Author: Tuantuanyuan

The two-year-long pandemic has accelerated the integration and electrification and digitization transformation of the automotive industry. In this big change of the automotive industry, the actions of traditional car companies are crucial.

“Yue Jia Yan” is the media annual conference regularly held by BMW Group, where everyone reviews the past and looks forward to the future. I still remember seeing Mr. Gao Le, the President and CEO of BMW Group Greater China, wearing a Tang suit at Yue Jia Yan at the beginning of last year. Due to epidemic prevention and control reasons, this gathering has been changed to an online “cloud gathering,” where there is still plenty of content.

BMW: At Home in China

In the face of China’s rapid development in automotive intelligence and networking and the vast and highly potential Chinese market, BMW has long realized the importance of “deeply cultivating China.”

Currently, BMW Group has more than 25,000 employees in China and over 21,000 employees at the BMW Brilliance Shenyang production base.

BMW Group has built the largest R&D system outside Germany in China, with a team size of over 1,650 people, including about 600 software developers:

-

The earliest established Beijing R&D center is mainly responsible for vehicle engineering, testing, and certification and also has the only “User Experience Research Institute” outside Germany.

-

The Shanghai R&D center focuses on digital products, software development, and local digital ecosystem and innovation community connections.

-

Shanghai also has a BMW Group DesignWorks design team, which carefully observes the aesthetic and needs of the younger generation of customers.

-

The Shenyang R&D center focuses on local electric vehicle development and R&D work after mass production of domestic models.

In software development:

-

In 2019, BMW established the Leading Digital Company in Beijing, focusing on creating a seamless customer digital journey.

-

In 2021, BMW partnered with Nangjing Chengmai to establish a joint venture, leveraging local software talent to deeply cultivate in-vehicle software development.

In production and sales:

The BMW Brilliance Shenyang production base is the largest production base in the BMW Group’s global production network, with two vehicle factories in Dadong and Tiexi, a powertrain factory, and a development center, producing approximately 13,000 BMW models per week.

From January to October this year, the production of Huachen BMW reached 560,000 units, an increase of 17% compared to the same period last year. The output value reached 178.4 billion yuan, an increase of 18% compared to the same period last year. In 2022, BMW Group will welcome the opening of three new or upgraded factories in Shenyang and Zhangjiagang.

From January to October this year, the production of Huachen BMW reached 560,000 units, an increase of 17% compared to the same period last year. The output value reached 178.4 billion yuan, an increase of 18% compared to the same period last year. In 2022, BMW Group will welcome the opening of three new or upgraded factories in Shenyang and Zhangjiagang.

As of the end of 2020, Huachen BMW has reached 400 local suppliers nationwide, including 101 in Liaoning and 77 in Shenyang. The amount of domestic procurement is as high as 55 billion yuan, while nearly 60% is in Shenyang.

Furthermore, BMW Group is continuously expanding its dealership network in China and currently has over 600 dealership outlets. In the first three quarters of 2021, BMW Group delivered more than 1.93 million vehicles globally, of which about 670,000 were delivered to China.

This means that for every three BMW vehicles, one is delivered to a Chinese customer.

Advancing the “Three Directions” China Strategy

In the BMW Group’s China strategy upgrade, it will firmly transform along three directions: electrification, digitization, and sustainability.

Electrification

Although the Chinese market does not have the highest electrification rate in the world, China is absolutely the most concerned market in the global automotive industry, considering factors such as the improvement of Chinese market consumption capacity and the advancement of electrification development.

Unlike domestic brands, as a global automaker, it is difficult for BMW to create exclusive models for a single market due to the diversity of its consumer groups and the multiple markets where it operates. However, if BMW has released a “China First” strategy, it means that while maintaining strategic coordination globally, it must have sufficient independence when facing the Chinese market, especially in the product concept phase, where it should fully consider the needs of the Chinese market and consumers.

BMW will accelerate its electric journey with the BMW i family.

In 2017, Huachen BMW established the first power battery center for luxury car brands in China, and completed its phase two project in 2020, with a total production of over 100,000 power batteries to date.# BMW iX3 Pure Electric SAV is manufactured and sold globally by BMW Brilliance Automotive at its Shenyang production base. In the first 11 months of this year, 17,000 BMW iX3s were sold in the Chinese market, with an expected sales volume of 20,000 units for the first full year of sales.

In 2022, the BMW Group will present five pure electric models to Chinese customers, including the innovative BMW iX that was just launched this year and the innovative BMW i4, which will be officially launched next year. Additionally, the pure electric BMW 3 Series will be produced in Shenyang.

Recently, the BMW i7 prototype was tested in winter at the BMW Group’s winter test center in Arehlplog, Sweden. As a new model, the BMW i7 perfectly combines the luxury, comfort, and pure electric drive system of BMW’s luxury flagship sedan.

According to the BMW Group’s plan, by the end of 2023, the BMW Group will offer 13 pure electric products in the Chinese market.

At the same time, BMW is continuing to strengthen its cooperation with domestic battery companies, energy companies, and high-tech companies to enhance its overall strength in electric vehicle research and development, production, and service. By the end of 2021, the BMW’s networked public charging piles will reach 360,000, including approximately 150,000 DC fast charging piles.

Digitalization

BMW Group’s digital innovation in China covers all related fields, including research and development, production, vehicle intelligence, and digital services.

In mid-2021, the BMW Group announced that it would upgrade the iDrive 7.0 infotainment system to the latest version for more than 1.3 million BMW cars globally via OTA. Among them, more than 360,000 cars in the Chinese market were involved in this OTA upgrade, which included new additions and optimizations for Tencent’s localized in-car light application ecosystem “Tencent Xiaochangjing” and some autonomous driving assistance features. This also demonstrated BMW Group’s efforts to cater for the independent development of the Chinese market in the digital era.

Based on the new electronic and electrical architecture, starting with the innovative BMW iX and the innovative BMW i4, BMW Operating System 8.0 will be officially launched.

In addition to digitalization of automobiles, BMW’s sales and service are gradually undergoing digital transformation.

The MY BMW App, developed jointly by Lingyue and BMW’s R&D department, already has 3.4 million users, including more than 1.4 million monthly active users. With Lingyue’s support, BMW is promoting the “BMW Network Innovation Project” to about 600 dealers nationwide, optimizing customers’ brand experience through software and hardware upgrades and digital transformation.

Sustainable

In addition to electrification and digitalization, BMW’s higher goal is sustainable development, creating sustainable modes of transportation through sustainable production methods. Simply put, products must be environmentally friendly and factories must be sustainable.

BMW is the first German carmaker to join the Paris Agreement’s target of limiting global warming to 1.5°C, with a goal of reducing average carbon emissions by 40% over the entire life cycle of each vehicle by 2030 compared with 2019 and reducing carbon emissions by 200 million tons.

BMW Group sees electrification as one of the biggest drivers for climate neutrality on the road, but the company’s sustainable strategy goes far beyond electric vehicles. Environmental friendliness should not only be reflected in products, but factories themselves are also a huge “product”. Since 2020, all the electricity used in BMW Group’s factories all over the world comes from renewable energy sources.

In fact, BMW Group focuses on carbon reduction across the entire life cycle of automobiles. In addition to the supply chain, production, and usage, recycling is also in BMW Group’s sustainable planning.

At the Munich Motor Show, BMW Group unveiled the BMW i cycle concept car, which uses 100% recycled materials and is 100% recyclable, representing its latest “circular design” concept.

Taking the innovative BMW iX, which is already in mass production, as an example, BMW uses hydraulic power in production, no longer uses rare earth materials in development and production, and the amount of recycled nickel in its high-voltage power battery has reached 50%, with the recycled aluminum content in the shell reaching 30%.## BMW in 2025

2025 will be an important turning point for BMW’s strategic transformation.

By then, the BMW Group will release “Next Generation” models, featuring a completely redesigned IT and software architecture, a new generation of high-performance electric drive systems and batteries, and a brand new sustainable concept that spans the entire vehicle lifecycle. During the development of “Next Generation”, the specific needs of the Chinese market will remain a top priority.

By 2025, the BMW Group plans to deliver about 2 million pure electric vehicles, with one-fourth of BMW’s sales in the Chinese market being pure electric vehicles. The BMW Group expects that by 2030, at least one out of every two cars sold will be a pure electric vehicle.

If you ask me, “Can BMW do it?”

My answer is: Yes.

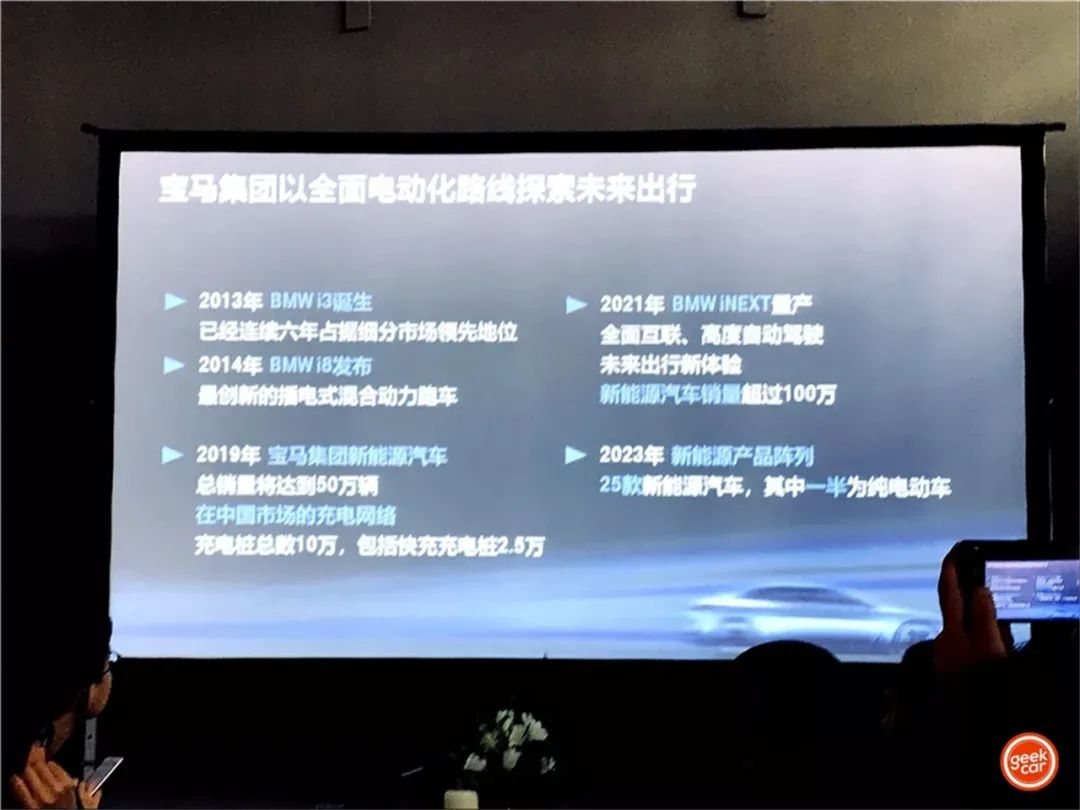

As for why, I participated in a small-scale technology sharing event with the BMW Group in 2019, during which several noteworthy goals were set:

- In 2021, BMW plans to achieve mass production of the BMW iNEXT;

- In 2021, sales of new energy vehicles will reach 1 million units;

- By 2023, the company will improve its new energy product lineup, offering 25 new energy vehicles, half of which will be pure electric models.

The mass-produced version of the BMW iNEXT is the innovative BMW iX, which was launched just recently. On December 6, BMW delivered a brand new BMW iX in Munich, which was the global 1 millionth new energy vehicle produced by the BMW Group.

In 2023, the BMW Group plans to offer 13 pure electric models in the Chinese market, including five models such as BMW iX, BMW iX3, BMW i4, BMW 3 Series pure electric version, and BMW i7, which are already available or have been introduced. This means that BMW is already halfway through its plan with two more years to go. There is plenty of time for BMW.

As we approach the end of 2021, looking back at the goals set in 2019, it is not difficult to see that BMW is making steady progress step by step.

In conclusion,How do traditional automotive giants deal with industry changes? I think BMW has already given its answer: Chinafication.

China used to be considered the most important sales market for global brands, but now its position is gradually shifting from selling cars for profit at the bottom level to production and R&D at the top level, which is a very important transformation. And BMW is undoubtedly the global brand that first understood the potential of China and took the lead in its globalization layout.

Through this different “family dinner” under this year’s epidemic, we can clearly see the turning speed of the “elephant” in the face of future changes.

In the eyes of many people, BMW may still be the one with good control among the “BBA”. But in my opinion, BMW has sufficient product strength at the product level, strong innovation capability in the R&D level, and a high level of localization awareness in the strategic level.

As BMW’s development layout continues to advance step by step, perhaps what we may see after 2025 is a “brand new” BMW in a new era.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.