Author: Lingfang Wang

Recently, Funeng Technology announced a new battery with an energy density of 330 Wh/kg.

According to Funeng, the electrochemical system was designed with advanced silicon negative electrode materials, single-walled carbon nanotube conductive agents, and a new type of binder formula, effectively overcoming the problem of silicon expansion and reaching a capacity of over 1500 cycles.

In addition, the battery can still provide 90% of its capacity at a temperature of -20℃.

Funeng is currently applying to authoritative testing institutions to conduct tests according to national standards. The testing cycle is expected to be about 3 months. After the testing, the battery can be sold and used.

How does this battery compare to others in the industry? What technology does it use?

How does the battery compare to others in the industry?

The 330 Wh/kg energy density is currently the highest in the industry.

A few years ago, Panasonic battery claimed an energy density of 300 Wh/kg, which was used in the battery pack of Tesla Model 3, but the actual energy density was only 256 Wh/kg.

Based on the certificate data of the entire vehicle issued in 2020, the Electric Vehicle Observer has not found any batteries with an energy density of 300 Wh/kg for installed vehicles.

According to the calculated data, the highest energy density of a single cell is the soft pack battery from CATL, which is 279.56 Wh/kg.

Overall, the average energy density of soft pack batteries is around 200 Wh/kg, with a mainstream energy density of 240-260 Wh/kg.

In 2020, the energy density of Funeng’s installed batteries ranged from 207-242 Wh/kg, with a system energy density of 140-170 Wh/kg, corresponding to a range of 400-500 kilometers.

Taking the cylindrical battery as an example, the LG cylindrical battery installed in Tesla has a single-cell energy density of 256-257 Wh/kg, with a system energy density of 145-161 Wh/kg, corresponding to a range of 445-668 kilometers.

According to the certificate issued in 2020, the highest energy density of the installed square battery is around 250 Wh/kg, with a system energy density of 180 Wh/kg, corresponding to a range of about 500 kilometers.

If Funeng develops a battery with an energy density of 330 Wh/kg and a grouping efficiency of 70%, the battery system’s energy density is expected to reach 230 Wh/kg.

Currently, the highest system energy density known in China is from Guoxuan High-Tech, which is used in the Beijing BJ7000USD8-BEV pure electric sedan, and the battery system’s energy density exceeds 200 Wh/kg. However, its range is only 470 kilometers.If Funeng can put this battery into mass production and use it in vehicles this year, it may set density records at both the cell and system levels.

Carbon nanotubes: helical graphene

How did Funeng achieve a significantly higher energy density in its newly developed battery than the current industry standard?

According to Funeng’s announcement, it uses silicon as the anode material.

Silicon has the highest theoretical capacity among known anode materials at 4200 mAh / g, far exceeding graphite anodes at 372 mAh / g.

However, the drawback of using silicon is its high volumetric expansion, which causes instability in lithium-ion battery structures and should result in cycling attenuation. What stabilizes this structure?

The answer may lie in single-walled carbon nanotube conductive agents.

To understand exactly what single-walled carbon nanotubes are, EV Obsession consulted relevant materials.

According to related studies, single-walled carbon nanotubes are closely related to graphene.

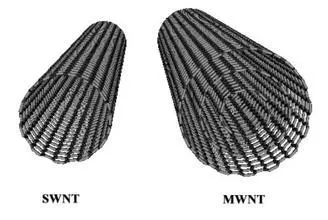

A single-walled carbon nanotube is formed by curling a single layer of graphene, while a multi-walled carbon nanotube is composed of two or more layers of graphene.

Fundamentally, carbon nanotubes and graphene are both graphite-like materials, but the arrangement of carbon atoms is different.

Graphene is a two-dimensional crystal composed of carbon atoms that are only one atomic layer thick, stripped from graphite. It also comes in single-layer and multi-layer (microscopic) graphene.

In other words, the helical structures are carbon nanotubes, while the sheet structures are graphene, so they both have some of the same properties as graphite, such as conductivity.

At present, the low power density is the biggest drawback of lithium-ion batteries, and during high-rate charge and discharge, the low ion migration rate and low conductivity and thermal conductivity at the electrode interface can lead to high polarization of the lithium-ion battery electrode.

Polarization results in more energy consumption during charging and the conversion of electrical energy into heat during discharge, which is not only uneconomical but also unsuitable for fast charging.

Carbon nanotubes have good electronic and ionic conductivity, which is more conducive to improving the battery cycle life and compensating for the cycling loss caused by adding silicon.

Specifically, due to its special tubular graphite structure and unique ballistic electron conduction effect, the electrical conductivity of carbon nanotubes can reach 1000000 s / cm at room temperature. When applied to lithium-ion batteries, this can increase the speed of lithium ion rapid insertion and extraction. In short, it is very beneficial for high-power charging and discharging of lithium-ion batteries.

For battery systems, Funeng’s response is a high nickel ternary system.

According to industry experts’ analysis, it is possible for the energy density of soft-pack batteries to reach the density of Funeng’s battery, which is likely still in the 8 series.

Still in the testing phase.According to a statement by Funeng, at present, the company has conducted safety-related tests on the battery, including overcharge, over-discharge, short-circuit and thermal performance tests, and passed all of them.

Funeng is currently in the process of applying for the new national standard GB38031-2020 testing, which is expected to take about three months at China Automotive Engineering Research Institute Co., Ltd. Testing Center, after which the battery can be sold and used.

According to Funeng, the reason for the development of this product is due to an American company’s cooperation project undertaken in 2017, with a delivery date set for the end of 2020. The performance target of the project was 330 Wh/kg, which is the only requirement for the project by Funeng Technology.

The battery has been tested both internally by the company in China and in authorized laboratories in the United States, and the data is consistent. The U.S. acceptance inspection was successfully completed in December last year.

This battery has an energy density of more than 25% higher than that of mainstream battery products in the industry, and is expected to help achieve a range of 1000 kilometers for the whole vehicle. The cycle performance test can reach more than 1500 cycles of life span.

According to Funeng, the high energy density and high cycle life of the new battery can achieve a million kilometers of mileage for electric vehicles within the life cycle.

It is worth noting that the single-walled carbon nanotubes used in the Funeng battery are not cheap. However, Funeng claimed that the cost will not increase significantly after large-scale production in the future.

Considering that the soft pack batteries are currently small in scale, cost reduction could be difficult in the short term. As such, it is most likely that the new battery will be first applied to high-end models rather than mid- to low-end models with price sensitivity.

However, it is certain that with the mass production of this battery, Funeng Technology can enhance its competitiveness and market share, attracting some consumers to pay attention to and use the product, thereby improving its status in both domestic and global markets of the industry.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.