A Systematic Study of Rivian’s Battery, Drive, and Entertainment Systems

Rivian, which has recently become a rising star in the American market, is also one of the most popular companies in the US electric vehicle market as the accelerated growth of the electric vehicle market in the US in 2022 drives forward. In light of this, I think it is necessary to conduct a systematic study of Rivian, including its battery, drive system, entertainment system and more.

By the way, Rivian’s work pace is exhausting for workers. A friend of mine had to take a long break because Rivian’s pace overwhelmed him. Currently, all the new power vehicle companies worldwide are working at full capacity, which will have a significant impact on the entire industry landscape.

Note: I think the automotive industry will welcome a new round of intense competition in the future, and while 996 might be a little exaggerated, the overall work pace will follow the route of iterative development of consumer electronics and the Internet. Brothers and sisters, I am not manufacturing anxiety, but this is reality, and everyone will need to work hard in the future.

Rivian’s Models and Battery Systems

According to Rivian’s vehicle plan, there are three main types of mass-produced vehicles:

The main private customer market in the US includes the R1T five-seater pickup truck model (67,500-73,000 USD), which is being gradually launched in September, while the R1S seven-seater SUV model (70,000-75,500 USD) will start delivery by the end of the year.

Both the R1T and R1S models are based on the Skateboard Platform, and Rivian had previously bought prototype design and development services from Ford, paying $74 million.

The battery system comes in several specifications, including 180 kWh and 135 kWh, which should have been developed. The low-cost 105 kWh solution will be released within six months, and the battery’s fast charging power is limited to 160 kW.

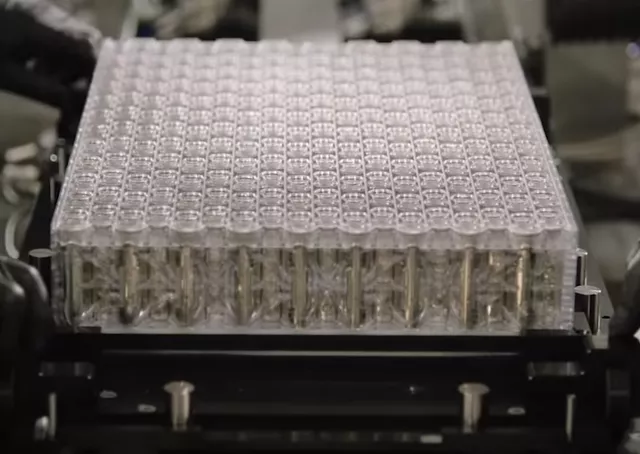

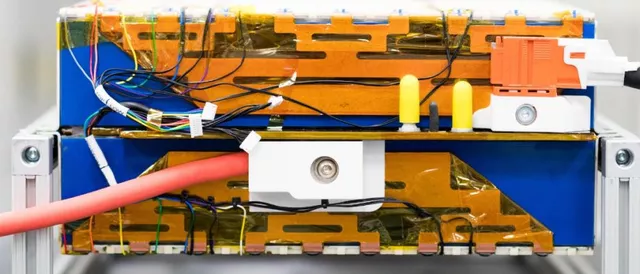

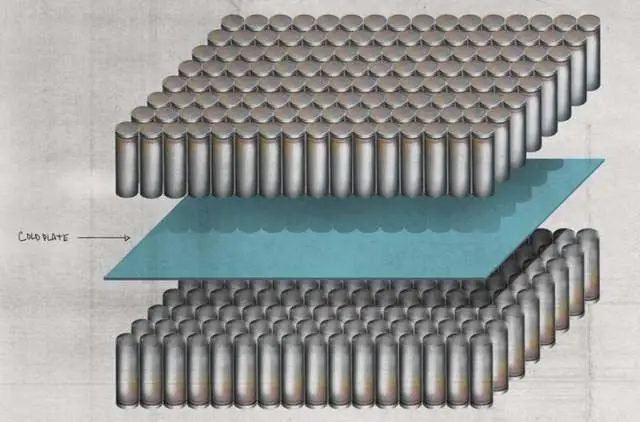

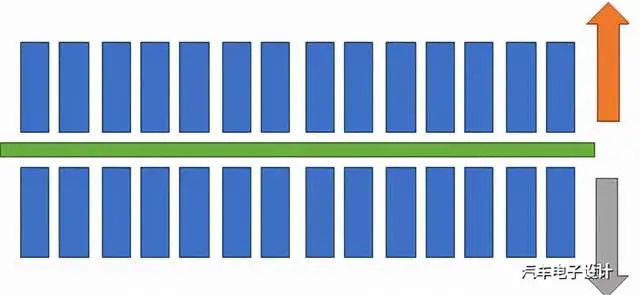

(See Figure 1 and Figure 2 for details of Rivian’s battery system)

In an article I wrote in 2019, “Rivian’s Pickup Battery System,” I actually described Rivian’s battery design.

Rivian’s design approach also starts with 21700 cells and mainly utilizes a sandwich structure with upper and lower module configurations and a cooling plate for Z-direction height insensitivity for pickup trucks and commercial vehicles.This represents a different path in the iterative design of cylindrical batteries, with single-sided top and bottom cooling via two modules, separated by a large cold plate. The batteries are positioned upside down, and the single-block battery module is actually quite tall, equivalent to stacking two 21700 modules together. The front of the module features output cables which are bridged using quick-connectors, while the upper and lower bus bars are connected via busbars on the other side of the battery module.

With these large modules, Rivian can assemble very large battery systems.

Currently, the US market mostly uses pouch and cylindrical batteries. With Rivian’s design, it is predicted that US automakers will accelerate their adoption of cylindrical batteries. According to reliable sources, major US automakers will also explore different options beyond pouch batteries to enrich their battery choices, mostly in the direction of cylindrical batteries.

Rivian’s Battery Supply

I recently discussed battery supply with friends from Samsung SDI, and Rivian is a very important incremental customer for SDI. Based on the IPO, Rivian’s demand for batteries is not low. In fact, as early as April, Rivian CEO RJ Scaringe stated that Samsung SDI will provide batteries for its electric vehicles. In addition, SDI may build an electric vehicle battery factory near Rivian’s factory, apart from the previous JV between SDI and Stellantis.According to Bloomberg, Rivian needs to establish its second electric vehicle factory in the United States from an investment perspective, and then plans to build a factory in Europe (to produce commercial vehicles by the end of 2023, but I think it’s unlikely to sell electric pickups).

What’s interesting about Rivian is that, due to its choice of cylindrical battery technology, it is considering building battery manufacturing facilities in Arizona, Michigan and Texas.

In summary, I believe that as the new forces grow, almost every car company is starting to reserve talent in the field of battery cells and trying to enter the battery manufacturing field at the right time, which is almost a clear sign. I think there is a high probability that some teams of small battery companies (process talents at the manufacturing level) and some assets will be acquired by M&A.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.