Development of Skateboard Chassis in the Automotive Industry

Invited by General Manager Qiu, I would like to talk about the development of skateboard chassis in the industry. Rivian’s recent success in landing on the US stock market with a high valuation is attributed to the full support from its shareholder, Amazon, and the delivery of the first all-electric pickup truck, which is the hottest trend in the US. The use of skateboard chassis in all-electric cars has become Rivian’s distinguishing feature. In China, whether similar entrepreneurial companies can replicate this business model is still up for question.

Success of Rivian and The Application of Skateboard Chassis

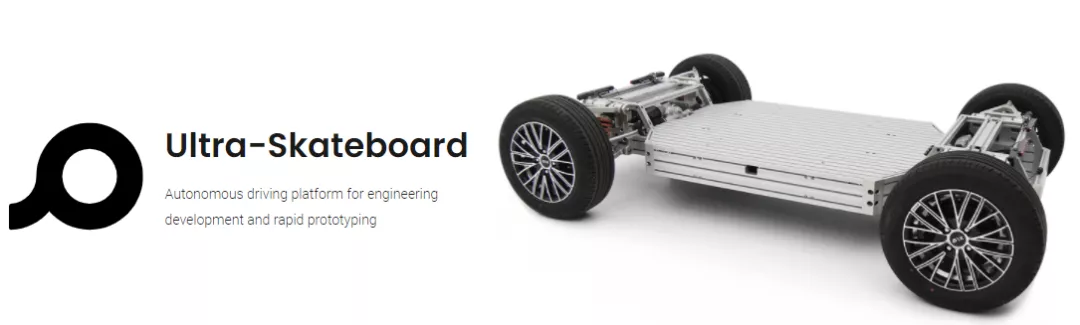

Looking at the development of electrification and intelligence integration in the automotive industry as a whole, modular motors, integrated battery chassis, and overall configurable chassis are definitely the direction of the future.

In large terms, implementing a skateboard chassis is a means to reduce development time and achieve universal parts with minimal components in the automotive industry. Logically speaking, a skateboard chassis is more like a non-load-bearing body structure that has been reinterpreted in electric vehicles. According to one’s interpretation, a skateboard chassis is equal to the non-load-bearing body structure plus a wire turning/braking system and an integrated battery chassis.

It is necessary to return to the differences between non-load-bearing and load-bearing body structures in passenger cars:

-

In non-load-bearing body structures, the entire vehicle has a rigid frame (a beam frame for the chassis). In fuel vehicles, the engine, transmission system, and body components are all fixed on the frame using a suspension device, and the frame is connected to the wheels through the front and rear suspension devices. The advantage of this system is its high strength and good anti-shock performance. However, the drawback is the rigid connection between the body and the frame that produces vibrations while driving on the road and discomfort for the customers.

-

Load-bearing body structures have evolved from passenger cars and do not have rigid frames in their design. Instead, the front, side enclosure, rear, bottom, and other parts have been strengthened, and the engine, front and rear suspension, and transmission systems have been assembled in the desired locations accordingly. The load of the body is transmitted to the wheels through the suspension device (the entire body is a unit, and the suspension directly connects to the body). This design has significantly improved safety and stability, with lower inherent frequencies of vibration and noise, which makes it more lightweight, compact, and easy to assemble. Therefore, for most cars, this structure is preferred.

Therefore, the vast majority of passenger cars in China have a load-bearing structure since comfort is what most people seek. Car manufacturers have replaced non-load-bearing structures with load-bearing structures in most subdivisions that could be replaced. Only the heavy-duty pickup trucks and off-road vehicles still retain a non-load-bearing structure due to their heavy payload and the need for clearance on harsh roads. Flipping the switch in the era of electric vehicles is a little confusing.

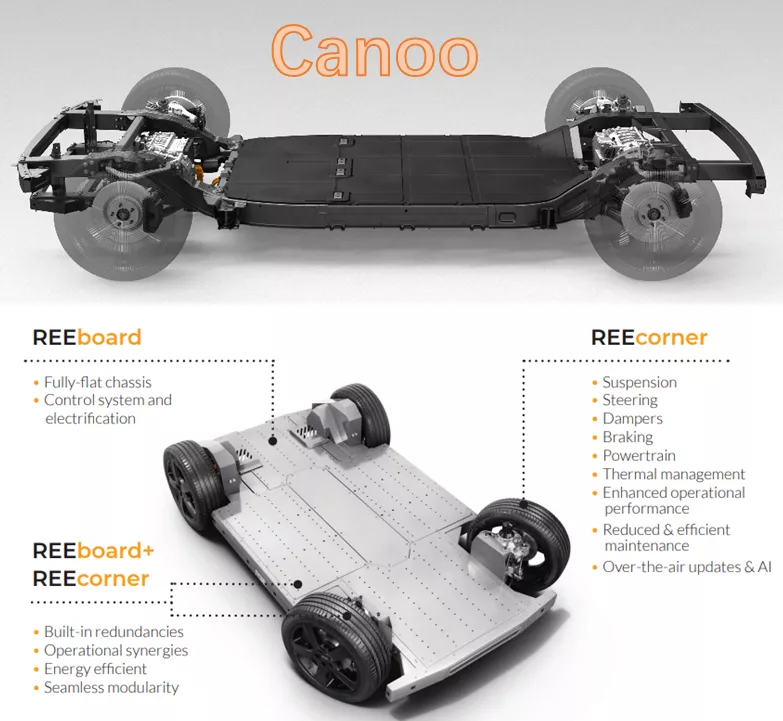

Note: Some media outlets have included all-electric vehicle platforms (such as Tesla, MEB, EMP, and eTGNA) under the design of a skateboard chassis. This is a bit of a confused concept.From a holistic design perspective, there are several companies in the automotive industry that focus on developing skateboard platforms for large vehicles outside of pure electric platforms, mainly including Rivian, Arrival, Canoo, and REE (with valuations of Rivian: $100 billion, Arrival: around $10 billion, and Canoo and REE both being around $1-2 billion).

1) Rivian originally attracted investors and car manufacturer collaborations through their skateboard platform manufacturing concept, and eventually grew into a new American automotive company. After receiving the approval of Amazon’s CEO, Jeff Bezos, Rivian built its own brand and began producing its own cars (in 2019, Amazon ordered 100,000 electric delivery vehicles from Rivian and made a subsequent investment, becoming a key turning point for Rivian). Since then, Rivian has found several investors and automotive companies to collaborate with under the endorsement of Amazon. Rivian has released a pickup truck, an SUV, and a van truck. From a product logic perspective, the relationship between Rivian’s products and skateboard platforms is very close.

2) Arrival focuses on commercial people and cargo transportation, and previously received support from Hyundai and UPS. The overall roadmap includes electric buses, electric trucks, and some smaller transportation vehicles.

3) Canoo and REE are both more technologically advanced. Canoo is a start-up founded by three former BMW executives, with three vehicle models: Canoo Lifestyle Vehicle, Multi-Purpose Delivery Vehicle, and Pickup Truck. These three vehicle models are all designed to be manufactured by third-party companies and sold under the Canoo brand, providing innovative vehicle subscription services for end-users. REE emphasizes high modularity and flexible combinations, and is mainly focused on technological breakthroughs in the vehicle interface and production process.

If we were to categorize the key points here, they would roughly include:1. Electric platforms developed by carmakers are based on load-bearing car bodies, but the logic of non-load-bearing car bodies exists in the US where there is strong demand for pickup trucks and large SUVs. There are differences in the main passenger car path and the application scenarios of the sliding chassis for car companies.

-

The sliding chassis is more like a technology that requires cooperation with car companies to be effective. Both parties need to have common interests in order to collaborate effectively.

-

The sliding chassis actually has nothing to do with remote control. To make it work, only mature technology is needed. Rivian has succeeded in the current stage and is the first company to deliver pure electric pickups ahead of Tesla, Ford and GM.

Can China have Rivian?

I actually hold a negative attitude towards whether China can have Rivian. The logic is very clear that there are so many car companies in China that are developing their own pure electric vehicle platforms, and the overall demand in the Chinese market for car models based on non-load-bearing car bodies is very low.

But we can still take a look at the startup companies in China that focus on sliding chassis.

- PIX Moving

This company is actually still in the conceptual stage, with a story that revolves around developing a super style chassis, integrating the control system, steering system and other components onto the chassis, reducing mechanical parts and making the chassis structure smoother. What sets it apart from its American counterparts is the adoption of “software-defined” and “universal modular flat chassis” by using remote control and software.

Personally, I feel that although this story is favored by investors, the level of difficulty is much higher. Startups still need a lot of resources to develop chassis structures, and integrating the software and hardware of chassis control in one go makes the task even more difficult.

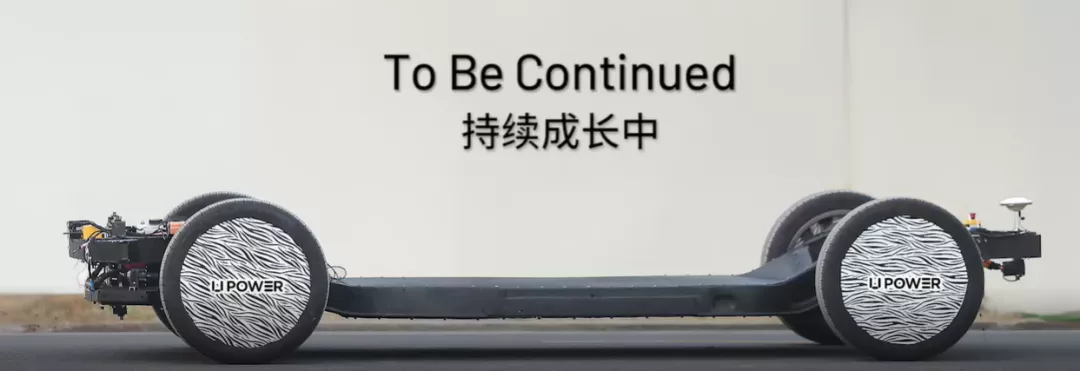

- Upower

Upower is a newly established startup company that focuses on high-speed vehicle sliding chassis. Its founder, Peng Li, previously worked on the Salon project. The company has received investment from Bosch’s Boryn Capital, Sinovation Ventures and other institutional investors, and is developing electric vehicle sliding chassis. In the future, Upower may launch a chassis integrated with batteries, similar to the CTC (Cell to chassis) technology planned by CATL.

This direction may directly cut into the passenger car market, somewhat similar to the CTC scheme that involves load-bearing car bodies.

# This Concept is Facing Logical Problems in China

# This Concept is Facing Logical Problems in China

If you want to properly integrate different carmakers with this concept, which is to create various upper body vehicles based on your well-designed chassis and battery system, there exist significant logical problems in China.

-

Firstly, it is very expensive. That is to say, you make the chassis that integrates motor, battery, intelligent driving chip, steering and brake, and locomotive mechanism which accounts for almost 40-50% of the cost of the entire vehicle. Then what do the carmaker’s engineers and purchasers do? What about the existing DRE engineers (Design Release Engineer/Product Engineer) in the carmakers?

-

With limited resources, how can you design and test the skateboard chassis (even CTC design for the body-in-white with partnership with carmakers) and have it verified? This system requires significant investment in dynamic handling and collision safety, and effectively digesting these development costs is a big problem. It is not something that can be accomplished by simply drawing a CAE. It requires a lot of experimental verification and on-road testing.

Conclusion: Therefore, personally, I believe that when all Chinese carmakers are investing heavily, no carmaker will allocate time and energy to cooperate with such third-party enterprises. Instead, it is more likely to have a reverse control of some carmakers by providing a chassis solution such as Ningde Era, and then outputting possibility.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.