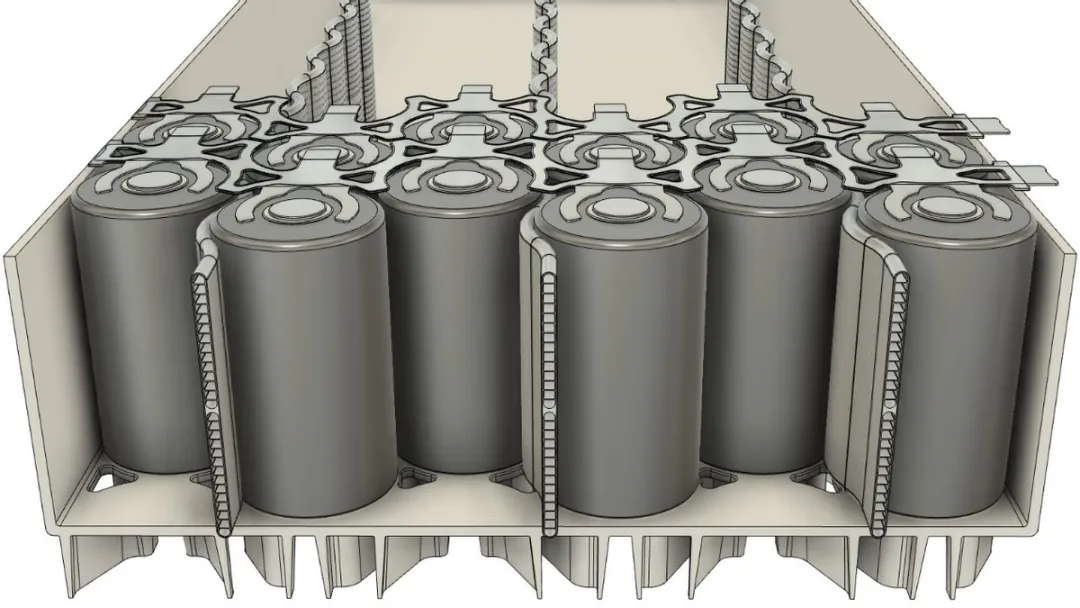

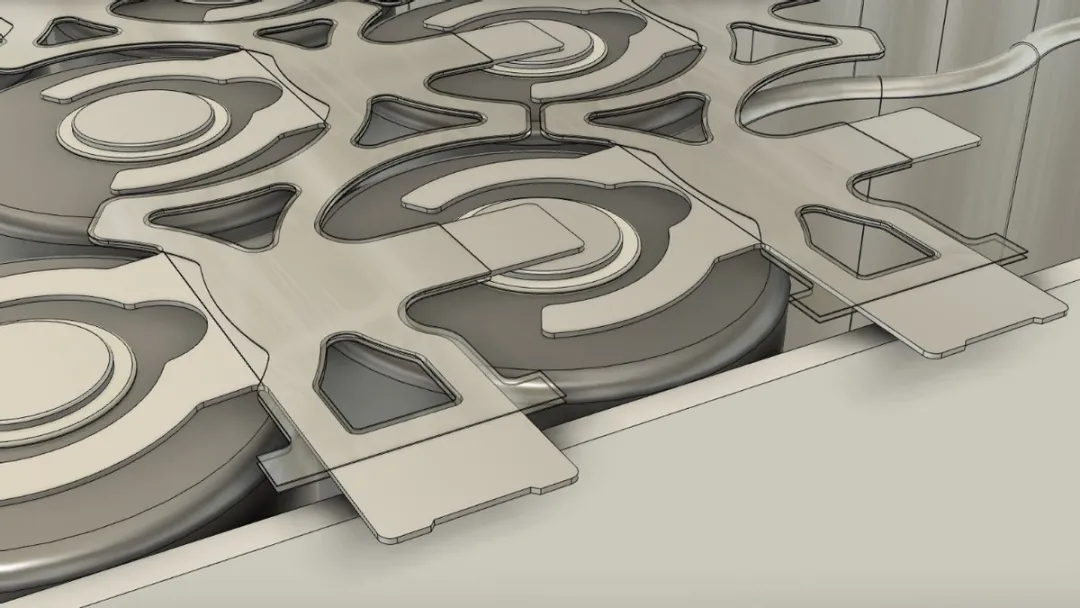

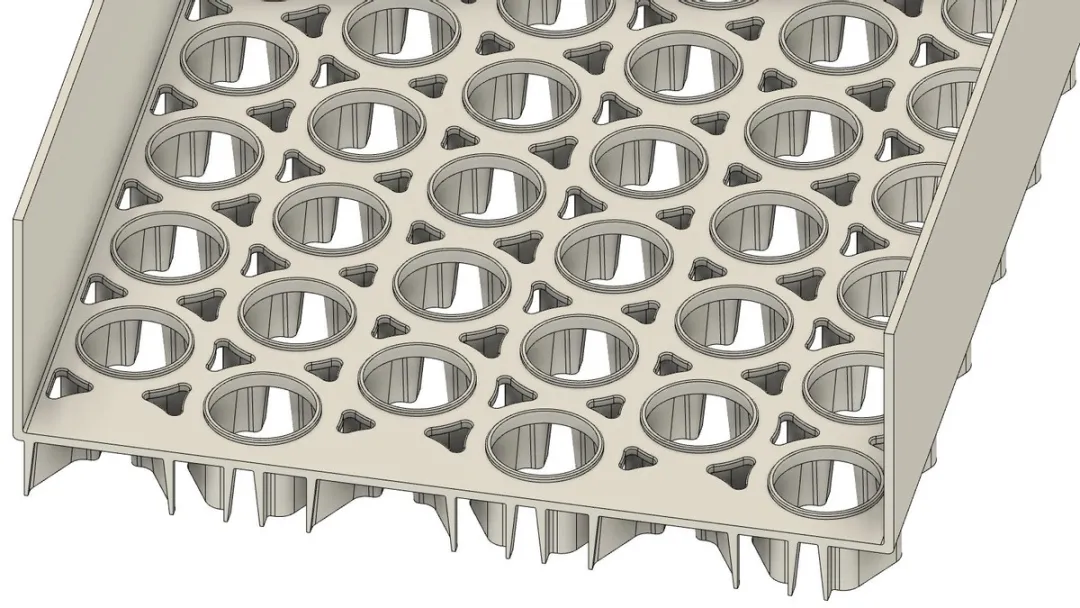

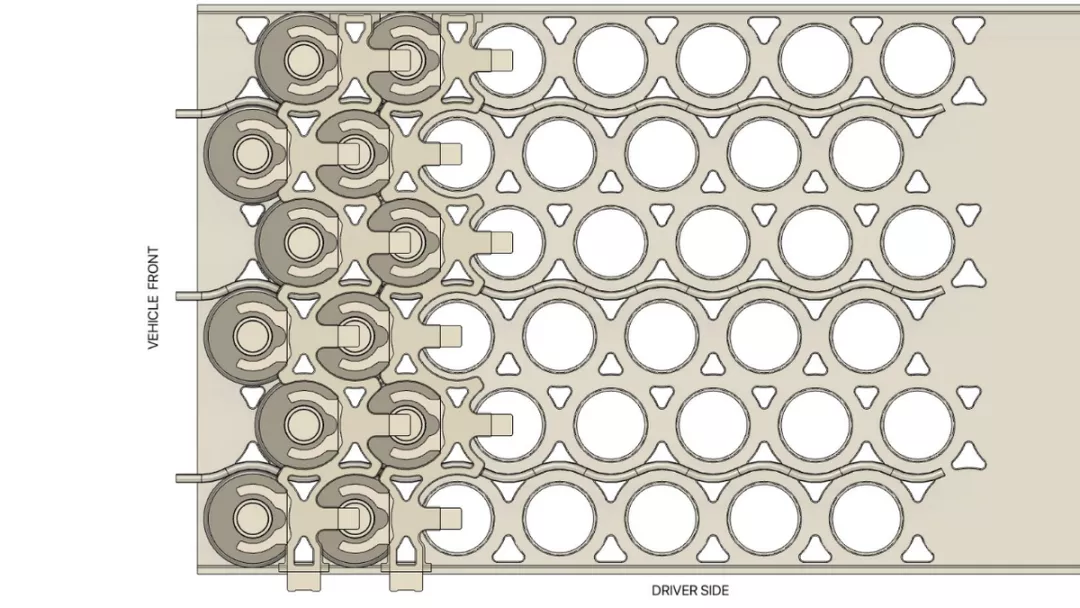

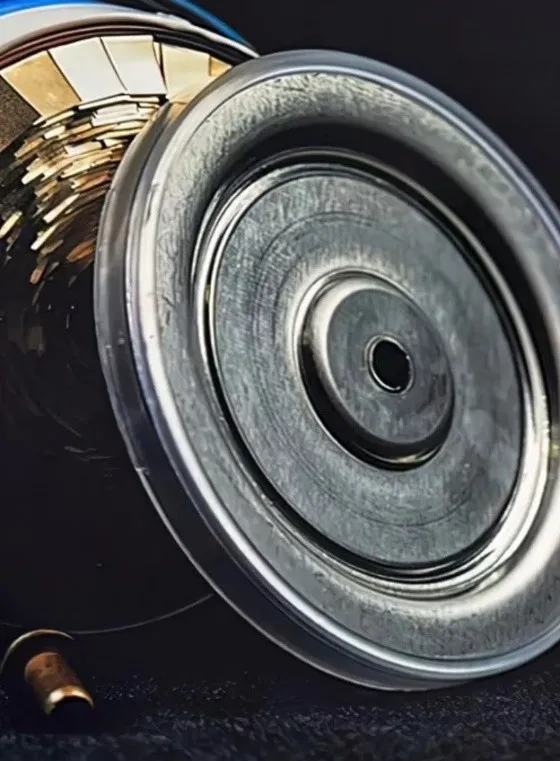

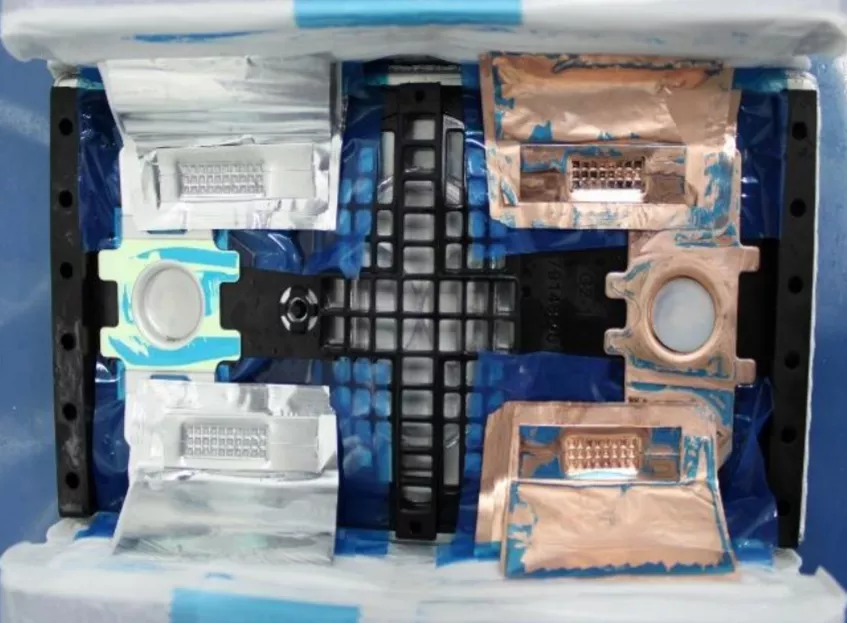

Design of the 4680 Battery

My Thoughts on the 4680 Battery

(I’ll try to make a video here later)

I have recently received a lot of questions, and I think I can list them as follows:

(1) Does the cylindrical battery have advantages over the square shell under high nickel content?

I think mainly in the absence of large-area contact, the overall design is better for doing some thermal runaway control, and the same CTC square shell is more difficult to handle.

(2) Can the 4680 large cylindrical battery be made into a lithium iron version?

Yes, a global leading OEM thinks this way, making an ultra-low-cost solution.

(3) Why did BMW, who knows about the square shell battery, switch to the cylindrical battery in the sixth generation of batteries?

From my understanding, BMW actually has both square shell and cylindrical camps, and the core difference depends on the standpoints of each technician. The iNext and i4 mode of making small square shell batteries of 4P and 5P instead of large square shell batteries is fundamentally no more convenient than cylindrical batteries.

(4) Differences between CTP and CTC import and battery differentiation?From the current perspective, CTP has achieved great breakthroughs in breaking the boundaries of VDA355, 390, and 590 by focusing on structural innovation, but it is essentially a structural change, which then achieved the strategic goal of the battery factory entering Pack manufacturing and taking the entire package back to the customer.

The strategic goal of CTC is actually to strictly link battery production and vehicle production, so it is foreseeable that Ningde needs to build a battery factory for Tesla in Lingang to ensure the progress of CTC.

(5) The era of large cylindrical batteries and the struggle of new players

The breakthrough of large cylindrical batteries may actually overthrow the era of prismatic cells for several reasons:

1) In the 18650 era, cylinders were a standard product, and the transition to 21700 indeed iterated much faster in terms of power, developed towards larger capacity, and the usability of this type of battery can promote many fields, which means that in the era of prismatic cells, Ningde is a monopoly. However, when faced with this high-quality standard product, Panasonic, LG, SDI, and SK from overseas can all produce it, and China’s EVE Energy is also following suit.

2) In the era of large prismatic cells, optimizing the shells of several cells and turning them into a winding in parallel. Ningde adopted this approach, which actually widened the gap between it and its prismatic shell competitor, SDI and Panasonic, reduced costs significantly, and formed tremendous cost pressure on LG Chem. This is a strategic capability!

However, compared with the 4680 Cascade, the biggest flaw in this solution is that, under similar cost conditions, fast charging cannot be achieved- this design basically puts the bottleneck of fast charging in the battery, and the impedance on these tabs is difficult to reduce. If consumers not only have a demand for endurance mileage (Ningde actually contributed to the global promotion of endurance mileage), but also have requirements for charging experience in the future, I think the original advantage will become a disadvantage.

In summary, in the long run, with Tesla’s entry into the 4680 and impacting the entire pattern, challenges are posed to the entire dynamic battery around the VDA prismatic era. This is what I think needs to be observed most at the technical level. The next revival stage of soft packs is either transformed into short and long blade module, or waiting for solid-state.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.