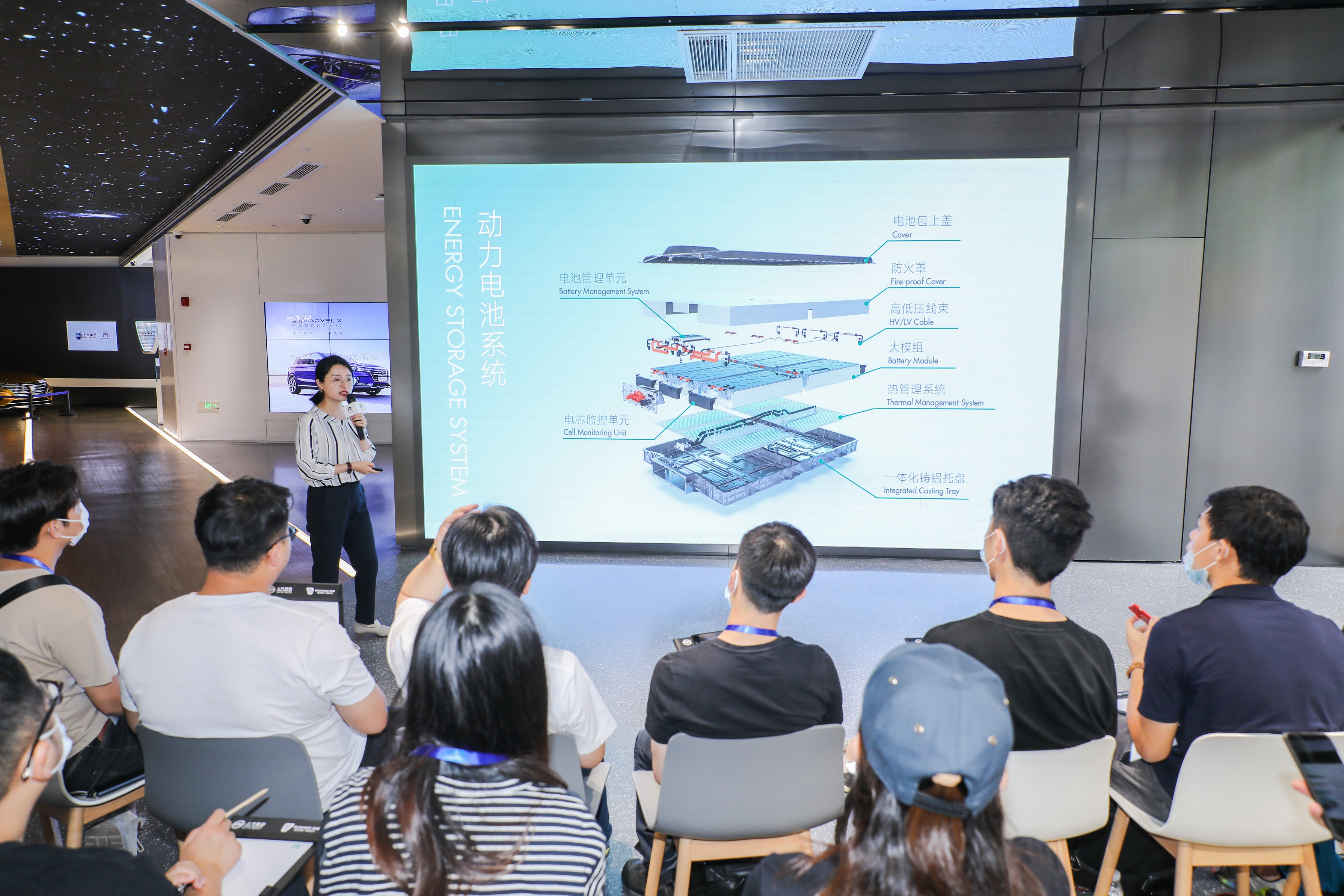

The ROEWE R ER6 Three-electricity Analysis Meeting is the first technical sharing event I am attending this year, and it is also the first public appearance of the ER6.

The ER6 is the first car product of the ROEWE R brand after changing its new logo. The first product of the new brand debut chose such a hardcore way. It really made me unable to help but praise ROEWE. More importantly, this event has dispelled many of my doubts.

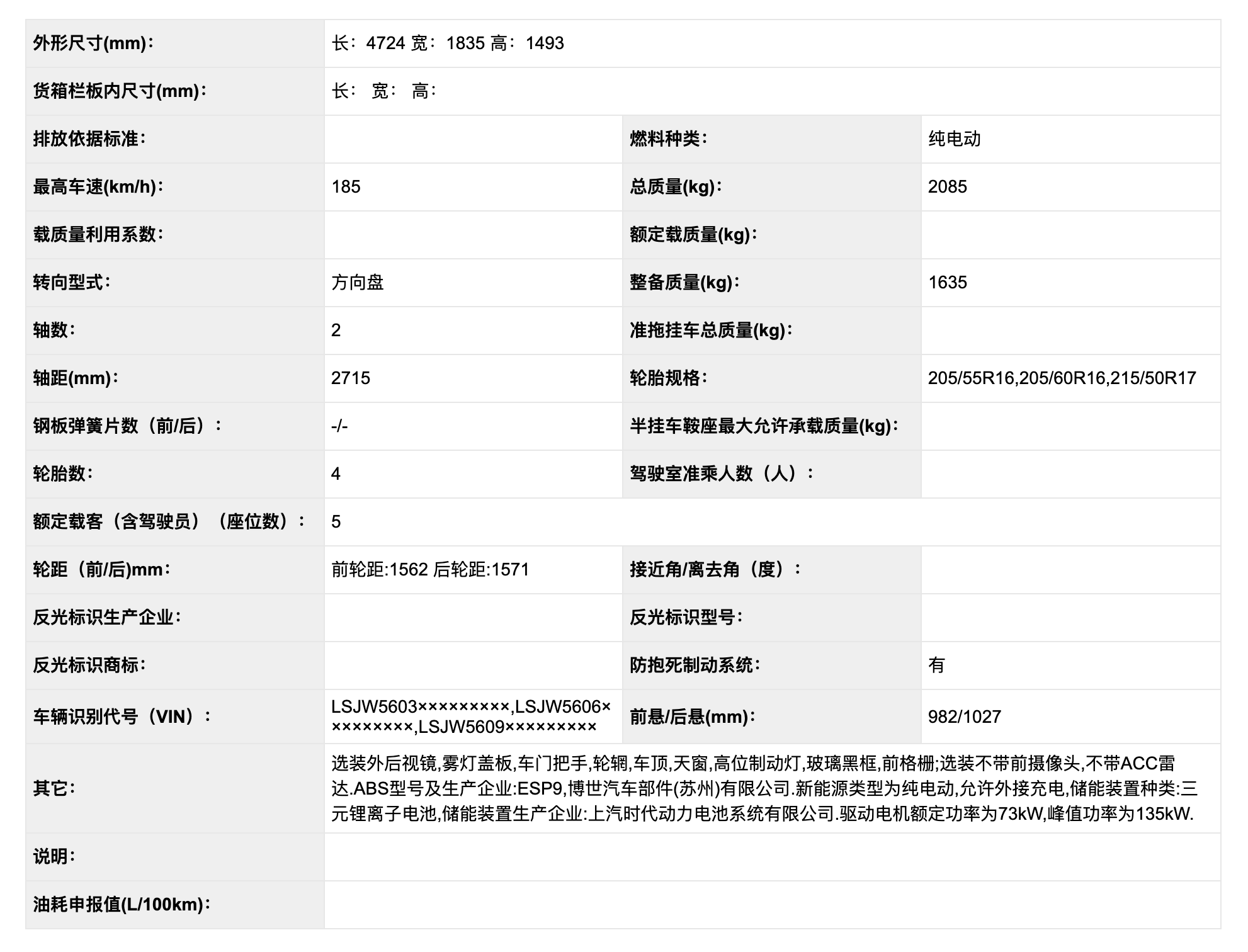

This is the parameter screenshot of the ER6 when it was listed in the MIIT in April this year. From the parameters in the table, the ER6 is not very attractive.

- LengthWidthHeight: 472418351493 mm

- Wheelbase: 2715 mm

- Curb weight: 1635 kg

- Max speed: 185 km/h

But if we add a parameter “NEDC range 620 km”, isn’t it very surprising? Of course, along with the surprise, there is also curiosity.

How big should ROEWE’s battery be to achieve a range of 620 km? How to fit a battery of more than 70 kWh in a wheelbase of 2715 mm? How to control the vehicle weight within 1635 kg? How can 523 battery cells achieve an energy density of 180 Wh/kg? How to control energy consumption within 12.2 kWh/100 km?

Today, we will answer these questions.

72.7 kWh, 180 Wh/kg, 523 formula

The NEDC range of ROEWE R ER6 was finally set at 620 km, which is very close to the 668 km of the Tesla Model 3 rear-wheel drive long-range model.

At this time point in 2020, the NEDC range of the first echelon of electric car models in the electric car camp has reached 600 km+, and under the premise that the electric drive efficiency has not undergone revolutionary breakthroughs, everyone’s way of achieving long-range is not surprising, that is, stacking batteries.

In the 2715 mm wheelbase of the ER6, ROEWE R squeezed a 72.7 kWh battery with an energy density of 180 Wh/kg. Three years ago, if one wanted to squeeze a battery of over 70 degrees, the wheelbase was basically over 2900 mm.

I am not surprised to see the energy density of 180 Wh/kg, but what surprises me is that ROEWE R is willing to put a 72.7 kWh battery on a car priced below 200,000 yuan.When looking at the configuration table, it can be seen that the ER6 has the largest battery among vehicles of this level. Due to the fact that the cost of batteries still accounts for over 40% of the total vehicle cost, a larger battery means higher costs, so few automakers are willing to equip vehicles of this level with such large batteries.

When I naturally matched the energy density of 180 Wh/kg with the 811 battery, a new problem arose: how can high-cost batteries be used to create a car priced at less than 200,000 RMB while achieving longer range?

According to engineering friends from Roewe, in order to achieve longer range at a lower cost, the battery pack used in the ER6 achieves an energy density of 180 Wh/kg, but uses 523 batteries, which not only lowers the cost, but also provides higher safety. Although the cobalt content in the 811 battery is lower and the theoretical cost is lower, the production and yield rates for the 811 battery are still lower than the 523 battery, resulting in a higher cost.

To achieve the same pack energy density as the 811, the only breakthrough for the 523 battery, which has an inferior single-cell energy density, is to improve grouping efficiency.

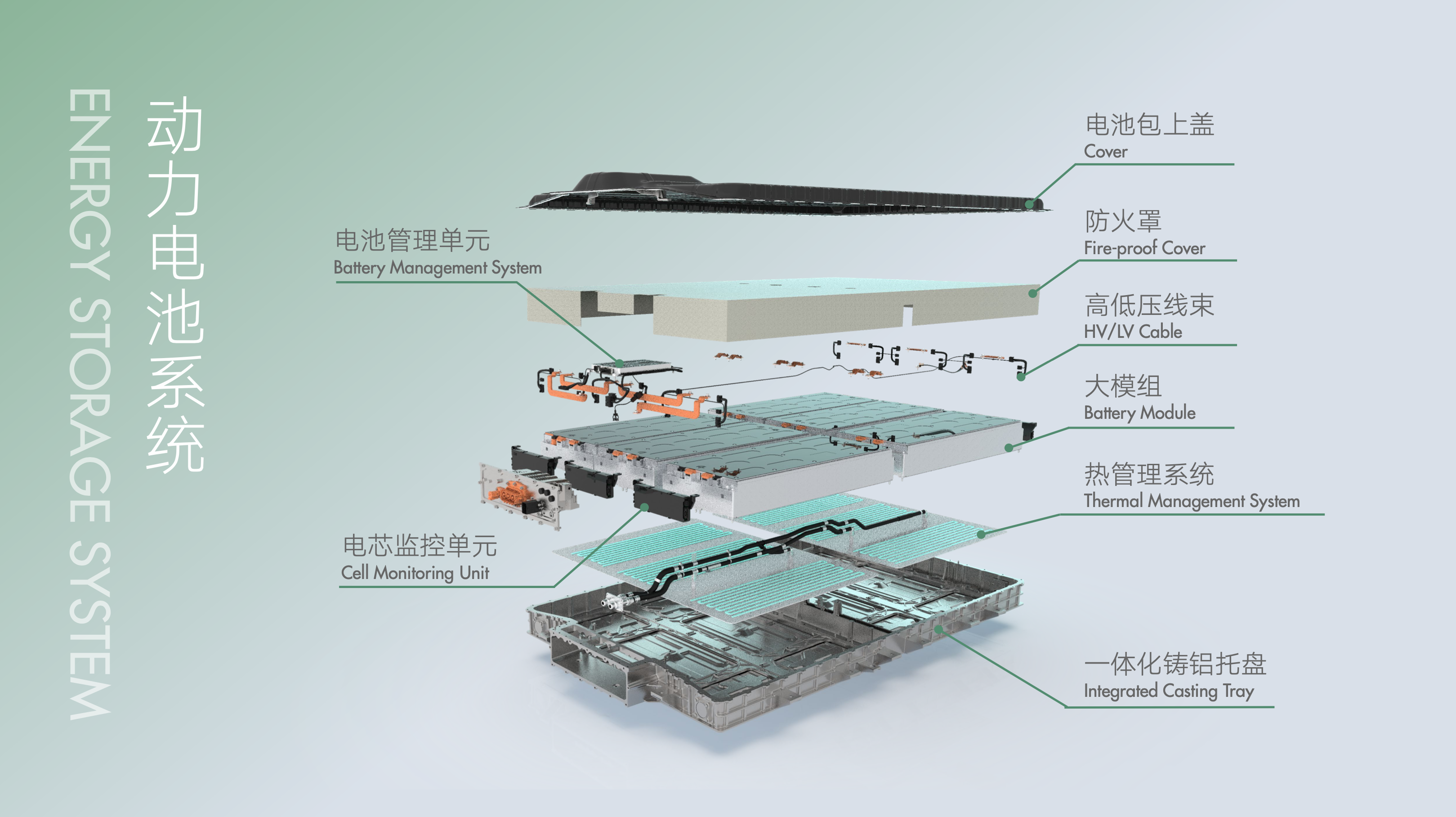

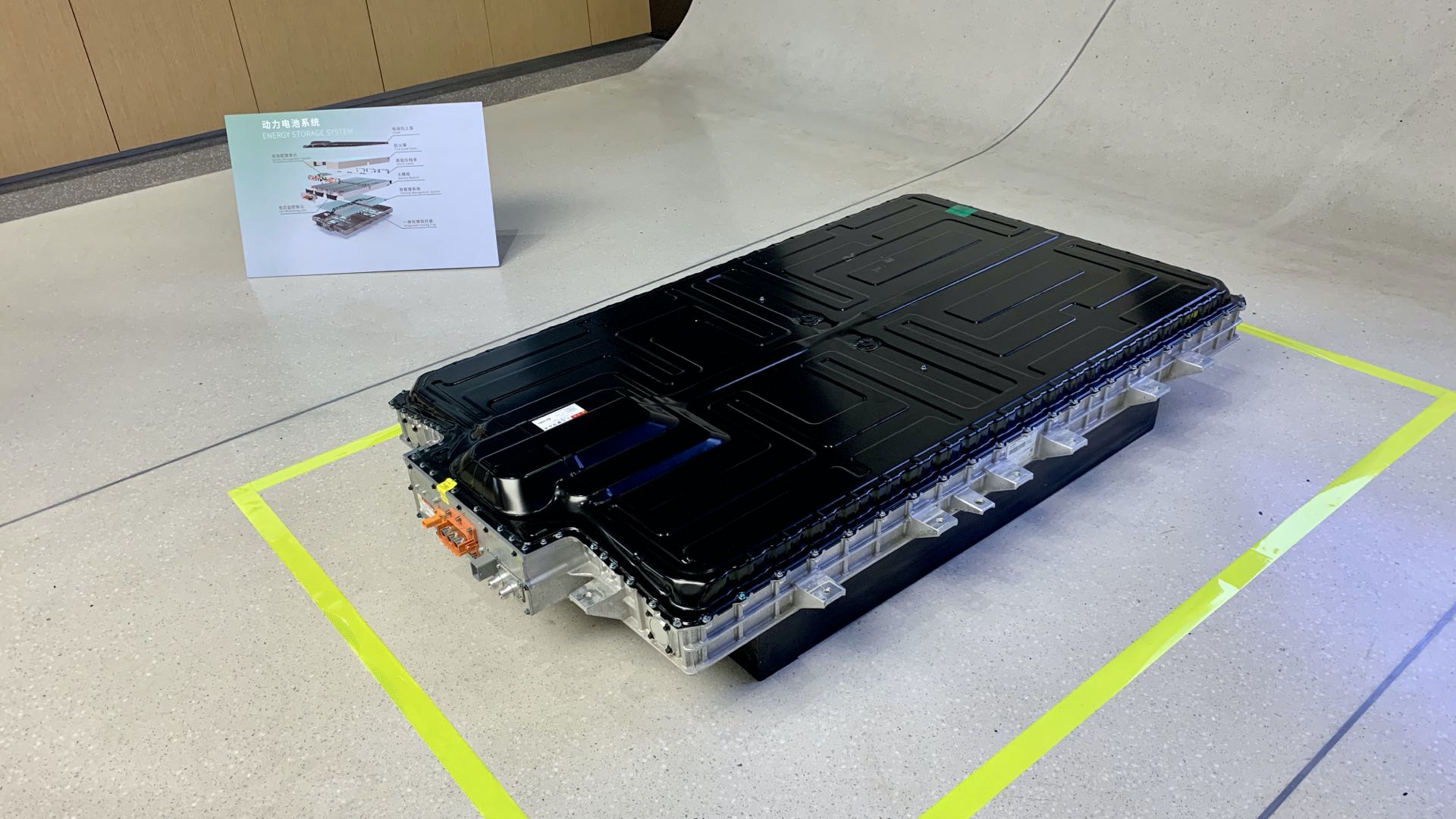

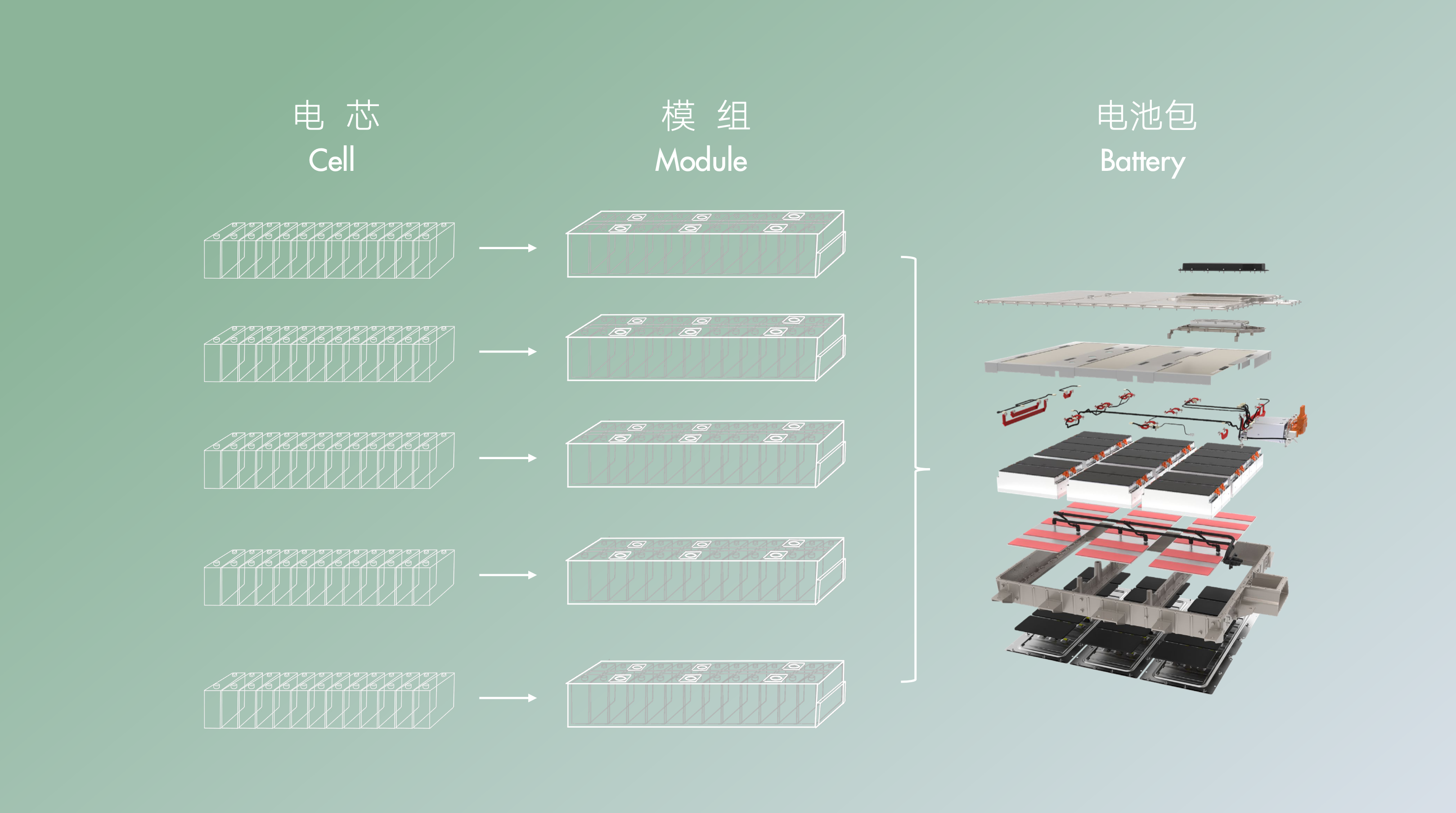

The production of a battery pack goes through a process of cell, module, and pack, where the cell is like a bottle of Yakult, the module is like a row of Yakult, and the entire pack is like a box of Yakult.

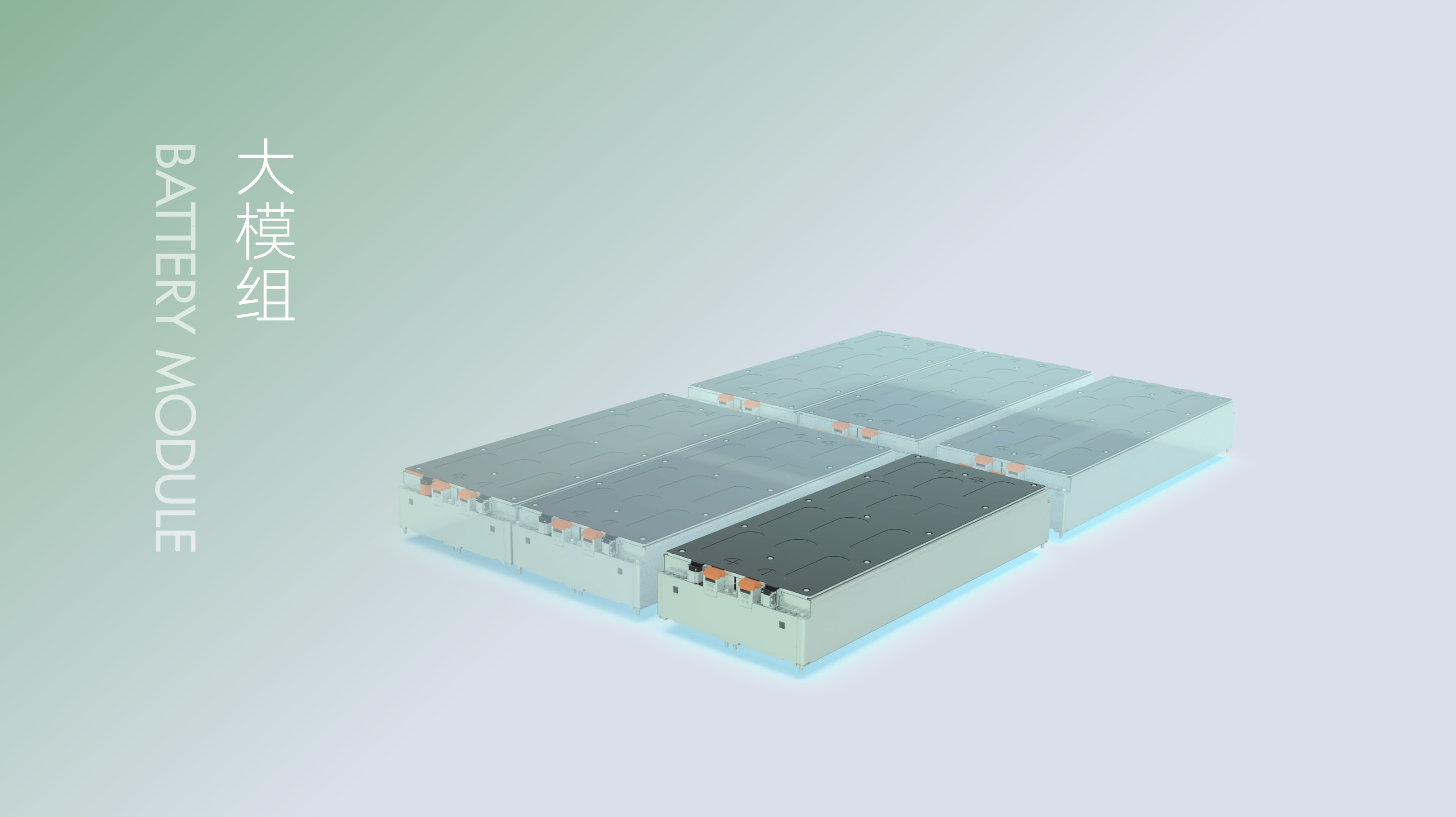

Based on data from SAIC, the current mainstream battery pack volumetric grouping rate for the 523 battery is around 40-50%, and the mass grouping rate is 65-75%, which means that half of the volume and one-third of the weight are not used to store energy.

By customizing a large module solution, SAIC has reduced the number of modules to six, resulting in a 34% increase in volumetric energy density and a 15% increase in mass energy density. To put it in more tangible terms, while a battery of only 54.3 kWh could fit in the original volume, it can now hold 72.7 kWh.

The battery is the cornerstone of achieving a range of 620 km in the ER6, and the motor is the icing on the cake.

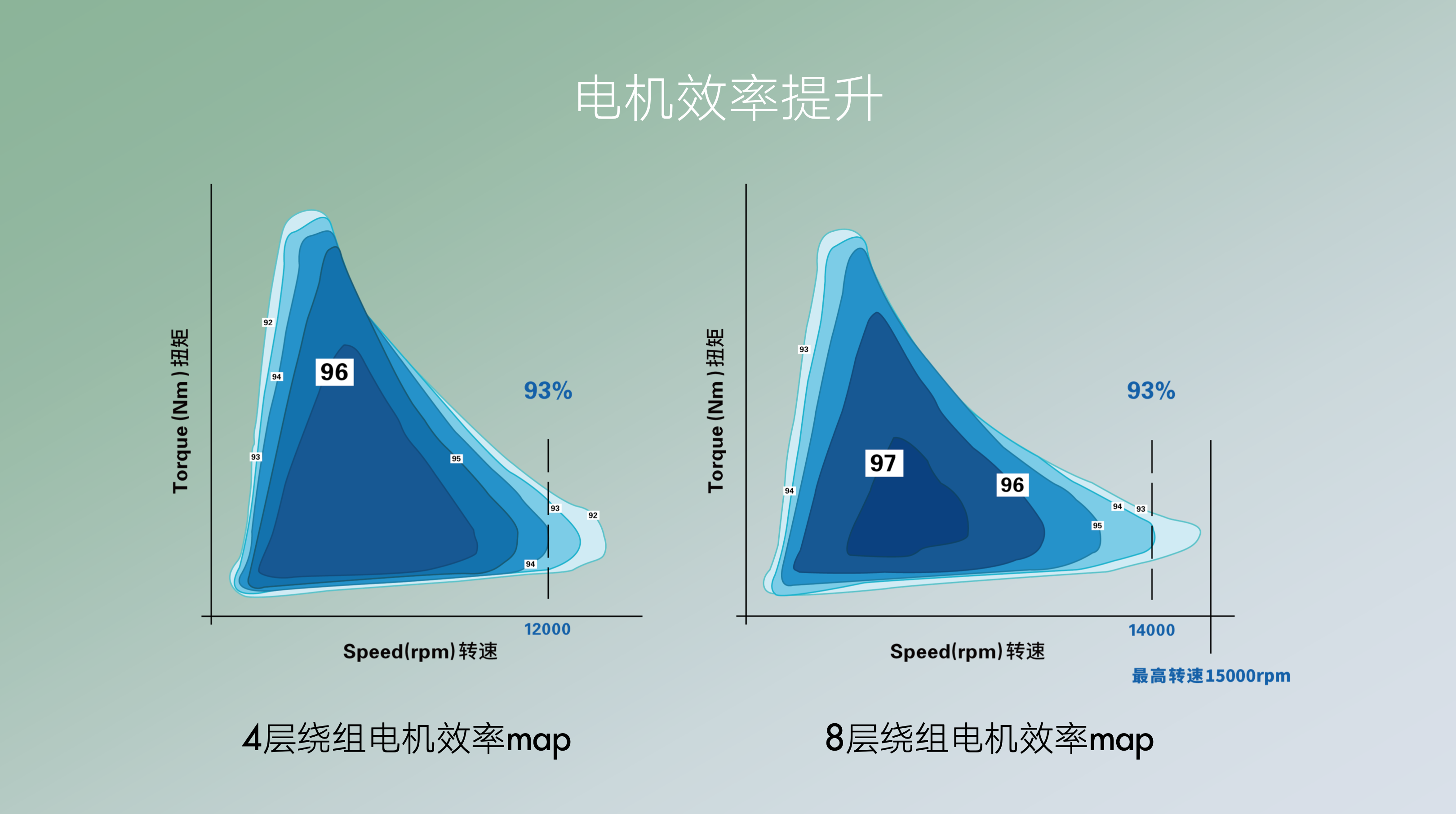

The first domestic motor to use 8-layer Hair-pin technologyThe MAP data from simulation software showed that, for the same ER6 model, when equipped with an 8-layer Hair-pin motor instead of a 4-layer one, the average power consumption under NEDC driving cycle decreased from 13.8 kWh/100 km to 12.2 kWh/100 km, a decrease of more than 11.5% in power consumption efficiency.

This data was shared with me by a SAIC engineer, and it was also a crucial factor for achieving a range of 620 km with a 72.7 kWh battery in the ER6.

To help everyone better understand the function of Hair-pin motors, let’s first have a brief introduction.

The rotor of a permanent magnet synchronous motor is made of a permanent magnet, and the stator is energized to produce a magnetic field to enable the rotor to rotate. To some extent, the larger the current passing through the windings, the stronger the motor’s driving force, and the lower the winding resistance, the higher the electrical efficiency. To improve the power density and electrical consumption level, all motor manufacturers are trying to accommodate as many copper wires as possible in the limited space provided.

Now that we have established this point, let’s talk about Hair-pin motors.

The Hair-pin design is a type of stator winding for motors. Compared to the traditional cylindrical painted wire winding, Hair-pin uses a flat wire design that can fit more copper wires in the existing space. The “fill factor” is significantly improved, and the efficiency and power density are further enhanced. Let’s use some data to illustrate this.

Compared to the previous model, the overall efficiency of the new model has been improved from 96% to 97%, and the maximum motor speed has increased from around 13,000 rpm to 15,000 rpm. When the old motor reaches approximately 12,000 rpm, its efficiency drops to 93%. However, in the new motor, the efficiency can still reach 93% even when the speed reaches 14,000 rpm. In simpler terms, the new motor has a wider high-efficiency range, resulting in lower power consumption at high speeds, and hence longer driving range.

However, there are many types of Hair-pins, including 2 layers as shown in the picture and 4 layers. The Roewe R ER6 uses 8 layers.

In order to maximize the advantages of the 8-layer Hair-pin winding, a knowledge point is explained here: “skin effect”.

Whether it is an asynchronous AC motor or a permanent magnet synchronous motor, AC electricity is used. However, AC electricity has a significant “skin effect”, which means that when the copper wire is too thick, the current will only pass through the surface of the copper wire, resulting in wasted middle areas and low efficiency.

In order to make the most of the Hair-pin winding, Roewe reduced the thickness of each copper wire, but packed 8 copper wires in each slot, which reduces the skin effect and allows for more copper wires to fit in the same space.

As for whether it is necessary to use a 16-layer winding, the Roewe engineer told me that it is not necessary because the 8-layer flattened copper wire has already greatly reduced the skin effect. Adding more copper wires would increase the amount of insulating paint surrounding the wires, occupying more space and reducing the proportion of copper wires in the slot.

During the conversation with the Roewe engineer after the event, I also learned that the Hair-pin manufacturing equipment was purchased from Italy. However, it coincided with the peak of the epidemic in March. If the equipment arrived later, the mass production of the Roewe R ER6 would have been delayed. Although the equipment procurement cost is high, this investment can achieve co-linear production of different products, ranging from 100 kW to 250 kW.

This “three-electrics” lesson on the Roewe R gave me a new understanding. With so many new technologies being integrated, what is the actual range of the ER6? I would like to try it out myself.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.