As one of the few new car-making forces in the United States, Rivian has attracted the attention of major media and giants in the United States. Everyone is looking forward to Rivian bringing some fresh blood to the industry like Tesla.

At the Los Angeles Auto Show on November 28, 2018, Rivian officially released two pure electric vehicle models, the R1T pickup and R1S SUV.

These two models will be equipped with a maximum of 180 kWh battery pack, with a range of more than 400 miles, and are matched with a 4-motor drive system, with a peak output power of 522 kW and a peak torque of 1120 N·m, and 0-60 mph acceleration of 3.2 seconds. From a data perspective, Rivian has created multiple new records for electric vehicles, and these two models are also the most popular models in the US market.

After the release, Rivian received more than 2.85 billion U.S. dollars in investment from companies such as Amazon, Ford, Cox Automotive, and T. Rowe Price. In addition, Ford also indicated that it will jointly develop a pure electric vehicle model with Rivian when investing in Rivian. Amazon CEO also plans to purchase 100,000 electric trucks from Rivian.

What makes Rivian strong?

On January 6, 2020, Rivian Vice President Richard Farquhar was interviewed by the media Charged, during which Farquhar introduced to us in detail Rivian’s skateboard platform and tri-electric technology.

Richard Farquhar originally served as the Powertrain Director at McLaren Automotive and now leads Rivian’s powertrain, battery, power electronics, and thermal systems engineering teams.

* The following is the original interview text, from Charged, translated by Dragon.Charged: Rivian calls its electric power system the skateboard platform. What systems does the skateboard platform architecture include?

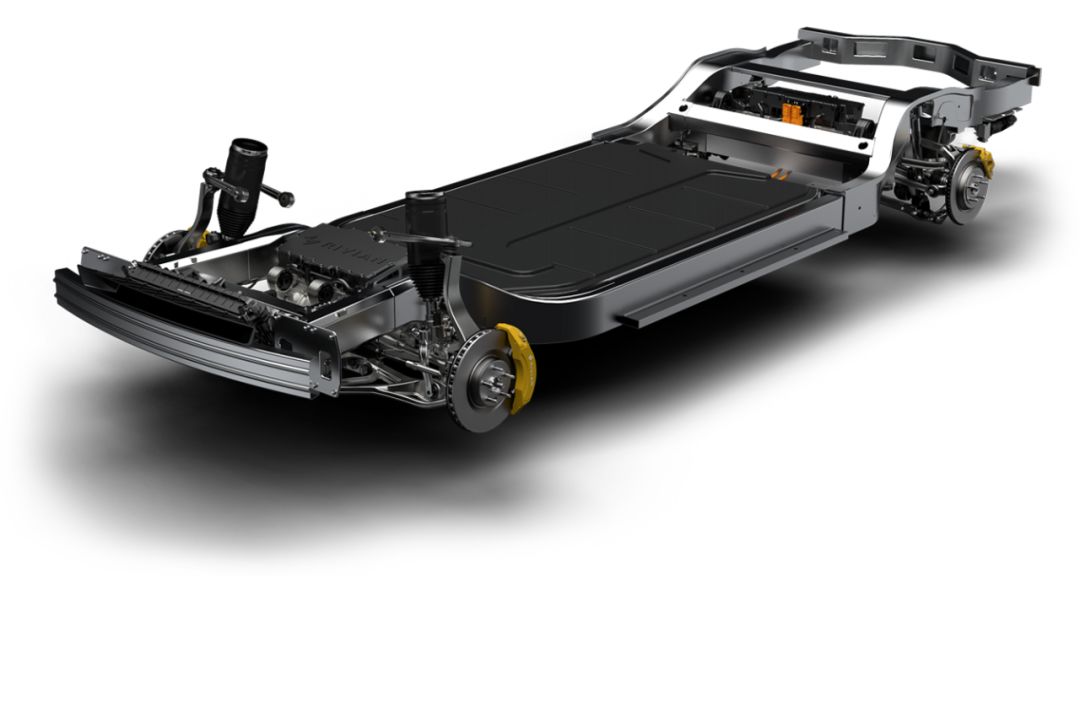

Richard Farquhar: The skateboard is the core of all Rivian vehicles, and we can create different models based on this platform.

The platform consists of an energy storage device (battery), which is located in a lower position between the front and rear axles. This design aims to improve the dynamic control performance of the vehicle, reduce the center of gravity of the vehicle, and increase the polar moment of inertia.

We have equipped each axle of the vehicle with a drive unit, with two motors for each drive unit. Therefore, a total of four motors are installed on the skateboard, which are independently connected to the four wheels through a fixed gear ratio single-speed gearbox.

For each wheel, we also configured an independent torque control device, which has a fast response speed and high operating accuracy. Therefore, there is no better design for vehicle handling and driving than this one.

However, for us, the off-road handling of the vehicle is the real important performance. Independent torque control for each wheel helps us achieve the best off-road vehicle performance.

The skateboard also includes a complete thermal system, with three thermal control circuits in total for controlling the electric drive unit, battery, and cabin temperature respectively. In order to achieve the best performance of electric vehicles, we need excellent thermal control and management, which is exactly what we focus on to maximize the performance and efficiency.

The last key element of the Skateboard is the chassis system. We have achieved comprehensive ride height control in the air suspension and adaptive roll control on the hydraulic system, which is from front to rear and from diagonal to diagonal.

In terms of engineering mechanics, we have achieved such a degree of propulsion and chassis systems that no one can do better than us.

Charged: You just mentioned symmetrical drive units. Did you configure four sets of identical motors and drive units for the skateboard?

Richard Farquhar: Yes, we configured four motors, each set on the left and right sides of the front and rear axles.

The torque and power values of each wheel are the same, aiming to achieve optimal performance. With our efforts, the total torque on the ground of each wheel in the test vehicle exceeds 14000 N·m, and the maximum speed reaches 125 mph (approximately 201 km/h).

With a fixed gear ratio single-speed transmission, there is no need to shift gears or use a two-speed transmission, which can minimize the efficiency loss caused by gear engagement, and at the same time, maximize our performance goals.

The inverter is an important component of the propulsion system, like a gem on a crown, and the device is designed completely in-house by us.

We have designed a dual-power inverter that is integrated into the electric drive assembly and can efficiently control two motors on an inverter assembly.

We have invested a lot of effort from the battery to the inverter, to the motor and wheel. A dual combination inverter is installed on each axle, which allows us to maximize electrical efficiency and thereby maximize the vehicle’s range with the given energy.

Charged: Were the motors also designed in-house?

Richard Farquhar: For the motors, we worked with a partner to jointly design the core electromagnetics and motor assembly, which was then integrated into our drive unit.

This is similar to the design of battery modules. We work with multiple partners to obtain battery cells, design and develop modules, and then precisely encapsulate them according to our wishes.

Therefore, for Rivian, the motors are unique, because the integration of motors into the electric drive assembly, installation, contact of the inverter with the motor, motor cooling, configuration into our transmission, and other aspects are all done in-house by Rivian.

Charged: You just mentioned that the maximum performance of an electric vehicle is related to thermal management. Could you explain in detail which performance areas will become limiting factors for thermal management?

Richard Farquhar: The design of electric vehicle systems always revolves around trade-offs and performance optimization, and thermal management factors are always at the forefront.

In terms of the boundary conditions of electric vehicle performance (corner cases), whether it is DC fast charging, power distribution at a constant rate, or traction and high torque, they all come down to thermal constraints of the motor, inverter, and battery.By adopting three independent refrigeration systems and equipping them with intelligent valve control devices, we can monitor energy consumption–the heat being generated–and achieve optimal refrigeration through a very smart way, thus achieving the best performance.

The battery has a dedicated circuit for heating and cooling. We can intelligently adjust the battery temperature to the optimal temperature as needed. If the vehicle is in extremely cold environments, we can heat the battery to increase its temperature, thereby maximizing efficiency and increasing the vehicle’s range.

The traction system also adopts the same principle–an independent circuit designed to ensure that the motor and inverter are at the optimal temperature. The motor and inverter have a coolant circuit that cools the stator and power electronic components.

In addition, there is a third circuit for cabin and HVAC use. Therefore, we equipped these three independent circuits with intelligent valves and control systems to optimize their performance.

There is also an intelligent control component in the thermal system. We can intelligently control the vehicle’s thermal management system through the intelligent connected vehicle control function.

For example, if you charge using high-power DC fast charging, we need to know the optimal temperature for this operation and then use the cooling system to lower the battery temperature to that range.

This is not limited to the thermal management system itself. We have also independently developed a complete set of modules and battery packs, used them as a set of mechatronic systems, and produced the above devices in our new Normal assembly plant in Illinois.

In addition to the hardware of the battery management system, we have also developed software, algorithms, and control strategies, and connected them to the intelligent connected vehicle platform.

Of course, this platform is also independently developed by Rivian. So not only can we control the functional performance of the battery to optimize its service life and performance, but we can also change the parameters of the battery management system, which is tailored for individual users and understands their driving habits, charging preferences, and energy return rates.

Based on this, we can provide customized services to customize our battery use methods, thereby optimizing the battery’s service life and efficiency, and provide you with the best performance.

Therefore, we have indeed achieved true intelligent control of the battery management system (BMS) connected to the Rivian intelligent connected vehicle platform and the user’s vehicle usage methods.

Charged: Can you explain the design of the battery module and battery pack?Richard Farquhar: If you narrow it down, we firmly believe that Rivian currently has the highest volumetric energy density battery modules and packs in the world, which are 20%-25% higher than any other similar product on the market, measured in Wh/L.

The key to achieving these advantages lies in the construction of the battery modules, each of which has two layers, each containing 21700 cylindrical batteries.

Each battery module has an energy of 15 kWh, our standard battery pack has 9 battery modules, and the high-end version has 12 battery modules, with a total energy of 180 kWh. Therefore, the vehicle’s range can reach more than 400 miles (about 644 kilometers).

The core of this module lies in a cooling plate between the upper and lower layers of the battery cells, which allows us to control the cooling of those cells in the most efficient medium, the medium is cooled axially.

We take the heat out through the center of the cell, which is the most effective way compared to radial heat dissipation. This allows us to tightly pack these cells together to achieve the highest volumetric energy density available today.

Charged: Did you use a thermal interface material between the cells?

Richard Farquhar: We did not use such materials, there is only air between the cells. We do not need to put anything between the cells that are packaged together. The space between the cells is designed to ensure that the module itself, the battery pack, and the vehicle are as safe as possible under any circumstances, safety is an important issue in our work schedule.

When each wheel is equipped with independent torque control devices, such off-road vehicles can go anywhere. We need to consider this type of driving scenario.

For example, when you climb rocks on the road and drive down steep slopes, we need to form good protection for the vehicle battery from a structural perspective, integrating it highly with the body structure. There is a bulletproof shield under the battery pack, as an important part of the vehicle’s main structure, designed to prevent impact events from the ground.

The battery pack is wrapped in extruded aluminum to prevent collision accidents and ensure that the battery will not be damaged in the event of a frontal or side collision. Passive safety is our top priority, and the battery cells inside the pack are also protected from impacts and vibrations caused by long-distance off-roading.

The battery pack is wrapped in extruded aluminum to prevent collision accidents and ensure that the battery will not be damaged in the event of a frontal or side collision. Passive safety is our top priority, and the battery cells inside the pack are also protected from impacts and vibrations caused by long-distance off-roading.

Furthermore, this type of packaging also provides excellent protection for the battery pack. For example, all high-voltage, low-voltage, and cooling systems in the nine modules inside the battery pack are encapsulated in the spine, which is located exactly on the vehicle’s centerline. Therefore, in any collision accident, this position should be kept as far away from the outer edge as possible, and the battery components in the center of the battery pack are well protected. We have considered many aspects to ensure the integrity of the battery pack from a passive safety and off-road driving perspective.

Charged: Rivian claims that this type of vehicle can drive in water up to one meter deep. Will all of the drivetrain components be submerged? Can you discuss the engineering design challenges of the water submersion system?

Richard Farquhar: Yes, one of our requirements is that the vehicle can drive in water up to one meter deep for a period of time. If you look through the entire vehicle from front to back, all of the components I mentioned – our cooling system, HVAC cooling module, battery pack, drive unit assembly, motor, and inverter – fall into the category of submersible components.

So how do these components breathe? How do they operate? What temperature changes will occur when they are submerged in water for a long time? We have considered these issues in vehicle design. In fact, if you drive into deeper areas, the vehicle will start to float, and its body weight will prevent the vehicle from sinking further.

In fact, the engineering design challenge is about thinking about the laws of physics. Whenever a vehicle with heat flow enters cold water, you will see thermal expansion and contraction, so there are many temperature protection (delta temperature) issues to be addressed, which is called the engineering design difficulty.

With the change of temperature, how will these devices breathe? Obviously, you must seal through all the gaps. As long as you have dynamic and static water pressure, these parameters become an important part of the design standard level test standard. Ventilation and drainage are very important, which undoubtedly provides an interesting and challenging engineering design problem for our research and development process.

Charged: Rivian claims that it will officially start vehicle production at the end of next year. What stage is the company’s R&D process at now? What will be the work content of the next stage? Will you freeze the design or continue to control the main design changes during the production process?Richard Farquhar: We carry out product development work based on RDP (Rivian Development Process), and we are very clear about the series of measures formulated in this process, which are all necessary steps to initiate production.

We have listed the deliverables and milestones that need to be achieved on time for each stage. Our work is mainly divided into four stages: Concept Year Phase, R&D Phase, Validation Phase, and Gradual Realization of Mass Production.

We have built a large number of prototypes and conducted extensive testing of components and systems. In addition, we have also adopted Rivian’s internal processes, which have been constantly maturing and now allow over a thousand people to collaborate and deliver such products. Therefore, this is a very clear process, with relevant milestones set along the way.

Regarding the question you want to know: how do we manage design changes? In the early stages, we want to maximize the vehicle’s (performance) attributes. We have defined the performance, features, and characteristics of the vehicle, with a lot of creativity and innovation in terms of quality, energy, cost, and other aspects, to achieve the design goals in the most efficient way possible.

I think you might say that we enter the true creative and innovative stage through the R&D and Validation phases. After that, we will focus on the reliability, performance, and excellent quality related to product maturity.

We have built multiple testing vehicles and are in the early stages of vehicle development, currently committed to building more prototypes to test more vehicle attributes and high-level automotive components for mass production.

We concentrate on the so-called Validation Phase, where we will build dozens of production-intent validation vehicles, aiming to complete all validation, reliability, durability tests, and initiate the certification process to obtain mature quality vehicles and achieve mass production by the end of next year.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.