About Tesla’s 4680 production line

I want to summarize the information I found about Tesla’s 4680 production line, and focus on the overall production capacity planning for 4680.

Overall perspective

Tesla’s production capacity planning is discounted from the previously announced 100GWh by 2022. The actual production capacity is about half (50GWh under construction), and the effective output is further reduced by half to 25GWh (which is not bad). But the overall design concept of 4680 should still be on the right track.

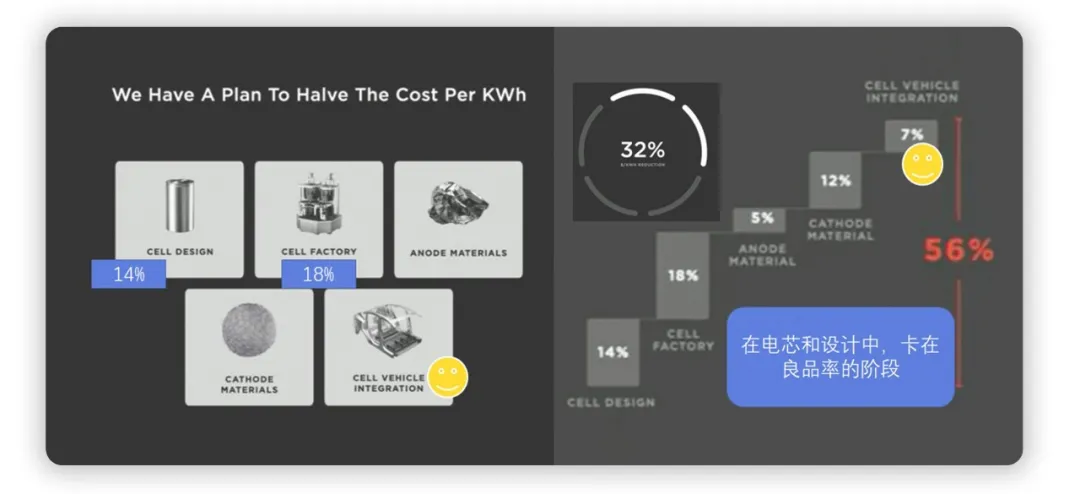

Cost reduction

At present, the yield of the 4680 battery cell is still stuck at around 80%, which makes it difficult to effectively switch to the 2170 cell. With the gradual improvement of the production process, it is expected that we will be able to see a batch of 4680 products go offline in 3-6 months, and there should be a lot of 4680 products going offline in 2022.

Long-term perspective

We should have more expectations for whole vehicle manufacturers entering the battery production field.

Tesla’s 4680 production capacity planning

According to the current situation, there are four factories in total to cooperate with Tesla to produce 4680 battery cells:

-

California, USA (also the development base of 4680 battery cell): this is the first production line established by Tesla’s research and development team, and a starting point for experimentation.

-

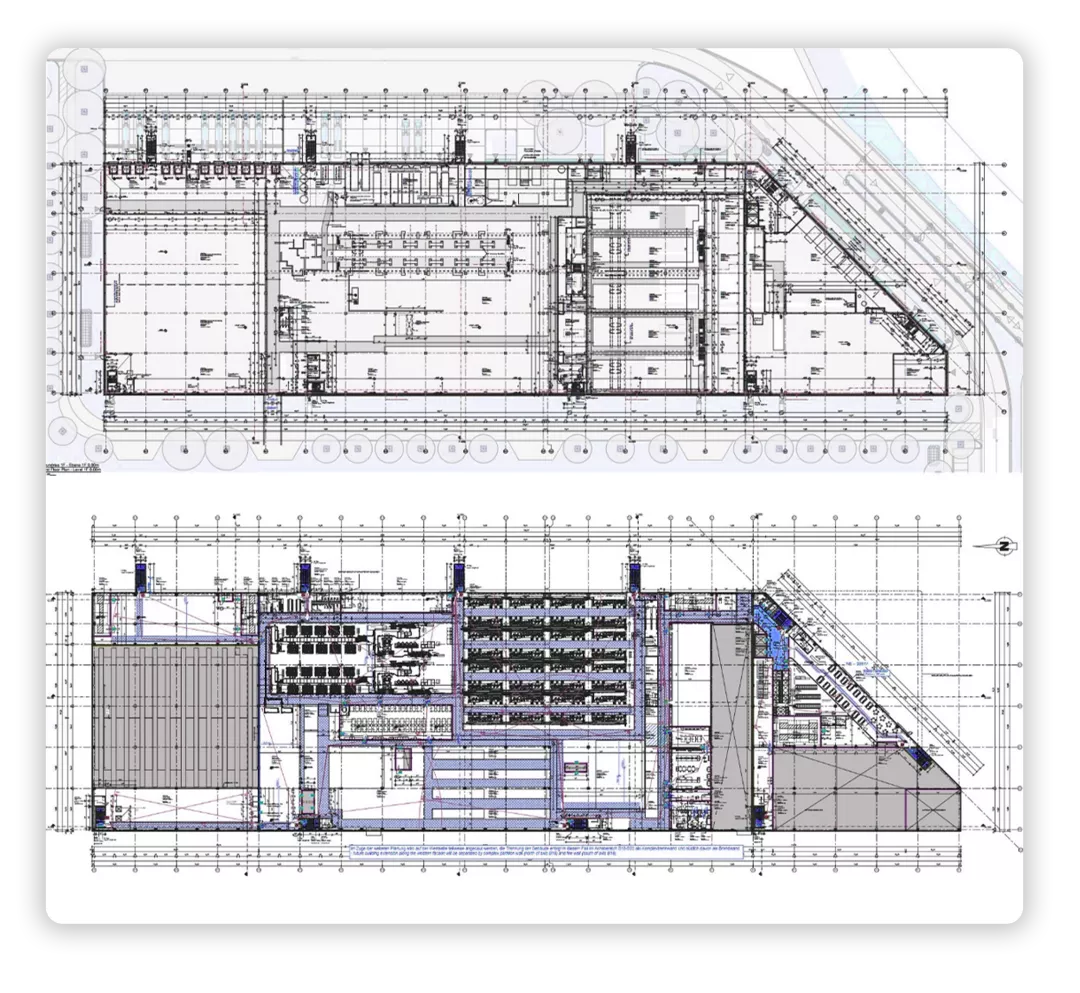

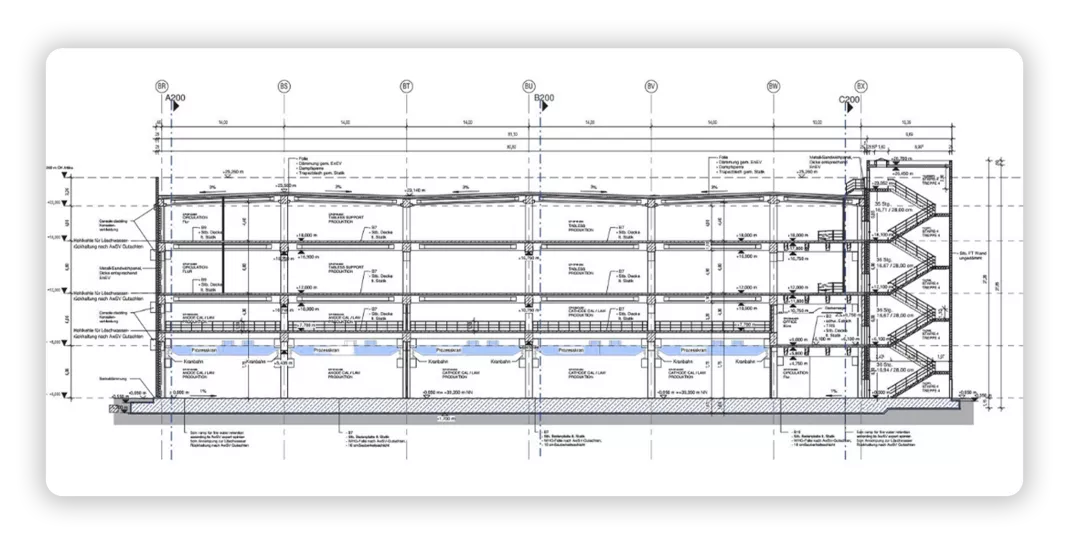

Berlin, Germany: this production line is from the first to the third floor, with a planned output of more than 20GWh, which will be put into production after Q2 2022.

-

Texas, USA: the equipment has started to enter the production line, and the planned production capacity is relatively high, which will match the production capacity of the Texas factory. It is expected to start trial production in Q2 2022.

-

To be determined (said to be built in Canada)

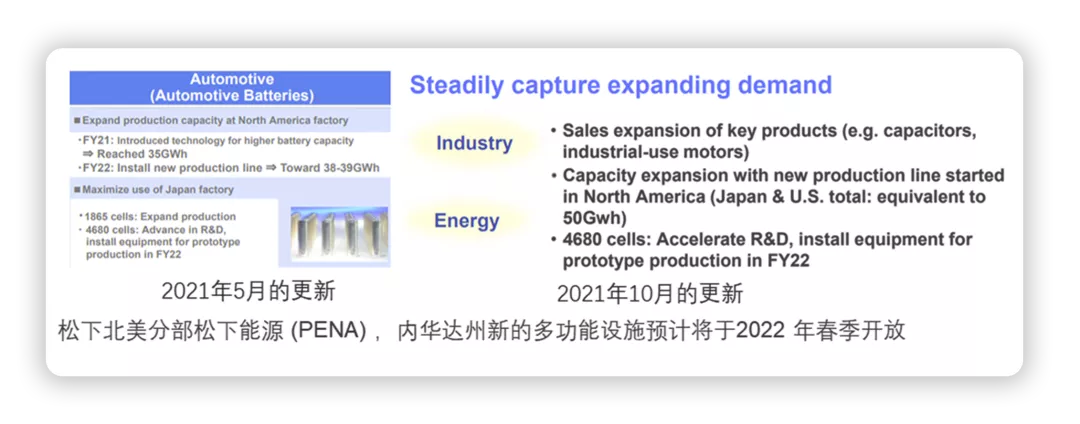

Therefore, according to the current assessment, Tesla’s core factories are built according to the plan, and the application of 4680 is mainly based on cooperation with overseas cylindrical battery cell manufacturers (Panasonic and LG) and self-owned production capacity.

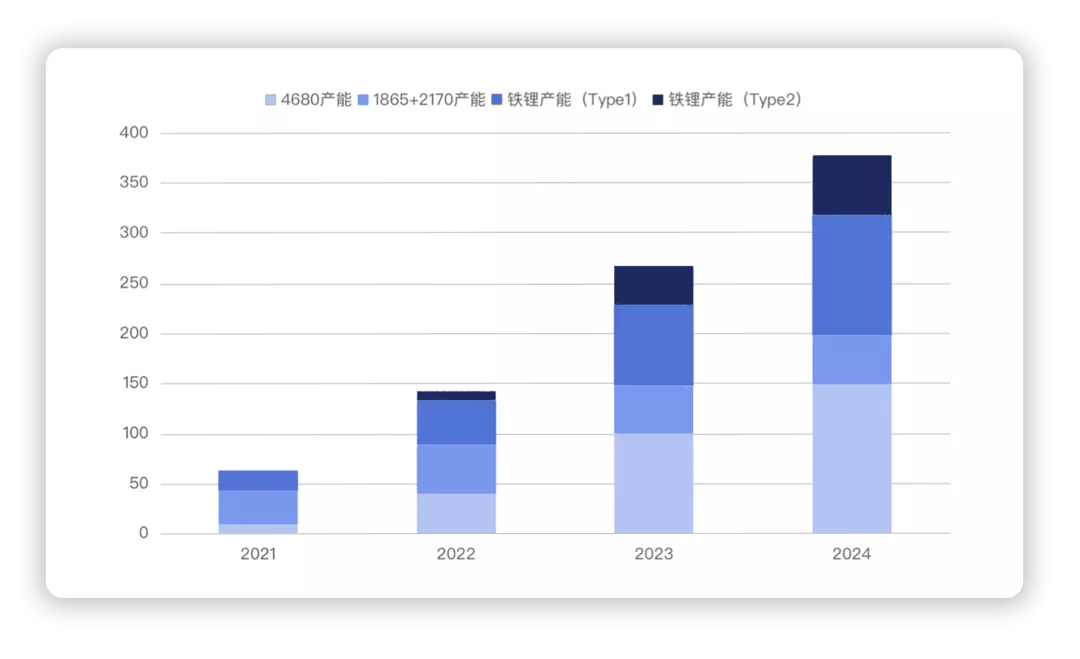

From the current information:

○2022:

External procurement, Panasonic provides new 4680 batteries for trial production of Model Y in the US, then imports LG’s 4680 batteries in Europe, and cooperates with its own tens of GWh capacity construction (the actual capacity is estimated to be only 10GWh+10GWh).

○2023-2024:

After a 20Gwh capacity step, the mid-term goal of producing 4680 batteries by oneself is 100-200Gwh.

Note: the 4680 batteries bring a large increase in the single-car battery capacity, estimated to reach 100kWh.

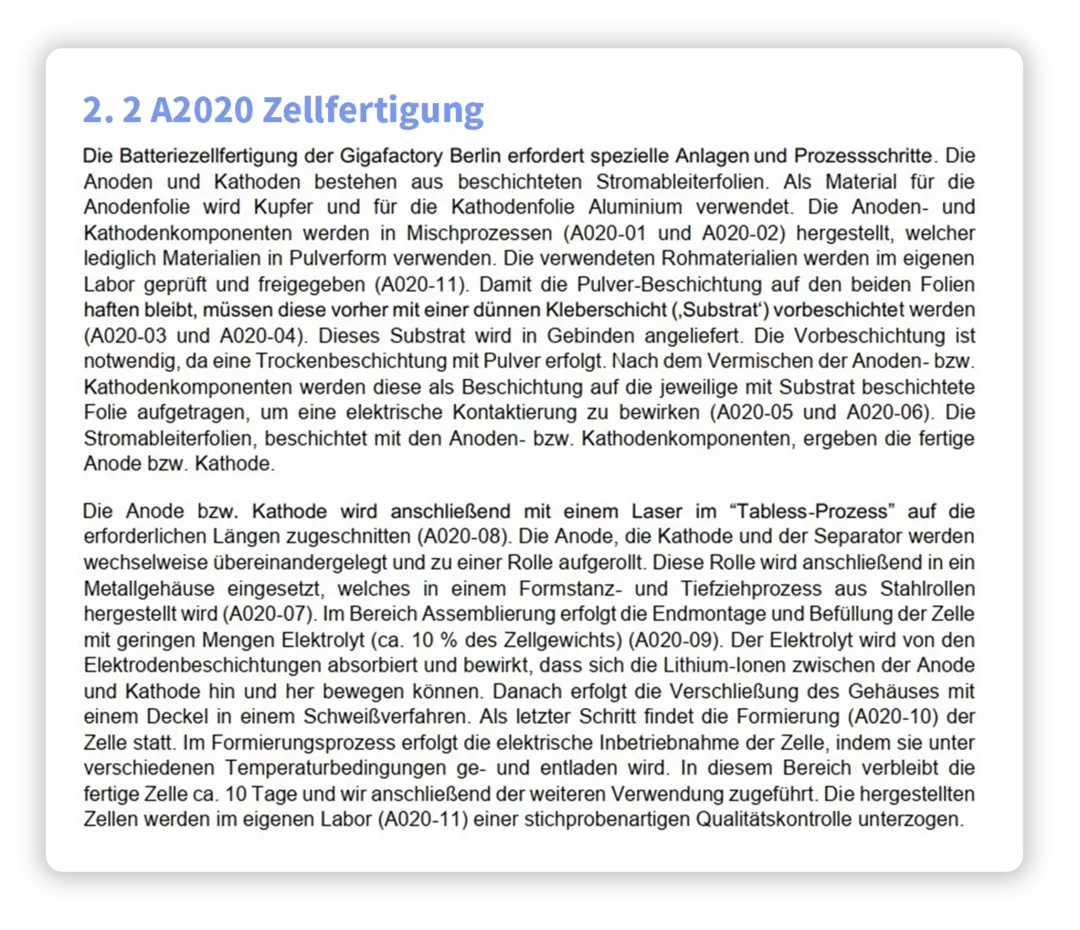

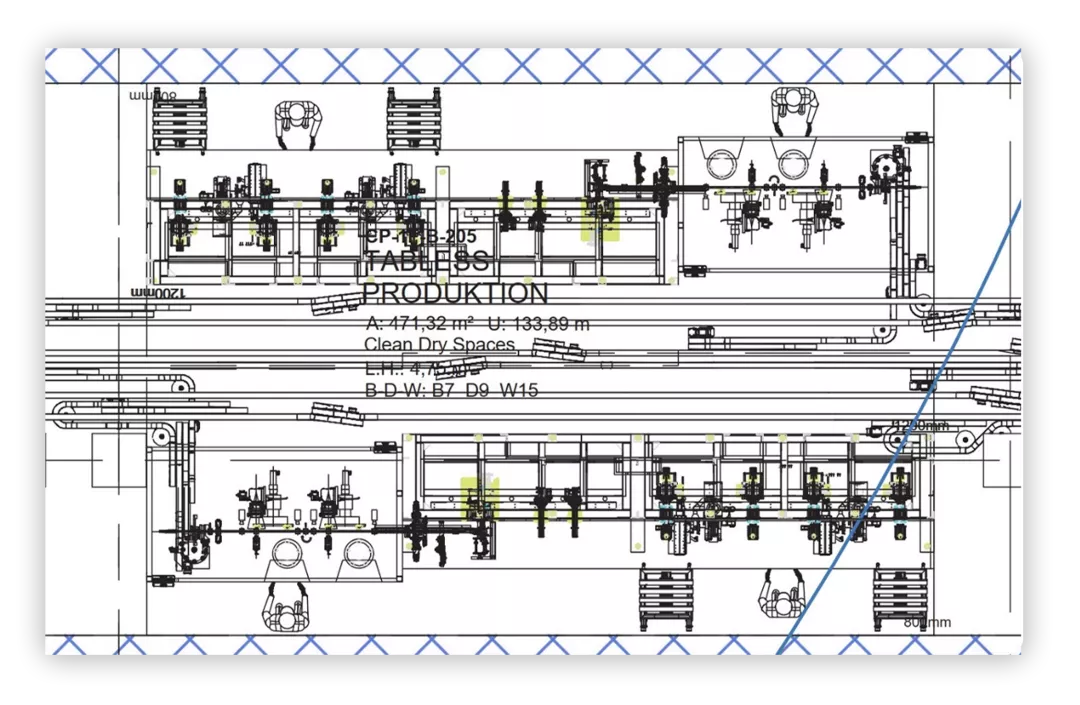

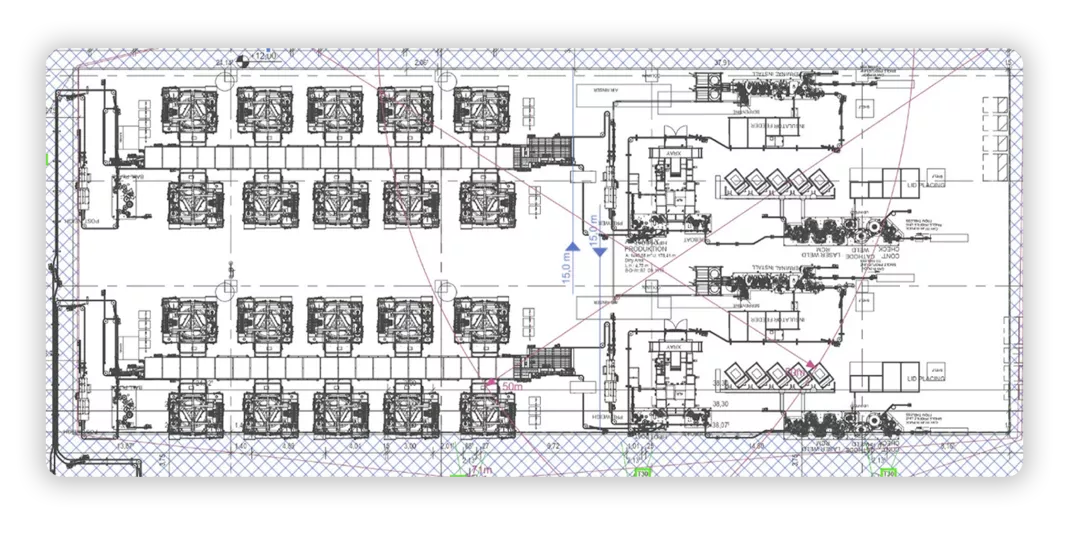

About Germany Factory Documents

I found some interesting pictures online, mainly about the part introduced in the German environmental assessment report.

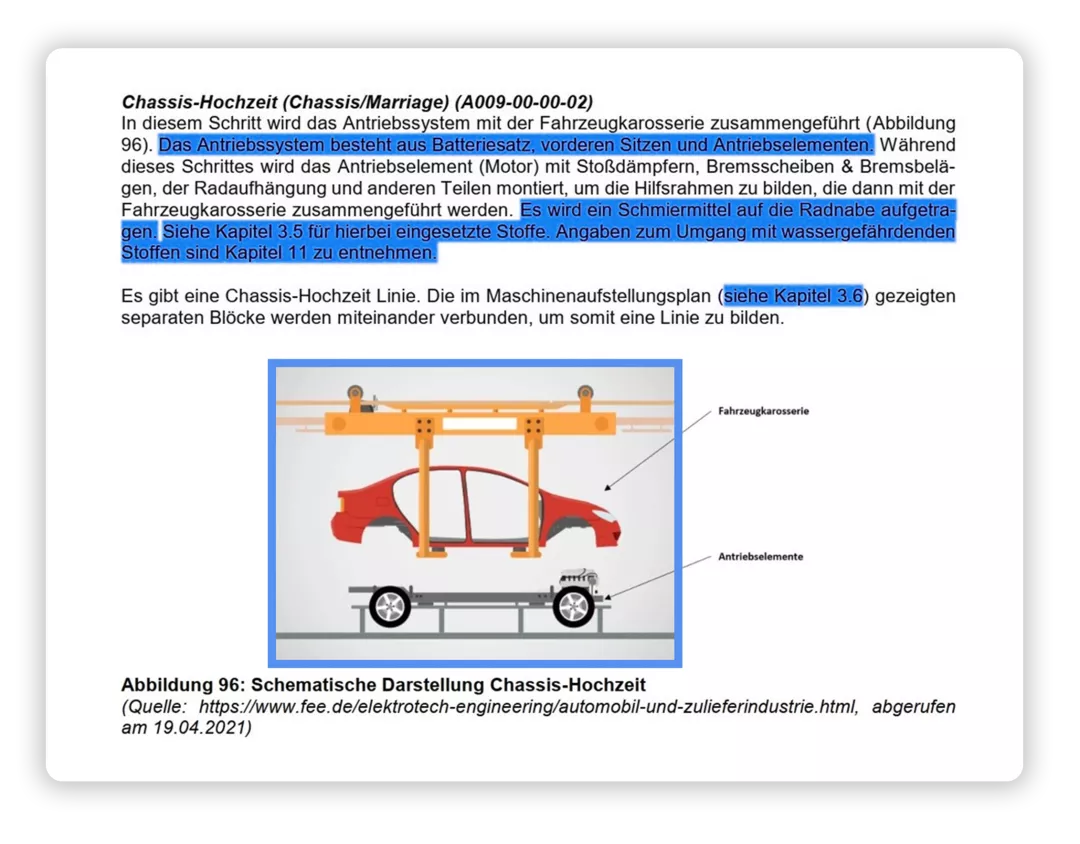

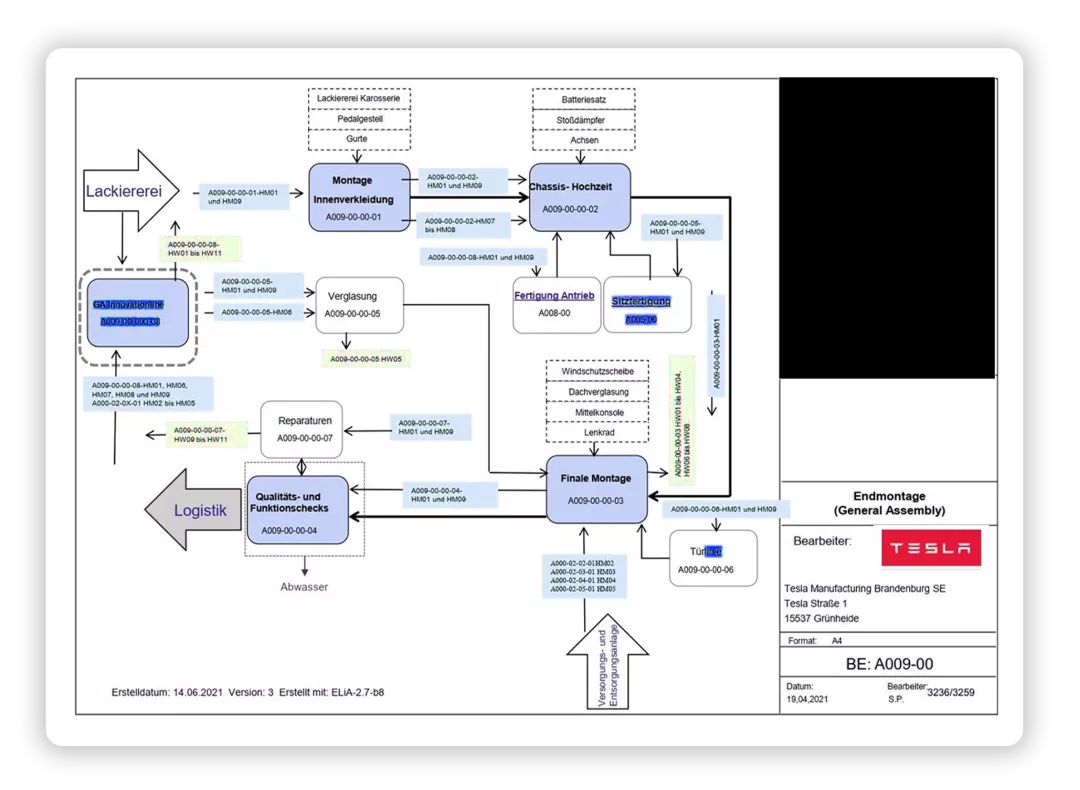

●CTC process

Tesla’s CTC assembly mode is still similar to before, that is, how to deal with the sealing of the battery without the upper cover-this is worth thinking about.

That is to say, the overall welding of batteries is still in a separate workshop.

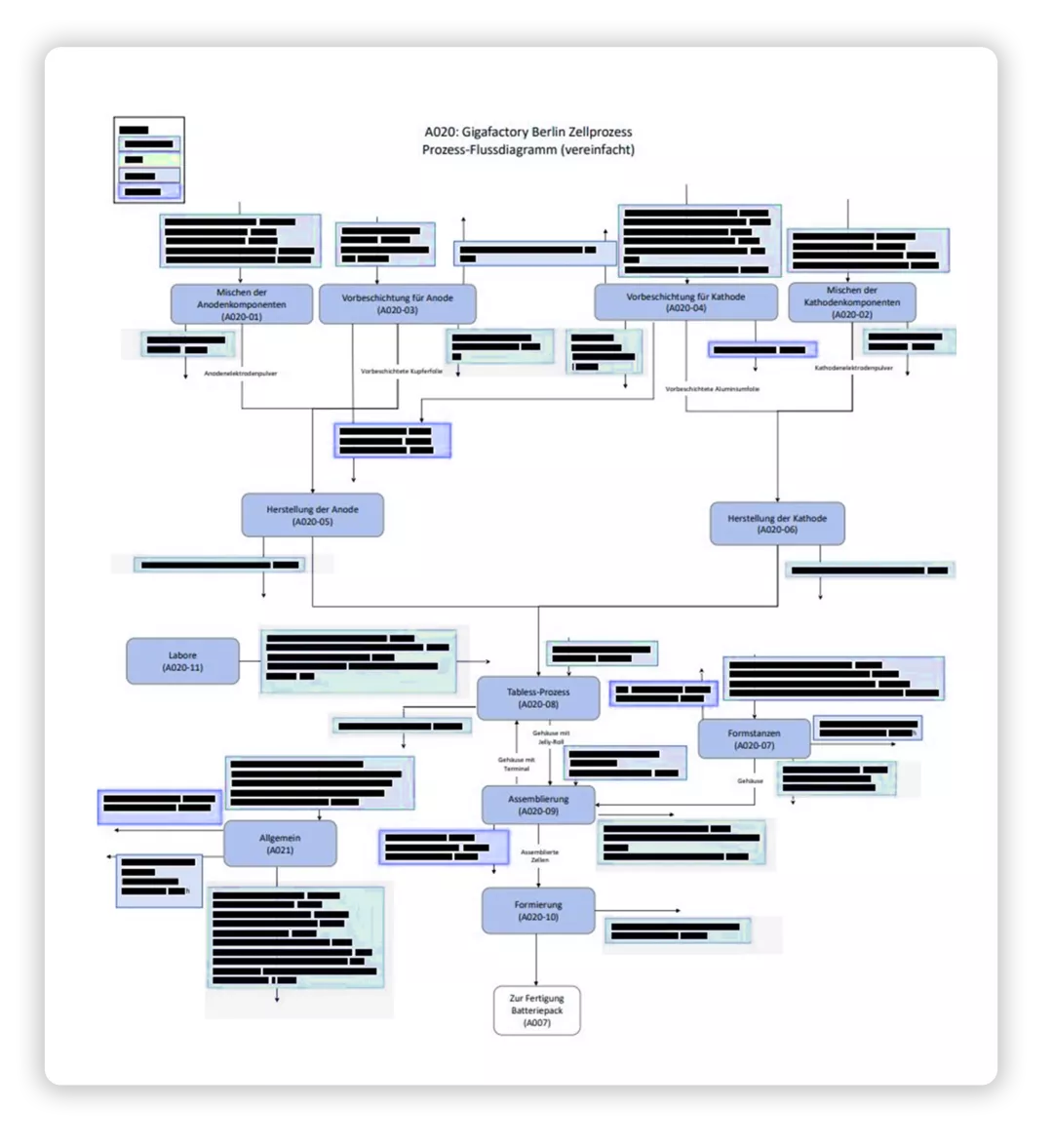

●Diagram of Battery Cell Process

In the document, there are some simple drawings of producing battery cells, but key parts are covered up, as shown in the figure below.

Summary: It seems that the entry of Tesla into battery production may have a significant impact on the future landscape, after many years of automobile companies calling for such entry. However, this process, from design to production, requires a certain level of expertise. It may not be fair to compare the production of chips and batteries, as there may not be as large a divide in terms of equipment and processes as imagined.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.