I think that for the recent rebound of lithium iron phosphate batteries and the upgrade plan of lithium manganese iron phosphate batteries, there needs to be a clear understanding – after the adjustment and continuous improvement of the high nickel front-end technology, there may be a turning point around the balance between safety and energy density.

From a safety perspective, the composite flow collection fluid is an important breakthrough in safety technology in recent years, and CATL’s layout can be said to be a beacon in China.

On the other hand, foreign battery standards may also have some development under various barriers.

In the current situation, the biggest difference between European and American batteries and Chinese batteries lies in cost, and the increase in penetration rate depends entirely on cost. Therefore, it is relatively difficult for foreign countries to come up with a CATL, and whether a bunch of small innovative battery companies can continue to develop remains to be seen, as does the maturity of the European and American local battery industry chain.

Today’s article mainly introduces Soteria BIG (Soteria Battery Innovation Group). A friend had introduced this company to me before, and recently, a big brother in Canada contacted me for consultation, so I would like to spend some time summarizing it!

What kind of company is Soteria?

To start with, since deploying ternary batteries in 2017, we have received a lot of feedback. Most of the fire incidents are actually a probability issue, even for ternary batteries in the 5 series. On the one hand, there are problems in the manufacturing process, and frequent fast charging during operation can also cause potential thermal runaway. Although this probability is small, it also requires very high cost for big players like LG Chem.

Let’s not laugh at others, let’s be objective. We must solve this problem to do high-nickel.

Soteria is actually a very interesting company that mainly focuses on the design of safe batteries. This is different from the battery system safety that most of our automotive companies talk about. We solve the problem at the module and pack level, while Soteria’s safety solution mainly includes:

What Is the Secret of Soteria?

We can break down the components of the battery by dissecting a cell. Taking LG’s products used by Tesla as an example, we can see that the components can be roughly divided into 51.75kWh. The weight of the cell is 201.68kg, and the weight of the corresponding positive electrode material is 80kg, with nickel weighing 65.57kg and cobalt weighing 4.8kg.

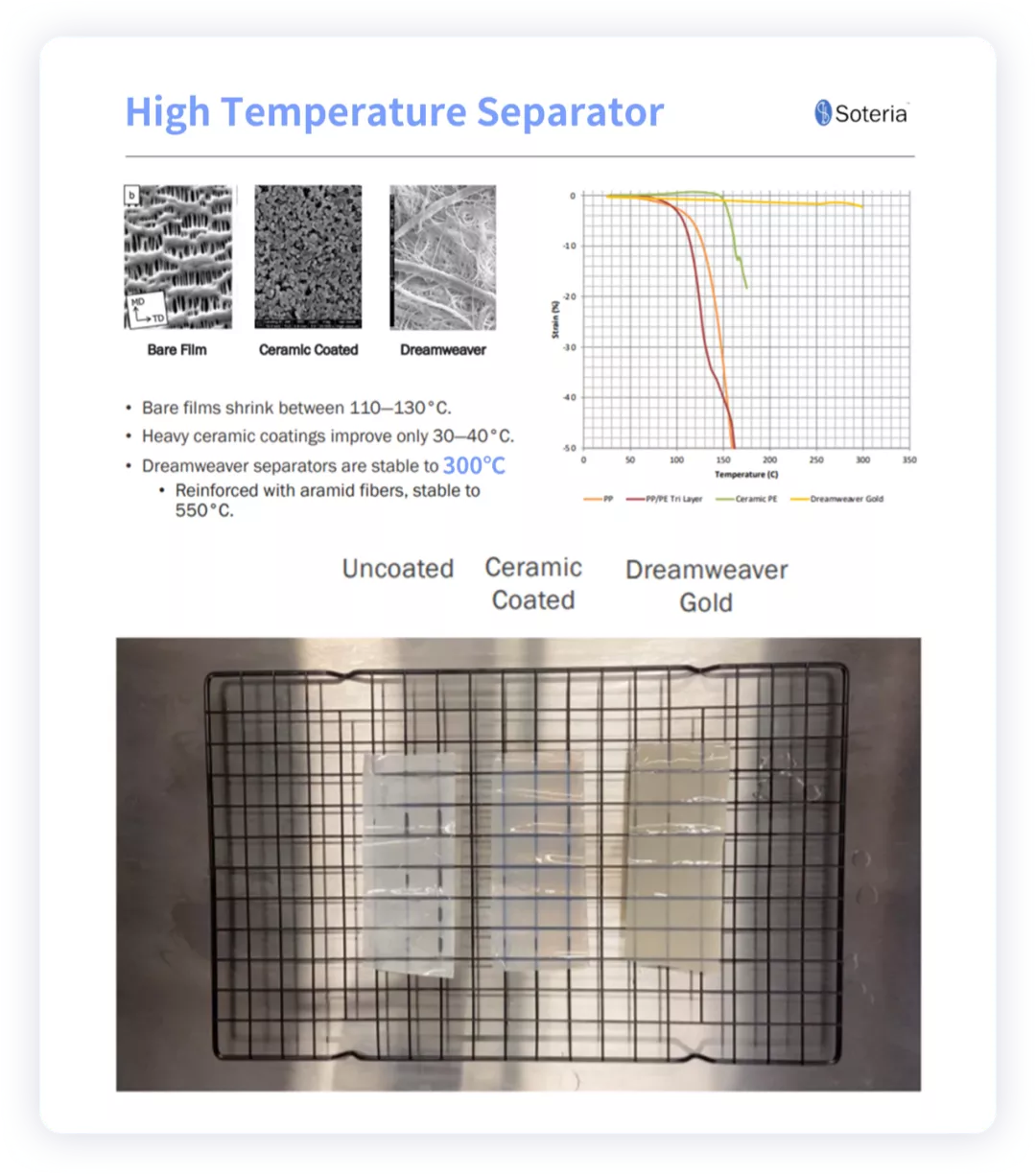

1) Dreamweaver Separator High-Temperature Membrane:

Dreamweaver may be a non-woven separator membrane that is stable at 300°C and does not shrink significantly according to Soteria. After being reinforced with aramid fibers, the temperature can be further stabilized at 550°C.

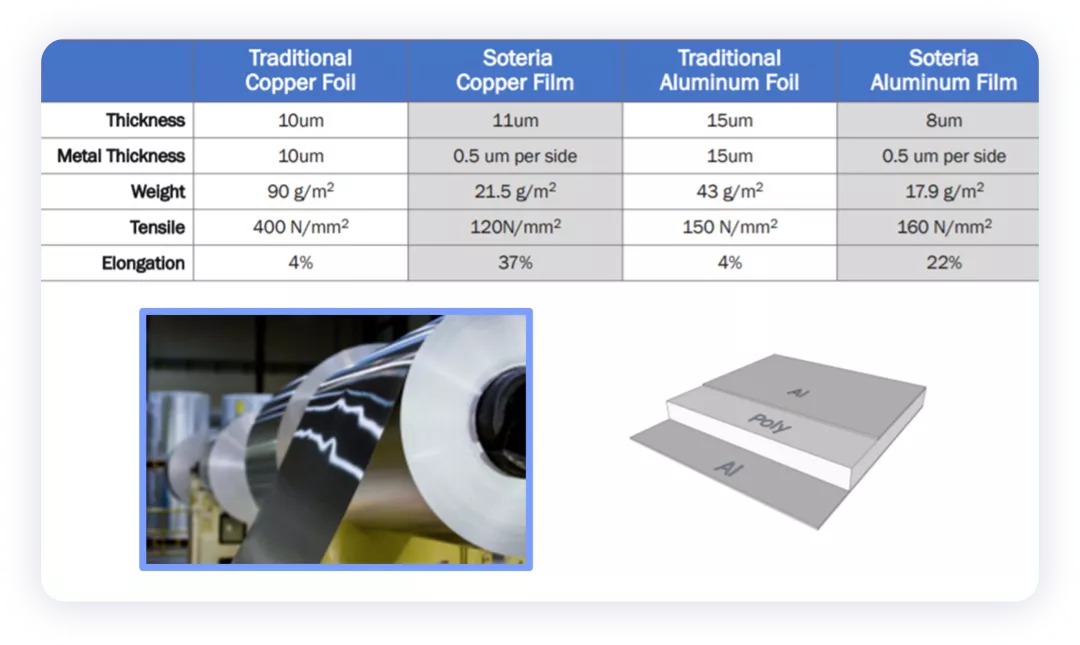

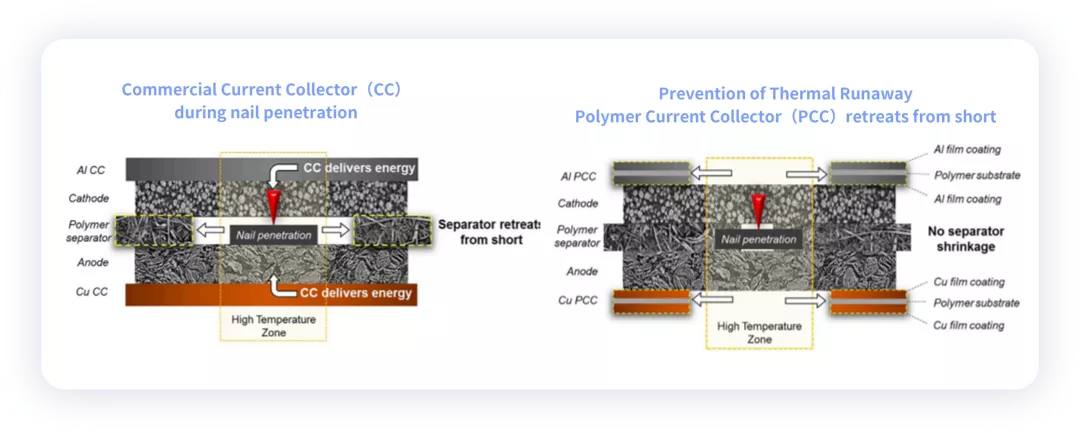

2) Polymer-Based Metal Plated Collector:

Soteria’s collector is the core technology of its safety design, and the materials used by Polymer are compared.

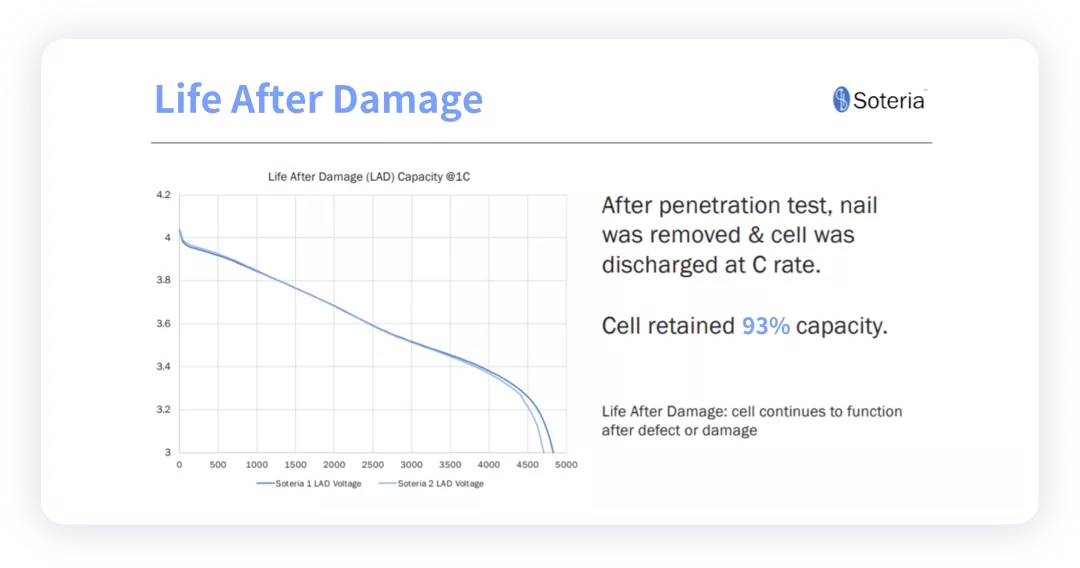

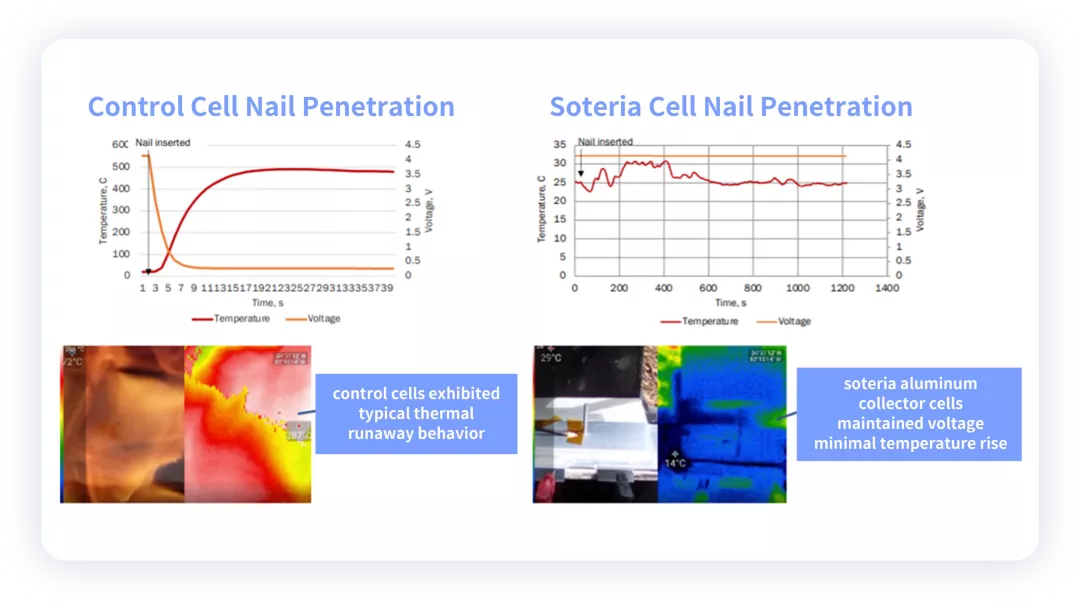

As mentioned earlier, Soteria showcased the 811/graphite 5Ah soft pack cell and subjected it to the most rigorous needle-puncture test. The punctured cell can still be used, and can retain 93% of its capacity.

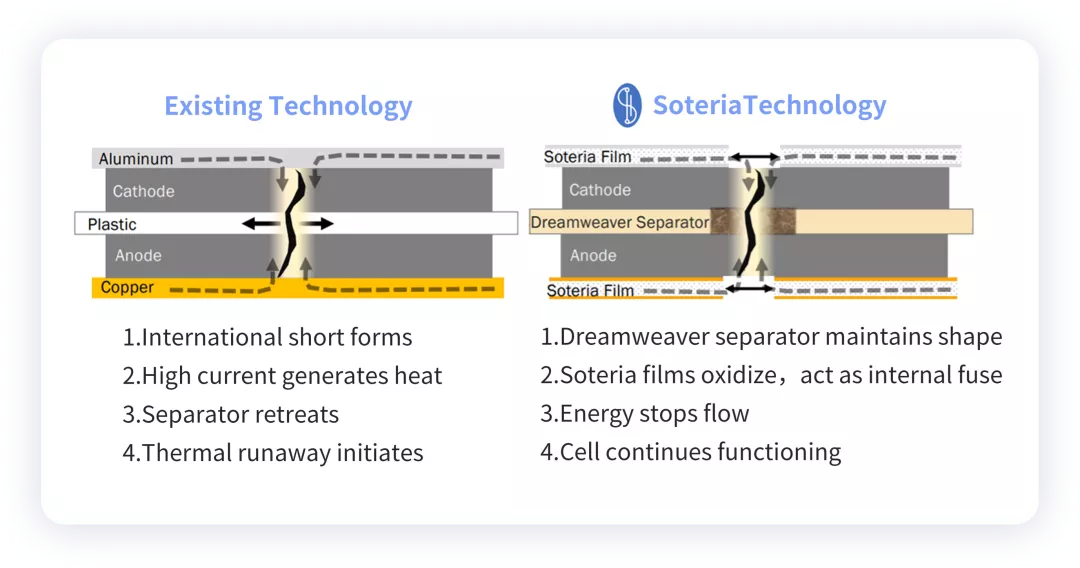

In order to achieve an effective safety design of the battery, Soteria relies on the combined effects of the high-temperature-resistant membrane and the composite collector. The high-temperature-resistant membrane does not cause a large-scale short circuit due to thermal shrinkage, and the polymer-based collector will melt and act like a fuse when it is heated up.

Conclusion: In my personal opinion, we should have confidence in the iteration of battery energy density. Not only can CTP and CTC technologies make the battery system stronger, but design at the battery cell level may also provide more room for continuous improvement. At some turning point, as the price of lithium carbonate continues to increase, the cost of high-nickel materials and composite flow batteries will decrease, and the technology roadmap will reverse!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.