Tesla introduced the latest developments of the 4680 battery in their earnings report and conference call, including:

- The reliability of the 4680 battery,

- The availability of the 4680 battery.

The 4680 Battery

At Tesla Battery Day in September 2020, the 4680 battery was unveiled as a key technological development for Tesla’s transition to sustainable energy. This battery, with a diameter of 46mm and a length of 80mm, delivers 5 times the capacity, 16% more range, and 6 times more power output than the 2170 battery, at a lower cost.

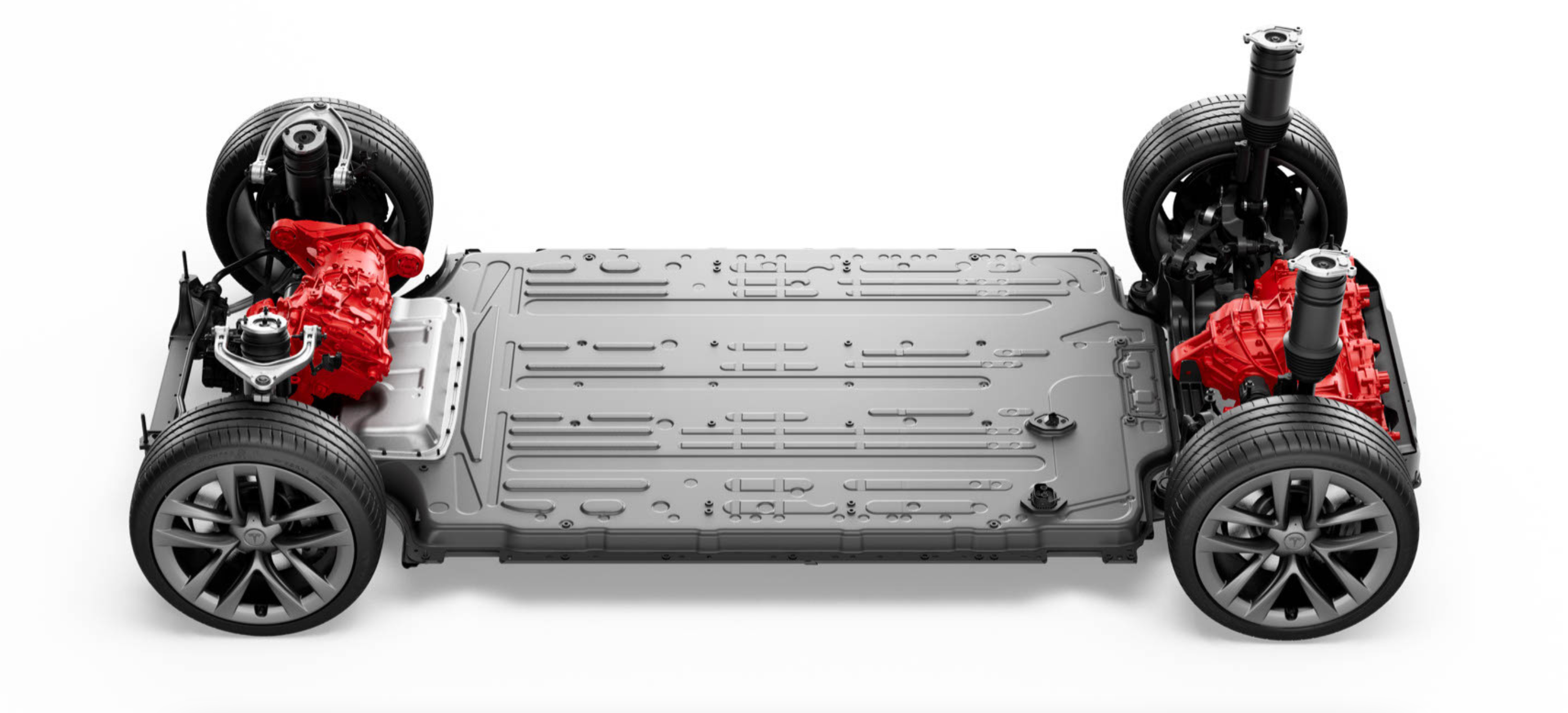

The 4680 battery is equipped with Cell to Chassis (CTC) packaging technology, which increases the stiffness of the entire vehicle body structure by incorporating the battery as a structural element.

Reliability

Tesla stated in their earnings report that validating tests of the 4680 cell have been completed without any problems with performance or lifespan. However, there are still about 10% of processes that need to be improved, which is a bottleneck for large-scale production.

In response to concerns about reliability, Elon Musk stated in the Q2 2021 earnings conference call that the small-scale production of the 4680 battery is already reliable, but much work is still needed to achieve reliable large-scale production in industrial manufacturing.

Supply Chain

Currently, Panasonic is setting up a test production line for the 4680 battery and is working on it as planned. Tesla estimates that by the end of next year, the production capacity of the 4680 battery will reach 100 GWh, and the Model Y produced in Berlin will be equipped with the 4680 battery.

In addition, if battery supply is sufficient, Tesla expects the annual production of Powerwall energy storage batteries to reach 1 million units next year, and their goal is to achieve an annual battery production capacity of 1,000 to 2,000 GWh with their suppliers.

Other

As Tesla’s third-generation cylindrical battery, the 4680 cell is optimal in size for both range and cost considerations. The bipolar electrode design significantly reduces the internal resistance of the 4680 cell and greatly decreases the heat generated during charging, creating little effect on charging time despite a reduction in radiating surface area compared to 2170 cells.Currently downstream suppliers such as Panasonic and LG are heavily invested in the development and production of the 4680 battery cells. Due to overall supply capacity limitations of the 4680 cells, Tesla has delayed the mass production of Semi until 2022, and the massive delivery of Cybertruck will also not be realized until next year.

As the production capacity of the 4680 batteries in the supply chain begins to climb, Tesla’s production and delivery progress of related models should theoretically accelerate as well. On the product side, Tesla’s integration of the 4680 cells with the CTC chassis and the front and rear integrated die-casting body structure will bring improvement in cost control, production efficiency, and vehicle performance. Cooperating with Tesla in producing the 4680 battery cells will also be a key factor affecting the power battery supplier pattern in the future on the power battery industry level.

🔗Source: TESLARATI

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.