Author: Michelin

Since previewing the Sodium-Ion battery technology at the shareholders’ meeting in May, the stock price of CATL (Contemporary Amperex Technology) has soared, surpassing a trillion yuan and all the way to the throne of the richest person in Hong Kong of its chairman, Zeng Yuqun.

Blade batteries, solid-state batteries, graphene batteries… Over the past year, we have heard too many new concepts and terms about power batteries. So what is the Sodium-Ion battery? Is it a gimmick to create concepts or a breakthrough product that will lead to a new era?

Two months later, CATL finally lifted the veil of mystery surrounding the Sodium-Ion battery.

“Why use ‘Sodium’ instead of ‘Lithium’?”

The Sodium-Ion battery, born almost at the same time as the Lithium-ion battery, is not a completely new concept.

In simple terms, the Sodium-Ion battery replaces the positive electrode material containing Lithium with a material containing Sodium on the basis of the Lithium-Ion battery, and replaces the electrolyte containing Lithium ions with a Sodium-ion electrolyte. The corresponding negative electrode and current collector materials are also replaced with materials more suitable for Sodium ions. The working principle and structure of the two are the same, the overall process is similar, and even the production equipment can be continued to be used.

No wonder CATL’s goal is to establish a basic industrial chain by 2023, as the infrastructure investment required for the production of Sodium-Ion batteries is not substantial after overcoming the technical difficulties.

Since the structure and process are similar and Lithium-ion batteries have become mature, why develop Sodium-Ion battery technology?

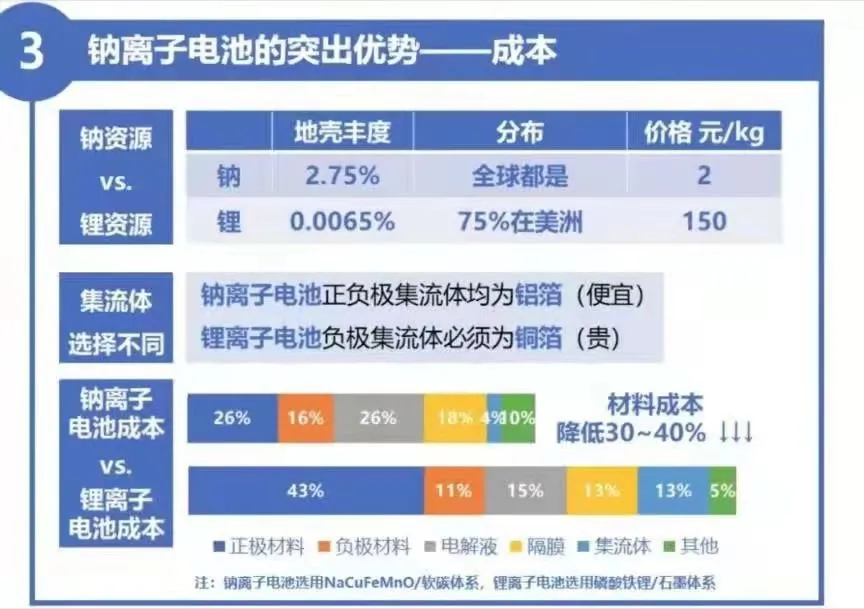

The most important reason is, of course, the raw materials. As a rare metal, the Lithium element is not abundant on Earth, mainly concentrated in South and North American countries. 70% of the Lithium used in domestic Lithium-ion batteries needs to be imported. In this way, the Lithium in Lithium-ion batteries is invisibly subject to the same whims of import as oil, and the price is rising year by year. Compared with this, Sodium resources are much more abundant, self-sufficient in China, and the price is only 1/75 that of Lithium.

At the same time, after replacing Lithium ions with Sodium ions, the current collector material used in the battery is changed from copper foil to aluminum foil, which is also cheaper.

The combination of these costs can reduce the cost of Sodium-Ion battery materials by 30% to 40%.

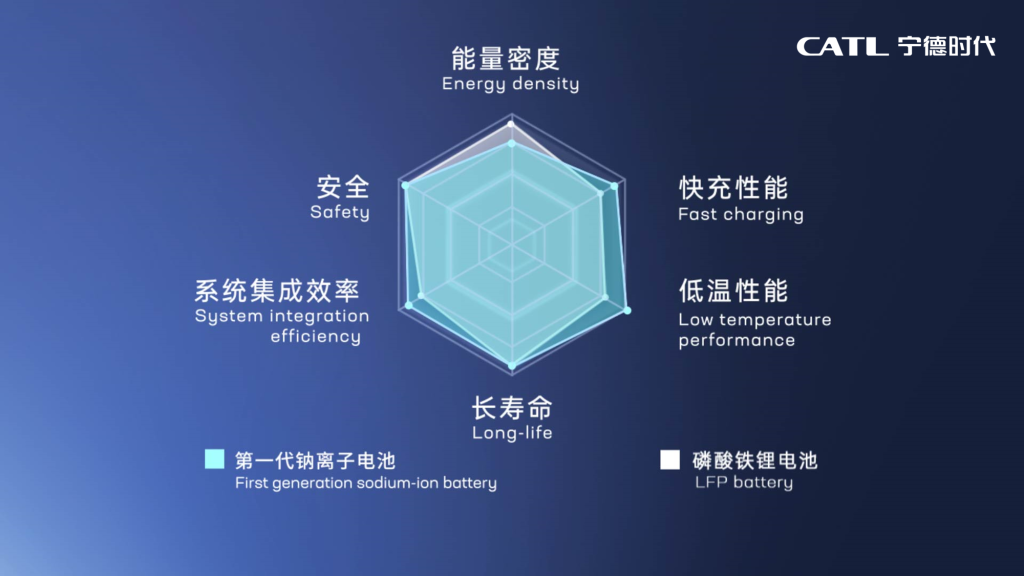

Of course, these need to be based on a mature, scalable industrial chain. The Sodium-Ion battery is still in its early stages, and its costs have not yet reached this level.Apart from the considerations of reducing costs and freeing up rare metals, sodium-ion batteries also perform well at low temperatures. Low temperature can be said to be the nemesis of electric vehicles and power batteries at present. The disadvantage of quick power loss in cold winter has somewhat limited the scope of application of electric vehicles and discouraged friends in cold regions. Compared with the fact that the capacity of lithium iron phosphate batteries is reduced below 0°C, and the performance of ternary lithium batteries is greatly reduced in cold winter, sodium-ion batteries have a discharge retention rate of over 90% at -20°C, which can ensure that the battery performance is basically not discounted when driving in winter.

Regarding safety issues that users are most concerned about, sodium-ion batteries are also more “tough” than lithium-ion batteries. Compared with the characteristics that lithium-ion batteries cannot be overcharged or over-discharged, although sodium-ion batteries cannot be overcharged, they can be over-discharged, and the probability of accidents occurring is lower when the battery is discharged completely and transported or stored without electricity. Even in the event of thermal runaway, the temperature of sodium-ion batteries is much lower than that of lithium-ion batteries, which makes the probability of ignition relatively lower.

The characteristics of cost, bottleneck raw materials, low-temperature performance, and safety have made sodium-ion batteries sought after by multiple domestic battery companies. However, with clear advantages and disadvantages, the large ionic radius and high activity of sodium-ion batteries have also become technical challenges for how to choose the positive and negative electrode materials of the battery and how to improve the energy density. This is why sodium-ion batteries and lithium-ion batteries were invented almost simultaneously, but the technology lagged behind for many years.

In the first generation of sodium-ion batteries, CATL (Contemporary Amperex Technology) restructured the positive electrode material in a solid-state form to avoid rapid capacity decay of positive electrode materials such as Prussian white in the cycling process; and used hard carbon materials with porous structures instead of graphite as the negative electrode to improve the battery performance. Therefore, the first generation of improved sodium-ion battery cell can achieve a single cell energy density of up to 160 Wh/kg and a system integration efficiency of over 80%, far higher than the previous sodium-ion battery. Moreover, it can achieve fast charging and can be charged over 80% within 15 minutes at room temperature.

Although in terms of performance, the current performance of sodium-ion batteries is still slightly lower than that of lithium iron phosphate batteries, as the first-generation product, it is not fair to compare it with lithium-ion batteries that have matured and tend to have stable energy density. After all, a few years ago, we did not expect the performance of lithium-ion batteries to soar so quickly.

Mixing AB batteries to get sodium-ion batteries on board quickly

At this stage, it is not realistic to directly replace lithium-ion batteries with sodium-ion batteries. However, application is the best means to promote rapid iteration and development of products. How to use the first-generation sodium-ion battery in the familiar electric vehicles is a critical issue.The answer given by CATL is: AB battery solution. The battery pack of the car consists of both lithium-ion batteries and sodium-ion batteries, allowing the two types of batteries to be mixed and used together. The BMS precise algorithm is used to achieve balanced control of different battery systems, enabling the two types of batteries to perform their maximum functions under their suitable conditions, complementing each other. High energy density lithium-ion batteries ensure the vehicle’s endurance; sodium-ion batteries have superior performance in low temperature conditions and can also ensure normal driving of electric vehicles in cold winters. In the future, mature mass production of sodium-ion batteries will even reduce the cost of the battery pack and make electric vehicles more affordable.

As for the future, CATL has set the energy density target of the next generation sodium-ion battery at 200 Wh/kg. If this target can be achieved, it will be similar to the current ternary lithium-ion battery and lithium iron phosphate battery. By then, the proportion of sodium-ion batteries used in mixed use may gradually increase, or even all lithium-ion batteries could be replaced by sodium-ion batteries.

In this way, the price of electric vehicles may be even lower, and it will not be a problem to use them in winter and in cold northern regions, making them applicable to even more scenarios.

Conclusion

As the first generation of sodium-ion battery, from 0 to 1, from nothing to something, it is hard to make higher demands on its performance. Its appearance has already brought us surprises and new possibilities.

As for the future, can sodium-ion batteries replace lithium-ion batteries, allowing electric vehicles to travel farther at a cheaper price? It is said that this sodium-ion battery has already been planned for use in certain car models and energy storage projects, and the answer may come soon.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.