After completing the monthly sales series, we spent some time contemplating the future development of automotive electronics.

Recently, due to work-related reasons, I have come across a lot of content on automotive electronic architecture and chips. Looking at the current state of things, the development of automotive electronics is no longer centered around the development of single functions and hardware stacking. Instead, it is focused on solid restructuring of the entire architecture and allocation of functions.

In the field of three electric, the relatively new developments revolve around the integrated design of battery hot runaway warning and detection, as well as the design of the next generation SiC and even GAN for electric drive systems.

In this article, we will mainly explore the development of hot runaway detection technology and BMS.

Integration of Dedicated Hot Runaway Detection Sensors and Relief Valves

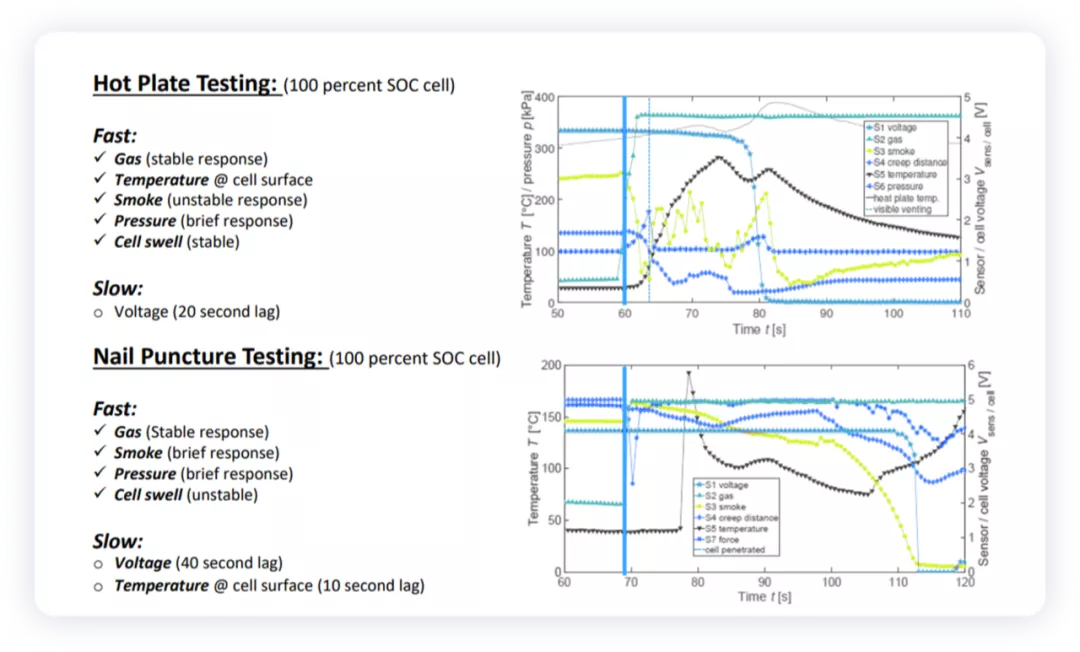

From a systematic testing perspective, the temperature (there are differences from experimental data to real-world data due to the heating method itself) combined with voltage (drop is relatively slow) mode for single cell hot runaway is relatively slow. The pointers that can be used include gas, smoke, pressure and cell expansion.

○ Gas: This is a stable release amount with different types of gas released.

○ Smoke: This pointer is not stable and has high variability.

○ Pressure: Under normal sealing conditions, the overall pressure difference is relatively uniform.

○ Cell Expansion: The triggering method may vary.

Note: Lithium-ion batteries are already widely used in various industries, not just in power batteries. In the future, there will be demand for energy storage, electric two-wheeled vehicles, battery swapping cabinets for electric cars, etc. Firefighting based on early warning signals is actually a strong requirement.

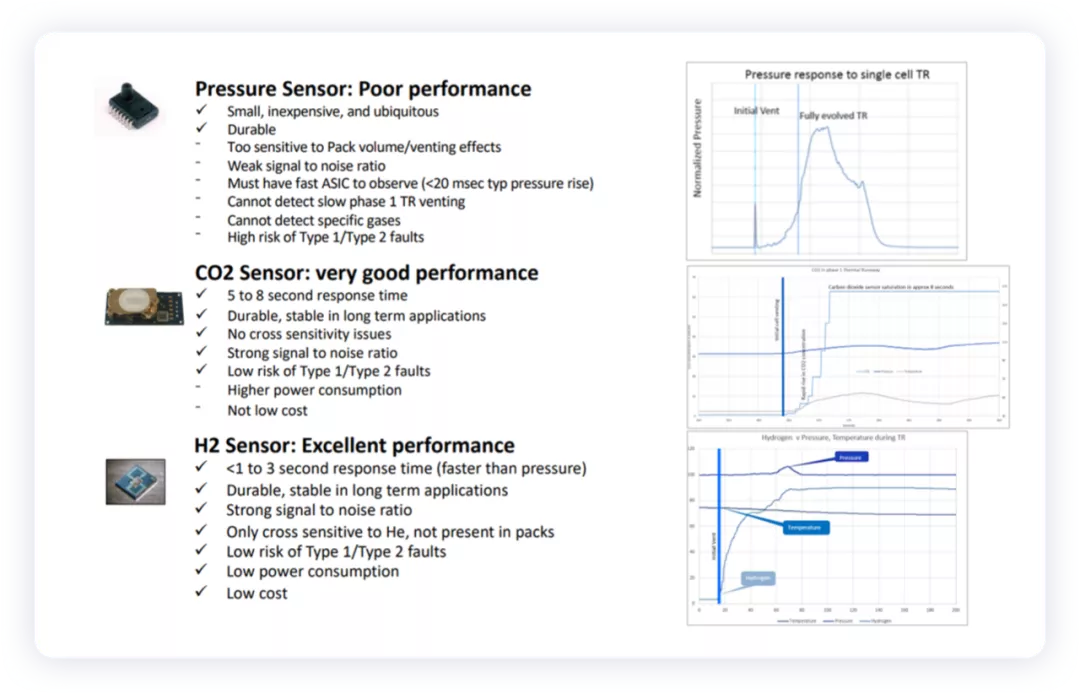

Therefore, there are two ways to proceed. One way is to extract the two parameters of pressure and gas from the previous firefighting experience and turn them into sensors.

- Pressure sensor:

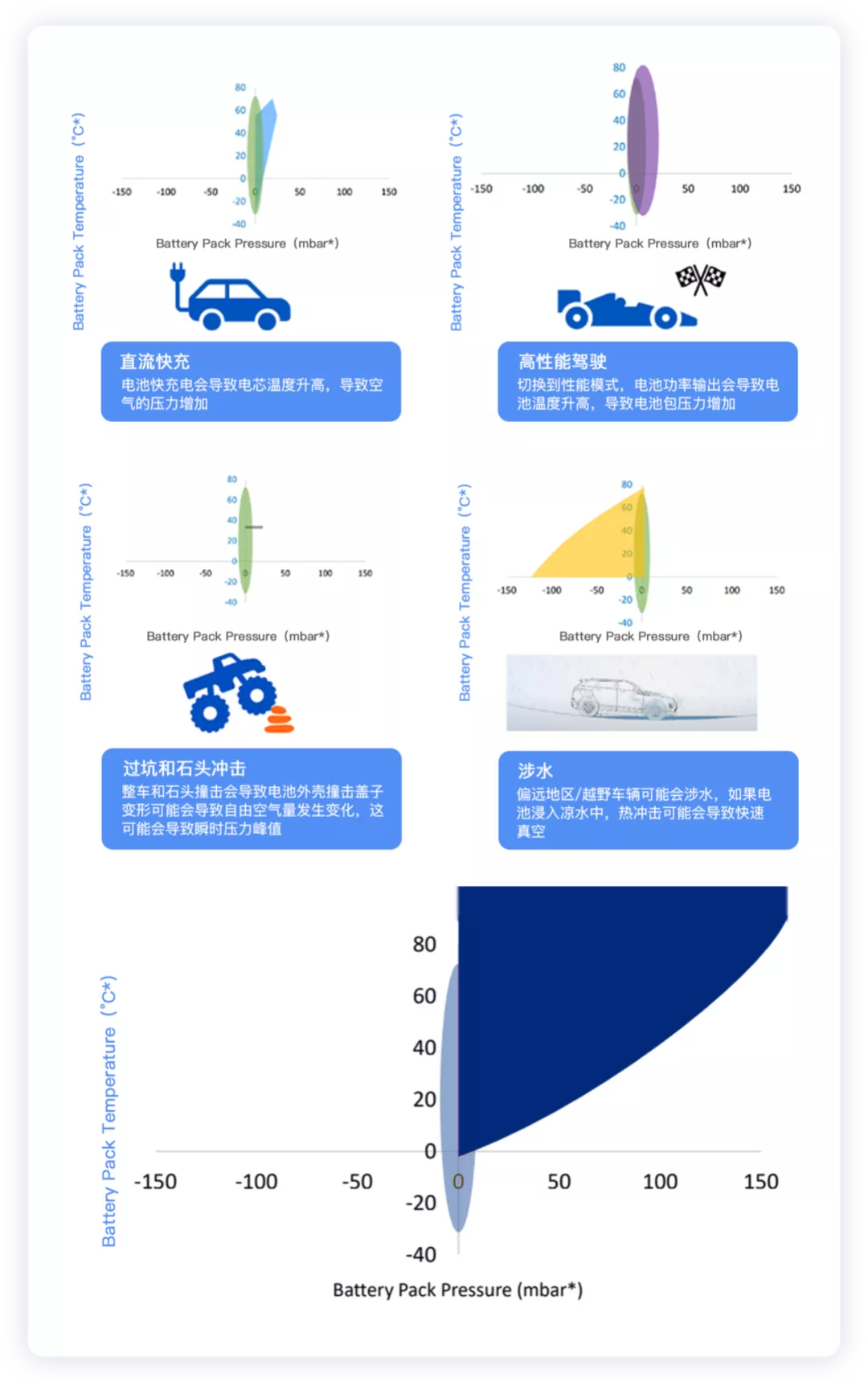

In fact, we found that in order to target different pressure release processes, covering cylinders (21700 to 46800), soft packs, and square shells, even high-precision pressure sensors are closely related to the overall pack design. I tend to think that it would be particularly difficult to achieve uniformity in this way, so putting the pressure detection on the valve opening might be better.

In the pressure changes in the battery system, temperature and impact are the main factors, as shown in the figure below.

- Automotive sensor.Translated English Markdown Text:

Due to the fuel cell, some of the past automotive sensor manufacturers actually have some technical reserves, mainly based on H2 leakage detection. Borrowing this for lithium battery thermal runaway detection is a good solution.

The Future of Battery Management Systems

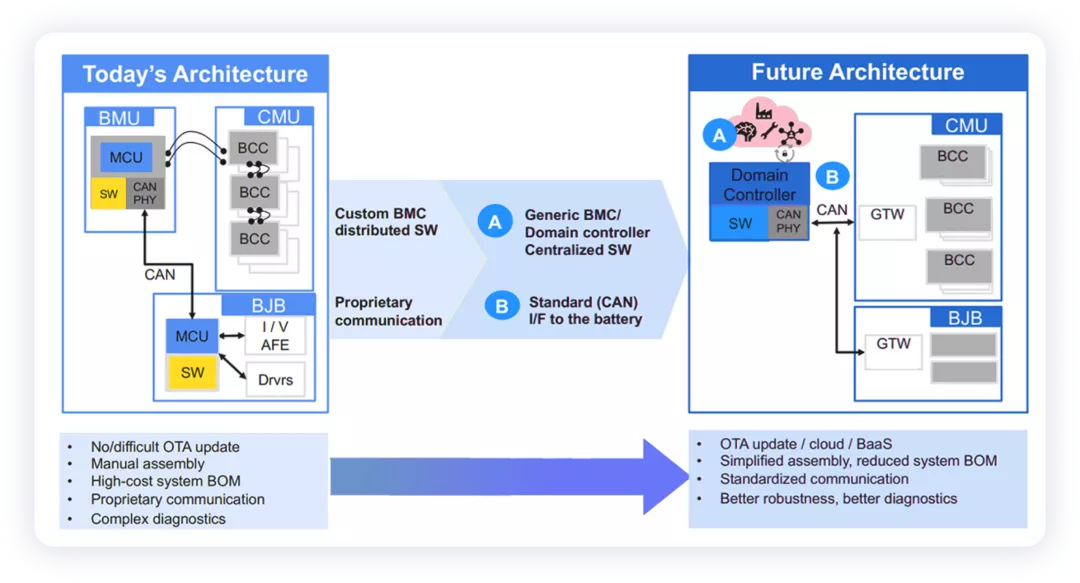

There is a typical chart in NXP’s Next-Generation Architectures For Battery Management Solution, we can see that in the three-electricity fields, there are occurrences of high and low voltage separation and hardware and software separation. In other words, in the future, distributed battery management software may be integrated into domain controllers and even into centralized computing platforms.

My understanding is that with the use of more thermal management components to alleviate thermal runaway, it is necessary to form a centralized processing mode to cover the many thermal runaway detections and thermal runaway delays mentioned above, while activating the hardware in the lower layer.

Note: This process is still relatively slow, mainly due to the real-time requirements of BMS computing.

Conclusion: In my personal opinion, in this field of battery detection and thermal runaway delay, more proactive control measures may emerge, requiring more resources to be called, which also makes the battery management software faster to enter the upper layer.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.