Recently, Zeekr is promoting the SEA platform and has released a lot of detailed information. I will give a deep analysis on the battery part that I am interested in. With the sharing of the SEA platform by Geely and many projects, we will be able to see it in many car models in the future, such as Zeekr, Polestar, Volvo, Lynk & Co, Smart, and Jidu.

According to my current understanding, the battery platform has the following characteristics:

(1) The battery uses the Ni55 system that everyone is using. The Ni55 battery improves its energy by increasing the charging cut-off voltage, with a charging cut-off voltage of 4.35V, which is 0.15V higher than the previous 4.2V. With the addition of thermal insulation materials between the batteries and the insulation on top of the module, this solution is called NTP non-thermal propagation technology, as shown in Figure 2.

NTP has several features: “Disconnect” uses Pyrofuse to achieve a millisecond breakpoint; “Exhaust” uses an exhaust design with a pressure relief valve; the multi-layer thermal insulation uses fire-resistant materials (ceramic rubber, ceramic glass fiber, and mica board), with the aluminum cover on top changed to a sheet metal cover; active cooling uses an emergency water pump control when triggered by the pressure sensor or CMU detection; the warning methods mainly include ambient lights, central control screen, mobile App, and so on, covering driving and parking states.

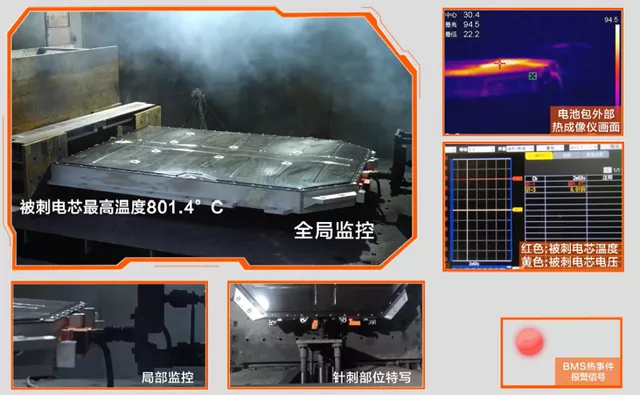

NTP verification uses the needle puncture test video that everyone is familiar with. When a steel needle punctures a single cell and triggers a thermal event, the BMS of the battery pack above triggers a thermal event alarm signal. Here, the infrared scan shows that the highest temperature of the cell reached 801.4℃, and the battery system emitted a lot of smoke. As shown, after a period of time, the voltage of the single cell drops to 0V, the temperature returns to normal, the thermal insulation and partition structure of the battery pack are intact, there is no obvious deformation, the external of the battery is not charged, the internal fixed structure and high-voltage connection of the battery pack are intact, and there is no thermal propagation.

After removing the battery cover, we can see the entire module situation, which is basically burned black.

After removing the battery cover, we can see the entire module situation, which is basically burned black.

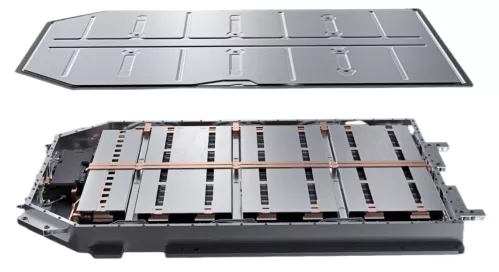

(2) The integration efficiency of the entire package is 72%, which has transitioned from the previous 590 design to the current dual-module integration method. It is divided into 6 dual-row modules (16 cells) and 2 single-row modules (8 cells).

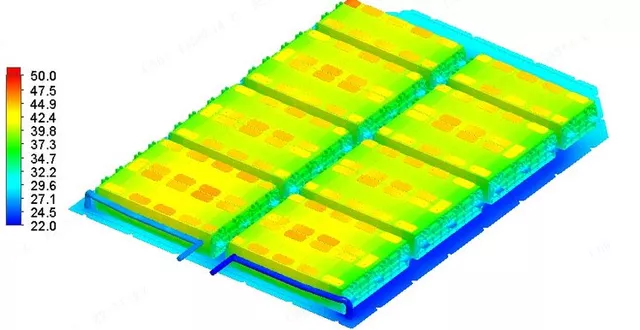

Here, the integrated “S” type parallel flat liquid cooling is used to achieve a pressure drop of 30kPa under the condition of 16L/min and reduce the energy consumption of the water pump. On the SEA platform, a heating system controlled by the inverter is also added, and specific data is to be checked.

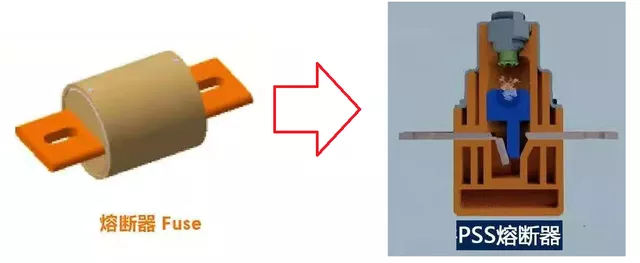

(3) On fast charging, we can achieve the highest 600A under low SOC. In actual demonstration, we saw 552A at 5% SOC, 535A at 6% SOC, and 466A at 22% SOC. Here, PyroFuse (PSS fuse) is introduced to solve the problem of heat generation of fuse-breaker under high current charging. Moreover, the charging rate of this cell is relatively high, estimated as 2.2C cell.

It seems that Geely has also customized a 400V 350kW charging pile, which adopts liquid cooling for heat dissipation under an outer diameter of 25mm.

In the case of the car interior, all aspects including the charging cable, high-voltage connector, and high-voltage contactor have also been tested for a charging capacity of 600A.

Note: Geely will also build charging piles, and is expected to build 2,200 charging stations by 2023.

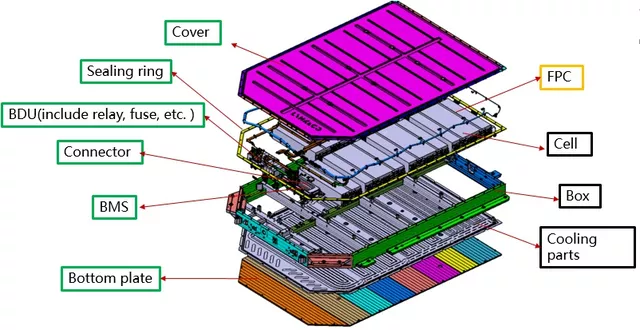

The overall situation of this package is shown in the following figure, and the line speed sampled by the electric is around both sides. It can be seen that this platform is compatible with the previous 590 design, and there may be two different ways for foreign and domestic markets. The cell can also be changed to an iron-lithium cell.

Summary: Currently, with the landing of automotive platforms, manufacturers have released very detailed information in the field of batteries. We look forward to the actual dismantling situation in the future for readers’ reference.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.