OutRide’s media outlet focuses on the evolution of the automotive industry

Author: Li Yizhi

On September 23rd, NIO announced the release of their new “Ternary Lithium-Iron” standard range battery pack, which is expected to be available for delivery starting from November.

As the name suggests, this battery pack contains both Ternary Lithium and Lithium Iron Phosphate (LFP). In fact, this is the first mass-produced battery with a mixture of both Ternary and Lithium Iron Phosphate.

The battery pack comes with some impressive figures which relieve the pain points of LFP batteries. It reduces the cold temperature range by 25% and has an energy prediction error rate of less than 3%. However, for the capacity that users care most about, its 75kWh capacity is only an additional 5kWh compared to NIO’s existing 70kWh Ternary Lithium battery pack.

The curious onlookers may ask, why did NIO go to such great lengths to upgrade the battery like this in 2021?

Delayed project

Shi Zhe, the Ternary Lithium Battery Project Manager and Vice President at NIO Battery Systems, revealed that this battery has been released a year late. NIO originally planned to release a 70kWh LFP battery and a 100kWh Ternary battery in November 2020, however, there were some issues with the former.

In 2020, LFP technology began to rise again in popularity for EVs due to its lower cost and better safety performance. This year, the competition in the market for LFP batteries is even more severe.

At that time, NIO also decided to use LFP technology. In addition to the two aforementioned advantages, they also considered that the full potential of LFP materials has already been discovered, so there is no need to worry about the plan becoming outdated in two or three years due to rapid technological progress. NIO has suffered a lot from the rapid depreciation of product power caused by technology evolution. For example, NIO recently launched a vehicle machine chip upgrade plan for old car owners, using Qualcomm 8155 to replace NVIDIA X1, which was unbeatable at one time.

However, the energy density of LFP battery technology is relatively low, and NIO’s battery pack needs to consider the compatibility with the battery-swapping stations. Under these two constraints, the battery team was able to come up with a 68kWh LFP battery pack plan in 2020.

However, this plan was quickly rejected by the management team.In the eyes of consumers in recent years, lithium iron phosphate (LFP) batteries have almost been synonymous with “low-end.” After a long period of practice, the problems of rapid discharge at low temperatures and inaccurate display of range have been fully exposed, and they have not been well resolved. Even Tesla, known for its strong BMS algorithm, still experienced these two issues after launching the standard range Model 3 equipped with LFP batteries in China.

NIO’s 70kWh ternary battery pack was launched in 2017. If they release an LFP battery pack in 2020 with parameters and actual performance that are inferior, will NIO still be able to maintain the “user experience” as the cornerstone of their company?

As a result, the 68kWh LFP battery pack was put on hold, and Zhejiang Xinzhiyuan’s team was asked to solve three core issues: battery capacity, State of Charge (SOC) estimation accuracy, and low-temperature performance.

With a tight schedule and heavy workload, NIO’s battery team communicated with suppliers, but they did not have a ready-made solution that could solve all three issues simultaneously.

Regarding power output, NIO tried a solution: adding more rows of ternary cells in the LFP battery pack to increase capacity. However, this increased the cost of the battery pack, and with R&D and mold-making costs, they not only failed to reduce costs but also incurred losses.

Finally, NIO chose Contemporary Amperex Technology Co. Ltd.’s (CATL) non-module CTP-S battery technology, which has higher efficiency when used in packs, increasing the system energy density to 142Wh/kg and increasing battery pack capacity to 75kWh.

The next step was to solve the problems of SOC estimation accuracy and low-temperature performance, which the battery team ultimately did by adding ternary cells. However, instead of adding more rows, they added a few cells. Therefore, NIO’s ternary LiFePO4 battery pack is essentially an LFP battery pack with ternary cells as a supplement.

But it was precisely the addition of these few ternary cells that may have solved the biggest pain point of LFP batteries.

Size measurement + insulation tile, can ternary cells save LFP?

Before we discuss how NIO turned things around, we need to add some background knowledge.

Why is SOC difficult to estimate accurately in LFP batteries?

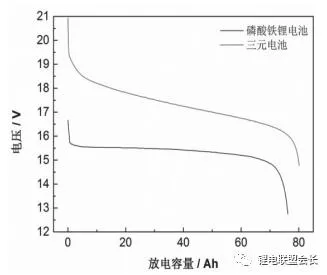

Because SOC relies on the characteristics of high voltage when the battery is fully charged and low voltage when it is discharged to calculate and correct through voltage measurement. However, LFP has a feature: a “plateau phase” in the middle of charging and discharging, during which the measured voltage does not change or changes very little, despite continuous discharge (or charging). Only after reaching a threshold does the voltage suddenly change.

When driving, users may see a sudden drop in their remaining range, despite having over 100 kilometers of estimated range just a few minutes ago. This is particularly true when the battery is low.

The poor low temperature performance of lithium iron phosphate batteries is due to their inherent characteristics. Compared with ternary lithium, the ion conductivity of lithium iron phosphate batteries is lower by several orders of magnitude, and the impedance inside the battery is greatly increased under low temperature conditions. This leads to a significant decrease in the capacity of lithium iron phosphate batteries at low temperatures, especially at temperatures below zero. It is like a person who has low energy to begin with, and becomes even less energetic when it gets colder.

It is difficult to significantly improve the inherent characteristics of lithium iron phosphate in a short period of time (or perhaps there may never be a solution), so the only way to improve it is to patch the battery system through engineering innovation. One way to do this is to add ternary lithium.

Ternary lithium is the opposite of lithium iron phosphate. On the one hand, its charge and discharge voltage changes linearly. On the other hand, its low temperature performance is better, and the capacity loss at low temperatures is not significant.

To address the problem of the inaccuracy of the state-of-charge estimation of lithium iron phosphate batteries, NIO’s solution is to use ternary lithium as a “ruler” in series with the iron-lithium battery cells, and calculate the battery capacity of the entire battery pack by measuring the voltage of the ternary lithium as a “reference answer.”

To address the issue of poor low-temperature performance, the battery team conducted tests and data analysis and found that the four corners of the battery pack dissipate heat the fastest and have the lowest temperatures. Therefore, they placed ternary lithium battery cells that are better suited to low temperatures at the corners to act as heat insulation tiles. They attached heating mats to the four sides with less heat dissipation and actively compensated for the temperature of the entire battery through active heating.

The solution seems simple, even trivial, but in fact, mixed packing of the two types of battery cells has not been mass produced by other automakers. This is because in the battery industry, there is a key word called “consistency” to ensure the controllability and safety of the battery operation. If the quality of battery cells in a battery pack is different, with some being sluggish, some being lively, and some having a shorter lifespan, the risk of thermal runaway will significantly increase. Solving consistency is the biggest challenge.

The most typical problem is that the working voltage of ternary lithium is higher than that of lithium iron phosphate, but its cycle life is shorter than that of lithium iron phosphate. Therefore, NIO battery team has done several things:One is to lock the lithium-ion battery at 10-90% of its capacity for charging and discharging, which not only aligns the voltage scale more accurately with that of lithium iron phosphate but also extends the battery life by reducing its workload, bringing it closer to lithium iron phosphate.

Secondly, a complex algorithm has been developed for real-time matching and calibration of the states of both ternary lithium and lithium iron phosphate batteries. This algorithm is said to be 10 times larger than traditional SOC algorithms, and it took 8 months of development and testing to complete.

In addition, a high-power DCDC converter is applied to discharge specific batteries and calibrate them to the required state.

Furthermore, NIO’s substantial amount of data and data analysis capabilities have also played an important role in improving the performance of ternary lithium batteries. For example, its SOC algorithm calculates customized battery estimates for different user driving styles for more accurate power level predictions. NIO discovered through big data-supported testing that maintaining battery insulation capabilities at -5° (rather than the traditional 0°) is actually the optimal energy consumption point, adjusting the layout of active and passive heat dissipation accordingly.

During the presentation of the technical solutions, Li Zhang, CTO of NIO, said something confident that sounded like “Can everyone do this? Actually, no.” The implication is that both know-how and sufficient data of battery technology are needed to complete this ternary lithium engineering innovation.

After completing the series of non-trivial tasks mentioned above, NIO finally launched a ternary lithium battery pack with only slight capacity upgrades. According to reports, because the new battery pack uses 300 sensors and requires redesign, development, and mold production, there is no significant cost advantage over ternary lithium batteries and widespread acceptance and deployment are required to further dilute the cost.

This shows that battery technology is indeed a highly innovative field that requires a lot of innovation (whether in material or engineering) to achieve some breakthroughs in cost, performance, and safety within the impossible triangle. However, for NIO to maintain its high standard of user experience, it adds an extra level of difficulty.

Would NIO users appreciate this battery? It remains to be seen over time.

But if NIO’s engineering innovation capabilities can be accumulated and reused in this battery upgrade, it will be good news for NIO.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.