“When discussing electric cars, we always talk about how big the battery is and how long the range is, but we rarely talk about how many motors the car has and how they perform.”

At a media exchange meeting at XPT’s factory, Qin Lihong said that the reason why the range of electric cars is being focused on by people is mainly because the range is currently a major shortcoming of electric cars so that everyone is concerned. However, the battery is essentially an energy storage module, which is equivalent to a fuel tank for electric cars, and attention to this aspect will gradually fade as the range improves. Although range is worth paying attention to, overly focusing on range can easily overlook other things. We do not discuss the size of your gas tank when discussing fuel cars, but instead discuss the engine displacement and horsepower. Similarly, the drive train of electric cars is also worth paying attention to.

Therefore, this time we will talk about motors.

Why dual motors

Three reasons from NIO

Li Bin previously stated that using a single motor for an electric car is a rogue move, which caused a lot of controversy. Qin Lihong said that Li Bin’s statement was not rigorous enough, the complete statement should be that for high-end electric cars, using a single motor is a rogue move.

So why must high-end electric cars be equipped with dual motors? NIO provides three reasons:

- Value Ascension

- High Performance

- Redundant Design

Let’s discuss them one by one.

The first point, value ascension, is simply symbolic of high-end “facade.” In fuel cars, one of the symbols of high-end cars is a large-displacement engine. If a car is using a 4.0-liter V8 engine, it will naturally be considered a luxury car. But if you are using a 1.5-liter 4-cylinder engine, it is difficult to give people a high-end feeling intuitively from the perspective of power configuration. The same logic applies to electric cars. More motors symbolize a higher-level power structure.

Qin Lihong also talked about the reason why high-end cars need dual motors from another perspective: electric motors costs are relatively low these days, with a single electric motor costing about 20,000 yuan or even as low as just over 10,000 yuan for some well-managed motor factories. A set of leather interior may cost a few tens of thousands, so the cost of electric motors is relatively low. Nowadays, consumers have many requirements for high-end cars, such as leather interiors and high-end sound systems. Why not require dual motors as well?The cost of upgrading engines on gasoline-powered vehicles is high. Upgrading from a 2.0-liter 4-cylinder engine to a 4.0-liter 8-cylinder engine can mean a cost difference of over 100,000 yuan. “But upgrading from one electric motor to two is relatively cheap and the technology is available,” said Qin Lihong, “and with car prices already reaching 300-400,000 yuan, there is no need to save money on electric motors.”

“As for high-end electric cars, if they don’t have dual motors, it’s because the manufacturer doesn’t want to, there’s no other reason,” said Qin Lihong.

The second point, high performance, is easy to understand. Dual motors usually mean higher power and 4-wheel drive, both of which are expressions of high performance. NIO models have never been stingy in terms of power or acceleration, and dual motors are one of the reasons for this. In response to skepticism about the “excessive performance” of dual motors, Qin Lihong said, “As a high-end electric car, power cannot be just enough, users may not need it, but you must have it.”

The “it’s not necessary until it’s necessary” philosophy in power can be seen as a redundancy consideration for different working conditions. The dual-motor structure of the double drive unit is also a kind of redundant design. “Redundant design” sounds like a pejorative term, but in fact it is a kind of safety design that increases reliability.

The turbojet engine on a civil aircraft is sufficient to ensure the airplane’s flight. The reason for having two is a redundancy design for safety considerations. If one of them fails, the plane can still fly with the other engine. Dual motors have the same principle. Qin Lihong said that in nearly 600,000 vehicles and 1 billion kilometers of driving, there has not been a single case of simultaneous failure of the dual electric motors, but single motor failures have occurred, which is the advantage of redundant design.

At the same time, Qin Lihong also mentioned that the L4 level of assisted driving has high requirements for vehicle redundancy design, which naturally includes the power system, so the role of dual motors is once again highlighted.

“I don’t completely agree with NIO’s views on high-end electric cars and dual motors,” he said. “In my opinion, the relationship between dual motors and high-end and performance is not absolute. Whether a product is high-end, high-performance or not depends on the final effect.”

In the mobile electronic industry, the number of cores in your SOC processor cannot determine the performance of your device. Apple’s A-series chips don’t rely on the number of cores and have been beating Qualcomm’s opponents every year.

In gasoline-powered cars, bigger displacement and more cylinders do not necessarily mean better performance. The 8.4-liter V10 mechanical supercharged engine on the Dodge Viper does not show the advantages of displacement and cylinders compared to the “smaller” 8-cylinder turbocharged engines of European competitors in terms of performance.In my values, making the structure small and light while ensuring performance is the direction that power system technology development should take, and quantity is not a necessary condition.

I agree with the redundancy value of dual motors, but if one day, some manufacturers can achieve high-performance dual motors with a single motor while ensuring balance in all aspects, and the volume is similar to that of a normal single motor, resulting in saving the weight and space of a motor for the whole vehicle under the premise of ensuring performance, then would dual motors still be the representative of high-end and performance?

Of course, this is just my consideration from a technical perspective, and no one can predict 100% what the future development route will be. On the road of NIO’s development and growth, various doubts have never been lacking, from the early positioning of pure electric high-end brands to the JAC factory to battery swapping and insisting on dual motors. NIO’s “unconventional” strategy is to do their own thing in the face of doubts, but the results so far are still good, and I believe that their considerations are based on the best comprehensive considerations of themselves. Let’s leave the controversy about dual motors to time.

Motors are not only technology, but also business

It’s not that they won’t sell, the domestic market does not need such high-end motors

At the XPT plant meeting, of course, this plant will also be discussed.

There have been many reports about the high automation and advanced technology of the XPT factory. After visiting the site, I also want to say that this is indeed a very modern and high-end factory. I will not repeat the relevant content here, we will mainly talk about the commercial aspects.

XPT is an independent company and has always had external investors, and is not a “special supply” factory for NIO. Qin Lihong said: “XPT has a dual mission to ensure the supply of NIO’s electric drive system and ensure the profit of shareholders.”Because all of NIO’s models use dual motors, and currently there is no external supply for XPT, the production volume of XPT’s motors can be easily calculated by multiplying the number of vehicle sales by two. Regarding the topic of XPT’s self-produced and self-sold profit equilibrium point, someone asked and Qin Lihong’s response was “around 100,000 units.” If this “around” figure is accurate, and considering NIO’s sales performance this year, XPT could already achieve profitability this year.

On the other hand, the reason why XPT has not yet started external supply is not due to a problem with the motors. In the early days of XPT’s establishment, NIO’s brand influence was not strong enough, and some OEMs had doubts just like everyone else, doubting whether NIO’s products would work or if NIO would go bankrupt. NIO has basically dispelled this kind of doubt in recent years, but the problem is that there are very few companies in China’s domestic market that do high-end electric vehicles like NIO, and most car companies only use single motors, with motor power only requiring slightly over 100 kW. High-performance motors like NIO’s are not what they need.

However, the new energy vehicle market is global, as Qin Lihong explained, some car companies in North America want to make high-performance pickups and need motors with high power. Currently, the two sides are in talks, and the first batch of XPT’s external supply orders is highly likely to appear in Western markets.

Qin Lihong concluded by stating that both NIO Energy and XPT are open platforms and welcome external cooperation. He even said that he hoped XPT could produce 500,000 motors a year, as long as there is sufficient external demand.

Best Combination for Dual Motors: Synchronous + Asynchronous

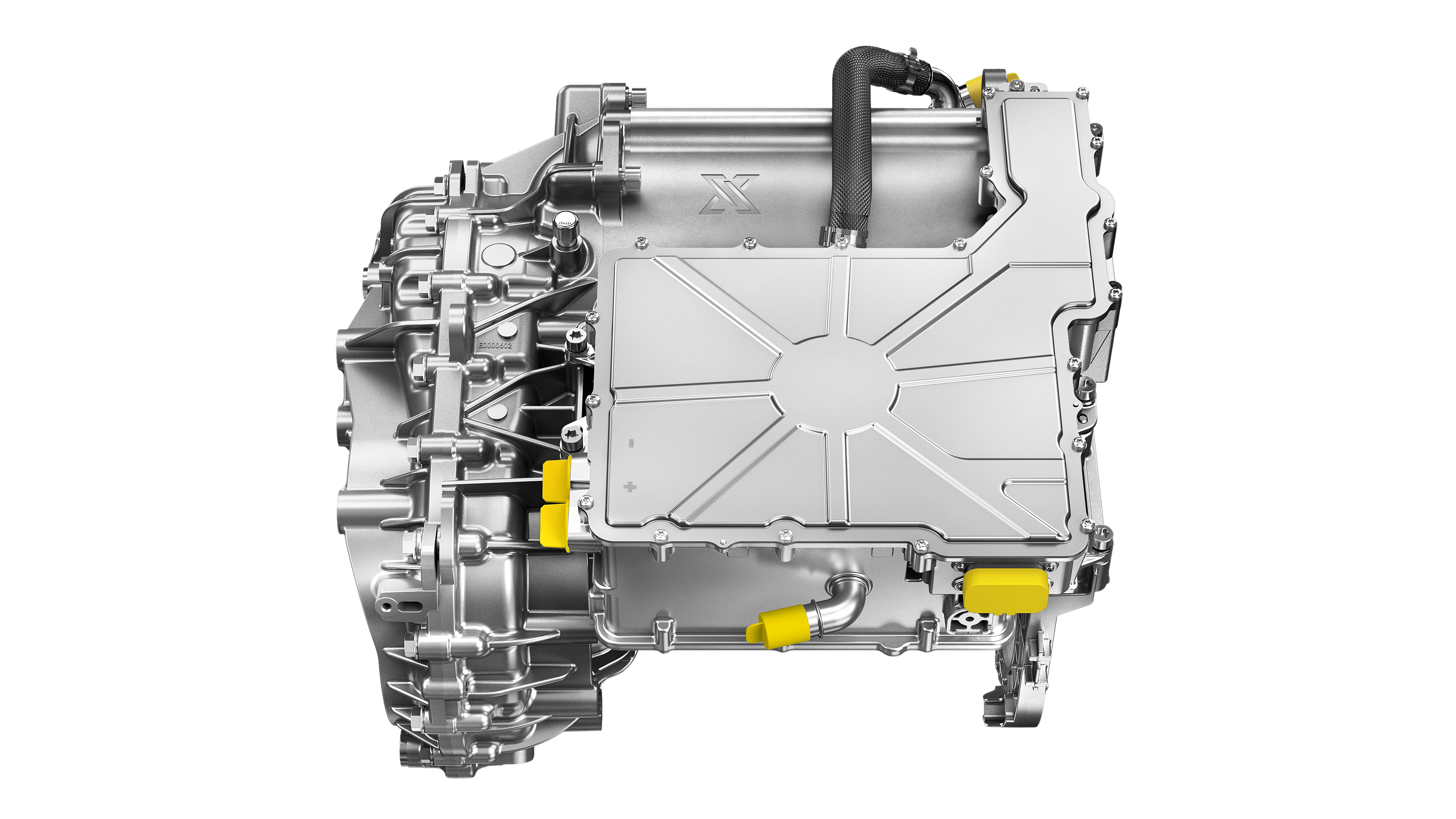

Currently, NIO is using two types of motors, including a 240 kW high-performance asynchronous induction motor and a 160 kW permanent magnet synchronous motor.

## Translation

## Translation

Here is a brief explanation regarding the difference between the two types of motors. Permanent magnet synchronous motors have better efficiency at low speed, but their efficiency rapidly decreases at high speed due to demagnetization. However, their energy density is slightly lower than that of asynchronous induction motors, and they produce a counter-electromotive force during drag rotation. On the other hand, the energy efficiency of asynchronous induction motors at low power is not as good as permanent magnet synchronous motors. However, their efficiency at high speed is better than that of permanent magnet synchronous motors, and they do not generate a counter-electromotive force during drag rotation.

Thus, it can be simply summarized that permanent magnet synchronous motors perform better under low-speed and low-energy consumption conditions, while asynchronous induction motors perform better under high-power and high-speed conditions.

NIO believes that the most balanced and optimal option is a dual motor combination of permanent magnet and induction, taking into consideration factors such as cost, energy consumption, performance, and high-speed capability. This configuration provides performance assurance when high power is needed, allowing the ability for the asynchronous induction motor to rest during low power consumption, while the permanent magnet synchronous motor operates alone to ensure energy efficiency.

In terms of motor development, NIO has made sufficient forward-looking considerations, with two mass produced models, two research and development models, and two pre-research and development models in the product plan. During this time, some information regarding NIO’s fourth generation motor was revealed: 220 kW, coaxial structure, and the power module will use silicon carbide Mosfet, providing greater overall power, higher energy efficiency, and a more compact design.

The following is a highly-discussed topic

Apart from the discussion about the dual motor, there were many other topics discussed during the conference. I want to emphasize that I cannot guarantee that the meaning of these topics is conveyed accurately through my interpretation, but like NIO’s attitude, I do not hope that these contents will be taken out of context and misinterpreted. These topics have their own value, but interpretation ultimately depends on the individual.

NIO’s factory is better than Porsche’s factory

Qin Lihong mentioned that Li Bin made this statement because he personally visited Porsche’s factory and felt this way. The factory was built in the 1980s, and today, it is a fact that NIO and JAC’s automated factory is ahead of them in terms of equipment and automation level. According to reason, with newer technology and equipment, NIO’s factory should be ahead of theirs.

As an engineering student in the manufacturing industry, I would like to express my own opinion on this matter.

Firstly, Li Bin’s statement is correct, as he focuses primarily on automation, and it is inevitable that Porsche cannot achieve high levels of automation.

The reason is that Porsche’s products are highly customized.Talking about the 911 series, there are currently 14 models available for sale in the 992 lineup alone, with a diverse range of options, from powertrain, chassis and suspension configurations to small details like materials and paint options for certain interior trims, brake caliper colors, and the presence, color, and finish of the rear emblem. These are only the mass-production options; for those who have the demand and budget, Porsche also offers customizable options. In Porsche’s words, it is almost impossible to find two 911s on the market with the same configurations. With such customization, the focus of Porsche’s production line is to balance flexibility and diversity, rather than achieving high efficiency and speed through automation.

While automation is a high-end representation of modern manufacturing, I believe that automation cannot be used to definitively determine the level of manufacturing sophistication. The engineering capabilities of Porsche are widely known to many, and I think this is one of the reasons why this topic is so controversial.

At the same time, in a certain time period, NIO could be better than Tesla.

“Surpassing Tesla is not impossible for NIO,” said Li Bin, but it is not simply a matter of comparing the two companies directly. The size difference between Tesla and NIO is enormous, and it is more meaningful to compare them based on a fixed time period from a specific starting point. For example, Tesla started delivering the Model S in 2012, while NIO started delivering the ES8 in 2018. Based on the delivery performance of the first car in the first two years, NIO was superior to Tesla. Qin Lihong mentioned during the meeting that Li Bin’s intention was to suggest that if NIO could maintain this momentum, it may be possible to surpass Tesla.

Qin Lihong also mentioned the differences between Tesla and NIO in terms of product value orientation. He expressed that NIO pursues performance while still prioritizing daily use and user experience. For example, the ES8 has impressive 4.4s zero to 100 km/h acceleration, and it could achieve even faster acceleration, but not at the cost of sacrificing rear passenger space. Tesla’s lightweighting is well-controlled, but on the other hand, the design and materials of its interior are too simple, and the seats lack padding. Elon Musk is a geek, and Tesla’s products are like Musk; they pursue excellence in certain aspects. However, NIO still cares more about practicality and user experience.

Comparisons between NIO and Tesla have never stopped in the past few years. I appreciate both companies very much, and there are many aspects of what Qin Lihong mentioned that I agree with. However, I believe that the times and industry are constantly changing and iterating, and it is difficult to achieve a highly consistent comparison, no matter how many adjectives and preconditions are added.NIO and Tesla are both companies with strong innovation and representativeness in the industry. I agree with Qin Lihong’s statement that “NIO and Tesla are two very different companies”. Therefore, I think NIO doesn’t need to compare itself with Tesla. Whether NIO is better or worse than Tesla is not important. NIO is already capable of becoming an industry benchmark and defining itself.

Conclusion

As mentioned at the beginning, electric drives as a part of electric vehicles’ power components lack sufficient attention from the public. However, the importance of electric drive systems is self-evident. As an independent electric drive company of NIO, XPT has faced no fewer challenges and questions in recent years than NIO’s electric vehicles. However, NIO, committed to building a high-end brand, has placed electric drive systems at a very high priority since its establishment.

“The attitude of ‘can not without it’ that NIO has is, to be honest, very consistent with the temperament of a high-end brand.”

Yes, I did mention earlier that I don’t completely agree with the definition of NIO’s dual-motor and high-end, and I also believe that there is still much room for improvement in NIO’s product performance. I also think that Tesla’s current advantages and ability to make continuous progress in some areas cannot be surpassed by many companies, including NIO. However, NIO’s excellence is still outstanding.

As the Chinese domestic brand with the highest average transaction price, and as a company that can persist in developing battery swapping despite Tesla’s abandonment and achieve unprecedented completion and commercialization, NIO’s yesterday and today are worthy of respect. At the same time, with more and more traditional car companies entering the market, and facing more intense competition, I also look forward to how NIO will perform tomorrow.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.