The Development Status Quo of Automated Parking

Parking has always been a thorn in the side of many drivers. In order to solve this pain point, domestic and foreign automobile manufacturers are constantly researching and popularizing automated parking technology. Nowadays, car models equipped with the Auto Parking Assist (APA) system have gone down to below 150,000 yuan.

On the other hand, automated parking technology is also constantly improving. When the APA is working, the driver is freed from using their hands and feet, but they still need to sit inside the car to start the activation button and monitor the entire process. Once an emergency occurs (such as a child suddenly appearing), the driver needs to take over in a timely manner and avoid collision accidents through braking or steering. This type of parking system still gives the driver a “task” and cannot fully meet the ultimate expectations of the public.

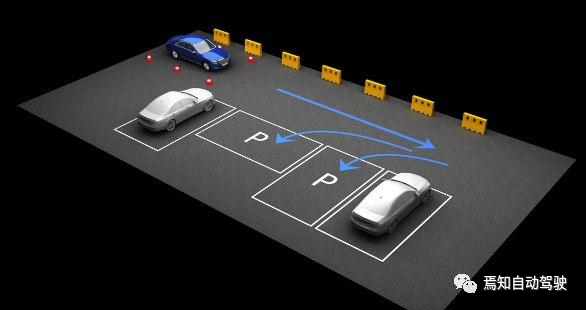

As a result, Remote Parking Control (RPC) and Automated Valet Parking (AVP) have successively landed. RPC allows the driver to get off the car and activate the process remotely (using the car key or mobile app), and the entire parking process is completed autonomously by the system. However, in general, the driver still needs to be within a certain range from the car (EU regulations ECE-R 79 require a radius of no more than 6 meters).

AVP is considered the optimal technical solution to solve the pain point of “the last mile of freedom” for users. In simple terms, AVP provides the following two major functions, fully satisfying the public’s ultimate imagination of automated parking:

-

One-Click Parking: The user gets off the car at a designated point, issues the parking command, and the vehicle can automatically drive to a parking space in the parking lot upon receiving the command, without the need for user manipulation or monitoring.

-

One-Click Retrieval: The basic requirements for this function are as follows: after the user has issued a retrieval command, the vehicle can automatically drive from the parking space to the designated pick-up point upon receiving the command.

Requirements for the Braking System for RPC and AVPFrom the current positioning of the system, both remote parking assist (RPA) and autonomous valet parking (AVP) systems, compared to autonomous parking assist (APA), not only free the driver’s hands and feet, but also free the driver’s brain — emergency monitoring and handling during the parking process will be completed by the system. The liberation of the driver implies an increase in the requirements for autonomous parking systems. Therefore, the system architecture of RPA and AVP is far more complex than that of APA.

In terms of implementation, the RPA and AVP solutions of various manufacturers vary greatly and present a diversified trend. However, if we only look at the emergency handling of the parking process, everyone takes the same course of action, which is to perform emergency braking. This type of handling is reasonable and easy to implement for parking scenarios, because the maximum operating speed of RPA and AVP does not exceed 15kph. Rapidly stopping the vehicle can avoid collision accidents or reduce the collision speed to a very low level, thereby reducing collision damage.

As a result, RPA and AVP must ensure the safety of the vehicle braking control. So the question is: How should the braking system be designed to ensure the safety of autonomous parking?

Because in the parking process of RPA and AVP, the driver’s monitoring and takeover are not considered, that is to say, RPA and AVP belong to “autonomous driving” rather than “assisted driving,” and the basic design concept of autonomous driving function is “redundancy design” — when the main control system fails, the backup control system can take over. Therefore, the braking system in RPA and AVP also needs to be brake redundant to ensure that its defined emergency braking measures can still be implemented in the event of a single-point failure of the system.

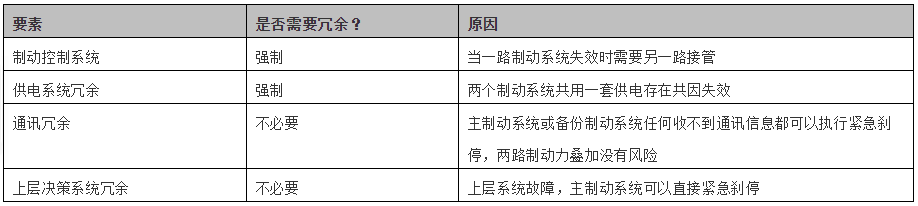

In RPA and AVP, the requirements for redundancy of the braking system are as follows:

The mainstream redundant combination of brake systems in the current market is the ESC+i-Booster combination provided by Bosch, which is used in the autonomous parking systems of Tesla, XPeng P7, NIO ES6, and Ideal ONE. Bosch’s electronic stability control system ESC (also known as ESP) and electronic brake assist system i-Booster have high installation rates in mainstream electric vehicles. Expanding this combination to meet brake redundancy requirements is a choice that balances performance and cost. However, this is not the only solution for redundant brake systems. For example, i-Booster is mainly used in hybrid or pure electric vehicles. Other brake redundancy schemes are needed to support RPA or AVP in models with only the ESC system. In this regard, the German Association of the Automotive Industry has given an answer in its VDA 305 standard, which is to modify the integrated electronic parking brake system EPB and combine it with ESC hydraulic brake and EPB caliper brake to achieve redundant braking required for autonomous parking. Next, this redundant brake system will be introduced.

The mainstream redundant combination of brake systems in the current market is the ESC+i-Booster combination provided by Bosch, which is used in the autonomous parking systems of Tesla, XPeng P7, NIO ES6, and Ideal ONE. Bosch’s electronic stability control system ESC (also known as ESP) and electronic brake assist system i-Booster have high installation rates in mainstream electric vehicles. Expanding this combination to meet brake redundancy requirements is a choice that balances performance and cost. However, this is not the only solution for redundant brake systems. For example, i-Booster is mainly used in hybrid or pure electric vehicles. Other brake redundancy schemes are needed to support RPA or AVP in models with only the ESC system. In this regard, the German Association of the Automotive Industry has given an answer in its VDA 305 standard, which is to modify the integrated electronic parking brake system EPB and combine it with ESC hydraulic brake and EPB caliper brake to achieve redundant braking required for autonomous parking. Next, this redundant brake system will be introduced.

Redundant Brake Solution for Integrated Electronic Parking Brake System EPB in Autonomous Parking based on VDA305

Background of VDA305

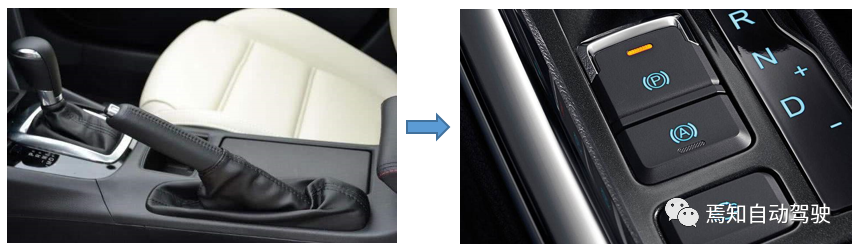

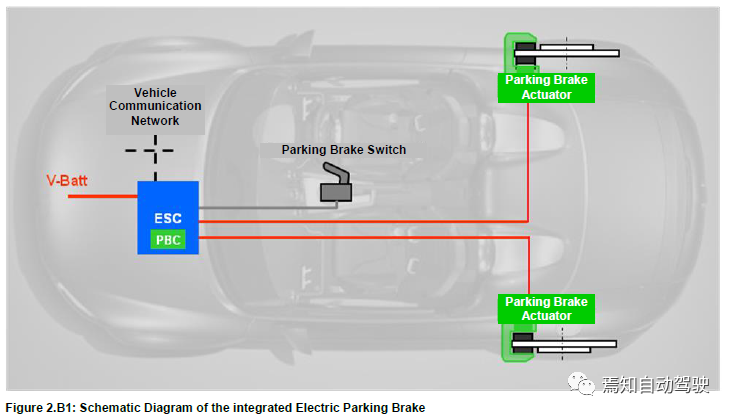

Currently, the electronic parking brake system EPB is almost a standard configuration for vehicles priced above 100,000, gradually replacing mechanical handbrakes. EPB consists of two parts:

- The parking execution mechanism that generates parking force (caliper and motor of control caliper)

- The electronic control unit (ECU) that controls the parking execution mechanism, including software and hardware.

Actually, 99% of EPB systems on the market are integrated, which means they share the ECU of Electronic Stability Control (ESC), integrate the software of EPB system into the ESC software, and make some modifications on the basis of the ESC hardware to support the hardware requirements of EPB.

Why is it designed like this? In addition to providing parking functions, the EPB system can also control the backup braking of the brake hydraulic during the driving process, and the hydraulic execution mechanism is integrated into the ESC system. The wheel speed sensors included in ESC system can provide the key parameter of vehicle speed for the EPB system to determine whether the current speed can park. Therefore, EPB and ESC are closely related in terms of functionality. If they correspond to independent ECUs, there will be many interaction interfaces between them. Integrating them into one ECU is a natural and cost-effective solution to reduce the complexity of the entire vehicle E/E system.On the other hand, suppliers specializing in ESC systems and those specializing in EPB systems are often not the same. For OEMs, if different EPB and ESC system suppliers work independently, there will be many problems when integrating EPB software into ESC software, and the primary issue is how to unify the interface definitions of EPB and ESC software. This is the background of the birth of the VDA 305 standard. The VDA 305 aims to standardize the architecture of the EPB system and the interaction interface of EPB software and ESC software, clearly define the responsibilities of EPB system and ESC system suppliers, provide the OEMs with greater flexibility in choosing suppliers, and make the collaboration among different suppliers more efficient.

EPB System Description Based on VDA 305

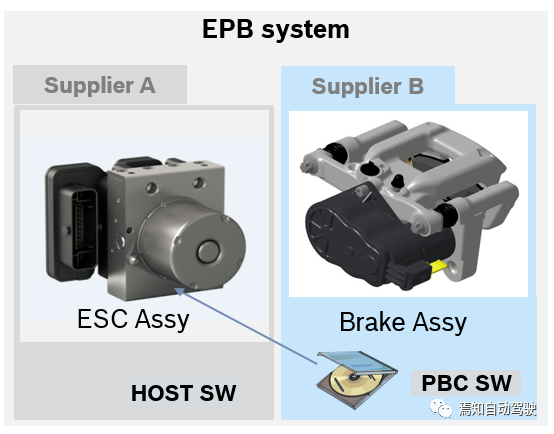

VDA 305 divides the EPB system into two parts, which can be provided by two different suppliers:

-

Brake Assy: Includes brake caliper, caliper motor, and motor control software (PBC, parking brake controller)

-

ESC Assy: Also called Brake Host, provides the EPB ECU and peripheral devices such as power supply, CAN communication interface, and hardwire interface

The purpose of this division is to:

-

Specialization enables suppliers to leverage their respective strengths to form more reliable products by complementary strengths.

-

Define the supplier’s range of responsibilities

-

Ensure that a supplier’s testing work and product release will not be affected by the development status of the other party.

From another perspective, if we consider the EPB system and the ESC system as two separate systems, the EPB system consists of the following components:

-

Left and right brake calipers

-

PBC software that controls the caliper motor

-

Hardware electric drive bridge that realizes motor control

-

Diagnostic module, CAN signal or hardwired signal processing module, and wheel speed sensor signal processing module in the Host software

-

Shared hardware modules, such as microprocessors, electronic memory components, etc.

The components of the ESC system include:

- Hardware that implements the establishment of wheel cylinder hydraulic pressure.### Integrated EPB’s Brake Redundancy System Architecture and Degradation Strategy

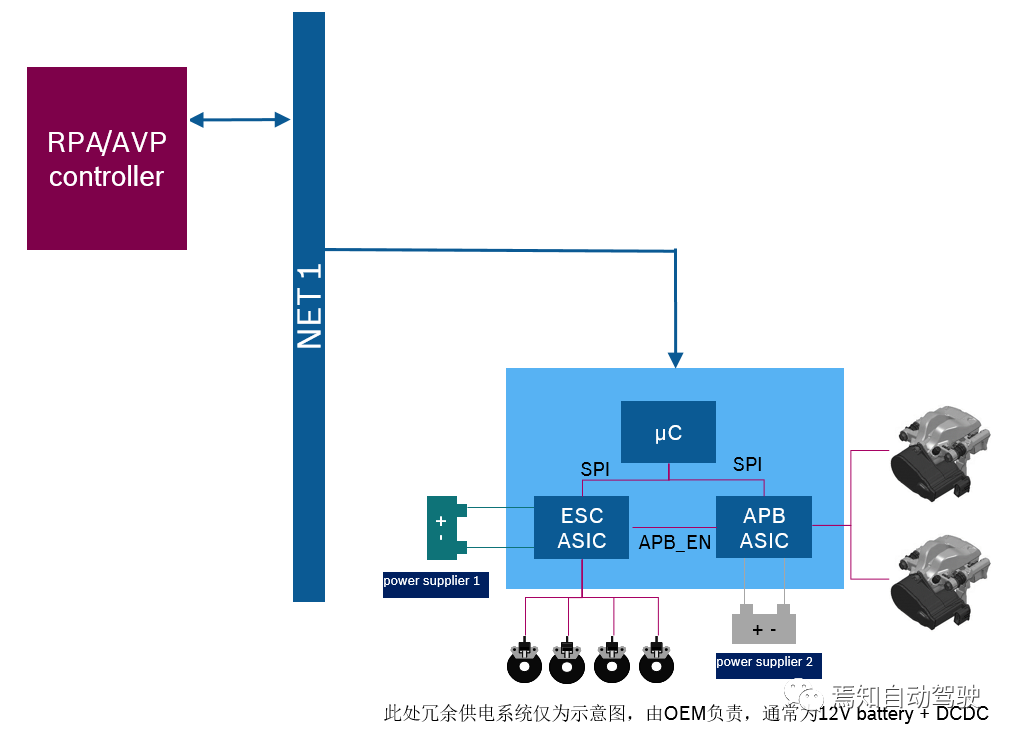

From the above introduction, we can understand that the integrated EPB system can provide the following two types of braking force:

- ESC hydraulic braking force

- EPB caliper braking force

However, we can also see that EPB control and ESC control share the following elements:

- microprocessor (i.e. μC)

- power supply

Any failure of these two elements will directly lead to both ESC and EPB being unable to provide braking force, which means that there is a common cause of failure between ESC hydraulic braking and EPB caliper braking, which does not meet the brake redundancy required by RPA and AVP.

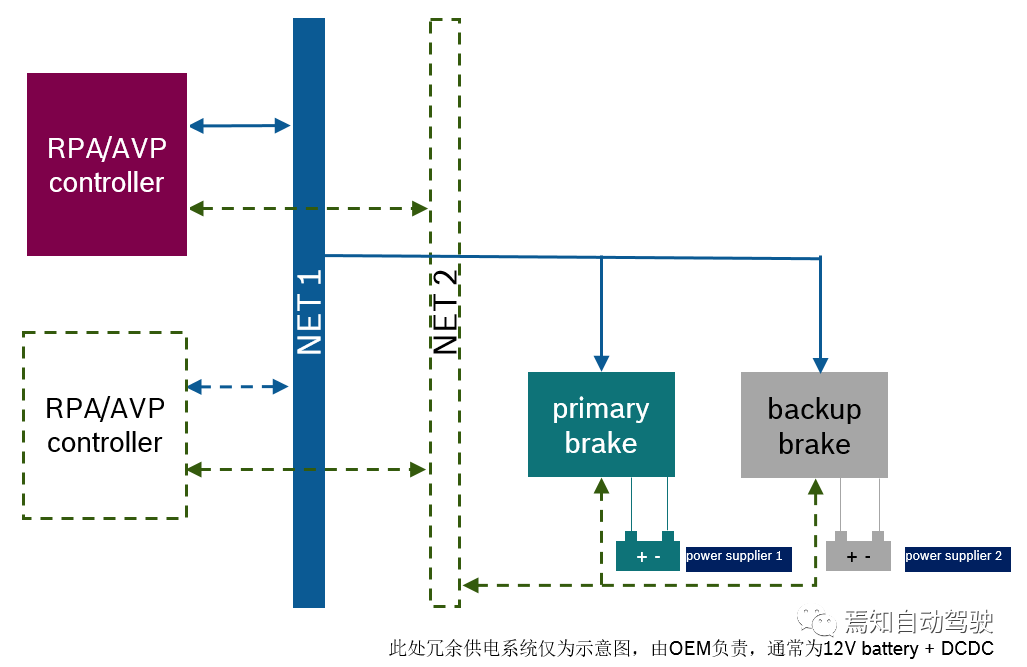

To achieve brake redundancy, in addition to software changes, special hardware modifications are also required. The hardware modifications mainly achieve the following two points:

- can receive two power supply sources

- when μC fails, the integrated circuit APB ASIC needs to be activated to drive the caliper

The brake redundancy architecture of the integrated EPB system is shown in the figure below.

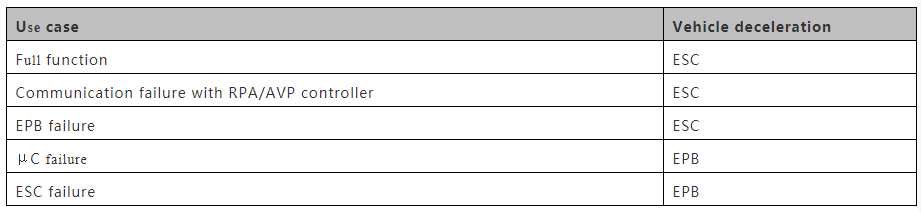

In this brake redundancy system, ESC hydraulic braking is the main braking system and EPB caliper braking is the backup braking system. The system degradation strategy is summarized as follows:

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.