Introduction

The high-end brand, Voyah, of Dongfeng has done something interesting in promoting their batteries by making some cuts:

1) Cylindrical batteries: In the first model, they used Samsung SDI’s cylindrical cells and integrated them with a foam-like flame-retardant material. From the form of this package, it seems to target a similar solution to the high-end Model S.

2) Pouch batteries: According to a previous announcement from Funeng, Voyah’s H56 project uses Funeng’s 590 module.

3) Blade batteries: This is used in extended-range models.

Overall, among the high-end brands in state-owned enterprises, Beiqi Blue Valley uses SKI’s cells in pouch packages. FAW and Changan use CATL’s shell pack. GAC has now found a similar cell in the development of Zhonghang for the iX3.

There are quite a few differences in the choices made by several Chinese auto-independence companies. Among private enterprises, Geely uses a compatible solution of pouches (Funeng) + shell packs (CATL), while Great Wall uses custom longer shell packs with stacked blade cells.

Part I: Versions of Cylindrical and Pouch Batteries

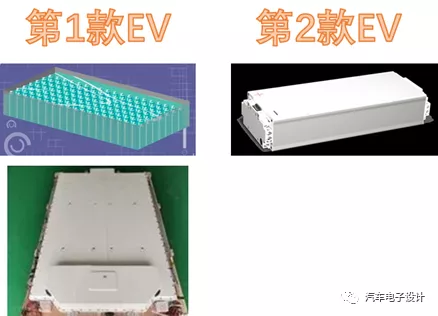

1) Cylindrical Version (to be launched in Q3 2021)

After last year’s widely-publicized lithium-ion battery fires, Voyah’s campaign this time focuses on promoting their heat run-away experiment. They use Samsung SDI’s 21700 cylindrical NCA cells, as shown below. The design of this package has some similarities with the Model S.

From the whole structure, it is also a flat system design, and the second-row rear seats are raised to accommodate more batteries.

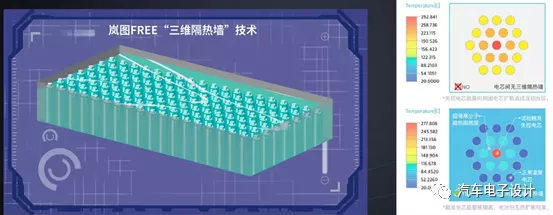

The design structure of the module is somewhat similar to the previoulsy mentioned Model S. According to the official statement, the three-dimensional thermal insulation is strong and it is made of high-polymer insulation and flame-retardant material.

It is not clear at present that there is no detailed cooling structure inside the module. Under the condition of thermal runaway propagation, this material can isolate the energy emitted by a single cell over 5 Ah (NCA + SiC, which should have a relatively high energy density). However, the heat generated by the cell during fast charging is also blocked. In the schematic diagram below, we did not see the cooling structure inside the module.

## 2) Soft pack version (2022)

## 2) Soft pack version (2022)

The soft pack battery cell is a standard module of 590 batteries used in the MPV of Voyah. Safety is not mentioned, but based on current conditions, it may have been designed for thermal runaway for 30 minutes (no longer requiring the current 5-minute requirement). The energy density of the battery cell is > 275 Wh/kg, and the highest charging rate can reach up to 2.2 C.

Why doesn’t Voyah use a square shell?

Before, it was not easy to choose battery cells. Tesla firmly launched its own 4680 design, hoping to upgrade from 21700 to this larger battery cell specification, and achieve systematic cost reduction, attracting Panasonic and LG Chem.

Interestingly, Panasonic wants to get rid of its dependence on Tesla, while LG may firmly embrace the cylindrical battery route after the public chooses the square shell battery as the next generation battery benchmark. Currently, the soft pack technology road map has been moving further away from the 590 battery standard to prepare for longer modules.

During the move towards high nickel, it is difficult to insulate thermal conductivity over a long range. This is why after a round of attempts with soft pack battery cells in Europe, more resources were invested in square shells. After all-in on the soft pack, Hyundai is now also transferring part of its usage to square shells.

In my opinion, everyone is betting on both ends. Voyah’s choice of soft pack and cylindrical battery cells may have several explanations:

1) After adopting the Korean series, the cylindrical battery cell is similar to Tesla’s design standards, and many of its features can be borrowed.

2) Regardless of soft packs and cylinders, the initial design issues and the previous square shell choices from Dongfeng were separated. The public version plan given before had clear limitations in terms of fast charging speed and energy density.

But things have been changing rapidly in the past two years, as Tesla has also led the installation of square shell iron lithium (shorter battery cells), and many things are changing.

3) Differentiation is still necessary now. Voyah’s solution differs from everyone else’s, and the way of promoting a single little cylindrical battery cell that does not experience thermal runaway when the entire module is overheated is confirmed. The overall ignition probability of the ternary version of Model 3 + Y is indeed much lower than that of the previous generation, and the design improvements are confirmed.

ConclusionI am actually curious, if Volkswagen defines the size of prismatic battery cell, will other companies such as SKI and LG also purchase the prismatic cell shell to make their own prismatic cell in their own lamination process, similar to what was proposed by CATL before, as the difference is not so great.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.