Hey everyone. I’m here to write another brake knowledge post.

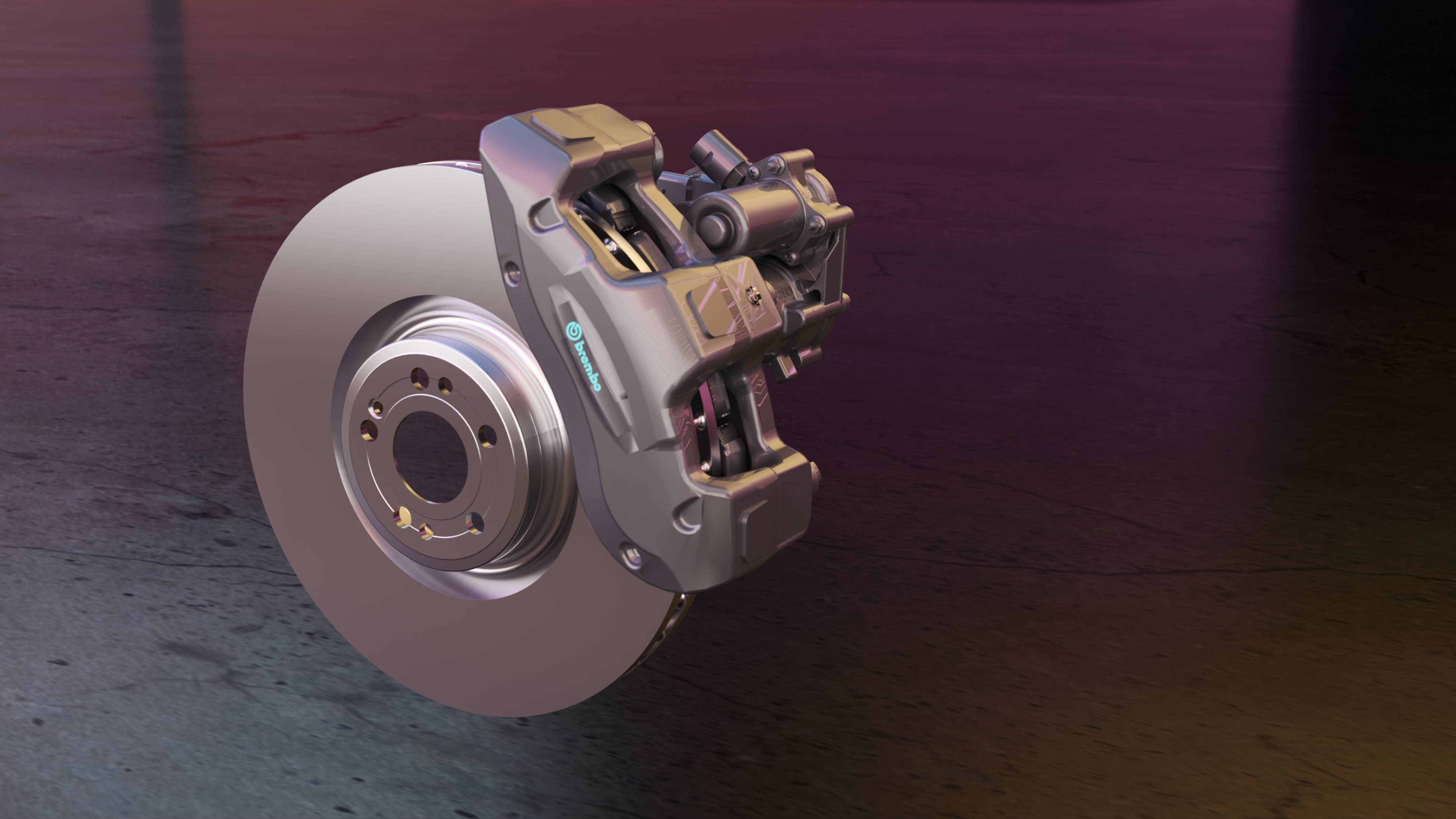

From the market leader Tesla to the domestic newcomers NIO and XPeng; from the foreign brands Polestar 2 and Mustang Mach-E, to the domestic brand BYD Tang, these cars all have one thing in common: Brembo brake calipers.

And I also found that these brake calipers have made many improvements in details to meet the requirements of low carbon and low emission. Interested students can read more: “After driving the Mach-E, I wrote a brake knowledge post”

OK, let’s get to the point.

Just last Saturday, December 18, 2021, precisely because of the above article, I had the privilege of receiving an invitation from Brembo for a test drive to experience their SENSIFY intelligent braking system at their headquarters in Nanjing.

Given that the following content may be quite intense, let me talk about the results first:

Too, too strong… this makes me full of expectations and confidence in the arrival of future wire-controlled brakes. I suggest that Brembo consider splitting SENSIFY for sale (so that I can invest)!

Next, I will give you some knowledge about what Brembo’s SENSIFY is, and whether it is more hype than practice.

Basics of Brake Assist Systems

Before introducing Brembo’s SENSIFY, we need to talk about the power-assisted braking methods currently available on the market.

Vacuum-Assisted Brakes

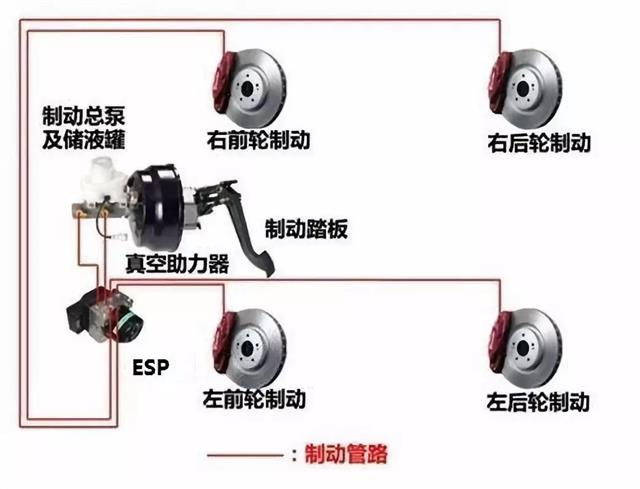

The above diagram shows the most basic power assist method currently available.

Yes, although brakes can still be used without assistance, in that case, you may not have enough strength to lock the brakes, only suitable for racing and some low-speed applications.

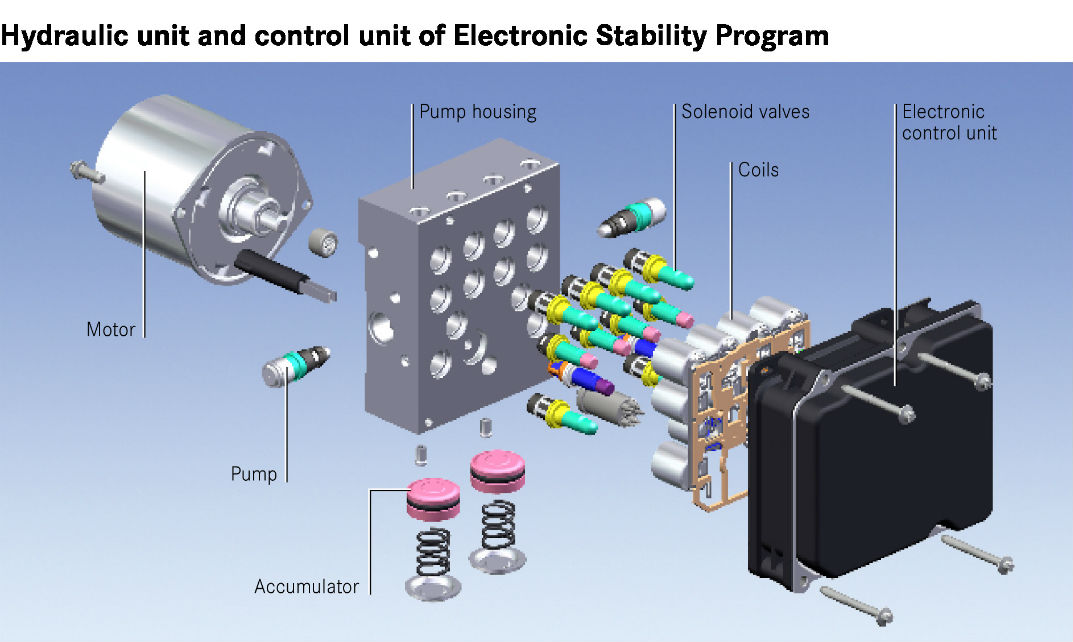

When you step on the brake pedal, this action will be linked through a lever structure, and with the help of a vacuum booster (requires a vacuum source, such as an internal combustion engine) to push the brake fluid in the master cylinder. This fluid will be allocated through the ESP pump and electrically controlled valves to the four brake calipers (through separate pumps), thereby applying braking force to the brake disc to generate friction, and bringing the vehicle to a stop.

So the question is, as more and more electric cars appear, it means that more and more vehicles do not have engines, which means that more and more vehicles cannot generate vacuum, which means that vacuum-assisted brakes cannot be used.

Electric Assist

In fact, similar to the transition from vacuum hydraulic power steering to electric power steering, brake assist in recent years is also following the same development trend._20211221164838.gif)

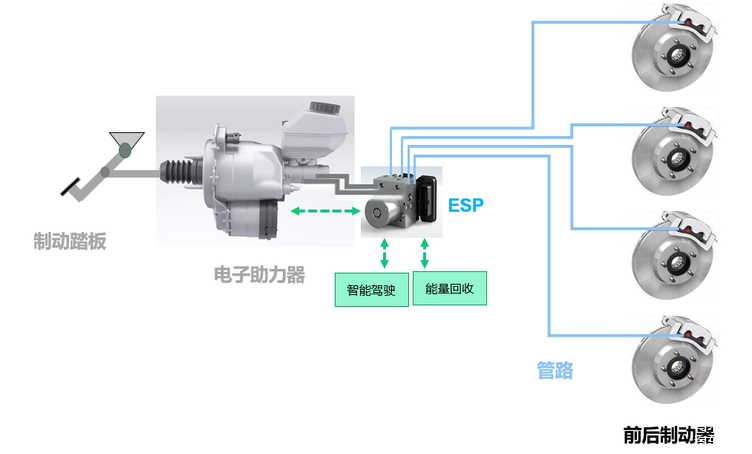

Due to the fact that it does not need a vacuum source and can be driven as long as it has electricity, and its power assistance can be easily changed through software, there are many benefits to electric boosting:

-

It is compatible with more car models;

-

It can build pressure faster;

-

It can change the pedal feel;

-

It can be more seamlessly integrated with kinetic energy recovery.

One-Box VS Two-Box

Ordinary electric brake boosters simply replace the vacuum booster with an electric booster. As the ESP pump is still separate, there are two modules in total, so it is commonly called the Two-box solution.

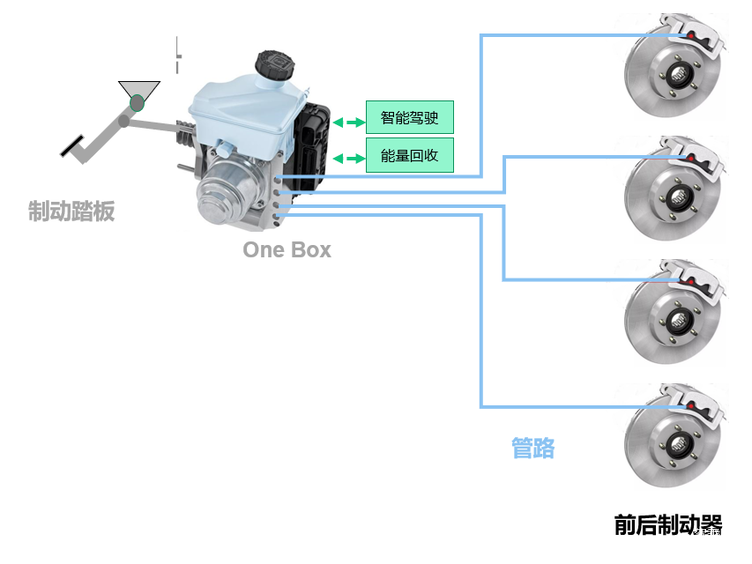

The most advanced brake booster solution currently available on mass-produced cars is the One-box solution, which integrates ESP.

It is worth noting that in the current One-box solution, there is no mechanical connection between the pedal and the hydraulic system. In the link between the generation of braking force and the input of the foot, line control has actually been achieved. This means that no matter how hard you step on the pedal, you are only providing positional information, and the pressure in the brake system is all established by the motor.

ESP pump, it’s good and bad.

However, with this approach, another problem arises: in order to meet the dual redundancy requirements of autonomous driving, an external ESP module is still needed to provide backup brake fluid pressure.ESP still operates within the traditional electro-hydraulic range, and there are bottlenecks in response speed and frequency when controlling the vehicle body under extreme conditions.

The originally simple system has added a redundancy, which seems to be a bit of a tail-wags-the-dog situation, but this is also a regulatory requirement at this stage. So, it’s really hard to say when the mechanical backup can be removed.

What makes SENSIFY different?

Very different.

Structure

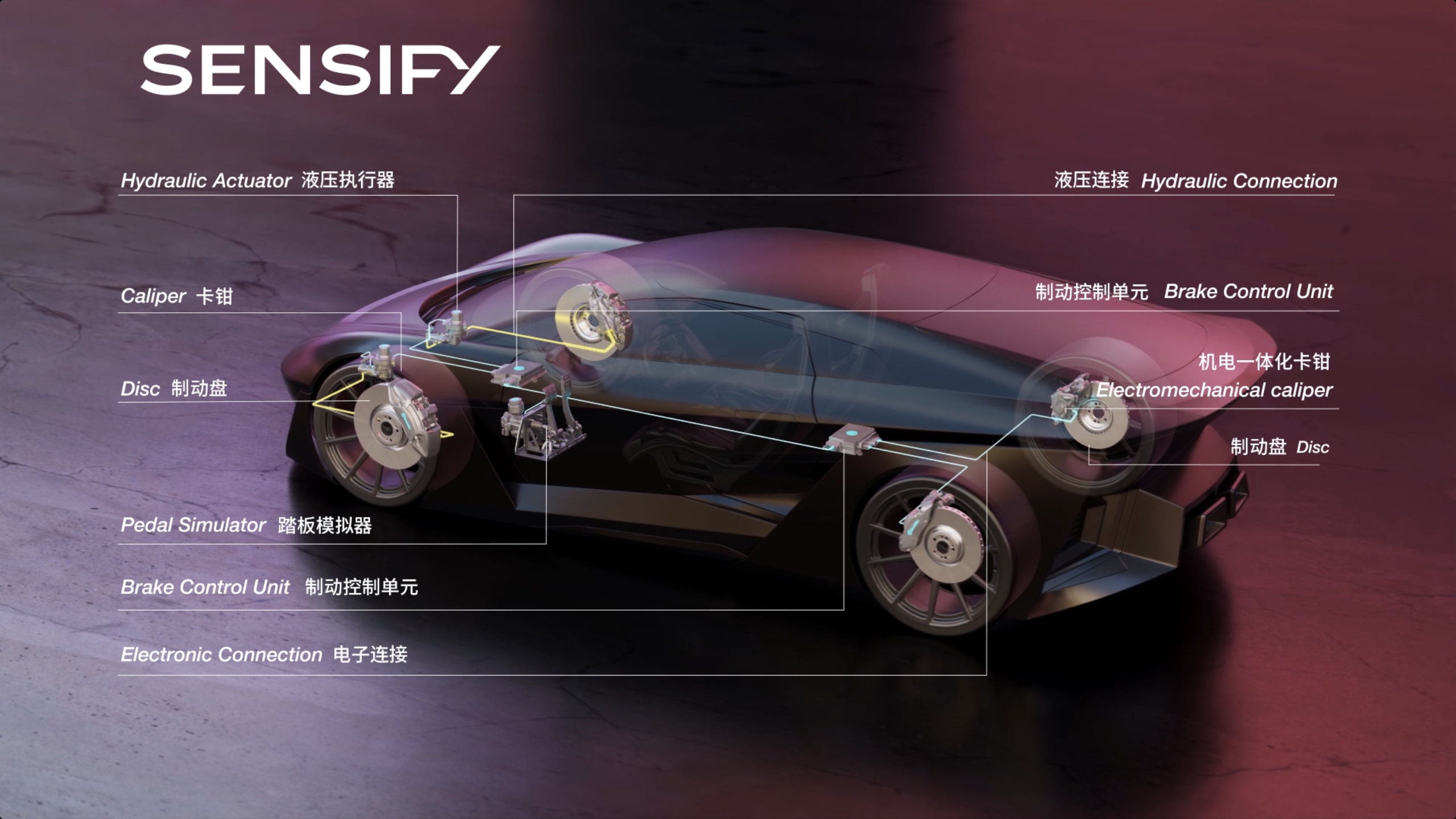

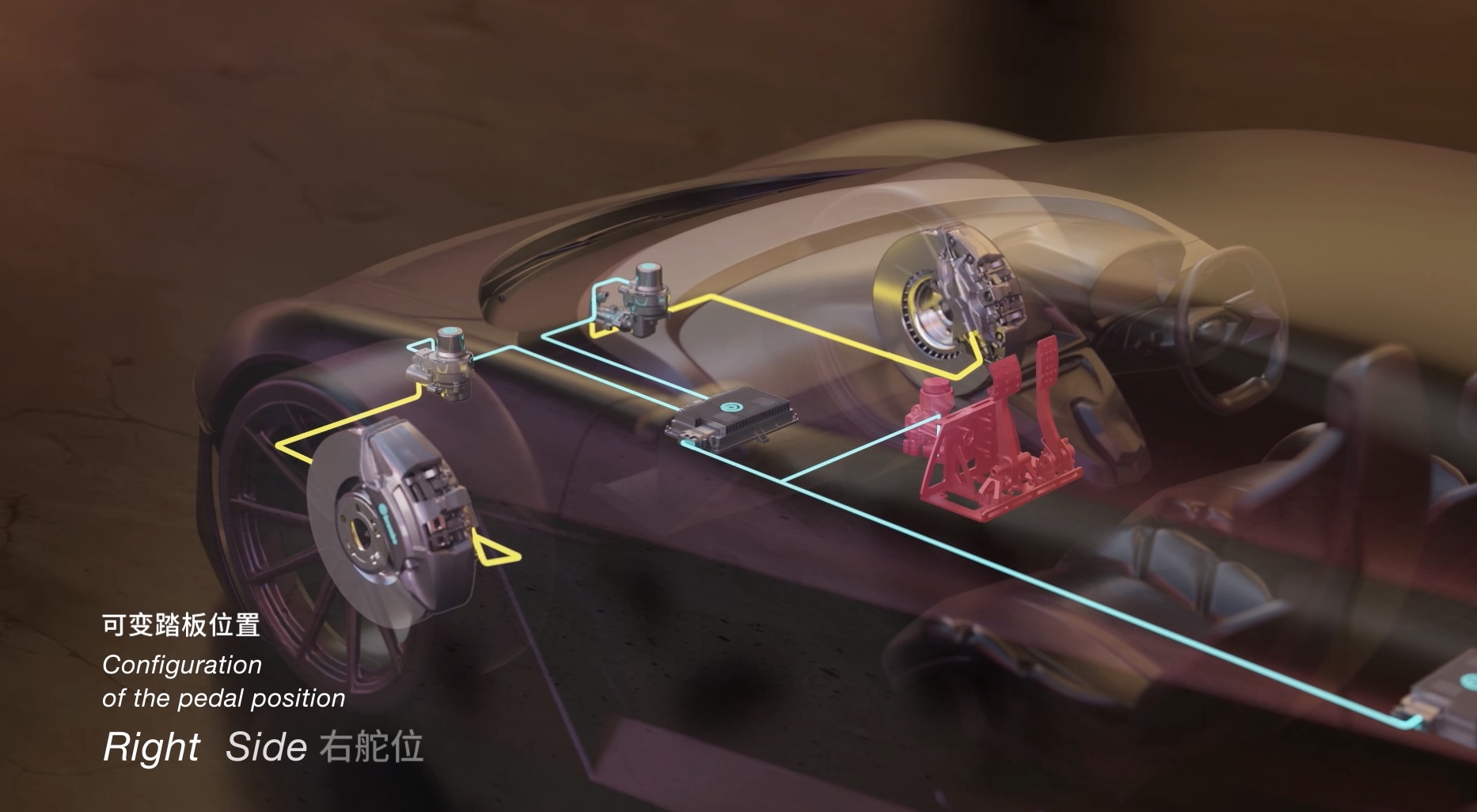

The name “Brembo” comes from the surnames of the two founders: Breda and Bombassei. Similarly, SENSIFY is a combination of the words “sense” and “simplify”. In addition to traditional brake calipers, brake discs, and oil circuits, this system consists mainly of:

-

Pedal simulator;

-

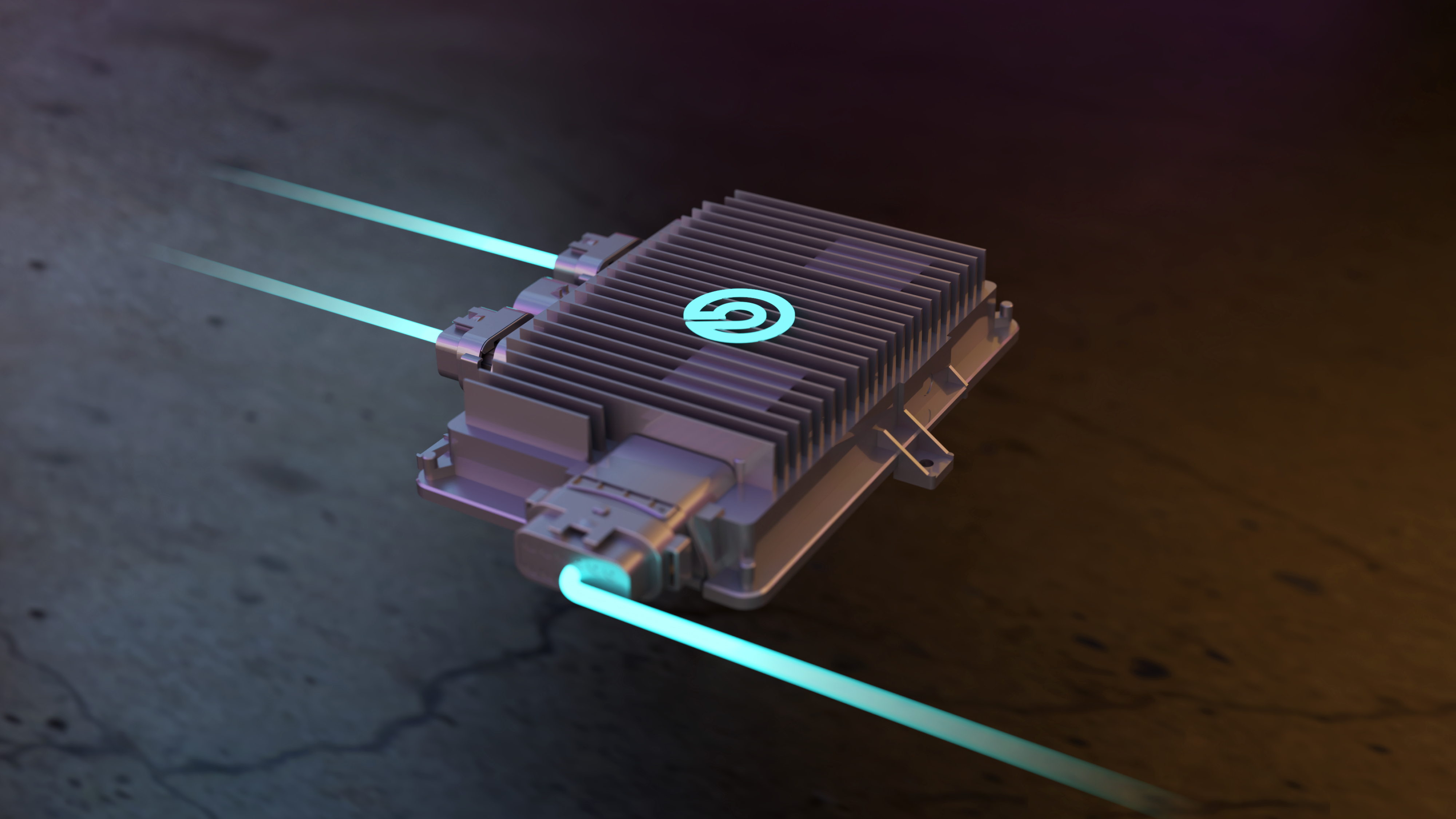

Brake control unit;

-

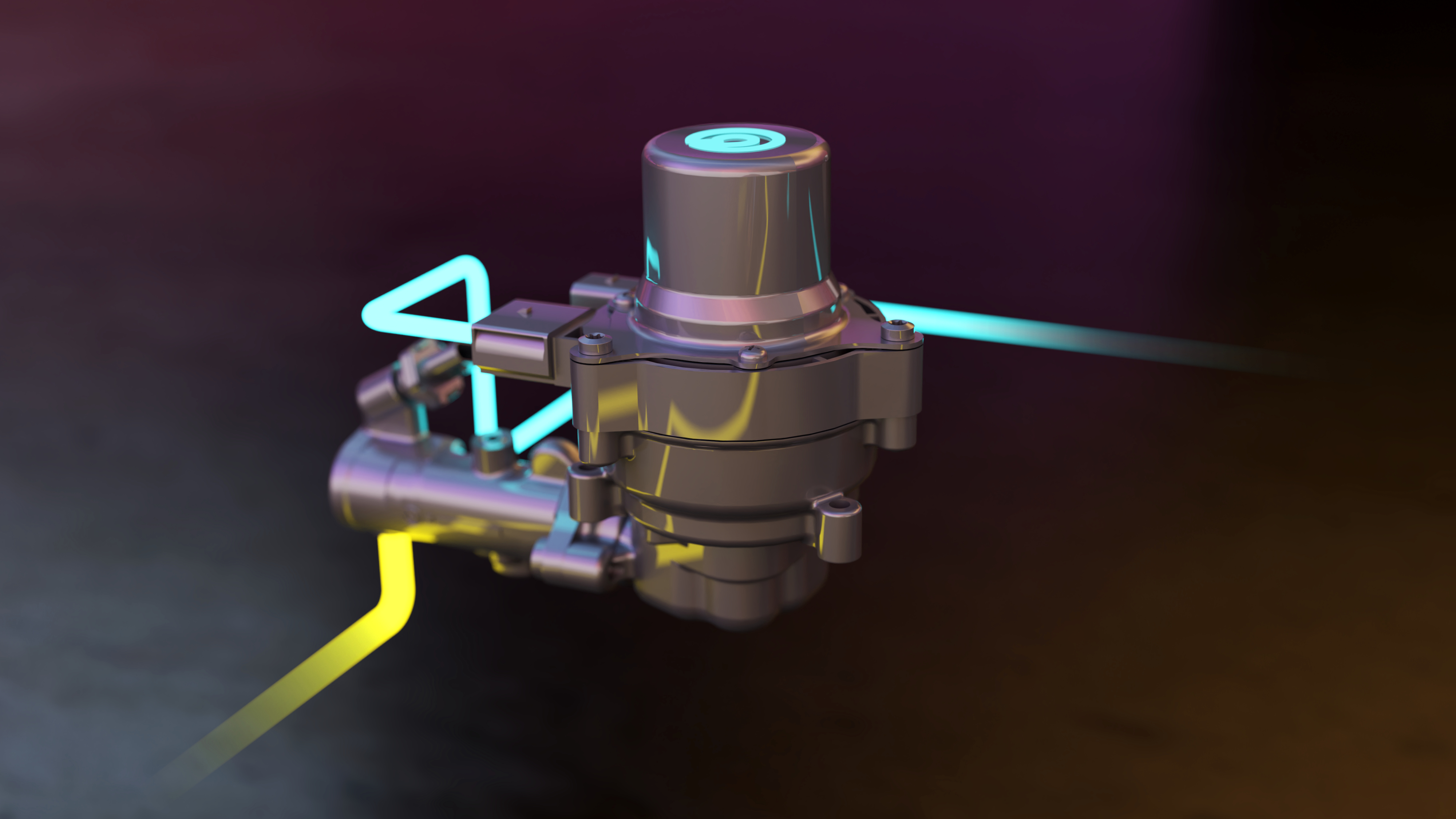

Hydraulic actuator;

-

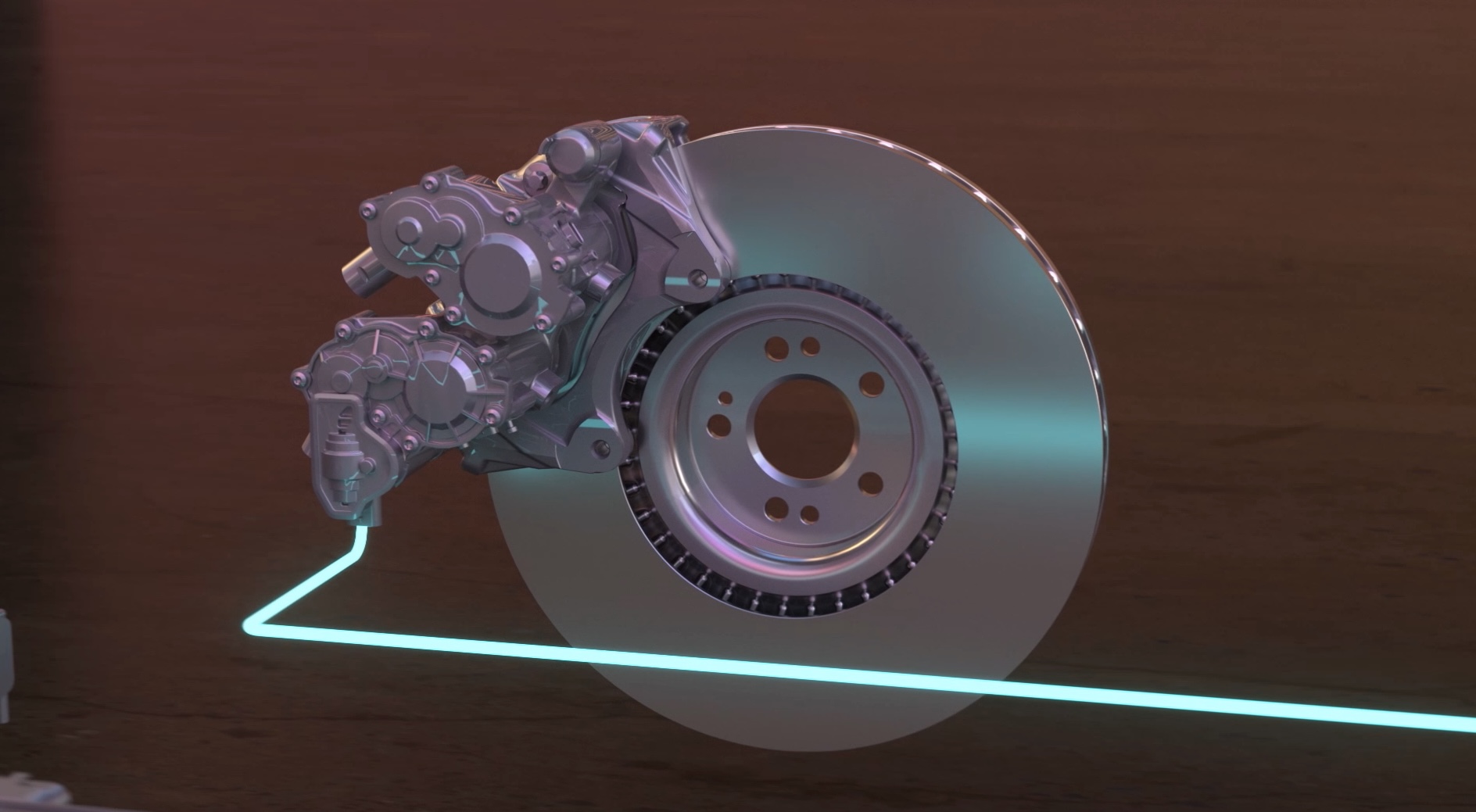

Mechatronic integrated caliper.

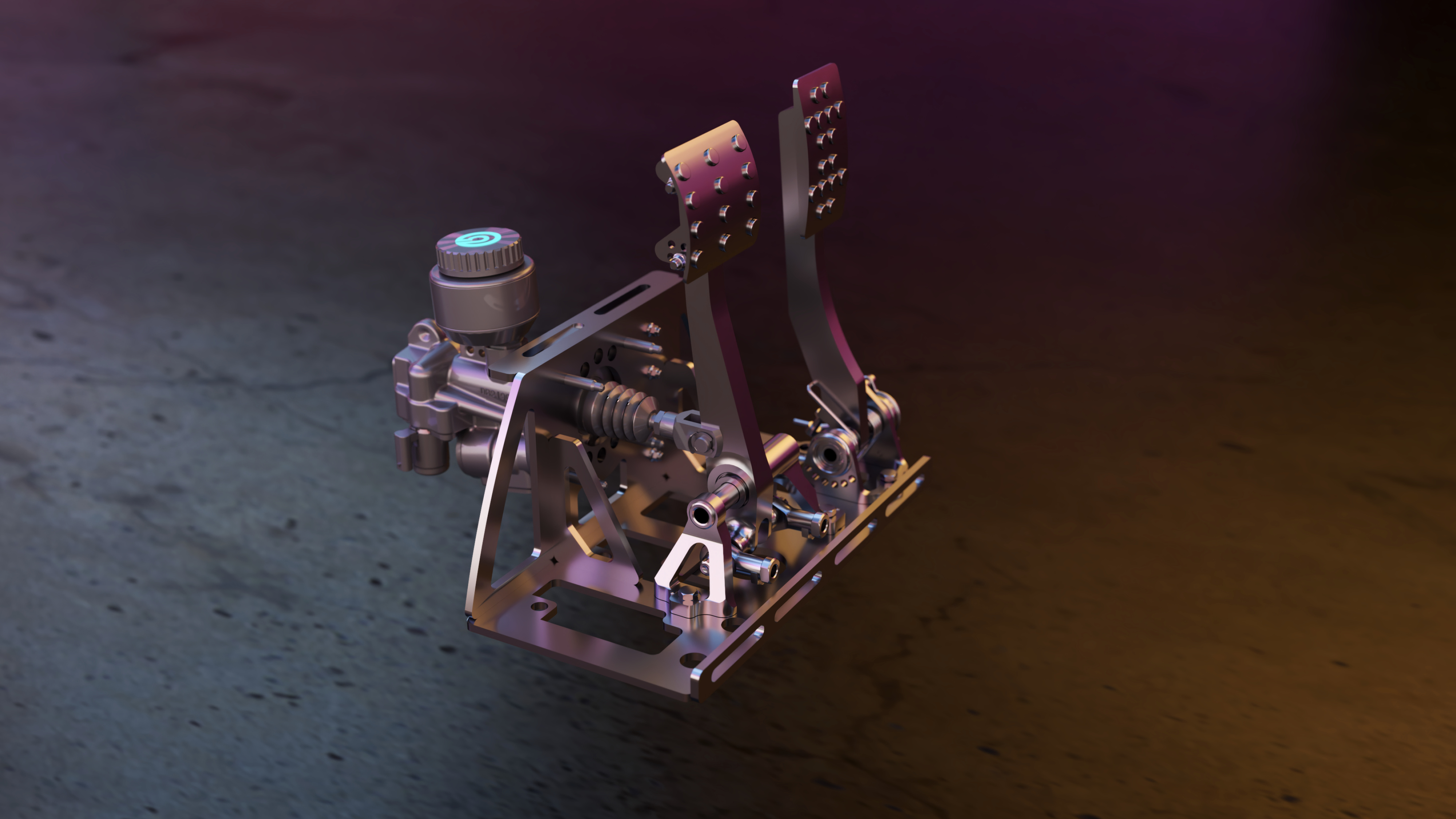

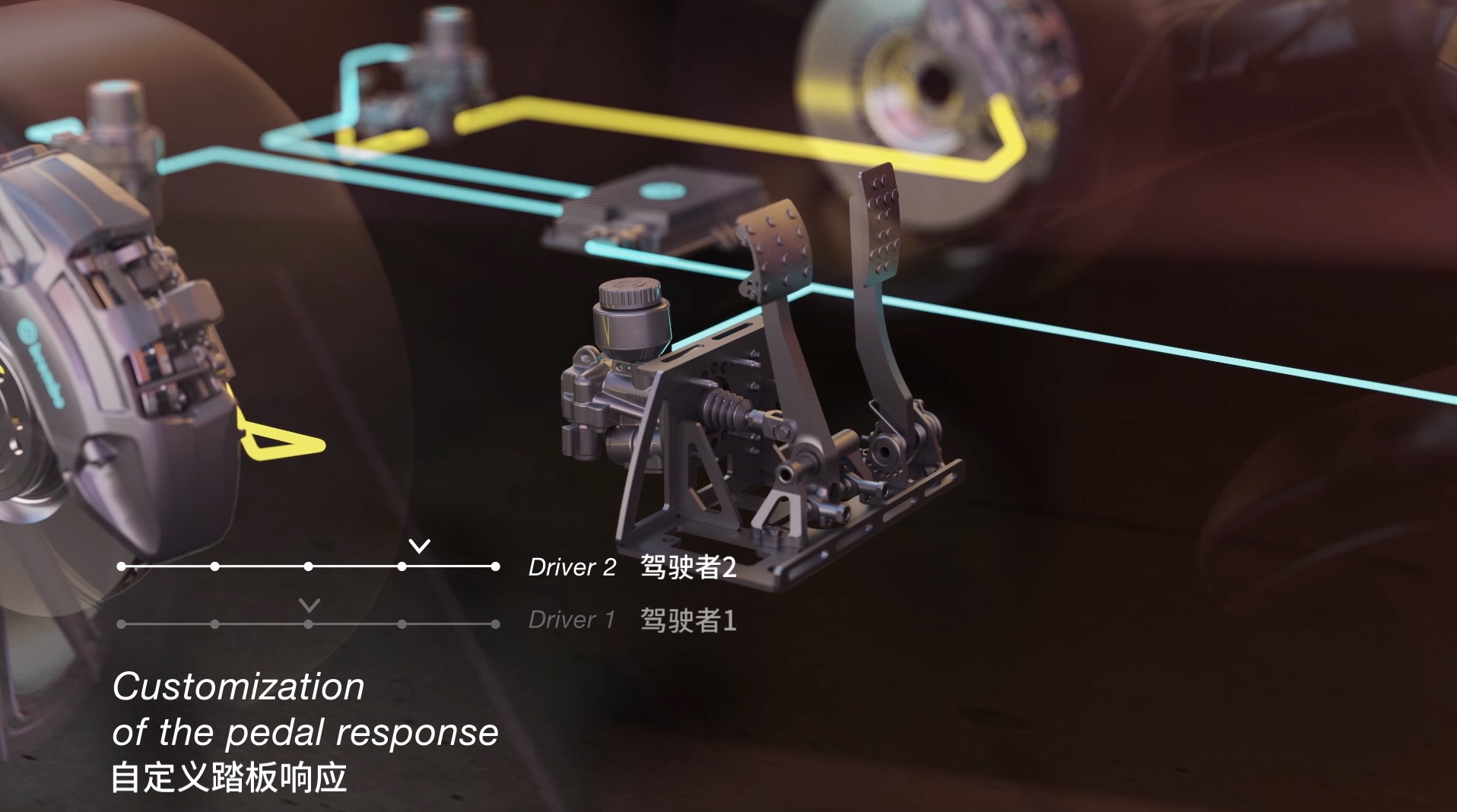

The reason why SENSIFY’s pedal is called a “pedal simulator” is that, like the One-box system on the market, it’s just a position sensor for the braking pedal.

In fact, it’s nothing more than a racing game pedal simulator with a better pedal feel, higher cost, better material, and stronger reliability.

The electric signal generated by this pedal is transmitted to the brake control unit (which can be understood as the brake domain controller) for processing and then issues commands to the corresponding wheel brakes.

If your vehicle is equipped with traditional hydraulic brake calipers, this signal will be transmitted to the hydraulic actuator to push the brake for braking.

If your vehicle is equipped with traditional hydraulic brake calipers, this signal will be transmitted to the hydraulic actuator to push the brake for braking.

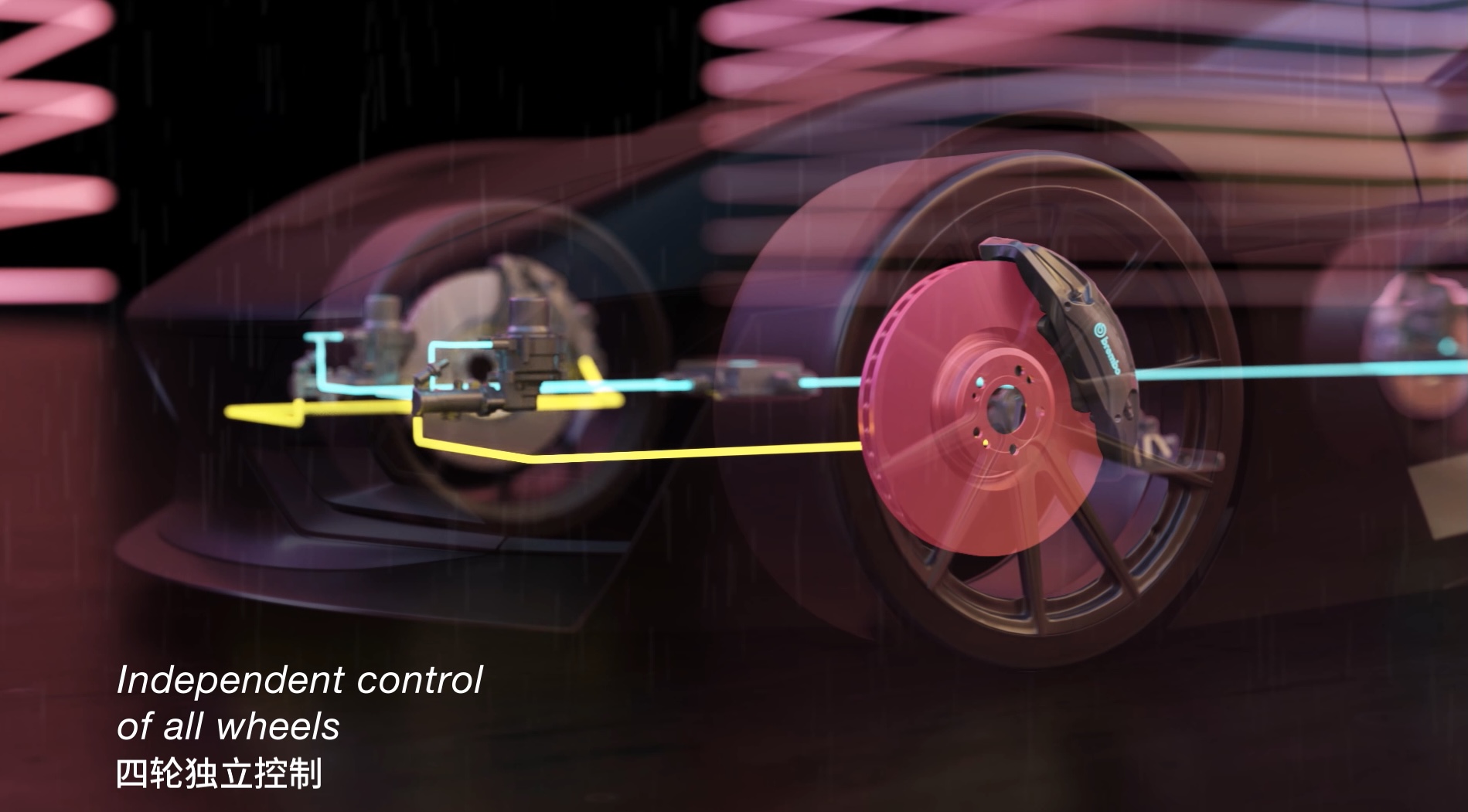

If your SENSIFY system is also equipped with electromechanical integrated calipers, the braking control unit will directly order the motor on the caliper to exert force to clamp the calipers without the need for brake fluid.

If you think that this system is the same as the One-box solution mentioned above, and it will be finished once the electronic system fails, then you are wrong. Because, from the oil tank on the pedal simulator in the above picture, it can be found that SENSIFY retains the oil path connection from the pedal to the downstream braking system. According to the on-site engineers from Brembo, this part of the oil path will only be opened when the main system fails.

Flexibility

In terms of the number of parts, SENSIFY doesn’t seem to conform to the Simplify represented by the second half of its name. However, it really improves the flexibility of car production and makes brake intelligence simpler.

Flexible Match

SENSIFY has flexible customized solutions for different models. If you need greater braking force or a more advanced caliper configuration, you can still choose traditional high-performance multi-piston fixed calipers and push them through the hydraulic actuator. But if it is for small vehicles, low-configuration models, or the rear brakes of electric vehicles where the braking force is not high, the task can be completely completed by using the electromechanical integrated calipers in the above picture.

For the complex regulations of racing applications, there can be such a system that cannot control four wheels independently and is more concise. If you are as careful as I am, you will find that there is only one brake controller in this system that drives two hydraulic actuators. And if four-wheel independent control is required, two brake controllers are used in the figure above.

So here’s a question I have:

Why can’t one controller independently control four wheels?

But Brembo is an Italian brand after all, capisci? Long live understanding!

Freely Positioned

As long as the future intelligent cockpit develops advanced enough, theoretically, you can drive with VR or a large screen in any posture in the car.

Freely Controlled

Like the One-box system, the fully decoupled brake pedal can not only maximize the range of energy recovery utilization but also simulate and adjust various styles of brake “foot feel” through software. In comfort mode, you can have a relaxed foot feel like a grocery shopping car, while in sport mode, you can have precise braking force control like a racing car.

Although it is possible to achieve this with traditional ESP modules, it is still faster to control them with four independent motors for each brake!

According to the information I obtained from the on-site Brembo engineer, SENSIFY can achieve a response time of 60 ms. Typical Two-box systems require 120-150 ms, and traditional vacuum hydraulic braking systems require 300-500 ms. If this is reflected in the braking distance calculated from the moment the foot is pressed down in high-speed driving, it can even make a difference of more than ten meters, which is equivalent to improving safety.

Real driving experience

A brake manufacturer’s brake product honed for 20 years can truly be felt from calibration.

The test drive was conducted by AB comparison. Among two vehicle models from the same manufacturer, one was equipped with the full SENSIFY braking system, while the other remained in its original factory state.

Smooth EBD

In addition to its ultra-fast response speed to braking operations, the ability of four-wheel independent control combined with the theoretically 5 ms dynamic braking force adjustment ability allows the test vehicle equipped with the SENSIFY system to exhibit better tracking performance during trail brake (braking while entering a turn).

Actually, before experiencing it, I had low expectations for SENSIFY because the handling of electric vehicles is already not bad, and the electronic systems they come equipped with are newer versions on the market. However, SENSIFY was able to give me a more expected driving line in turns, and the car’s heading direction during braking was more consistent with my expected direction.

Non-perceptible ABS

Although One-box systems, as decoupled braking systems, can already eliminate the annoying kick back when ABS is triggered, what impressed me about SENSIFY was its finer control at the wheel ends. Thanks to the independent electronic control structure, more high-frequency control logic brings a smoother experience with anti-lock braking.Generally speaking, when ABS is activated, the tire status oscillates back and forth between locking up and regaining traction. However, with SENSIFY, it feels like the tire is on the verge of locking up, resulting in less tire noise and more constant acceleration in the X direction. The result is a shorter and more comfortable braking distance. For those who miss the traditional ABS feel, you may be left behind. In the future, more and more car buyers may consider this phenomenon as a remnant of the non-intelligent era of automobiles. After all, stopping is the key.

Braking on Icy Surfaces

When braking in low-adhesion conditions such as on a plastic road surface covered in lubricant at the same speed, the SENSIFY-equipped vehicle demonstrates finer and more stable control of the braking, with no danger of the vehicle turning sideways during braking. As all four wheels are independently controlled, even if one or even two wheels fail during braking, the vehicle can be stopped in a straight line with precise and rapid braking force distribution. In fact, during one of the test drives to evaluate the feel of low-speed braking, the braking force became weaker, but since the vehicle did not deviate from the course, I did not pay much attention to it. Later, the engineer told me that he had actually turned off the braking function of two of the wheels at that time…

The Era of Low Emissions and Intelligent Braking is Coming

Set to be mass-produced in early 2024, I heard that some manufacturers have already signed up.

Deceleration is for better acceleration, and reducing excessive deceleration is also for better energy efficiency. Intelligent braking systems not only provide better braking performance, but also allow for the proper allocation and adjustment of braking force, enabling more work to be done by energy recovery to reduce energy waste and brake powder emissions, and ultimately reducing various types of emissions.

In addition, reducing or eliminating brake fluid not only reduces maintenance cycles, but also reduces environmental pollution and the use of chemical raw materials.

Brembo’s SENSIFY intelligent braking system not only fills me with imagination about the future of braking systems, but also gives me a different perspective on Brembo, the Italian company at the pinnacle of braking systems.In the not-too-distant future, braking will also enter an era where not only hardware but also software matters. The more decoupling achieved on the hardware side, the more software can accomplish and the higher the degree of freedom. By then, braking performance will be not only about who has more pistons, larger discs, and better design, but also about whose software development team has a strong capability, whose data interface is comprehensive, and even whose AI capability is stronger.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.