Tesla’s Products

From left to right, they are: Model S, Model 3, Model X, Model Y, Cybertruck, ATV (Cyberquad), Roadster, and Semitruck.

Tesla’s product line can be described with four letters: SEXY CARS, which is quite emotional.

Familiar with Tesla friends from the figure can be seen that SEXY are cars that have been released and mass-produced, and CARS are cars that have been released but have not yet been mass-produced.

When Tesla released the Model S, it wasn’t well known, didn’t have much industry influence, and maybe wasn’t very confident. Therefore, you can see that the Model S is fairly similar to traditional cars, with a relatively conventional interior layout and decoration. The Model S is slightly more dazzling with its breakthrough exterior design, and the grille-free design in 2010 was indeed very sci-fi.

Tesla later launched the Model X, which had a high price tag that made people hesitant. The interior layout of the car was still quite conventional. Although the falcon-wing doors design subverted a lot of people’s understanding of car doors, Tesla experienced various production problems because of this design.

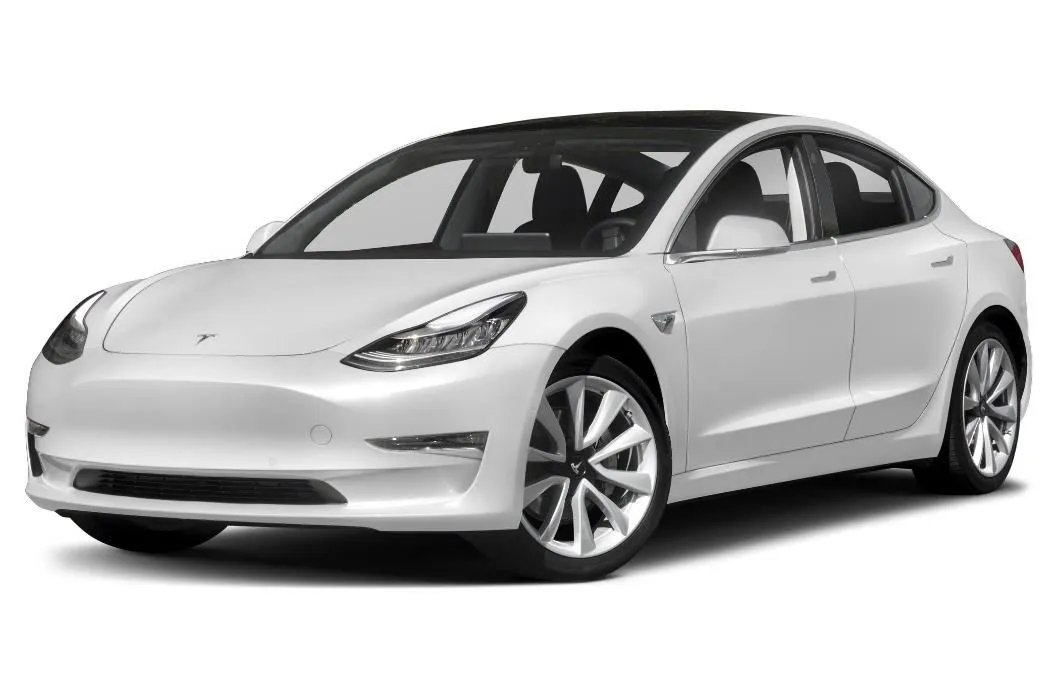

However, by the time of the Model 3, there were significant changes and even subversion in every aspect of the car.

Personally, I think there are two reasons for this. First, it may be because Tesla’s reputation has grown, and well-known Tier One suppliers began working with Tesla and were willing to customize the production of parts.

Second, Elon Musk has experienced various complex function designs for Model S and Model X, especially the Production Hell of the falcon-wing doors for Model X, and the team’s design has become more mature.

The Independent Model 3

So why do we say that the Model 3 has undergone significant changes and even subversion in every aspect of the car? Let me try to deconstruct it from three aspects.

First, use first-principles thinking to rethink the layout.

For example, the Model 3 cancels the traditional instrument cluster and replaces it with a large center screen for the whole car.# Translation in English Markdown

I used to think that an instrument panel was a must-have for cars, but I had never really thought about why it was necessary and what it actually brought to me.

In the past, I had many friends who liked to modify their cars. They not only had instrument panels but also installed several Defi (a well-known brand of modified instrument) tachometers, turbo pressure gauges, etc., on their instrument panels.

After careful consideration, I realized that these things fundamentally bring more vehicle information to drivers, enabling them to have more accurate control of the real-time status of the vehicle.

I think it is necessary in the racing field mainly to prevent cars from exceeding their limits. But in 99.99% of civilian applications, we do not need to know this information about the vehicle. In fact, this information can be a hindrance to our daily driving and can increase additional costs.

Moreover, the structure of electric motor drive is very simple, which is the output of current to the motor, which also means that it does not need traditional information such as tachometers and turbos.

In short, you can drive well without this information, so why do you need an instrument panel?

So, let’s get rid of the instrument panel.

In addition, facing the row of physical buttons for traditional car air conditioning, multimedia, driving modes, etc., can’t we optimize them further?

This reminds me of a quote from Steve Jobs when he presented the first iPhone. Traditional phones all had the same design, with the keyboard occupying half of the phone.

If we could turn the phone’s keyboard into a screen, the entire phone would be able to display different interfaces when different apps are opened. Imagine, when watching a video, the screen could be full, when typing, it could turn into a keyboard, and when playing games, it could turn into a joystick. So, let’s get rid of the physical buttons, and this is our smartphones today.

So why do we still need physical buttons in cars? Can’t we integrate the functions into the screen? Therefore, let’s get rid of the physical buttons.

Ultimately, it becomes a large screen.

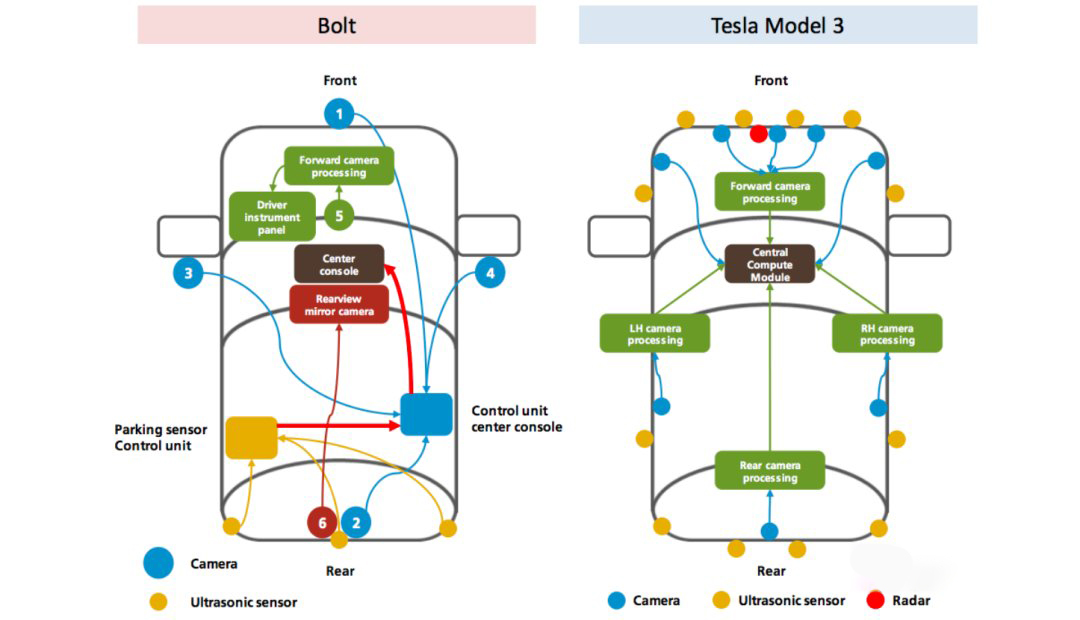

Secondly, integration, greatly reducing components and wiring.

For example, all the functions of the body of the Model 3 are controlled by a unified central controller, instead of different suppliers developing controllers for different functions, and then connecting them to controllers distributed throughout the body of the car, as in traditional cars.

This also brings the benefit of being able to optimize upgrades OTA as a whole. In traditional cars, various components are completed by Tier ONE, such as manufacturers like Bosch and Continental, whose software code is responsible for implementing the part.

This also brings the benefit of being able to optimize upgrades OTA as a whole. In traditional cars, various components are completed by Tier ONE, such as manufacturers like Bosch and Continental, whose software code is responsible for implementing the part.

The linkage between the control modules of the car factory and the traditional car is often completed by sending execution instructions. This means that the code inside the component is like a black box to the car factory, and they never try to understand the coding inside the black box, so they cannot improve these codes.

Therefore, traditional cars cannot achieve full-vehicle OTA upgrades fundamentally, unless traditional car manufacturers rewrite all the codes and merge all the codes together, and unify the compatibility of hardware.

The future that traditional car manufacturers pursue is the level of Tesla at present. So, the CEO of Volkswagen said that Tesla’s software level is ten years ahead of the industry.

Thirdly, simplify production.

For example, after being optimized by first-principles and highly integrated optimization, Model 3 should have greatly simplified conditions in the production process.

This is also the core reason why the Shanghai Super Factory was built and put into production within one year, which means that Model 3 is simple enough and highly modular from a design perspective, and has the genes for rapid production expansion.

These three aspects interact with each other and have successfully enabled Tesla to create a good, intelligent, and low-priced car.

Tesla’s Iteration Logic

Elon Musk said that Tesla will no longer continue to iterate the Model S. From a literal perspective, this means that there will be no new versions.

But I think there will still be new versions of the Model S, but they will only be small iterations based on the current version of the Model S, not major upgrades. What Elon Musk said about not continuing to iterate probably means that he will not invest resources in researching its successor, which means there will be no next generation of models.

From the perspective of a traditional automaker, it is unreasonable for a popular model not to be replaced. But let’s try to understand Elon Musk’s philosophy. He said Tesla’s mission is to accelerate the world’s application of new energy. This has not changed in the past decade, from 2008 to 2018.

To achieve this vision, we need to find a product that can rapidly expand and meet the needs of most people in all aspects. Model 3 is Tesla’s first mature product that combines the genes of good driving experience, intelligence, and low price.

As mentioned earlier, Model S is no longer iterating, probably because it does not have many outstanding features that Model 3 has.

So let’s try to speculate on Tesla’s future product line logic.So, in fact, Model 3 is such a product, the most suitable product in the Tesla product line to accelerate the world’s application of new energy.

Therefore, based on first principles, Tesla should focus on these products that can achieve this mission and abandon the iterative logic of the traditional industry.

It takes a long time to truly accomplish a mission, even several generations, and the important criterion for judging whether he can persevere is the original intention of doing things, which is also the deepest source of decision-making power. In order to see if this man really insists on his original intention, I specially searched for his interviews in 2008 and 2018, which are ten years apart.

But I think that based on Elon Musk’s interview and Tesla’s mission to promote new energy, it is highly probable that a new product line will be launched in the future, which is even more compact and smaller than the Model 3 – the Model 2.

This Model 2 was proposed by Elon Musk in the second quarter of about after the outbreak of the first wave of the epidemic, when Model 3 sales in the European market suffered a cliff-like decline. At that time, Renault Zoe topped the European new energy sales chart.

His rough idea was that the European market needed a smaller model, and we are in the process of developing it. Based on what I have seen in Europe for more than three years, it is true that the proportion of small cars on European roads is much greater than that of medium and large cars. From this point of view, it is quite reliable that Tesla will launch the Model 2 in the future.

Moreover, from a cost perspective, designing a more compact and smaller Model 2 has more room for operation in terms of selling price and can create price reduction space to keep up with the tightening of state subsidies.

Therefore, it can be seen that Tesla’s iterative path should go towards smaller models, which will help sales and accelerate the world’s application of new energy.

Everything returns to Tesla’s mission.

Tesla’s factories

I personally have little knowledge about the Tesla factory, but it is not difficult to see from various media’s investigations that Tesla has used some innovative technologies, such as digital twins, simulated production lines, etc., to speed up the construction speed of the factory.Because the information is limited, I cannot delve into the specific functions of these technologies. But judging from the construction and production speed of the Shanghai factory, Tesla’s new generation production line is indeed built very quickly and can achieve production in the same year as construction. This means that Tesla can quickly and flexibly expand production lines according to sales volume, have the ability to quickly achieve production and sales balance. Additionally, Tesla can have a higher capital expenditure utilization efficiency.

From the situation of the Shanghai factory, the annual sales volume of domestically produced Model 3 is currently about 150,000 units, and the planned 250,000 production capacity of the Shanghai factory should reach a bottleneck after the production of Model Y. Based on the US market’s response to Model Y and the general preference of the Chinese market for SUVs, coupled with the observation that many friends are waiting for the release of Model Y, it is highly likely that Model Y will be more popular in the Chinese market than Model 3.

However, in the early stages, with the increase of production capacity and the decrease of prices, it is estimated that it will take several months for both supply and demand to be released before Model Y’s sales can catch up with Model 3.

At the same time, the idle production capacity of the Shanghai factory can be used to export Model 3, which can be supplied to the European market to solve the production capacity reduction caused by the pandemic in the US factories.

But accelerating the construction of the second phase of the Shanghai factory is imperative, because the continuous increase in domestic demand will quickly put Tesla’s 3 and Y production capacity into a bottleneck.

Tesla’s global factory layout is also interesting. Currently, two super factories have been built in the United States and China, and another super factory is being built in Germany.

From the perspective of tariffs, this layout has great advantages.

Tesla’s factories are located in the main sales countries of each continent, which can maximize the avoidance of international tariffs. Also, when two countries are in a tariff trade war, Tesla can flexibly allocate vehicles produced by third countries to bypass the trade war.

At the same time, because new energy subsidy policies of various countries are often linked to vehicle retail prices, avoiding tariffs helps to control the retail price within the range of the national subsidy policy, and allows consumers to enjoy local subsidy policies as much as possible.

Once Tesla’s Berlin factory is completed in 2021, it will form a tripod relationship with the Fairmont factory in the United States and the Shanghai factory in China, supplying the adjacent regions.

The German factory can effectively solve Tesla’s problem of high selling prices in the European market, resulting in the inability to obtain subsidies.

Because there is no tariff issue within the EU, Tesla’s selling price in Europe is likely to further drop within the range of new energy subsidies in countries like France and Germany, further promoting sales.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.