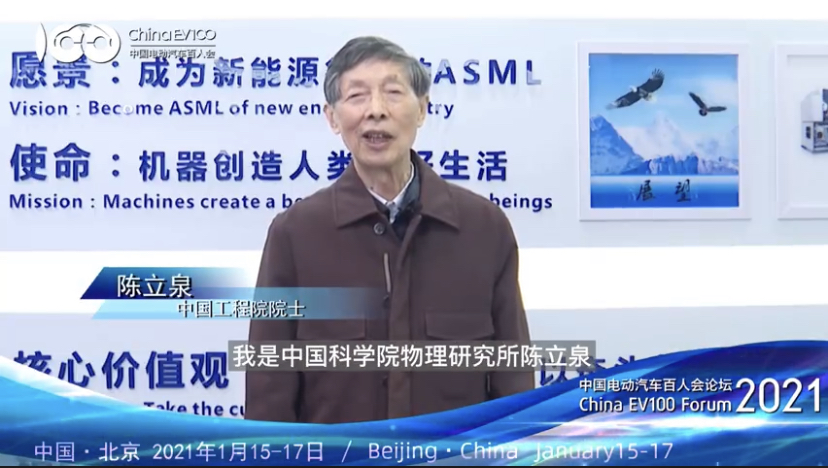

On the morning of January 17th, 2021, the Future Battery Forum of China Electric Vehicle Hundred People’s Conference was held in Beijing. Chen Liquan from the Institute of Physics, Chinese Academy of Sciences, gave a speech on “New Generation Battery Leading Electric China”.

Chen Liquan stated that the current battery is a lithium-ion battery, with a graphite negative electrode that everyone is familiar with, and a positive electrode made of lithium iron phosphate, ternary, or lithium cobalt oxide. The electrolyte is a flammable liquid electrolyte, which easily causes safety concerns. In addition, its energy density has reached 300 watt-hours/kg, which is already a limit of liquid lithium-ion batteries. Our next step or new generation batteries is to develop solid-state batteries or gradually transition to all-solid-state lithium batteries.

The negative electrode material of the solid-state lithium battery can be a composite of nano-silicon and graphite, and the positive electrode can be high-voltage lithium manganese oxide or lithium-rich manganese-based materials, or non-lithium positive electrode materials. The electrolyte is a solid-state electrolyte, and its energy density can be 300-450 watt-hours/kg. The next generation is the long-term future, such as lithium-sulfur batteries or lithium-air batteries.

At the same time, we should now develop sodium-ion batteries. Sodium-ion batteries are basically the same as lithium-ion batteries in terms of process technology. Its negative electrode is also made of carbon, which we are using smokeless coal. The positive electrode does not necessarily contain precious metals such as cobalt and nickel, and can only contain relatively inexpensive elements such as copper, iron, and manganese. The electrolyte is currently a liquid electrolyte, and the next step is to develop a solid-state sodium-ion battery. The energy density of sodium-ion batteries can reach 150 watt-hours/kg. If done well, it can reach 200 watt-hours/kg.

We must also introduce our current energy situation. Currently, our energy situation in China is abundant in coal, lacking in gas, and lacking in oil, and we are very short of oil. In 2018, our energy situation was that coal, oil, and natural gas accounted for 85.6% of the total energy, while water, wind, solar, and nuclear energy accounted for 18.3%. It should be said that fossil energy is dominant. In 2018, we produced 190 million tons of crude oil, and imported 460 million tons of foreign crude oil. Foreign dependence has reached 71%, and we originally recommended that foreign dependence should not exceed 50%. In fact, it has far exceeded 50%. The number of cars in China is 240 million. If calculated based on an average of 2 tons of oil per car, the 460 million tons of imported crude oil is just enough for our cars. Therefore, we must electrify China, develop electric vehicles, and replace imported oil. This is why we need to electrify transportation. At the same time, to achieve equipment intelligence, intelligent devices also need batteries.### President Xi Jinping’s Energy Goals for China

President Xi Jinping advocates for the construction of a global energy internet, which will fulfill global power demands in a clean and green way. He recently identified that China’s carbon emissions must reach a peak before 2030 and non-fossil fuels must account for 25% of total energy. This means more than 1.2 billion kilowatts of wind and solar energy need to be installed by 2030, which requires an annual increase of 70 million kilowatts for the next ten years. China aims to achieve carbon neutrality before 2060, which is an ambitious target.

Therefore, we must emphasize the importance of energy interconnectivity to promote low carbonization. The development of rechargeable batteries, including lithium-ion and sodium-ion batteries, is critical to the success of energy interconnectivity.

The electrification of transportation is also key to achieving President Xi’s energy goals. There are three aspects to this.

Firstly, the development of electric cars, which started in 2000.

Secondly, we need to focus on electric ships. A large container vessel emits sulfur dioxide equivalent to 150,000 heavy-duty trucks, and therefore the development of all-electric and unmanned ships can greatly reduce pollution.

Thirdly, there is a growing focus on electric planes, with China having convened three consecutive electric aviation conferences since 2017.

All three of these aspects: electric cars, ships and planes, play critical roles in improving the environment.

The five characteristics of the energy internet are; the use of renewable energy sources, distributed and decentralized, interconnectivity, openness, and intelligence for control, all requiring the use of rechargeable batteries. Two types of rechargeable batteries that are commonly used are lithium-ion and sodium-ion batteries.

Lithium-ion batteries contain liquid electrolytes with graphite as the negative electrode and transition metal oxides as the positive electrode.Its energy density is limited to 300 watt-hours/kilogram or slightly higher, with occasional safety accidents such as ignition or explosion, so we need to develop solid-state lithium batteries or all-solid-state lithium batteries with metallic lithium as the negative electrode. At this stage, we can use nano-silicon or silicon-carbon composite materials as the negative electrode without metallic lithium. The positive electrode can utilize existing and relatively inexpensive positive electrode materials containing transition metals, and we can also develop lithium-free positive electrode materials in the future. The middle electrolyte is solid, which can be an oxide, sulfide, or polymer. Currently, we are implementing in-situ solidification, where the energy density can reach up to 350-500 watt-hours/kilogram, with high safety and no combustion or explosion.

The Institute of Physics has actually been studying solid-state batteries since 1976, when we began researching solid electrolyte materials. Since then, we have not stopped researching solid electrolytes, and recently we have discovered some new materials through calculations. We have also done a lot of work on the safety of solid-state batteries and found that they are very safe. We established the Weilan New Energy Company in 2016, and by 2018, the energy density of solid-state batteries reached 300 watt-hours/kilogram, with testing on sample cars. In 2019, we established a production base in Liyang, and now solid-state battery products are already being supplied for use in unmanned aerial vehicles, with battery safety passing tests. The raw materials, including silicon-carbon negative electrodes, are all being produced in large quantities, and the membrane needed for solid-state battery electrolytes can also be mass-produced.

Here, we introduce the core materials of solid-state batteries. Currently, lithium foils and membranes coated with solid electrolyte powders for pre-lithiation are already industrialized. Meanwhile, nano-solid electrolytes can be coated on positive electrode materials, especially high-nickel positive electrode materials. Without coating, their safety cannot be ensured. After coating, the capacity is quite high, up to 210mAh/g, and even higher at high temperatures.

As for nano-silicon, we currently use nano-silicon and graphite as composite negative electrodes. Actually, lithium-ion batteries also use nano-silicon. We began researching nano-silicon in 1996, and in 1997, we applied for the first patent for using nano-silicon as a negative electrode internationally. Over the past 17 years, from hundreds of milligrams to hundreds of kilograms, we have established the Tianmu leading company, specializing in producing nano-silicon materials that can supply both domestic and foreign demands in bulk. This is the current situation for the development of nano-silicon.

At the same time, we also pre-lithiate the nano-silicon, and the displayed capacity of the battery after pre-lithiation is also relatively high, up to over 1000 milliampere-hours per gram. The cycle performance of the displayed 18650 battery is quite good, as seen in its usage.## Introduction of In-situ Solidification

The upper part of the following figure is the collection fluid of copper foil, where the black part is the anode side, the negative electrode material is nano-silicon or silicon-carbon negative electrode. The green color on the bottom is the LATP (lithium aluminum titanium phosphate) coating on the separator, which is the electrolyte material that enables the liquid electrolyte to solidify in situ. It can also be seen that after several charge and discharge cycles, a layer of SEI (solid electrolyte interface) film is formed on the surface of the black particle on the anode material. On the surface of the separator, because a layer of LATP is coated, it also becomes a solid electrolyte with SEI film, and the positive and negative electrodes become one with the electrolyte, which is the in-situ solidification.

The figure below shows the cycling stability of the separator made of alumina and LATP solid electrolyte materials, respectively. It can be seen that the cycling stability of alumina separator is not good, while that of LATP solid electrolyte separator is quite good. This is some detailed information about the current process of solid-state batteries.

This is some new products from Wollong New Energy, and I would like to emphasize that the energy density of this battery can reach 1540 Wh/L, which is currently the highest in the world. Its weight energy density can reach 600 Wh/kg, and its battery capacity is 25 Ah.

The figure below shows the high-specific energy solid-liquid hybrid power battery with an energy density of 300 Wh/kg and a capacity of 58 Ah. The upper right part of the figure is the liquid electrolyte battery, which can catch fire and explode when pierced, while the solid-state battery has no problem when pierced. This shows the temperature of the battery, which basically remains unchanged. This is the situation of piercing voltage. As can be seen, once the nail is pierced, its voltage drops, but it can recover after a while. The cycling performance of the 58 Ah battery is also shown, with a capacity retention rate of 80% after 1400 cycles. In addition, its low-temperature performance is quite good, with a 78% capacity retention rate at minus 20 degrees Celsius. Its rate performance is also quite good, ranging from 0.2 C to 3 C, and the capacity change is very small.

This is a high-specific energy solid-state battery with an energy density of 400 Wh/kg and a capacity of 11 Ah. The middle part of the figure shows the situation of the battery, and the upper right corner shows its 0.3 C cycling performance. It can be seen that its safety is also good. After the nail is pierced, its voltage drops, but the voltage gradually rises as the nail remains inside. The temperature only rises by about two or three degrees Celsius during the piercing (the black and red lines represent the temperature on the positive and negative sides), so the safety of the 400 Wh/kg high-energy solid-state battery is also quite good.The displayed information is about one subsidiary company of Weiguo Chip Technology, a company founded by the Physical Society, called Weiguo New Energy Company. It won four first prizes in a competition last year. The first prize high energy density battery information displayed here is as follows: at 0.2C, the energy density is 610 watt-hours/kg, and at 2C, the energy density can reach 500 watt-hours/kg. So, it can be said that the energy density is quite high.

Now, let me introduce the sodium-ion battery. Why introduce sodium-ion batteries? Because lithium-ion batteries are currently being used all over the world. If all cars in the world used lithium-ion batteries and all electrical energy storage used lithium-ion batteries, it would not be sufficient. Therefore, we must consider new batteries, and sodium-ion batteries are the preferred choice. The lithium content is quite low, only 0.0065%, while the sodium content is 2.75%, which is quite high. The figure below shows a comparison to a lithium iron phosphate battery (the cheapest lithium-ion battery). Its raw material cost per watt-hour is 0.34 RMB, while the raw material cost of the sodium-ion battery is 0.26 RMB per watt-hour, which is cheaper. In addition, we can see that the price of lithium carbonate is still rising recently. On January 4, 2021, it was 54,000 yuan/ton, an increase of 12,000 yuan/ton over last year. Some companies even reported 63,000 yuan/ton. Therefore, it is important for us to develop sodium-ion batteries.

We have been studying sodium-ion batteries since 2010. After nearly 10 years of research, we started with raw materials, discovered four or five positive electrode materials, and four or five negative electrode materials. Finally, we selected the positive electrode material on the right-hand side. The upper right corner is a positive electrode material with copper, iron, manganese, and cheap metals. The lower right corner is a carbon material made of anthracite. This ensures that the material cost is relatively low.

Now, let’s talk about the energy density of the 6 Ah soft-packaged sodium-ion battery, which has reached 145 watt-hours/kg, which is already quite high. It can be quickly charged, and 5C charging/5C discharging is 90% of the capacity of 1C charging/1C discharging. 10C charging/10C discharging capacity is 70% of the capacity at 1C charging/1C discharging, so its fast charging performance is better than that of lithium-ion batteries. Its cycling performance is quite good, with a cycle life greater than 6,000 times at 1C charging/1C discharging and up to 3,000 times at 3C charging/3C discharging.The high and low temperature performance of the sodium-ion battery is very good. Charging it to 100% at 60 degrees Celsius in the top left corner and storing it at a high temperature of 60 degrees Celsius for 7 days will cause a slight decrease in its capacity, which can be quickly restored at room temperature. The figure in the bottom left corner shows the capacity decrease of a battery stored for 7 days at 85 degrees Celsius after being fully charged. However, the capacity can still be restored at room temperature. The figure in the top right corner shows the cycle performance at 80 degrees Celsius. The cycle performance of a typical lithium-ion battery at 80 degrees Celsius is quite poor, but the cycle performance of the sodium-ion battery at 80 degrees Celsius is still quite good, with a capacity retention rate of nearly 78% after nearly 1000 cycles.

Regarding low temperature performance, the blue curve in the figure shows the low temperature performance of the sodium-ion battery, which can be charged and discharged even at -40 degrees Celsius. The black curve is the discharge curve of a lithium iron phosphate battery, which shows that its capacity is already quite low at -30 degrees Celsius, only 40% of its original capacity. Therefore, the low and high temperature performance of the sodium-ion battery is very good. The sodium-ion battery was developed by the Institute of Physics, Chinese Academy of Sciences, and its various forms, including soft packaging, aluminum shell, and cylindrical shape, are shown in the figure.

The Institute of Physics, Chinese Academy of Sciences has been researching sodium-ion batteries since 2010. The figure above shows the research on materials for sodium-ion batteries, and the figure below shows the research on batteries. In around 2015, the first soft-packaged battery was developed. This was then followed by the development of electric bicycles in 2017, the first energy storage power station demonstrated in 2019, and an electric sightseeing car. This is the overall development situation of the sodium-ion battery.

In conclusion, “solid-state batteries are catching up quickly, leading China’s electric vehicle revolution,” and “sodium-ion batteries are joining forces to promote energy interconnection.” Thank you all!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.