Influence Report

Since 2019, Tesla will release the “Influence Report” annually during the summer and autumn.

The influence here does not refer to the brand volume or market sales, but specifically refers to the positive impact on the natural environment and society.

According to our usual understanding, articles related to environmental protection are generally serious and uninteresting, but the environmental friendliness of electric cars relies more on systems than concepts. This report not only discusses technology but also addresses production.

After several years, this annual “Influence Report” has gradually become Tesla’s “work report.”

It is no wonder that this report is getting thicker every year. I even dug out my own file collection. The 2018 report is 48 pages long, with a standard vertical layout. The 2019 report was upgraded to a larger horizontal layout, with page numbers that surged to 57.

The just-released 2020 report seems to continue Tesla’s doubling rhythm, reaching an astonishing 94 pages.

10 Years 500X, also Achievable Goals

What is even more shocking than the number of pages is Tesla’s 2030 target.

When many car manufacturers are still planning to transition to a pure electric vehicle company by 2030, Musk no longer wants to give competitors a chance.

The Influence Report stated at the beginning that Tesla’s mission is to accelerate the world’s transition to sustainable energy, and the best way to increase this impact is to continuously increase product capacity while reducing barriers to entry for consumers.

Therefore, Tesla’s vision is to sell 20 million electric vehicles by 2030, which is 40 times higher than the approximately 500,000 cars sold by Tesla in 2020. In terms of energy, it hopes to deploy 1,500GWh of energy storage facilities by 2030, which is 500 times higher than the 3GWh data in 2020.

Both of these numbers have been discussed by Musk on Twitter before, but what was most uncertain was whether Tesla is “serious” about it, since the annual delivery of 20 million vehicles is almost twice the current annual delivery volume of Volkswagen Group.

But this time, it was clearly written in Tesla’s official materials.

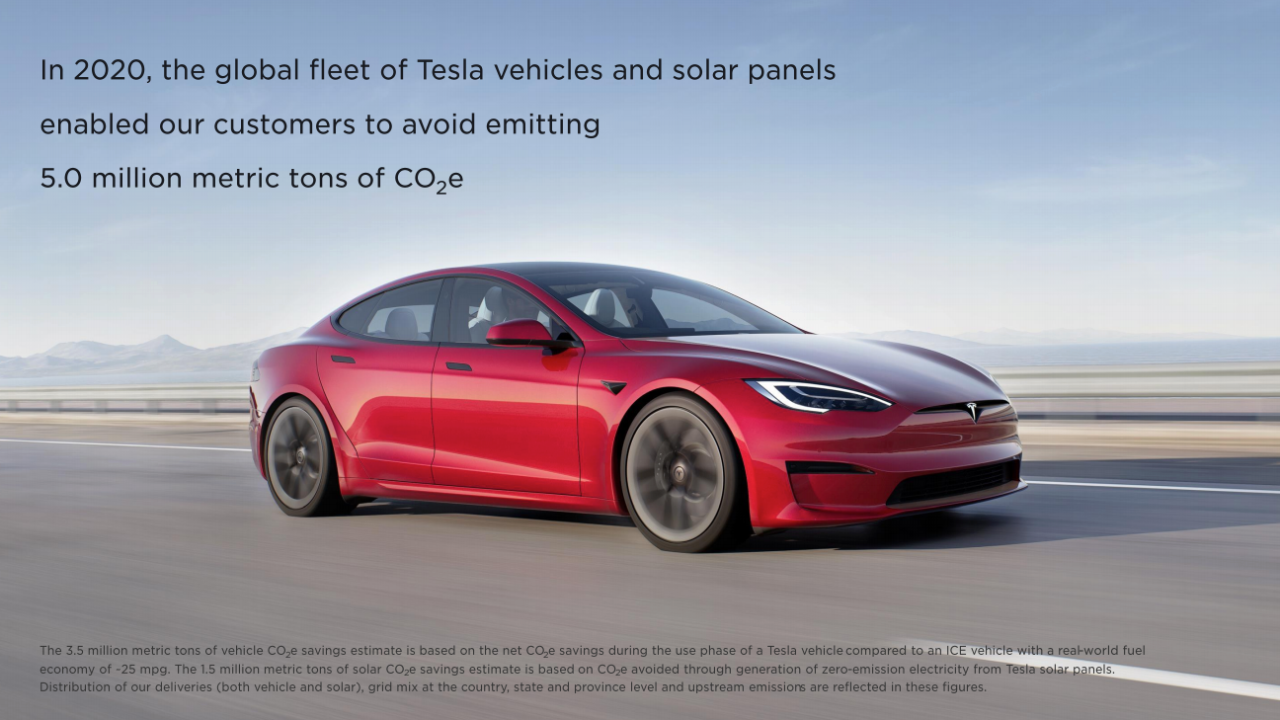

Despite Tesla’s product sales in 2020 being only one percent of Musk’s dreams, remarkable achievements have been made in reducing carbon dioxide emissions. The overall Tesla fleet reduced 5 million tons of carbon dioxide emissions throughout the year, demonstrating the significant impact of pure electric vehicle deliveries on the world when they reach a substantial scale.

Vertical integration for maximum impact

Tesla’s understanding of sustainability is worthy of being highlighted here.

“Sustainability drives Tesla, not only driving our products, but also our company’s values and mission. It is the core and greatest motivation of everything we do. At the same time, it is important to our consumers, employees, and shareholders. Therefore, our products and services focus on the sustainability of the transportation industry and energy production/storage industry.”

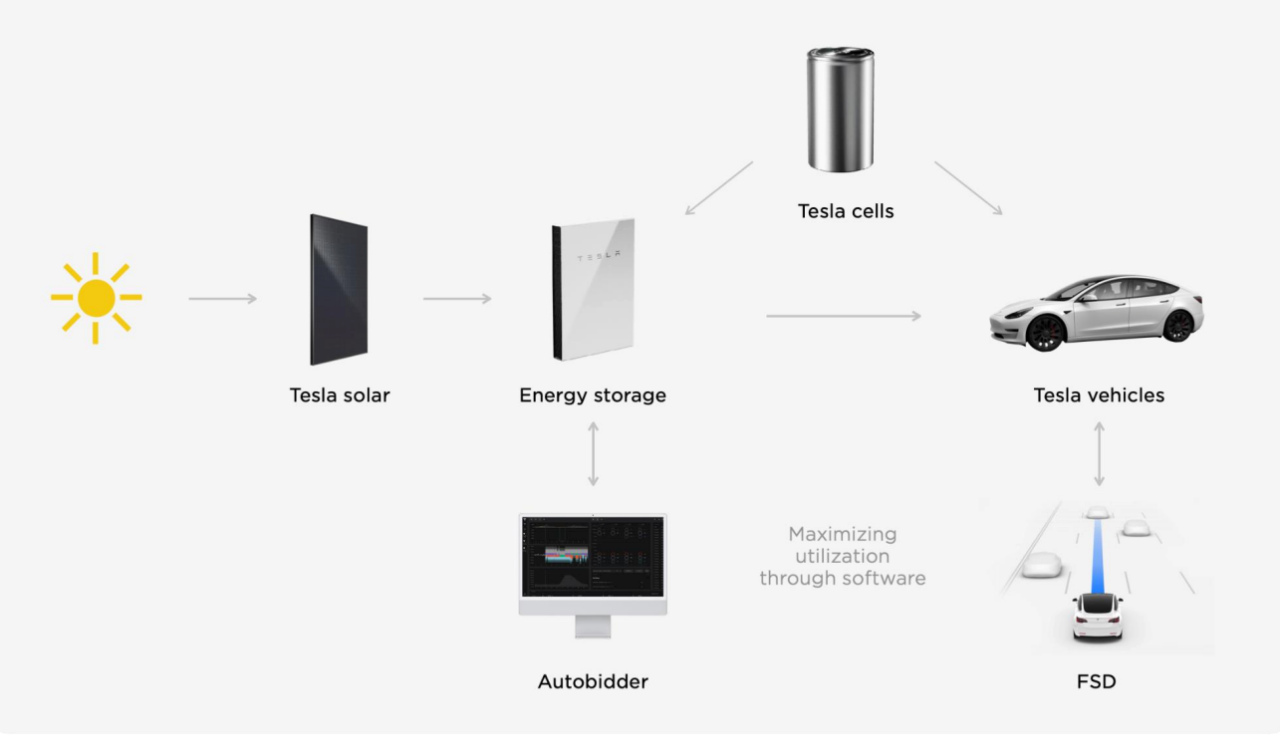

To this end, Tesla’s solution strategy is to design and manufacture a fully vertically integrated complete energy and transportation ecosystem.

From this complete structural diagram, Tesla’s overall planning for future energy structure and company product structure can be seen.

The two major intersections in the figure will definitely be occupied by Tesla’s vehicle and energy storage product matrices. What is worth paying attention to are the two expanding lines outside the intersection.

The first line is the development of advanced manufacturing capabilities, including Tesla solar and Tesla batteries. In this impact report, the importance of these two parts of production in reducing emissions was particularly emphasized. The logic behind it is that self-production can reduce the emissions consumption of related components in the transfer process, and self-research can reduce related emissions in production through the application of a large number of advanced technologies.

The second line is software development work, including Autobidder corresponding to energy storage and FSD corresponding to vehicles. The value of these two software technologies is that they can aggregate the scattered and personalized Tesla products into a network, and play a deep scale and reuse effect.

The former enables Tesla to have several virtual power plants, and the latter allows Tesla to have several ride-sharing networks, which means that the energy storage and cars, originally low-frequency used by one person or household, suddenly have the possibility of being frequently used by thousands of families.

The former enables Tesla to have several virtual power plants, and the latter allows Tesla to have several ride-sharing networks, which means that the energy storage and cars, originally low-frequency used by one person or household, suddenly have the possibility of being frequently used by thousands of families.

The more you use, the more you save.

Is EV really environmental-friendly? Tesla will tell you.

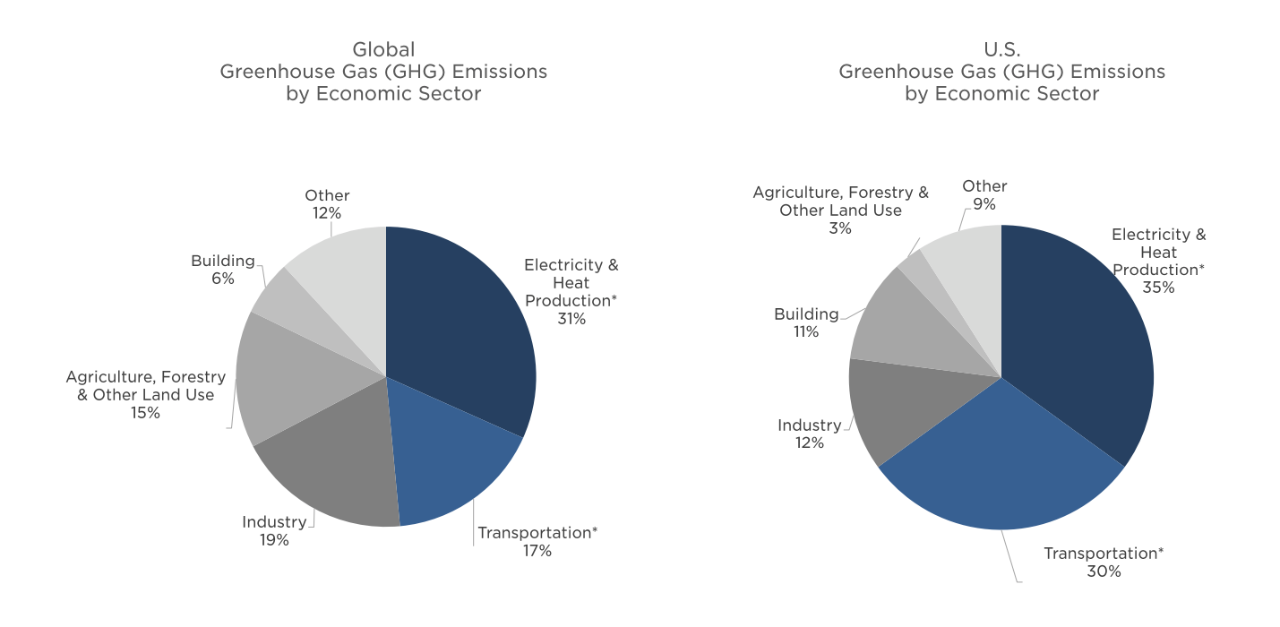

One of the biggest questions about EVs is whether they are environmentally friendly.

While EVs do have zero emissions during use, the production process and the use of technology and heavy metals in pure electric vehicles are also notoriously complex.

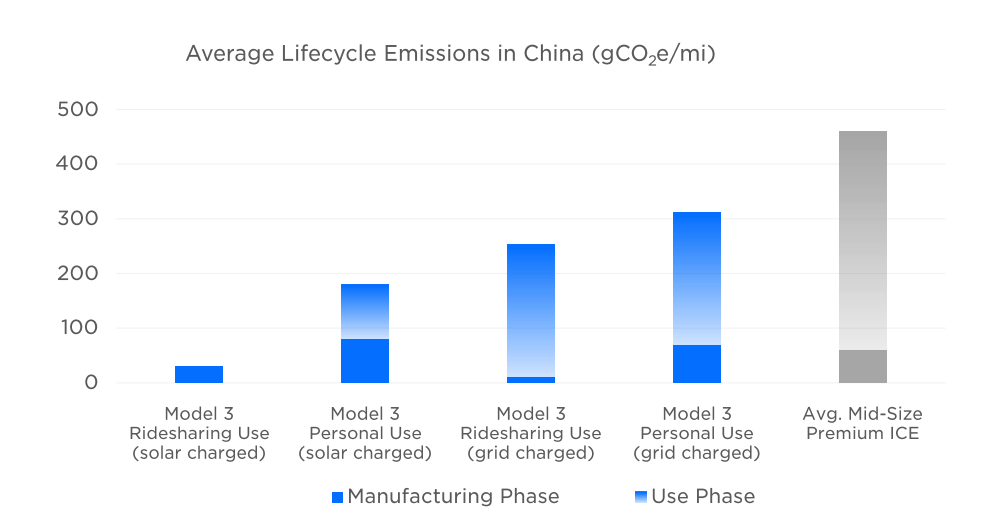

So, Tesla directly presents two figures.

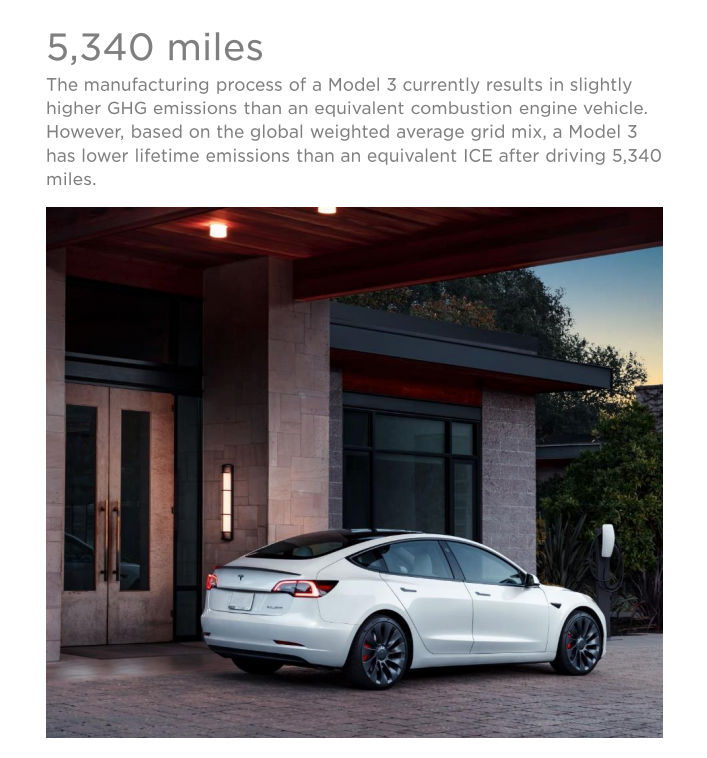

The first is 5340 miles (about 8544 kilometers). Although the environmental emissions of the production process of Model 3 are slightly higher than those of the same class of fuel-powered cars, according to comprehensive data, as long as the vehicle is used for more than 5340 miles, the total emissions during the entire life of the car will already be lower than that of a fuel-powered car.

The second is 69 tons, which is the amount of carbon dioxide emitted by the average fuel-powered car sold in the United States during its entire life in 2020.

In summary, as long as your Tesla is not a model for display, it will definitely be more environmentally friendly than a fuel-powered car.

In order to prove that EVs are more environmentally friendly, Tesla has whipped out NEDC, WLTP and even EPA, saying that these standards are all biased towards reality, but our calculations are based on the cumulative values of actual fuel consumption of all vehicles, which are truthful and reliable. Where does the data for fuel-powered vehicles come from?

— From Consumer Reports’ real statistical data.

And there is another hope for the whole village of EVs, which is renewable energy. As more and more energy in the vehicle charging network comes from renewable energy, the emissions of the entire vehicle will be further reduced.

Calculating this and that, Tesla has come up with a result: they are the most efficient electric vehicles ever.

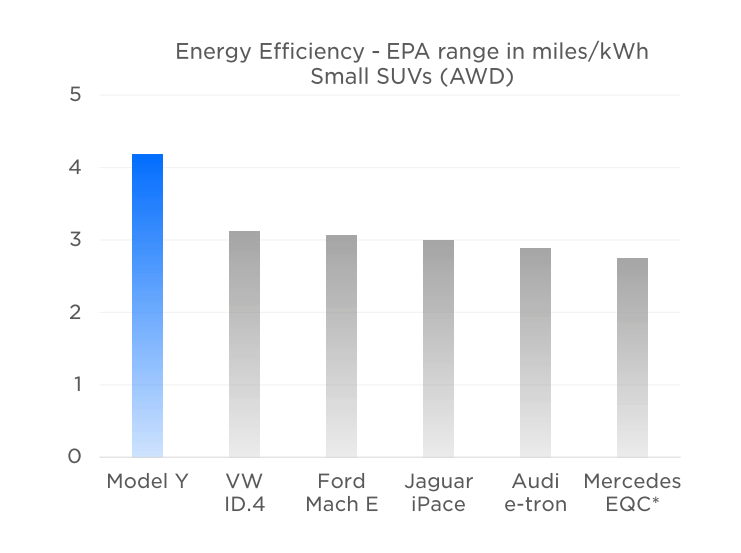

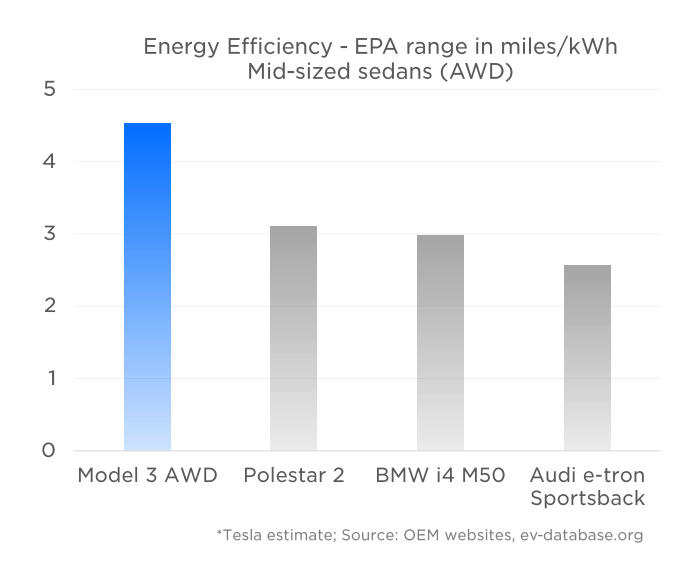

Naturally, the following is the part of beating competitors, Tesla said, “Compared with other EVs of the same level, Tesla’s cars can more effectively convert electric energy into usable energy. As we continue to develop our technology, the efficiency of our vehicles will continue to improve. Our Model 3 Standard Range Plus (SR+) is the most energy-efficient vehicle on the market and a significant example of such improvement.”

Just wondering, how come the Audi e-tron Sportback is classified as a sedan?

Tired of playing with cars, factories are more interesting

After reading the whole article, my impression was that for Tesla, playing with factories is now more interesting than playing with cars. After all, increasing size and cost is the nature of entrepreneurship. From the perspective of scale and value, factories and cars are not in the same category. Which means, their impact on the environment is also not in the same category.

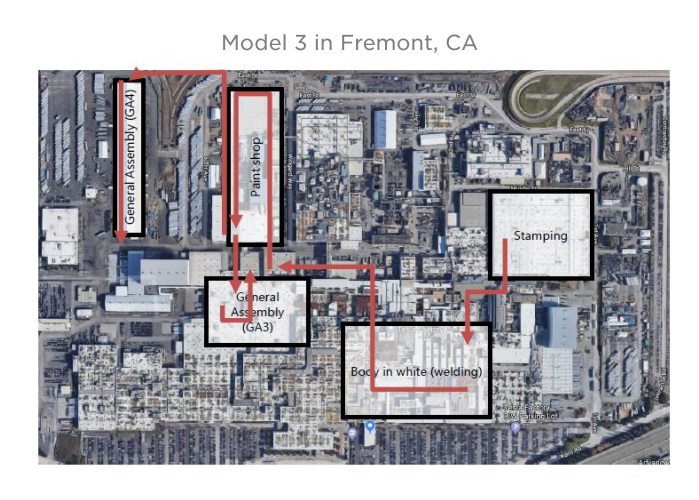

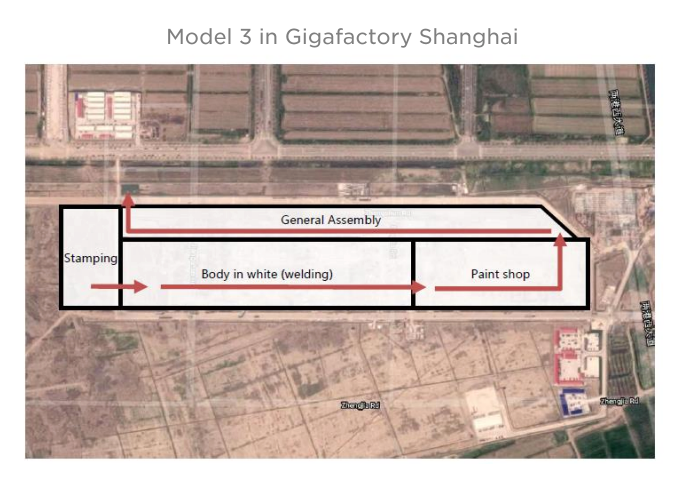

Therefore, you can also see Tesla’s understanding of factory iteration in the most important part of the article. Tesla mentioned that building new factories is particularly fun because it can reduce emissions in three ways: 1) use less materials; 2) reduce the logistics distance of more parts in the factory; 3) even robots can be used less after a reasonable layout is arranged.

The production process of Model 3 in the Shanghai factory and the Fremont factory were compared, it was self-explanatory. Shanghai’s internal path looks like it was drawn with a ruler.

However, this is still a small scale. How can we open up the perspective? You have to have a globalized vision. Localized production is regarded as an important part of Tesla’s global layout. Before the end of 2019, all of Tesla’s vehicles were produced in the Fremont factory, and vehicles delivered to any corner of the world had to be shipped from North America. With the construction of the Shanghai, Berlin, and Texas factories in the future, vehicle delivery and supply in several major markets can be radiated by local factories, which greatly reduces emissions caused by vehicle transport.

Just in the process of writing this article, the China Passenger Car Association announced Tesla’s delivery volume in July 2021. The majority of vehicles delivered that month were exported to Europe, which makes people curious about how to allocate production capacity reasonably between Shanghai and Berlin factories in the future.Translate the following Markdown Chinese text into English Markdown text in a professional manner, preserving the HTML tags inside Markdown, and only outputting the corrected and improved parts, without writing explanations.

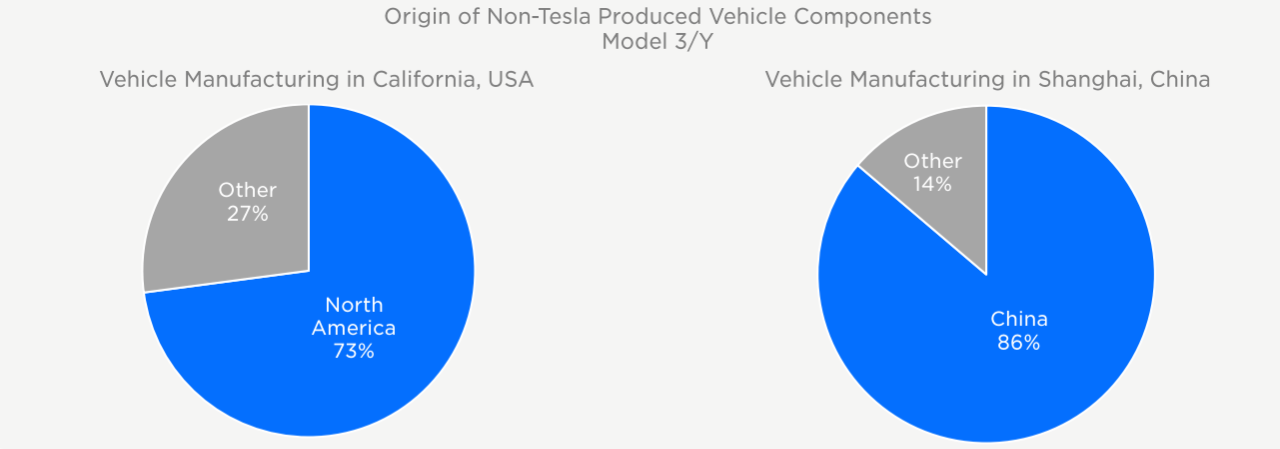

Similarly, in the car manufacturing industry, the shorter the distance of transmission for the various parts required for car production, the better. Tesla has provided a chart comparison showing the overall localization rate of Model 3/Y, with a localization rate of 73% for North American-produced models and 86% for Chinese factories.

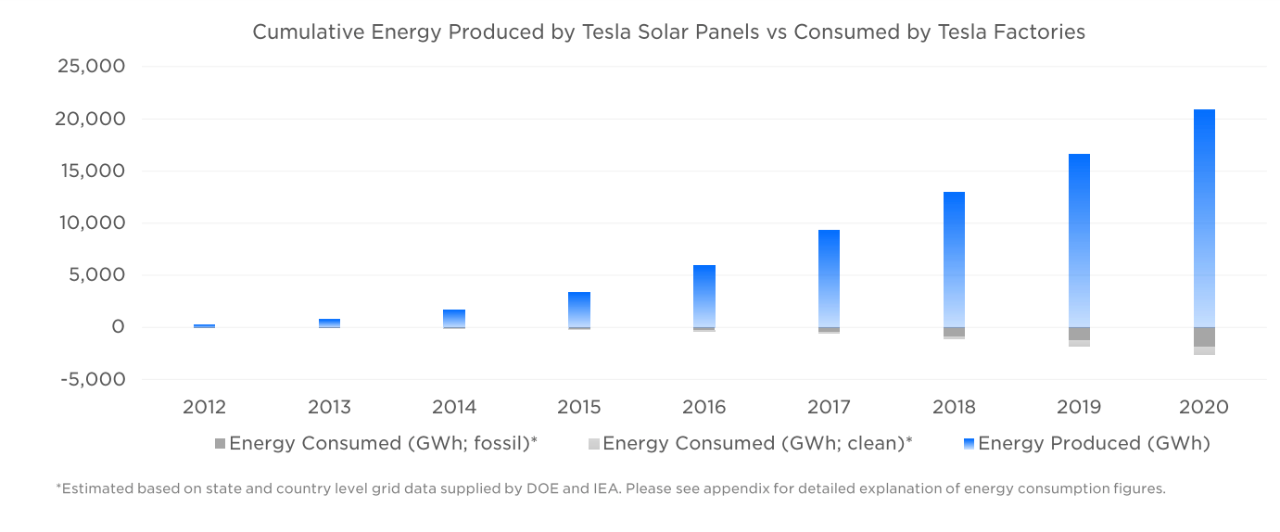

At Gigafactory 1, Tesla is conducting a large-scale social experiment by installing a large number of solar panels on the factory roof, with a total power of 3,200 kW, expected to reach 24,000 kW next year. This will make it the largest roof solar panel installation project in the United States and will be able to support the entire factory’s power needs next year.

With the improvement of the 4680 battery cell technology mentioned earlier and the use of large amounts of sustainable energy, energy consumption during the production process will further decrease.

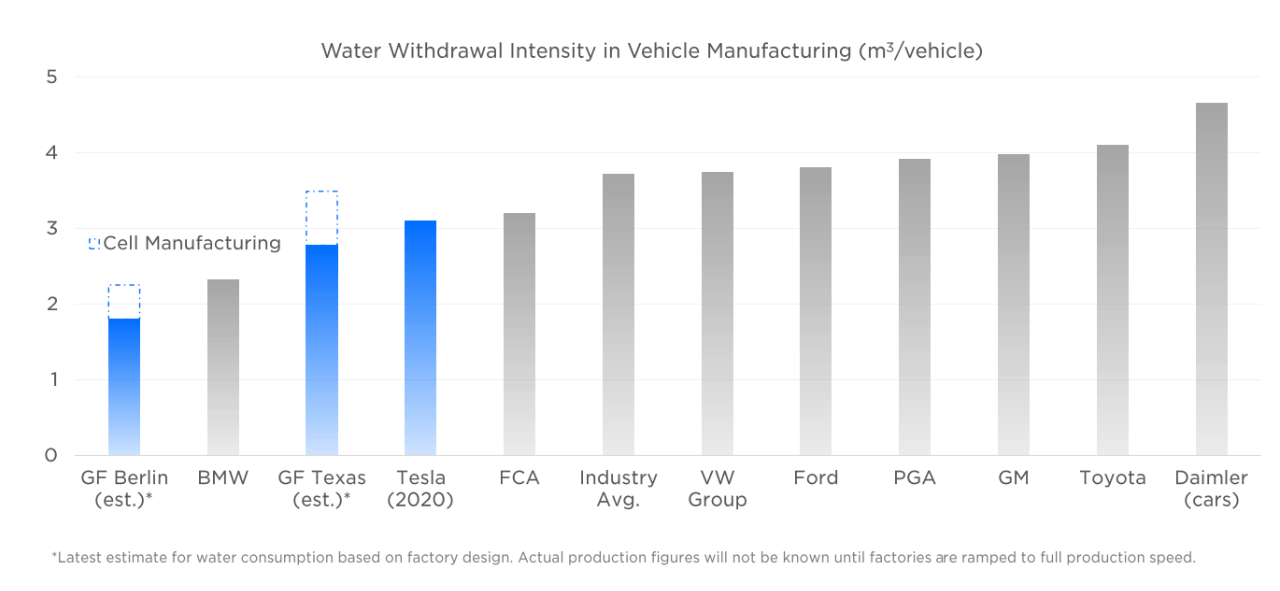

Tesla stated that the commissioning of each new factory in the future will be a new refreshment of comprehensive energy consumption. They eagerly listed a comparison of Tesla’s current and future factories’ environmental protection, and here I think… BMW is truly a miracle…

Opening a New Chapter in the Future

Under this slightly boring subtitle are several product news that we have been concerned about for a long time.

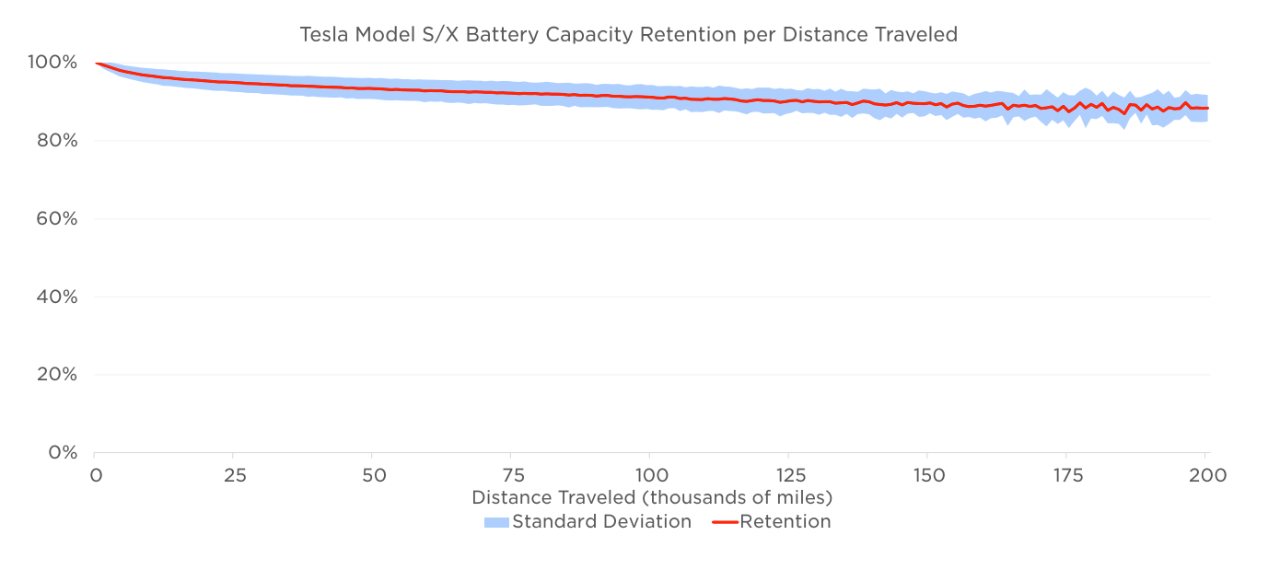

The basic one is the battery. Tesla’s determination to manufacture batteries with a durability of 1 million miles (1.6 million kilometers) remains unchanged. According to Tesla’s statistics, in North America, each electric vehicle is expected to be used for about 200,000 miles (320,000 kilometers) during its lifecycle, while this number is an average of 150,000 miles (240,000 kilometers) in Europe. Manufacturing batteries that can support approximately 4,000 charge and discharge cycles can significantly improve the overall lifespan of electric vehicle batteries and inevitably reduce emissions.

Of course, the extra one million kilometer lifespan is not just redundancy, but is for robotaxis.

Tesla’s definition of Robotaxi this time is: the core of achieving our mission to accelerate the transition to sustainable energy.In the United States, the average mileage of taxis, logistics vehicles, trucks, and buses is five times higher than that of private cars. Robotaxi, besides filling Tesla’s commercial blueprint, can fully exploit the value of each battery.

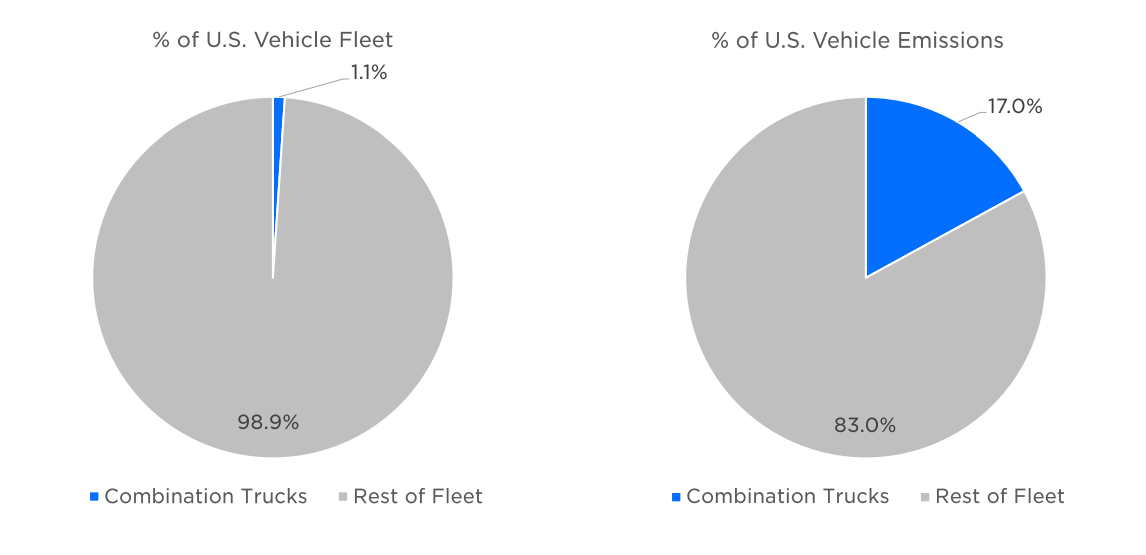

Then, the Semi truck received the highest honor among all Tesla models and had the opportunity to be featured in this special report, after all, the emissions of trucks account for too much.

In all US vehicles, joint semi-trailer trucks occupy only 1.1% of the total number of vehicle models, but the emissions of these trucks account for 17% of all vehicle models combined.

However, Semi is actually waiting for batteries. In order to ensure the usability and advancement of Semi, Tesla hopes that its theoretical range can reach 800 km. This requires at least a 500 kWh battery pack. Under a certain capacity, we hope that the battery will be lighter, for the truck, the vehicle’s battery weight has no power to compete with the goods. The lighter the vehicle’s battery, the more capacity the truck has to carry goods.

At the same time, the United States and Europe have set weight restrictions on electric trucks. In Europe, electric trucks are allowed to weigh two tons more than diesel trucks of the same specifications, while the United States only allows 0.9 tons more. Therefore, in order to meet the requirements for range, battery capacity, and weight, Tesla has to wait for the 4680 battery with higher energy density to enter production.

We have already been used to the convenience of Superchargers, and this time Tesla has also explicitly stated that it will build a more powerful Megacharger network. This higher power charging network will support Semi crossing the United States and Europe.

If Tesla’s financial report is more like a prophet of the future, then the “Impact Report” is more like a history textbook. You can put together a collection of annual reports, and fans can find all the information they need regardless of official succession in the report.

The 4,000 words introduced just now are only one-third of this year’s content. More details are waiting for everyone to explore between the lines.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.