To be honest, the flagship electric version EQS (EVA platform) of Mercedes-Benz is quite disappointing, as the brand didn’t have such a strong fortress without combustion engine and gearbox. However, the EQXX represents its next-generation modular architecture (MMA). Is it reliable, especially at the core system level? Let’s focus on this.

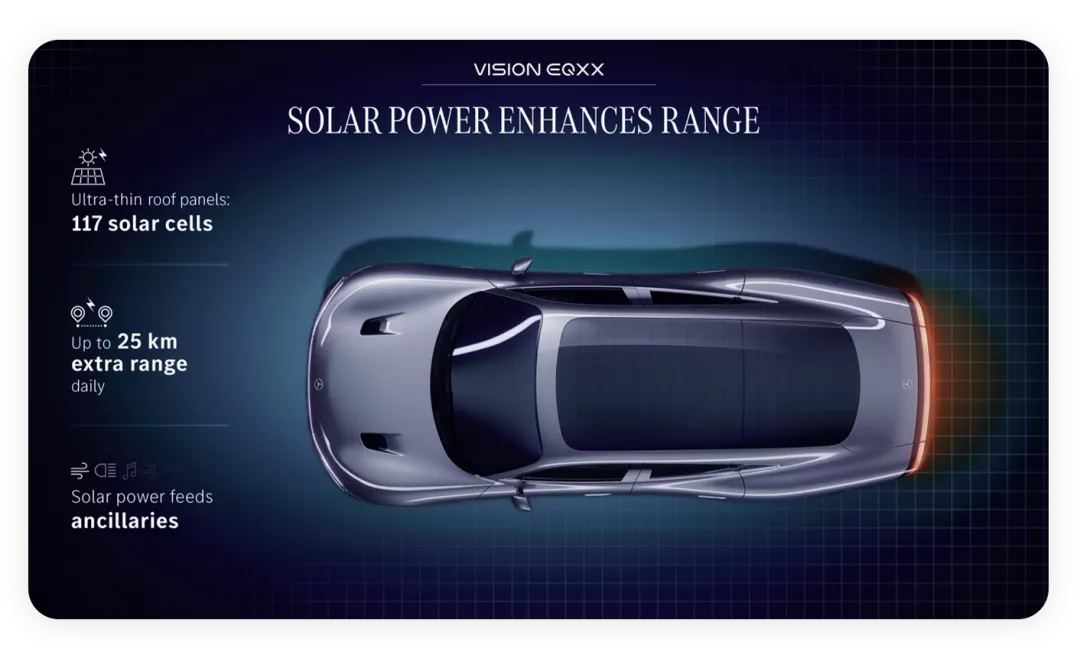

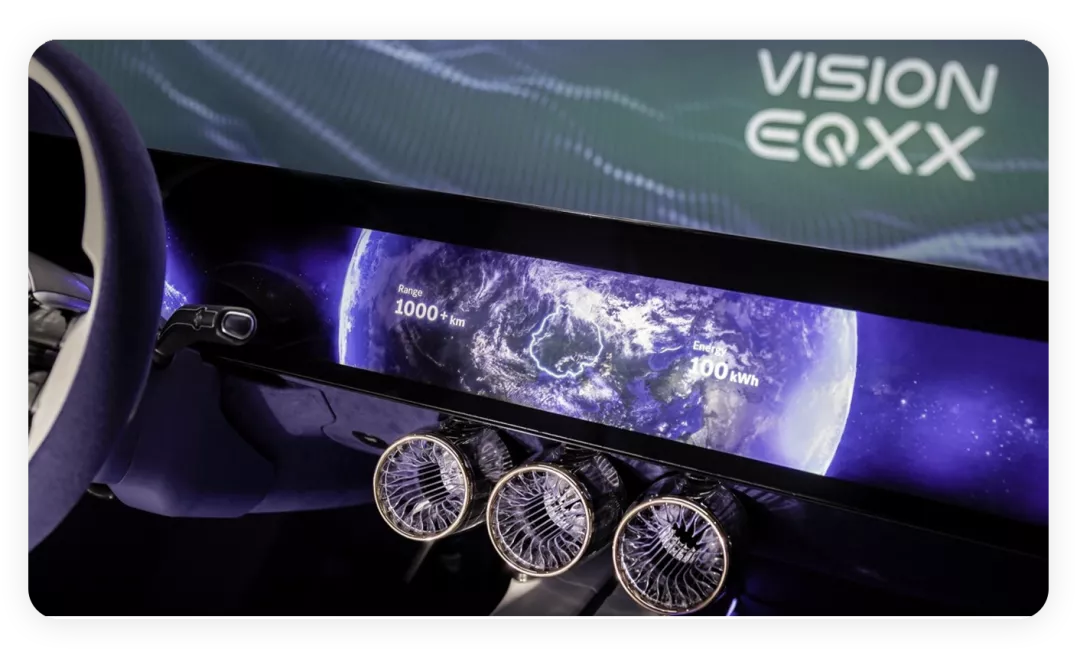

Mercedes-Benz set the flag using 100 kWh to run for 1000 km. Therefore, everyone regards 1000 km as the top benchmark, but some cars use 140-150 kWh, and the key point is how to control the energy consumption of the entire vehicle.

What has changed?

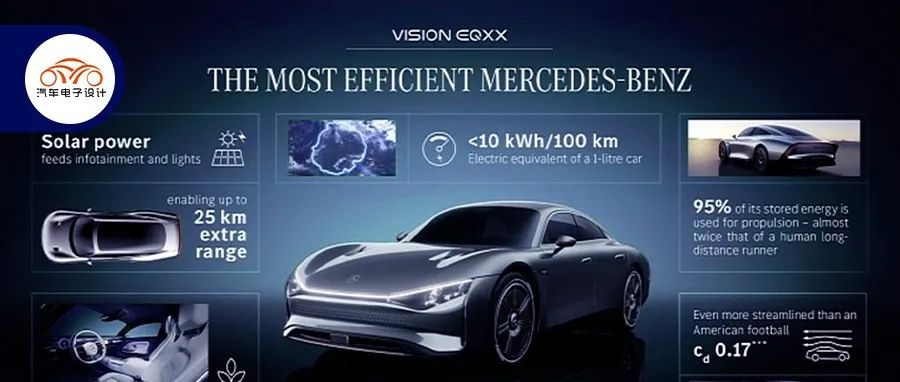

Despite many controversies regarding the appearance of VISION EQXX, the core technology is still to reduce the wind resistance to 0.17.

Another feature is lightweight design, which, similar to the previous BMW I3, reduces the weight to 1750 kg by adopting a light F1 subframe for the pure electric chassis.

● Battery size:

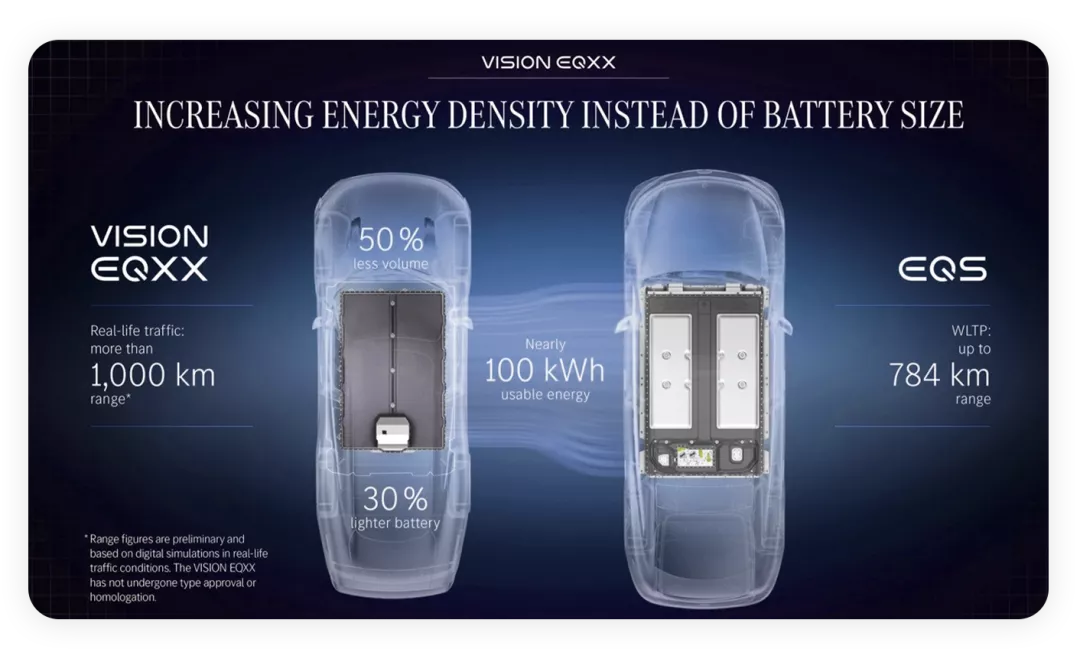

A significant size reduction has taken place through a compact design, which significantly reduces the width, length and height of the battery.

● Battery capacity:

100 kWh is reduced by 50%.

The battery weighs 495 kg, and the corresponding energy density is 202 Wh/kg (compared with EQS, the energy density is 20% higher while the weight is 30% lower, which represents a significant difference).

The battery cells used are Ningde era’s square shell batteries, and whether the CTC technology of this new type of square shell battery is comparable to the 4680PK is an interesting point.

Here, the official statement involves a series of chemical systems – I estimate that it ranges from high nickel to iron phosphate, which includes different battery companies’ schemes.

● Structural design:

They use the BionEQXX casting process, which, similarly to Tesla, integrates the battery shell into the subframe of the casting structure behind the vehicle with a single casting.Here is a statement about passive cooling. From my understanding, this is mainly a word game. To develop an 800V fast-charging system (with a design target of 300km in 15 minutes and 100km in 5 minutes), intelligent battery management is required. Alternatively, cooling plates can be integrated into the battery shell and ventilation ports can be opened when the temperature rises.

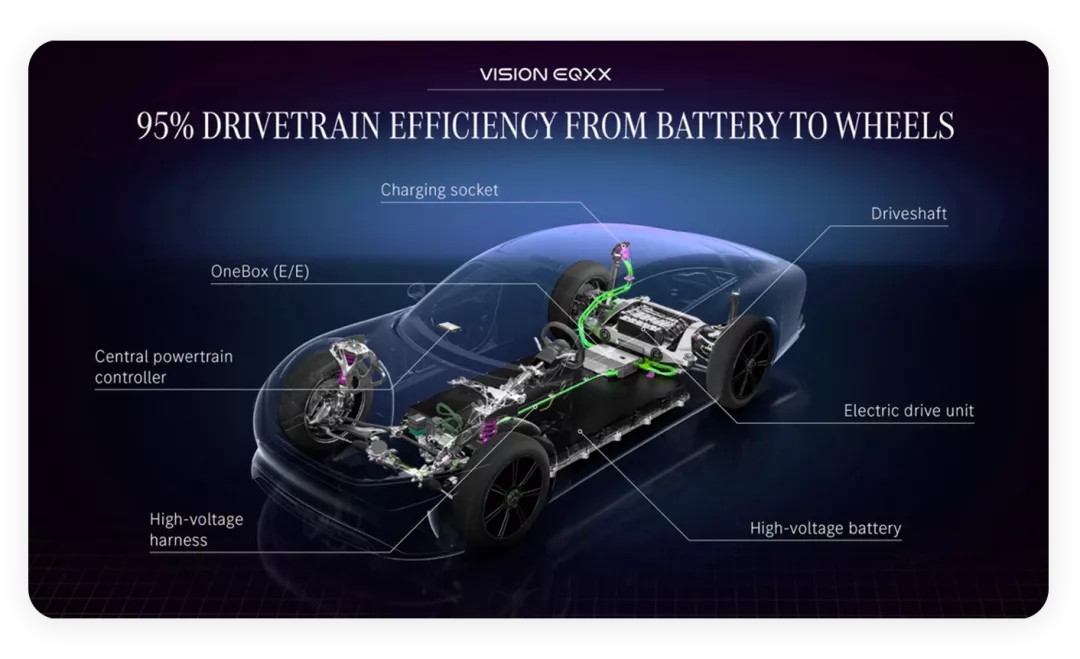

● From Figure 3 below:

This battery pack integrates DCDC and high-voltage fast charging relays. Next, Mercedes may also push for a no-OBC solution. Otherwise, it is not economical to have a separate OBC outside. From a weight and performance perspective, it is also appropriate to optimize it.

In this figure, there is no mention of OBC and AC charging, and the One Box (E/E) of the battery system is also relatively simple.

In order to improve the efficiency of the battery to wheel to 95%, Mercedes also adopted SiC technology, which seems to have become a standard configuration for the next generation of luxury cars and a key factor in reducing driving energy consumption. After upgrading to 800V, the power consumption of the motor can also be reduced, including losses in the thermal management layer.

EQXX Intelligentization

After Mercedes launched L3, I want to specifically review the progress in this area.

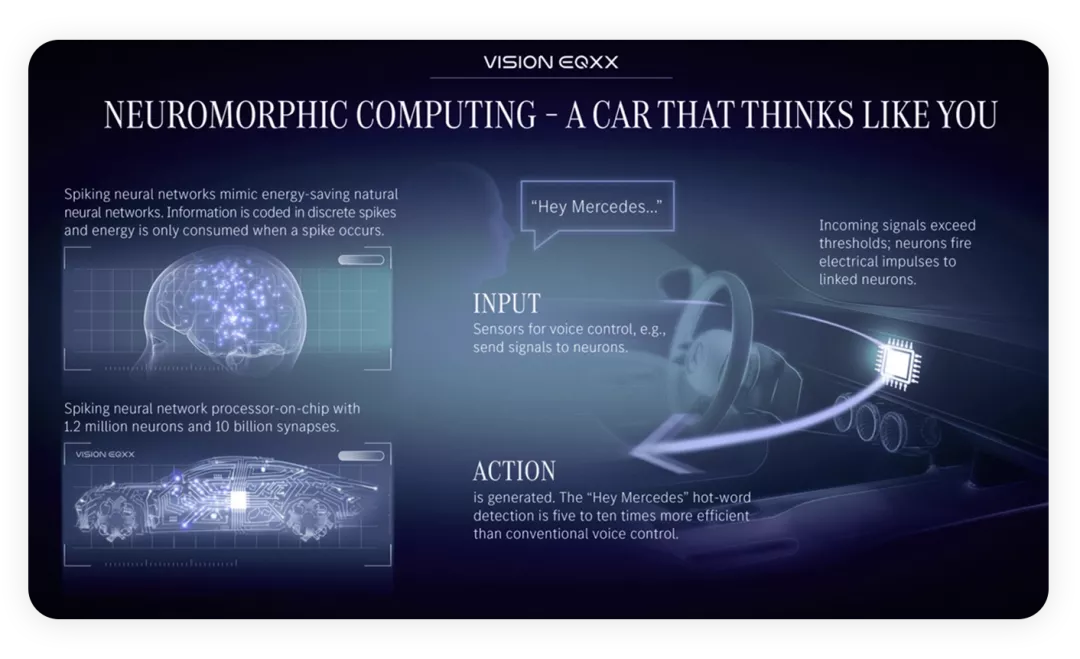

The interesting thing is that Mercedes-Benz is very determined to have a deep cooperation with NVIDIA in terms of cabins and autonomous driving. As for autonomous driving, the human-machine interface – especially the design of such a large screen, makes the entire design tend to homogeneity.

In conclusion, what I want to say is that now, China’s shell solution CTC and blade solution are in a systematic PK with the 4680. Currently, there is no particularly good solution presented in the design and development work of the next generation of German models. We may still focus on 4680 and high-pressure casting by observing the overall technical direction.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.