On November 16th, Tesla announced the price of Model 3 in China at the Guangzhou Auto Show. On the other side of the earth, Elon Musk sent an all-employee email with the subject of Model 3 production capacity. This topic has been covered in all-employee emails from Elon since last year, and I have been writing about it from last year until now. The curse of ramping up production capacity, which is haunting Model 3.

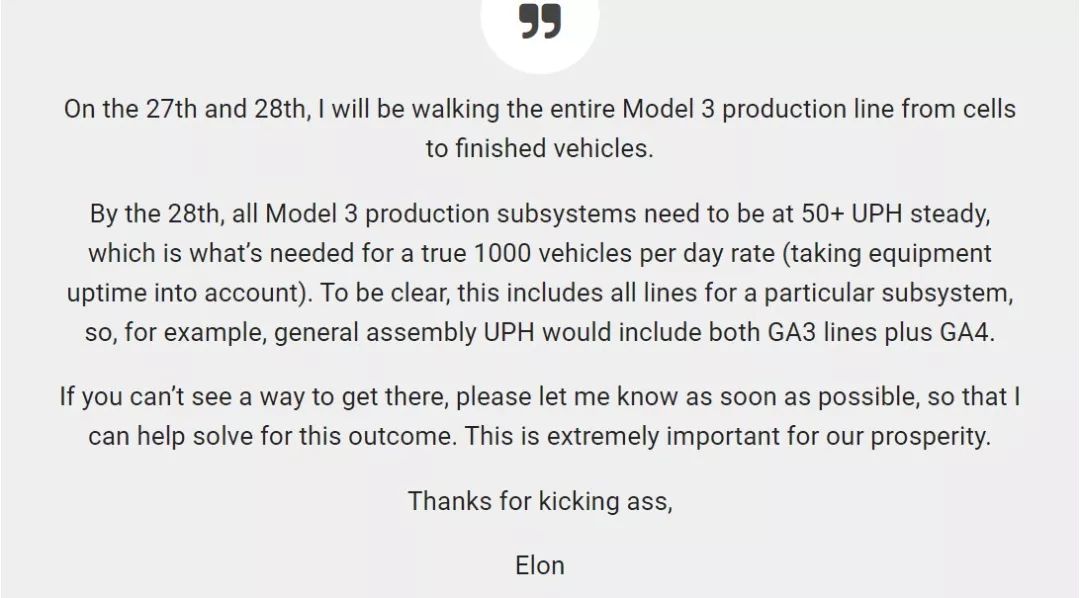

Let’s take a look at the email content.

On the 27th and 28th, I will go through the entire production line of Model 3, from battery cells to final assembly.

By the end of the day on the 28th, all Model 3 production subsystems must be at 50+ UPH and climbing rapidly. This is what’s needed to exceed 1000 vehicles per day (considering a 24 hour production day), which is the critical threshold needed for us to become financially sustainable and enable Tesla to continue to pursue our mission. It is of utmost importance that we achieve this rate of production without sacrificing quality.

If you can make it happen, please do so. This is a critical milestone for Tesla, and the entire team will be working 24/7 to achieve this goal.

Thank you very much for your hard work and dedication.

Elon

UPH stands for Unit Per Hour, or production output per hour. 50+ UPH can reach 1000 vehicles per day, and the workers have to work at least 20 hours a day, right?

The peak of Tesla workers’ hardships was during the production of the Model X in 2015. To this day, the Model X remains the only mass-produced vehicle with double-hinged falcon-wing doors. Behind the glossy surface is the blood and tears of workers.

In 2016, Tesla realized that long-term high-intensity overtime was unsustainable and established a 7×24 work system of four days on, three days off, and a three-shift system. The average working hours of workers also decreased to 42 hours per week. Therefore, working 20 hours a day is not necessary.

Back to the topic, because Tesla has built its own battery factory, the battery cell production line is actually the most upstream part of the production line, and the final assembly line is of course the last link.

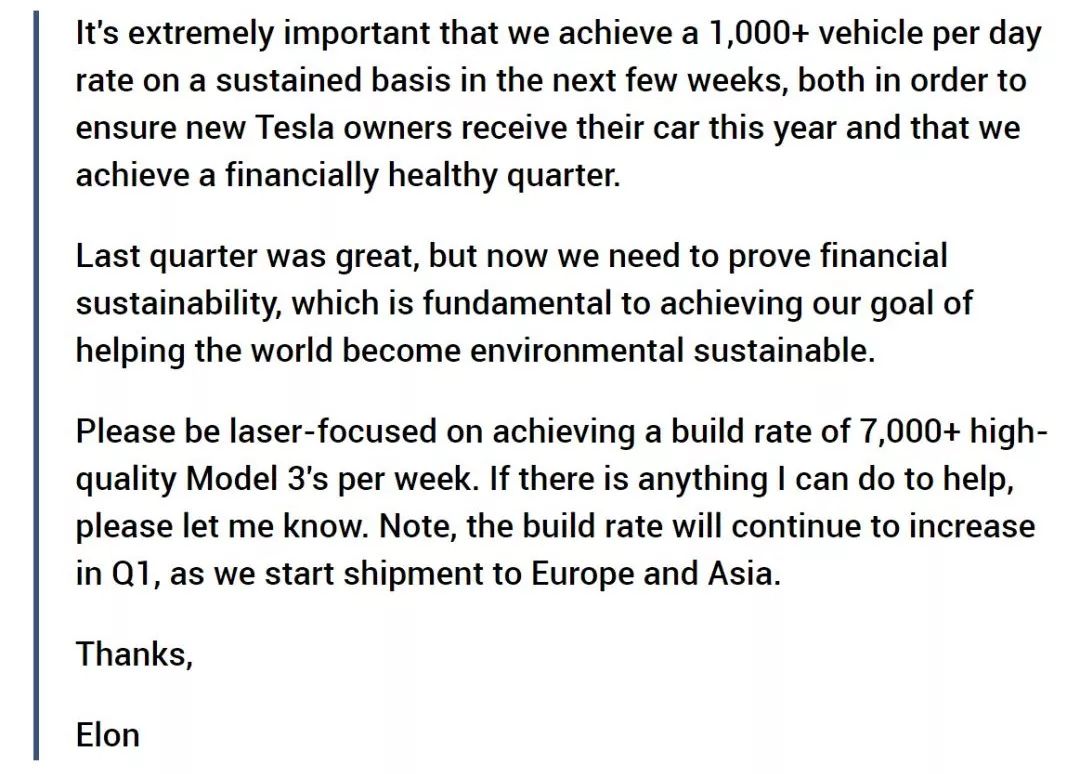

This email is quite direct, focusing directly on the goal of producing 7,000 vehicles per week. Indeed, this is a supplementary email. On the previous day, November 15th, Elon also sent an all-employee email.

### In the next few weeks, it is crucial for us to continuously achieve a production capacity of 1000+ cars/day, not only to ensure that pre-order customers can receive their cars this year, but also to achieve a financially healthy quarter.

### In the next few weeks, it is crucial for us to continuously achieve a production capacity of 1000+ cars/day, not only to ensure that pre-order customers can receive their cars this year, but also to achieve a financially healthy quarter.

Last quarter was good, but now we need to prove the sustainability of our finances, which is the foundation for achieving our goal of accelerating the world’s transition towards sustainable energy.

Everyone should focus on achieving a high-quality production capacity of 7000+ Model 3 vehicles/week. If there is any area where I can help, please let me know. Note that as we begin deliveries in Asia and Europe, our capacity will continue to grow in Q1 next year.

Thank you.

Elon

This email is very clear on why we need to achieve a production capacity of 7,000+ cars/week. Firstly, it’s to deliver as many vehicles as possible to pre-order customers in Q4. Tesla has already sold a cumulative total of 200,000 vehicles in Q3, and according to the U.S. subsidy policy, electric vehicles shipped in the season of achieving 200,000 electric vehicles sold (Q3 and Q4 in this case) are still eligible for a subsidy of $7,500. However, starting from Q1 next year, the subsidy will be halved to $3,750.

Therefore, Tesla needs to deliver as many vehicles as possible before the end of 2018, to reward those who have waited for two and a half years for the Model 3 with the highest subsidies.

Furthermore, in order to allow more customers who cannot afford the performance version of the Model 3 to enjoy subsidies, Tesla recently launched the mid-range Model 3 with an EPA-rated range of 260 miles (approximately 420 km). Elon Musk tweeted that for all new orders placed before November 30th, Tesla can guarantee delivery by December 30th – to receive the maximum subsidy of $7,500.

The second reason is to prove the sustainability of Q3 profitability.

Despite Elon’s previous efforts, Tesla has not been taken private. Since it will remain public, bears will continue to hover over Tesla. In Q1, bears went short because of weak growth in production capacity; in Q2, bears went short because of a fast burn rate; in Q3, Tesla turned a profit which cost the bears dearly, and they continued to go short by saying the profit wasn’t sustainable. Therefore, Tesla must use Q4’s financial data to prove that the profit is sustainable.## Translation

Big Short Stanphyl Capital Managing Partner Mark B. Spiegel, a middle-aged internet-addicted person who is more diligent than Elon Musk himself. He tweets negative news about Tesla and Elon every day on Twitter, tirelessly retweets news about Tesla’s competitors, and even follows XPeng, Lynk & Co, NIO, and SF Motors…

Because of their short position on Tesla, Stanphyl Capital’s revenue fell by 15% this year, and Spiegel firmly believes that Tesla will return to loss in Q4. Elon wants to prove that Tesla’s profitability is sustainable.

Profitability cannot be achieved without large-scale deliveries, which in turn comes back to production capacity. Over a year has passed, and it seems particularly difficult for Model 3’s production capacity to ramp up. So, where is the bottleneck of Model 3 production capacity now?

On the recently passed Thanksgiving Day, most workers at Tesla’s super factory took time off. After all, Thanksgiving is roughly equivalent to Chinese holidays like Dragon Boat Festival and Mid-Autumn Festival. However, the battery module and pack production lines of Model 3 were still running during Thanksgiving.

Tesla called on employees to voluntarily work overtime. Each sub-assembly line had managers to guard them and were responsible for compiling a list of volunteer employees who actively participated in overtime during the holiday period. These employees not only received overtime pay but also bonus holiday allowances.

Tesla spokesperson said that the overtime work on Thanksgiving was not to sprint for production capacity, but just to maintain the existing 7×24 shifts. Employees who were on duty on Thanksgiving Day could choose to hand over their work to volunteer employees who participated in overtime work.

In an email in which Elon announced the goal of ramping up production capacity to 5000 vehicles per week by the end of Q2, he mentioned that there were problems on the production lines, including battery modules, painting, final assembly, and welding… All four auto plant processes except for the initial stamping have had problems. Today, the problems are mainly concentrated on the battery module and pack production lines, which is considered to have made significant progress.

What does 7000 vehicles per week mean? At the end of Q3, Tesla’s Model 3 production capacity was 4300 vehicles per week. Therefore, this is an increase target of over 50%.

Therefore, we see that Model 3 has single-handedly surpassed the sales of all Mercedes-Benz and BMW models in North America; the start of production at Tesla’s Shanghai factory has been advanced from 2020 to the end of 2019; the delivery of the first batch of orders for Chinese Model 3, originally scheduled for the end of 2019, has been moved forward to early 2019.One after another, seemingly enthusiastic news is nothing but the fruit of Tesla’s team’s hard work. Therefore, focusing on this company may not be a good idea for Mark B. Spiegel and other short sellers of Tesla.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.