Author: Wang Lingfang

On August 29, Ora Cherry Cat, the world’s first new energy vehicle equipped with cobalt-free batteries, was released.

This marks the official mass production and installation of the first cobalt-free battery.

The supplier of this cobalt-free battery pack is the recently popular company, Honeycomb Energy.

The development of batteries is a balancing act. In terms of performance, it requires a balance of safety, energy density, and cost. In terms of supply, it requires a balance of raw material supply security, sustainability, and cost.

The common problem that battery companies face is how to make batteries that are more balanced in performance and meet vehicle standards at a lower cost.

With Honeycomb Energy’s mass production and installation of cobalt-free batteries, “Electric Vehicle Observer” summarized several representative companies in China that are currently addressing the above problems: Contemporary Amperex Technology uses CTP (cell to pack, non-module battery pack) and sodium-ion batteries; BYD uses blade batteries (also CTP scheme) and lithium iron phosphate technology; and Honeycomb Energy uses CTP and cobalt-free battery technology.

Comparing these technical orientations, “Electric Vehicle Observer” found that BYD and Contemporary Amperex Technology have both used positive electrode materials with lower energy density, which solved the problem of cost and supply security but sacrificed the performance of their products. Honeycomb’s solution not only takes into account cost and supply security but also can achieve minimum energy density loss, and even near-zero loss.

Cherry Cat’s First Appearance, Follow-up Models Gradually Revealed

To understand the cobalt-free battery, you need to look at Cherry Cat’s performance.

Cherry Cat is positioned as an A+ class SUV, equipped with a cobalt-free battery pack with a total capacity of 82.5 kWh, a system energy density of 170 Wh/kg, and a constant temperature driving range of 600+ kilometers, placing it at the forefront of similar products in China.

In terms of performance, Cherry Cat can achieve a hundred kilometers per hour acceleration in 5 seconds; the waterproof performance reaches IP67; and in low-temperature conditions, the energy retention rate is high, and the heating speed is fast.

Yang Hongxin, chairman and CEO of Honeycomb Energy, stated that their cobalt-free battery pack can achieve a heating rate of 49℃ per hour. In other words, it only takes less than half an hour to heat the battery from -20°C to room temperature.According to the introduction from CATL, the cobalt-free battery pack has undergone comprehensive performance and parts safety tests. Yang Hongxin stated that CATL’s cobalt-free batteries have met the highest standards in national and special safety tests, such as bottom ball impact, trampling, hammering, side pillar collision, battery pack, internal cooling liquid leakage, electrochemical corrosion, and rock impact, far exceeding the requirements of national standards.

In addition, the cobalt-free battery pack has passed a series of safety tests, such as 150°C hot box and 140% SOC overcharge, and obtained multiple certifications such as EC62660-3/GB T31486-2015/GB 38031-2020/UL2580.

In terms of low-temperature performance, the cobalt-free battery has also been significantly improved. The fast charge rate of CATL’s second-generation cobalt-free battery has increased to 1.6C, which means it can charge from 0 to 80% in less than 30 minutes, further expanding the application scenarios of cobalt-free batteries.

Based on this, the coverage range of CATL’s cobalt-free batteries ranges from A00 to B+ class, with a driving range of 400 to 800 kilometers or more.

However, it should be noted that CATL’s first-generation cobalt-free battery pack did not choose the CTP technology and adopted the modular of the MEB standard. Next, CATL will adopt large modules and CTP technology to further improve the volume energy density and safety of the battery pack.

Other cobalt-free battery models will be seen next year. According to Yang Hongxin, within the Great Wall system, two models with cobalt-free batteries have been confirmed, one is under the Euler brand and the other under the ORA brand; “Outside the Great Wall system, GWM commercial vehicles will have a pickup truck, and two new energy companies are in communication, and there is hope for designated points.”

In addition to Chinese domestic brands, several Japanese and German automakers are also testing CATL’s cobalt-free batteries.

Currently, CATL has planned 10 GWh of cobalt-free battery production capacity, and by 2025, the production capacity of cobalt-free batteries will exceed 50 GWh and achieve shared production with ternary batteries.

After understanding the basic situation of CATL’s cobalt-free batteries, let’s take a look at the choices made by Chinese battery companies to balance battery performance and supply security.

BYD’s Path: CTP and LFP

Represented by BYD, enterprises have begun to return to the route of lithium iron phosphate on a large scale.

As the most direct and cost-reducing, and supply security technology route, it is currently followed by a large number of Chinese automakers and battery companies, and the number of models using lithium iron phosphate batteries is rapidly increasing.The supply of lithium iron phosphate (LFP) materials is safe, cost-effective, and has a long cycle life, but the low energy density remains a problem. To address this issue, BYD has optimized the structure of its battery pack using CTP (Cell to Pack) blade battery technology, achieving a battery pack space utilization rate of over 60%. However, the fundamental low energy density of the material sets a upper limit.

BYD’s representative work of blade batteries is the Han model. BYD has already announced plans for the “P series” of pure electric vehicles, where all products will gradually adopt blade batteries.

According to the 2020 qualification certificate data, the single cell energy density of the blade battery used in the BYD Han model is about 166Wh/kg, and the energy density of the battery system can reach 140Wh/kg.

Currently, the highest energy density of lithium-ion batteries in mass production is around 200Wh/kg, which is still significantly lower than the energy density of ternary batteries. Due to the low energy density of the cell, the energy density of the battery pack after being grouped will only be lower, and its long-term development does not appear to be significantly advantageous.

CATL also uses CTP technology to increase the energy density of battery packs and reduce costs.

At a material level, CATL has taken a different approach from BYD and introduced sodium-ion batteries, avoiding the use of lithium. While sodium resources are plentiful and raw materials are not a concern, the disadvantage is that the industry chain for sodium-ion batteries is not yet complete, and the energy density of the cell itself is not high.

Lithium is not inherently scarce, according to USGS data, the global lithium resource total is 86 million metric tons of metal (about 458 million metric tons of LCE), and as exploration deepens, lithium reserves are expected to continue to grow. However, global lithium resources are not distributed evenly and are highly concentrated, with the “Lithium Triangle” in South America and Australian lithium mines accounting for 65% of global lithium resource reserves.

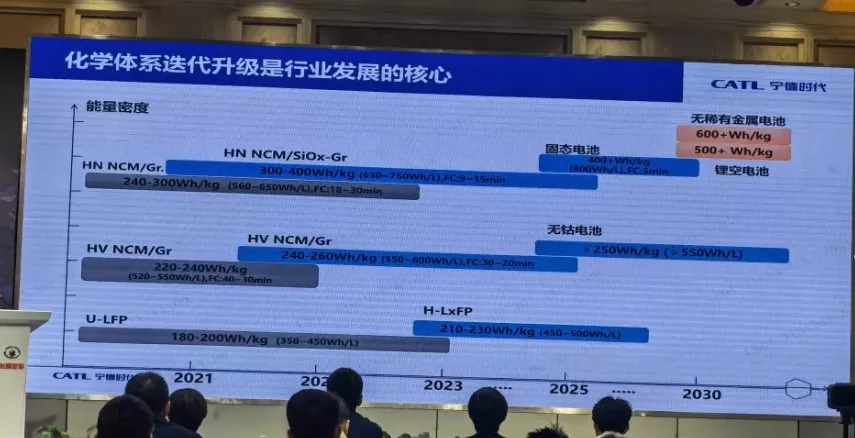

To reduce demand for lithium, CATL has released sodium-ion batteries. According to CATL’s presentation, the energy density of the first generation of sodium-ion batteries is 160Wh/kg, and the second generation is 200Wh/kg.

Currently, sodium-ion batteries have a lower single-cell energy density than LFP batteries. To address this issue, CATL employs the approach of combining sodium and lithium-ion batteries to make up for the shortcomings of low energy density in battery packs. It is currently inferred that the approach involves mixing ternary lithium-ion batteries with sodium-ion batteries.

Employing sodium-ion batteries balances cost, safety, and supply safety, but their energy density is currently still lower than that of LFP batteries. Moreover, the more sodium-ion batteries are used, the lower the energy density of the battery pack.At present, the solutions of BYD and CATL essentially balance cost and supply security by sacrificing battery energy density, that is, battery performance, and the energy density ceiling of the two technologies in the short term is relatively low.

The CTP and Cobalt-free Battery Route of CATL

In addition to adopting the CTP battery pack solution that is currently popular in the industry, CATL is considering removing cobalt elements from ternary batteries at the material level.

This is not a new idea. As early as 2018, Panasonic announced that it was developing cobalt-free electric vehicle batteries. Tesla CEO Elon Musk stated on social media that the cobalt content of Tesla Model 3 batteries had been reduced to less than 3%. They will continue to improve the technology and strive to completely abandon cobalt in the next generation of batteries, but there is still no product landing at present.

However, CATL is the world’s first company to have a landing cobalt-free battery.

Currently, the cobalt-free H energy density of CATL’s mass-produced battery cell is 240Wh/kg, and the cobalt-free H plus that can be achieved in the SOP (Start Of Production) in 2023 can reach 250Wh/kg, which is significantly higher than lithium iron phosphate and sodium-ion batteries. By removing cobalt with minimal or even close to zero energy density, the cobalt-free battery of CATL can effectively reduce raw material costs.

The energy density of the cobalt-free battery pack carried by Cherry Cat has now reached 170Wh/kg, which is much higher than the level of 140Wh/kg of lithium iron phosphate batteries.

According to Yang Hongxin, CATL’s cobalt-free batteries in the future will adopt the form of CTP or large modules, and the energy density of the battery pack is expected to exceed 180Wh/kg.

In addition, it is more secure than the current high-nickel ternary battery. It can pass a 150℃ thermal chamber test, 140% SOC overcharge test, and a 2mm shallow needle puncture test.

In terms of the sustainability of raw materials, the supply of cobalt is more tense than lithium. The world’s known cobalt reserves are about 7 million tons. It is worth noting that nickel, manganese, aluminum and other minerals are reserves of tens of billions or even hundreds of billions of tons, and in comparison, it can be seen that cobalt belongs to a very scarce metal. Based on the 2019 global mining volume of 140,000 tons, cobalt can still be mined for about 50 years.

China has even less cobalt reserves. China’s proven cobalt reserves are only 80,000 tons, accounting for 1.14% of the total global reserves. Without a cobalt-free solution, China can only rely on imports.Another problem with cobalt is that the production is very centralized, mainly in Congo, Australia, and Cuba, and concentrated in the hands of several large mining groups such as Glencore, China Molybdenum, Eurasian Resources Group, etc., which may result in weak downstream bargaining power, and during the price rise period, the price is likely to far exceed the battery companies’ ability to bear.

Of course, Honeycomb Energy is not the only company that deeply cultivates cobalt-free batteries. Material scientists in South Korea and the United States are also researching cobalt-free cathode materials, and many researchers believe that the cobalt problem has basically been solved.

CATL plans to launch cobalt-free batteries around 2024.

To sum up the above routes, both BYD and CATL have used lower energy density cathode materials, which have solved cost and supply security problems but sacrificed product performance. Honeycomb’s solution can achieve a small sacrifice of energy density while balancing cost and supply security, thus maximizing the advantages of the ternary battery’s energy density.

Honeycomb Energy seems to have more advantages in this regard.

Of course, it needs to be made clear that as a brand new solution, the reliability of cobalt-free batteries still needs time to verify.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.