A friend asked me about this composite fluid technology some time ago. After investigation, I found that there are two applications of this technology that are worth sorting out:

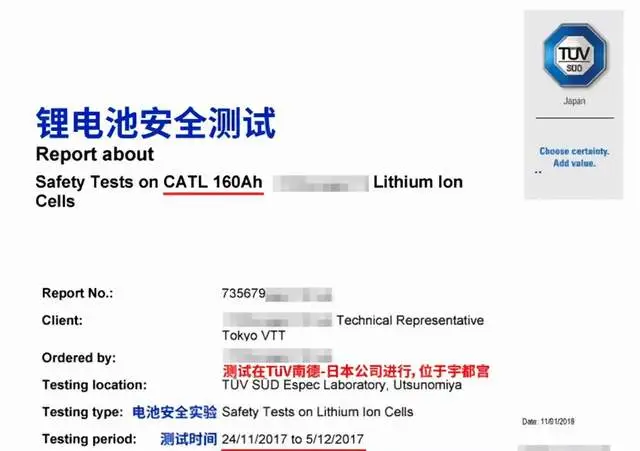

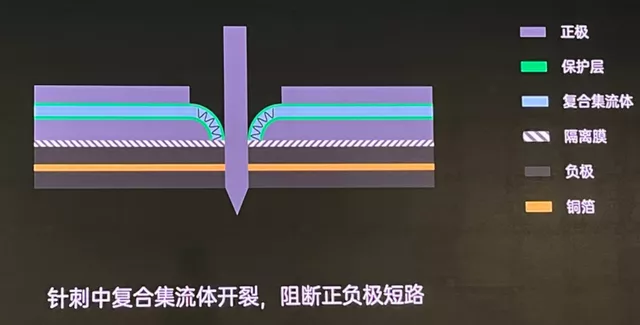

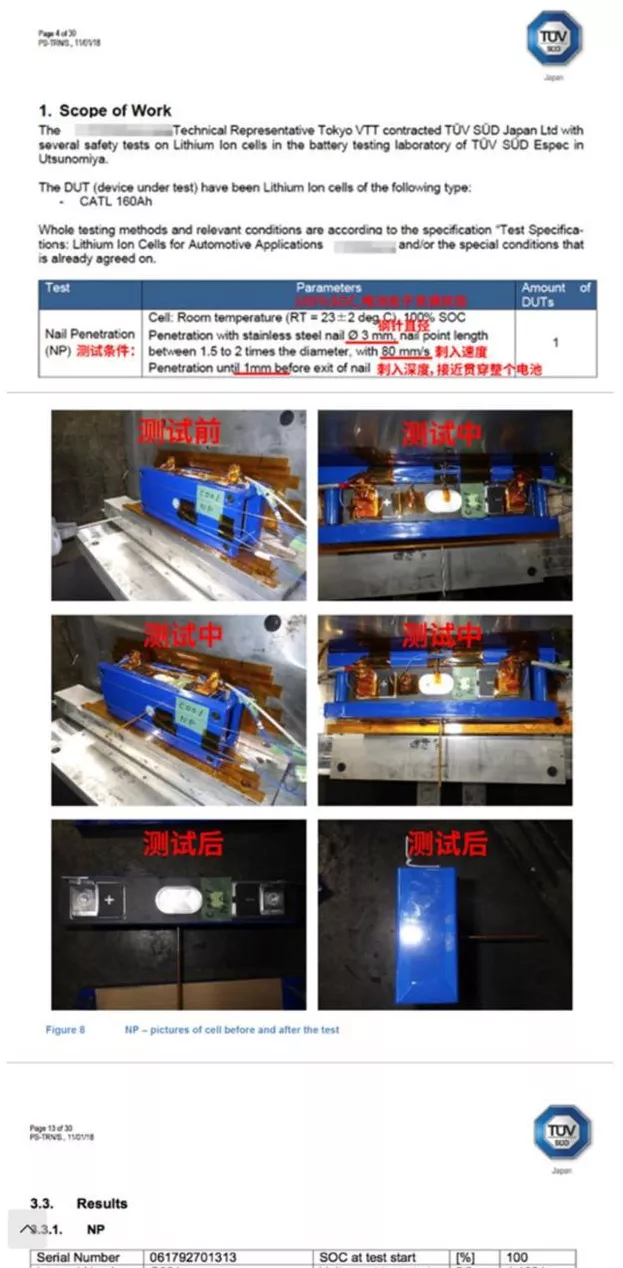

(1) Power battery: In C’s application for the Hainan New Energy Conference, it mainly includes a “metal conductive layer-polymer support layer-metal conductive layer” sandwich structure composite fluid technology. There are many descriptions here, but no pictures. The application material uses a VW needle-penetrating battery cell as an example.

(2) Consumer battery: This is OPPO’s battery in July. I think that the development of power batteries and energy storage can also be related to the development of mobile phone batteries. Both silicon doping and composite fluid technology are available. In OPPO’s design, a new type of composite polymer material is used as the matrix, and two layers of aluminum are specially plated to form a three-layer sandwich structure fluid collector. Compared with traditional aluminum foil fluid collectors, its reliability is higher, and it can better avoid positive and negative electrode short-circuits. With two safety coatings on the upper and lower sides, the final five-layer safety structure is formed.

First, let’s sort out these materials:

OPPO’s composite fluid technology

OPPO released this battery technology at the “Flash Charge Open Day” in July. This technology is named “sandwich safety battery” and is aimed at the safety of the battery cell itself and the safety of charging technology. It uses a new type of polymer composite material as the base, plated with two layers of aluminum, and coated with safety coating to form a five-layer safety structure sandwich fluid collector.

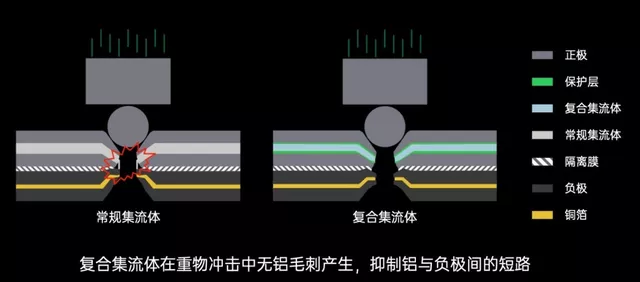

When the battery is subjected to external compression and collision, the five-layer fluid collector of this structure can greatly reduce the probability of internal short-circuit of the battery. The polymer material in the sandwich layer can also isolate the positive and negative poles. OPPO demonstrates the difference between normal fluid collectors and composite fluid collectors through two demonstration methods: external impact and needle penetration.

Composite fluid collector technology by C Company

I will simplify the contents of the declaration material:

1) Safety

Aluminum foil was used to simulate the short-circuit of the internal battery through thermal-mechanical load interruption. Vacuum gas deposition technology was introduced to construct a sandwich structure of “metal conductive layer-polymer support layer-metal conductive layer” for the composite fluid collector. By utilizing the multi-coupling relationship between the mechanical, electric and thermal properties of the metal layer and the polymer layer:

In the case of “point contact” short-circuit, the conductive layer cracks and peels off under force at the short-circuit point, or melts instantly with high current, cutting off the short-circuit current circuit in milliseconds;

In the case of “surface contact” short-circuit, the support layer collapses partially into collector structure under thermal melting and shrinking at the short-circuit surface, cutting off the short-circuit current loop before thermal runaway.

With this design, the problem of short-circuit in high nickel batteries has been solved, and the industry problem of batteries easily causing thermal runaway due to internal short-circuit has been completely solved.

2) Life and reliability

Integrated nano-riveting and three-dimensional conductive repair technology, which improves the bonding force between the metal layer and the polymer layer by 10 times, while repairing the conductivity attenuation caused by cracks on the metal layer surface, achieving a 15-year lifespan. Compared with metals, polymer materials have a low elastic modulus and can form a layered ring-shaped sponge structure around the active material layer inside the battery, absorbing the expansion-contraction stress generated by the lithiation and de-lithiation of the active material layer, maintaining the long-term integrity of the electrode interface, and achieving a 5% increase in the battery’s cycle life.

3) Process and manufacture

The in-situ passivation and continuous roll welding process and equipment have been developed to solve the shortcoming of difficult material and structural subversion in scaling up production of the collector fluid collector. The production rhythm can reach 20ppm.

4) Increase energy density

The intermediate layer of the composite fluid collector uses lightweight polymer materials, reducing the weight ratio of pure metal fluid collectors by 50%-80%. Meanwhile, the thickness of the composite fluid collector is reduced by 25%-40% compared with that of pure metal fluid collectors in the industry, thus giving more space inside the battery to the active material. Traditional pure metal fluid collectors can account for up to 15% or even more of the weight of the battery. As the weight proportion of the composite fluid collector decreases and the proportion of the active material inside the battery increases, the energy density of the battery can be increased by 5%-10%.

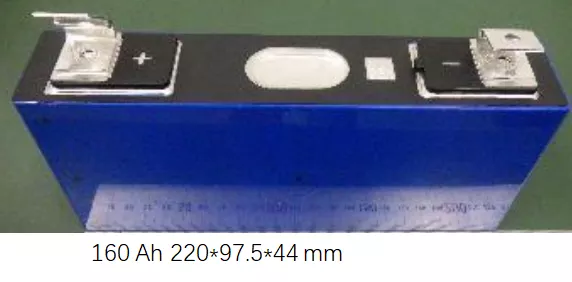

As shown below, this figure is the product that C Company presented when it was in the spotlight. I think this technology is very important for the long-term cost advantages of future high nickel cores. The battery was actually tested for three different needle depths of 1mm, 5mm, and 10mm, and the results showed that it could pass the needle test under the conditions of fine needle.

#### Summary:

#### Summary:

I believe that the technology of composite flow fluid has already been implemented in both the process and production stages. In the future, it is necessary to continue observation, as it plays a decisive role in determining the overall technological path.

Translated Markdown text:

Summary:

I believe that the technology of composite flow fluid has already been implemented in both the process and production stages. In the future, it is necessary to continue observation, as it plays a decisive role in determining the overall technological path.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.