Introduction: Start with the easier task of using two-box to solve the problem of line control, and then introduce more integrated products. This may be the optimal solution for oneself, others, and society.

In 2021, the line control brake system can be considered as one of the hottest capital feasts. Automakers such as BYD, Great Wall, Zhongqi Chuangzhi, Bertelli, and traditional tire 1 companies have released their own solutions. With the increasing penetration rate of ADAS systems, the rigidity requirements of the line control brake system have further promoted the development of the line control brake system.

Line Control Brake: A Necessity of History

The line control brake system mentioned here is one of the two well-known braking systems, and the handbrake, which is the parking brake – electronic handbrake (EPB), is now basically standard equipment in passenger cars. The line control brake system is a more critical braking system for driving.

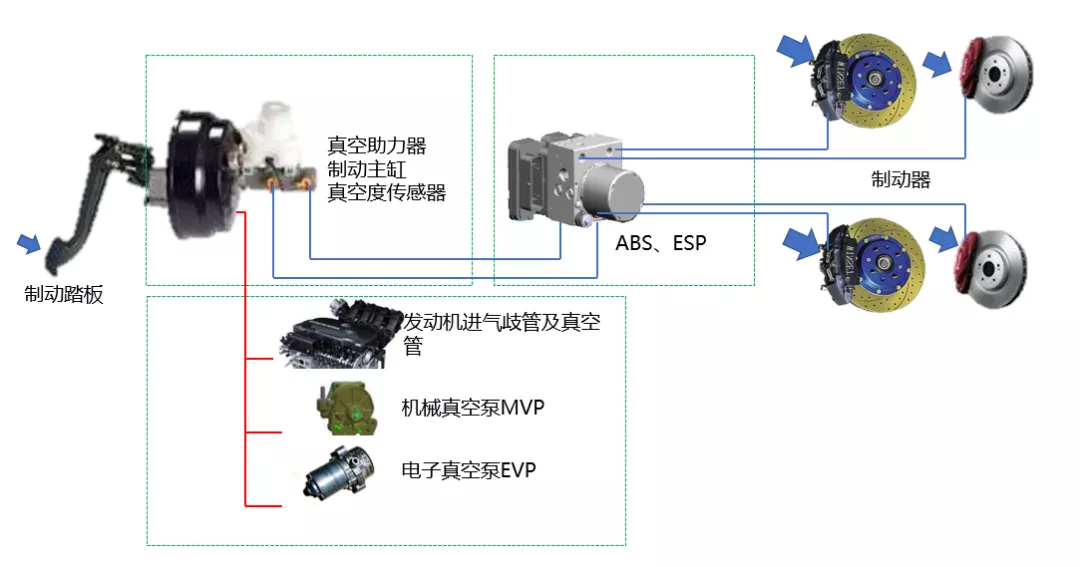

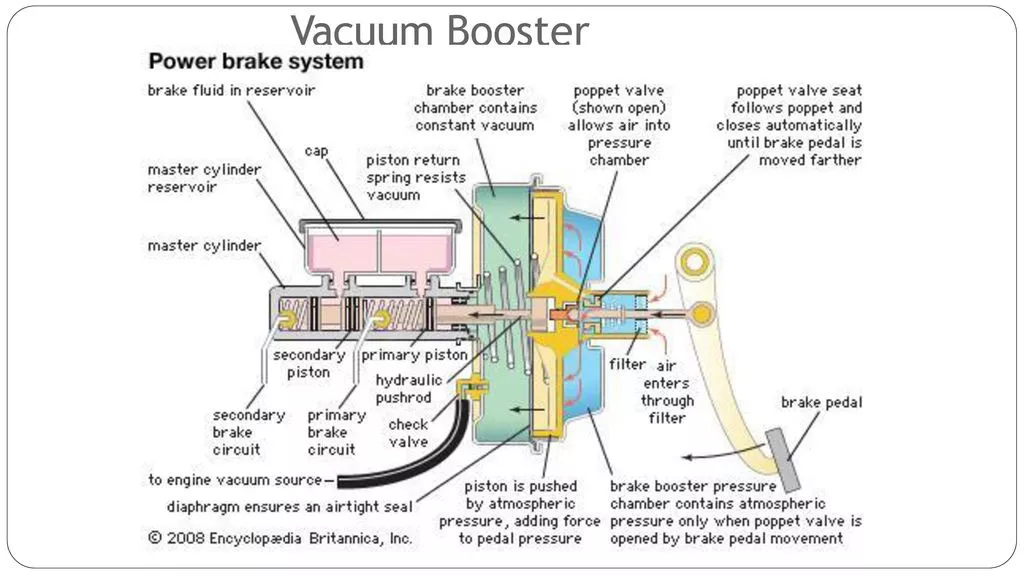

The traditional braking system relies mainly on the vacuum booster and the braking master cylinder structure in the hydraulic brake system, which is achieved by the driver’s muscles plus the assistance of the vacuum booster to slow down, park, or stop temporarily on a slope.

Many people with driving experience should have experienced the situation where the brake pedal could not be pressed down easily after the vacuum booster lost vacuum assistance. When braking, a part of the force pushing the master cylinder comes from the driver, and a substantial portion comes from the vacuum booster (the working principle of the vacuum booster is to use the pressure difference between the two air chambers of the booster (one is at the normal atmospheric pressure, and the other is under vacuum) to provide a forward driving force to the driver).

Generally, the vacuum source (negative pressure) of the vacuum booster comes from the intake manifold pressure of a traditional internal combustion engine. With the changing times, there are more and more vehicles with turbocharging structure. The characteristics of the turbocharged vehicle structure result in a drop in negative pressure in the intake manifold, which means that the vacuum booster loses a stable and reliable vacuum source. Therefore, many turbocharged vehicles must add a separate mechanical or electronic vacuum system to provide a reliable vacuum source for the vacuum booster.

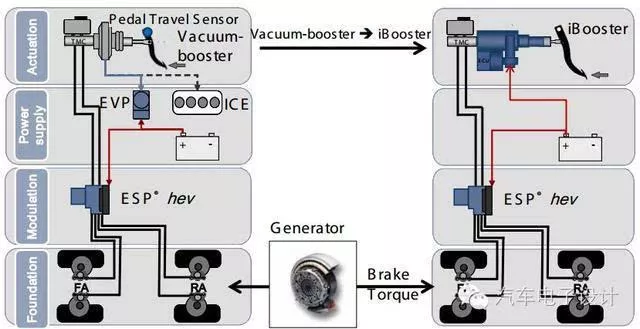

Nowadays, the penetration rate of new energy and electric vehicles is increasing, especially electric vehicles. Using the vacuum booster structure for the braking system requires the addition of a separate vacuum pump, control system, air tank, pipeline, etc., to ensure a reliable vacuum supply.On the other hand, the popularization of ADAS technology, especially higher-level autonomous driving vehicles, has raised demands for wire-controlled brakes. At the same time, in the era of low carbon, energy recovery from braking is an unavoidable issue. Traditional vacuum-assisted brake systems cannot achieve balance between braking experience and energy recovery efficiency. If energy recovery efficiency is high, braking experience is a nightmare, and it is impossible to comply with regulations.

To sum up, wire-controlled brakes are a must for new-age cars.

In terms of performance, wire-controlled brake systems have fast response and high pressure gradient (peak pressure time for traditional brake systems is usually over 500ms, while corresponding pressure time for wire-controlled brake systems is generally around 200ms or even less than 150ms), and high level of intelligence. In terms of performance, wire-controlled brakes can completely crush traditional brake systems, and can be said to be the gravedigger of traditional vacuum-assisted brake systems.

In reality, traditional leading companies in the field have already stepped ahead.

In 1996, Bosch conducted on-road tests on their developed wire-controlled brake system, which was later widely used. TRW, Conti and other companies also successively developed similar wire-controlled brake systems, and obtained a series of patents around 2000-2002.

Nowadays, everyone talks about ADAS and L1, L2, L2+, L3. Strictly speaking, without wire-controlled brakes, the function of L1 will be greatly discounted. Therefore, as the penetration rate of ADAS system increases, wire-controlled brakes will gradually cover the full range of models of various passenger car manufacturers. Although it is not currently a standard configuration for all models, the technological reserves have been basically completed. The market pattern of this new wire-controlled brake system still seems to be a continuation of history, even if the matching cost is often in the range of tens of millions to hundreds of millions. Most domestic car companies still choose traditional leading enterprises such as Bosch and Conti.

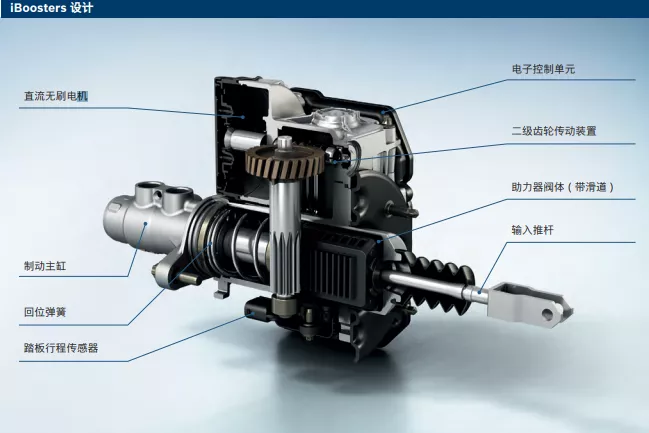

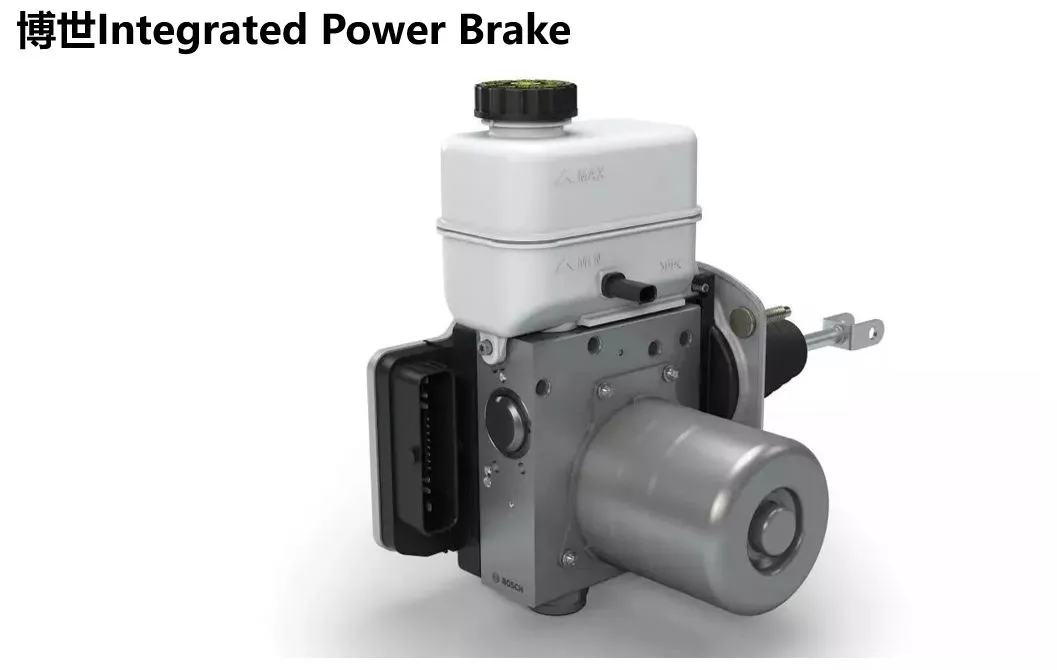

The implementation of the wire-controlled brake system can be described as “each to their own strengths”. There are various solutions, and Bosch’s solution is perhaps the most representative and market-approved. Bosch’s two solutions can be summarized as “two-box” solutions represented by ibooster generations 1 and 2, and “one-box” solutions represented by IPB.

The two-box solution represented by ibooster can be understood as replacing the traditional vacuum booster with an intelligent and electric e-booster system, which has an electrical interface and an energy system. Besides assisting the driver to complete the braking task, it can also independently complete all driving braking functions (this is called brake-by-wire wire control braking) outside the driver. At the same time, the ABS, ESC and other pipelines downstream of the brake master cylinder can be structurally identical to traditional brake systems.

Bosch’s ipb (integrated power brake) is more powerful and compact, integrating the functions of the booster and the esp into one component.

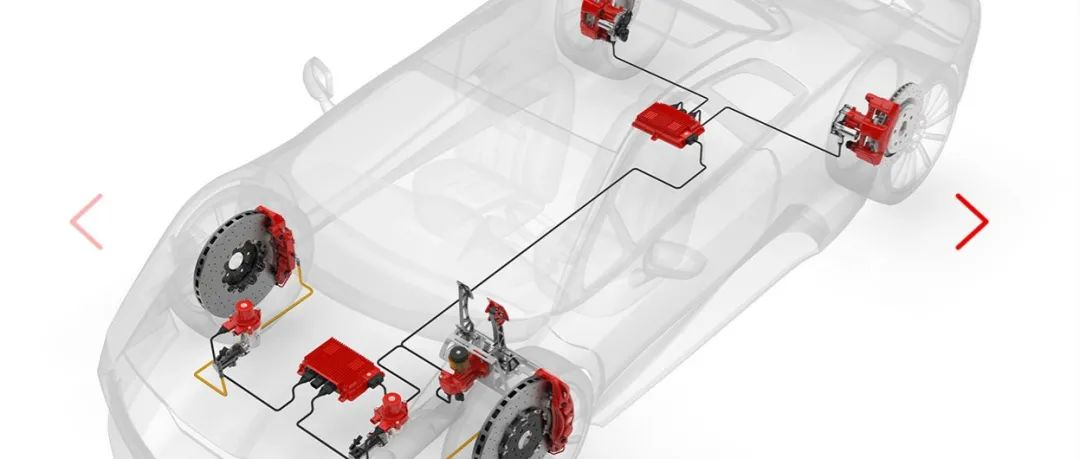

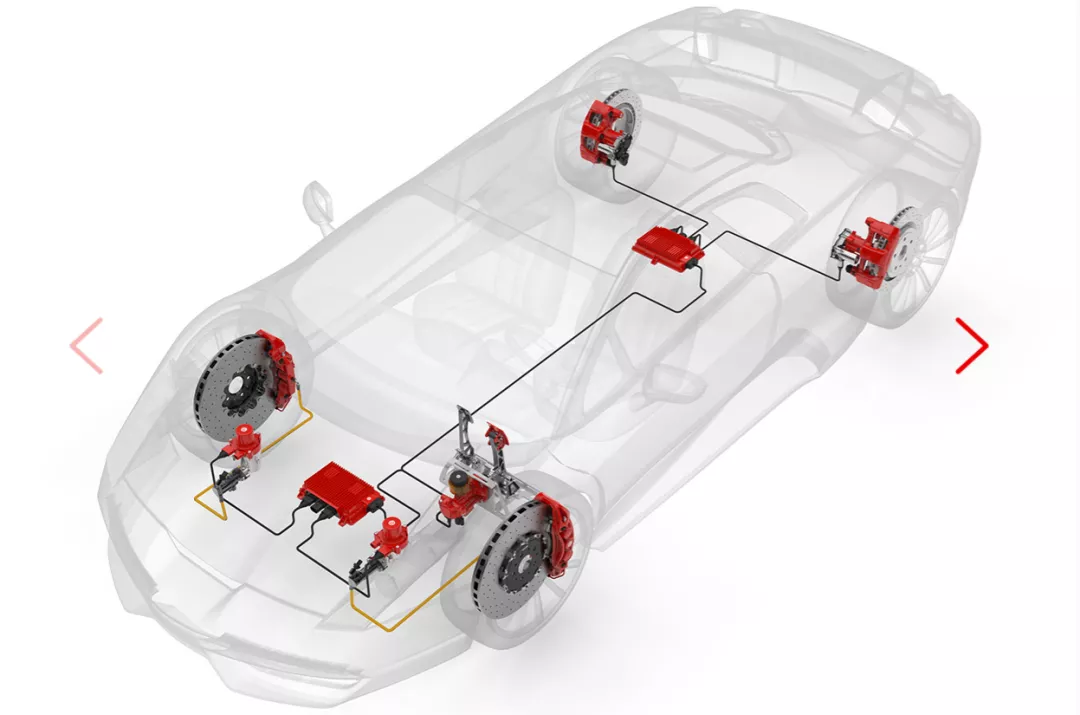

The popular brake market star Brembo has released a more aggressive solution for online controlled braking.

This system has independent actuation units on all four wheels, with hydraulic actuation systems on the front wheels and EMB systems on the rear wheels.

Localization: Cannot be Overzealous

To be frank, compared to other components of vehicles, domestic online controlled braking systems are basically synchronized with foreign traditional giants, and can be said to be only half a step behind companies like Bosch. After all, systems like EMS (engine management system), ABS and other systems have basically matured and been mass-produced overseas, while domestic production of these systems is still in its infancy (even now, domestic substitutes for these systems are still weak). Online controlled braking systems are just a little slower compared to the currently matched components in the global market.

However, there is a concern that domestic online controlled brake manufacturers should be patient and not move too fast.

In my opinion, in terms of system difficulty, the difficulty coefficient of a stand-alone two-box online controlled braking system (using an e-booster instead) might be 1; while e-booster + abs, i.e. a complete set of e-booster and ABS offered by an online controlled braking system manufacturer, would have a difficulty coefficient of 2 or above; and a one-box system would have a difficulty coefficient of 4 or above.Why would that be? For one thing, just for the perspective of electronic control systems, as a new product and technology, there must be a lot of pitfalls to fill before large-scale validation. It seems that several domestic companies in the electronic control system have already encountered problems. Even Bosch, which is a leader in the industry, has encountered more than 3 problems within this area, including struggling with Dongfeng Honda. Secondly, not to mention the ESC system, most of the ABS technologies from electronic control system manufacturers are probably difficult to be accepted by OEMs. If we directly put the one-box on top of this foundation, how difficult would the system control be? What is the acceptance level of OEMs? After testing several ESC products in China, an OEM big factory brake expert once rated China’s ESC system like this: it is ridiculous with ESC installed as compared to not having ESC installed!

Compared with two-box, there seems to be some deficiencies in safety backup of one-box. At the vehicle level, the redundancy backup of two-box can have ESC, EPB, and brake energy recovery (motor regenerative braking), while one-box, when the entire one-box fails, the most effective ESC backup will no longer exist. This may be a major flaw for electronic control system in the stage of growth and gap-filling. At the same time, this may also be a very negative gain: when mature ESC adds safety locks on two-box, inexperienced ESC on one-box will probably add a lot of variables and uncertainty, adding countless pitfalls.

From a rational perspective, one-box should be treated with more caution. Otherwise, due to this big leap, one mistake will make the society unable to bear the risk of one-box failure. The confidence in the domestic substitute for electronic control system from Chinese OEMs cannot withstand toss.

Taking an easy step first and tackling the electronic control system problem with two-box first, and then introducing higher integration products may be the best solution for ourselves, for others, and for the society!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.