At the Chengdu Auto Show, the Chery Cat with Cobalt-Free Battery by Great Wall Motor’s Ora brand had its debut. This car will have two versions released. The version with lithium iron phosphate battery is 61kWh, with a NEDC range of 470km, while the cobalt-free lithium-ion battery version from Honeycomb Energy provides an 82.5kWh battery pack with an NEDC range of 600km, which is the world’s first new energy electric vehicle with cobalt-free batteries. I would like to discuss the overall direction of battery technology based on this and conduct some interviews and communication with Honeycomb Energy.

The Technological Direction of Power Battery

Judging from China’s current power battery technology roadmap, Ningde Times mainly involves iron phosphate, high-nickel voltage, high-nickel ternary and sodium batteries, which are divided into two major development paths of high cost-effectiveness and high energy density, supplemented by long-term planning such as sodium batteries. BYD, on the other hand, has returned to iron phosphate from the ternary cathode chemistry system, focusing on two directions, EV iron phosphate and PHEV iron phosphate. Domestic second-tier battery companies such as CATL, Guoxuan High-tech, and Funeng Technology also follow and replace the strategic direction of iron phosphate and ternary based on the overall pattern. These two technological directions have also become the mainstream directions in China at present.

The First Type: High Cost-Effective Battery

Iron phosphate battery has the biggest advantage in that it has less metal restraint. Therefore, more and more car companies are choosing iron phosphate for entry-level models. In the past two years, the technology roadmap for large battery cells for iron phosphate power batteries has energy density between 180-200Wh/kg (volume energy density 350Wh/L-450Wh/L), which is close to the data for current ternary batteries of 520Wh/L and can replace the demand for below 65kWh. The core change here is that iron phosphate batteries have achieved high volume utilization through current module and CTP process.

In 3-5 years, with the optimization of material systems and processes, it is expected that iron phosphate will move towards a quality energy density of 210-230Wh/kg (volume energy density 450Wh/L-500Wh/L). From the overall trend, the future technological direction of iron phosphate can cover all A0-B level entry-level models. Especially when we see that BYD currently uses a blade battery iron phosphate method that covers all models.

The Second Type: High-Performance Battery, High-Nickel Route

This type of battery has the goal of developing high-capacity batteries based on high-energy density, built on high-nickel systems and silicon-carbon anodes.At present, the quality energy density of high-nickel batteries is between 240-300Wh/kg (volume energy density 560Wh/L-650Wh/L), with fast charging time of 18-30 minutes (3.3C-2C). In the next stage, the quality energy density of high-nickel batteries is expected to reach 300-400Wh/kg (volume energy density 630Wh/L-750Wh/L) when silicon-carbon anode is introduced to the negative electrode, with fast charging time of 9-15 minutes (4C).

We can see that currently, several foreign battery companies are mainly oriented towards designing towards high-nickel direction from medium-nickel on the one hand, and reducing cobalt usage to make cobalt-free batteries on the other hand.

Cobalt-Free Route of CATL

I was wondering what CATL’s cobalt-free battery route is and whether it could possibly become a third possibility for China beyond the two current technological routes.

1) What is CATL’s cobalt-free battery?

This kind of NMX cobalt-free material uses two elements with larger chemical bonds to replace cobalt and is doped into the material, stabilizing the octahedral structure of oxygen by strengthening the chemical bonds. Then, the single-crystal technology and nano-network encapsulation are adopted to achieve a stable structure and a long-life design with reduced side effects of positive electrode materials and electrolytes.

2) Can CATL’s cobalt-free battery become the main route in the industry?

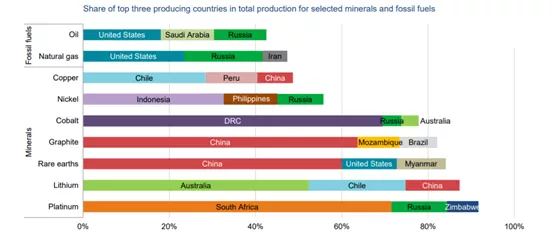

From CATL’s perspective, the iron phosphate system used in the industry currently has lower costs, but its energy density can only reach about 190Wh/kg, which limits its large-scale application. The energy density of the ternary system is higher, reaching over 250Wh/kg, however, cobalt elements are used in the ternary materials, which are constrained by the reserves and output of cobalt. The international market price of cobalt is extremely unstable and has remained high in the long term.

In contrast, CATL’s cobalt-free material achieves zero-cobalt elements, completely unaffected by the cobalt market and low in cost. At the same time, its energy density is comparable to that of ternary materials. Therefore, in the long run, cobalt-free batteries have significant competitive advantages compared to the iron phosphate and ternary battery technologies, and are an irreplaceable trend for the industry.

3) At the beginning, CATL produced anodes in-house and explored the cobalt-free route. Is it possible for third-party material and battery manufacturers to adopt this route? Is it possible to cooperate with CATL in some way?# From the perspective of a bee, BJEV has planned to reach a production capacity of 200 GWh by 2025, with complete coverage of the chemical system and a high demand for a variety of positive electrode materials. In terms of the technology of cobalt-free positive electrodes, BJEV has been attempting to vertically integrate the R&D and production of innovative and more competitively advantageous positive electrode materials in the industry. Materials such as cobalt-free and quaternary materials are the focus of their efforts. On the one hand, such a large production capacity is not entirely focused on cobalt-free materials, but also has a huge demand for traditional iron-lithium and ternary system materials. Therefore, BJEV still has a huge demand for traditional materials and will actively carry out third-party import and cooperation. Therefore, from the perspective of the cobalt-free technology, BJEV has a positive and open attitude, and multiple modes of cooperation can be explored, such as patent authorization, patent exchange, patent pool sharing, joint venture shares, and external material sales. The ultimate goal is to expand this technological route.

4) From the endgame perspective, can the cobalt-free technology route achieve the most cost-effective outcome? Does this technological route require large-scale industry collaboration, similar to the current status of the ternary and iron-lithium materials?

In removing cobalt from the raw materials for cobalt-free materials, the cost is first reduced from the perspective of BOM. Secondly, the cobalt-free material synthesis process can be co-produced with conventional ternary synthesis, eliminating the need for specialized production lines, which makes it easy to promote on a large scale. BJEV’s cobalt-free materials have been verified at the material level, battery level, module level, pack level, and vehicle level, and have achieved excellent results that fully meet the usage requirements. Vehicles featuring cobalt-free batteries will be available soon. After the cobalt-free materials have gained approval from users, large-scale promotion can be quickly realized. Of course, large-scale industry collaboration will undoubtedly be more conducive to generating economies of scale. After the demonstration effect of the company takes hold, peers in the industry, both upstream and downstream, will gradually join the technological route, and its position will become more prominent.

5) At the usage level, what is the positioning of the cobalt-free technology route? Which automotive technology products is it suitable for?The cobalt-free technology route is mainly designed to balance the electric vehicle users’ pursuit of long endurance, high safety, fast charging, and low cost. Based on the ternary system, the cobalt-free route of NMX needs product support. Currently, cobalt-free materials can realize the product design of high energy density battery cells. The battery products made by the cobalt-free cathode material of the Honeycomb Energy H platform have achieved remarkable results from test data. At room temperature, the cycle life of cobalt-free batteries will reach more than 2500 times. In terms of energy density, cobalt-free batteries can currently achieve 240-245Wh/kg, which is much higher than the mainstream lithium iron phosphate battery’s level of 170-180Wh/kg and is also very close to the level of 240-250Wh/kg of the 811 ternary lithium battery.

As for the safety that people generally pay attention to, besides having a natural advantage in preventing overcharging, the cobalt-free battery of Honeycomb Energy also has excellent thermal stability, with a completion of a 150°C heat box test, far exceeding the 130°C standard required by the national standard. Compared with the 811 ternary lithium battery system, this represents better thermal stability performance. Honeycomb Energy’s first cobalt-free product, 115Ah, has started mass production in July 2021. The Chery eQ5 series of vehicles equipped with this cobalt-free product will also be launched soon. In terms of the comprehensive performance of cobalt-free products, they are suitable for mid-to-high-end long-endurance automotive products.

As mentioned above, due to the energy density upper limit issue of the lithium iron phosphate system, vehicles equipped with lithium iron phosphate battery cells generally have a low range. At the same time, the low-temperature performance of the lithium iron phosphate system is poor, leading to a significant decrease in vehicle range in winter. Cobalt-free battery cells have an energy density significantly higher than lithium iron phosphate, and their low-temperature performance is clearly better than lithium iron phosphate. Therefore, for vehicles of the same grade, consumers will significantly perceive the increase in range when equipped with cobalt-free battery cells, and the range will be less affected by weather temperature.

Furthermore, facing the long-term cost competition advantage of lithium iron phosphate, the 115Ah battery cells born on the low-nickel cobalt-free E platform aim to improve the energy density by 20% compared with the same capacity lithium iron phosphate battery cells, and achieve a 17% cost reduction goal. In other words, the goal is to make the cobalt-free E battery cells have the performance and cost competitiveness to replace iron-lithium products in mid-range vehicles. This goal is very challenging, but once achieved, it also has the greatest potential.### Summary:

Through some interviews with Honeycomb, I believe readers may have a deeper understanding of the technical route that Honeycomb is implementing. I sincerely wish this route can be successfully implemented.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.