*This article was reproduced from the Autocarweekly public account.

Author: Ao Ao Hu

Don’t get me wrong, as a person who attaches great importance to pure electric platforms in Xixiang Street, Bao’an District, I don’t mean to overturn the meaning of “oil-to-electric”.

As we enter the end of 2021, as Tesla breaks through the trillion-dollar market value, as BYD makes its second attempt at breaking through the trillion-dollar market value, and as CATL’s stock price exceeds RMB 600, “oil-to-electric” seems like an ancient term that should be far away – it reminds people of the street rat named “60km/h constant speed endurance” from years ago.

But today, “oil-to-electric” not only hasn’t been swept into the dustbin of history, but carmakers continue to launch new models, some of which even perform well in the market. In just the first three quarters of this year, Porsche’s Taycan has sold 28,600 vehicles, second only to the Cayenne and Macan SUVs and substantially exceeding its gasoline-powered relative, the Panamera (20,300 vehicles).

Looking ahead, the three oil-to-electric siblings from BBA – the EQC, iX3, and e-tron – combined still can’t quite match the Model Y next door, but they have each carved out a niche in their own way.

The EQC and e-tron both struggle at the high end of the RMB 500,000 range, with only a couple of hundred sold in a month for the sake of visibility; while the iX3, after experiencing price reductions and terminal promotions, has become stable at monthly sales of over 2000, taking the first step out of being a niche car.

In the more mainstream RMB 200,000 electric vehicle market, some refined oil-to-electric models can even compete head-on with pure electric platform counterparts.

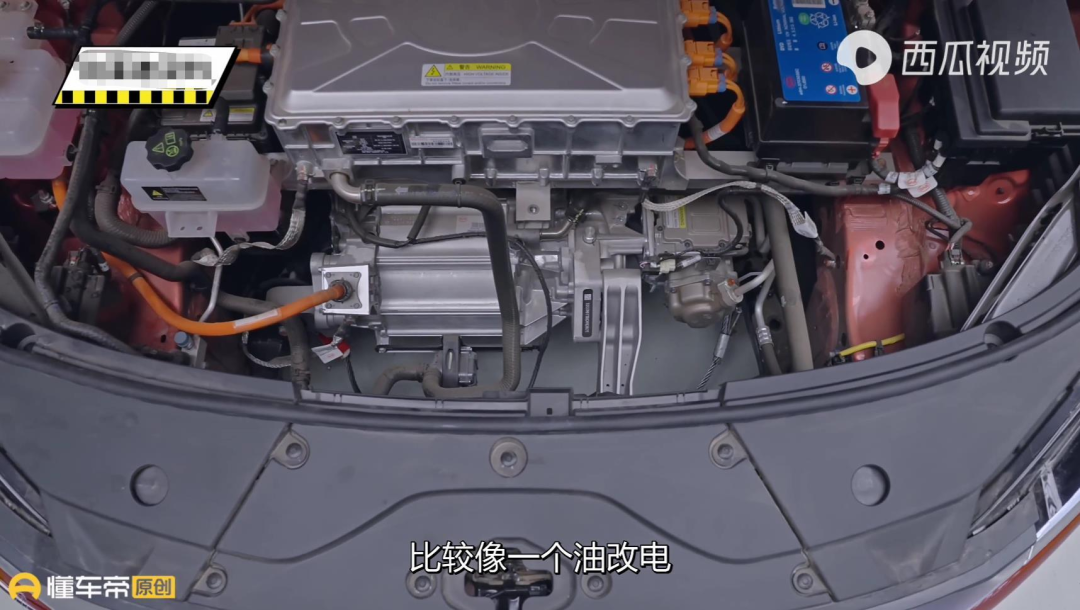

All of BYD’s main vehicle models to date, from Song to Tang, to Qin and Han, belong to hybrid/pure electric “common platforms.” Geely’s two major new energy brands, Geometry and Lynk & Co., currently have pure electric vehicle models that come from the CMA platform that “supports multiple power systems,” and the unique-shaped battery pack speaks for itself.

The first batch of oil-to-electric vehicles that were criticized as “industrial waste” have now almost reached the end of their lifecycle as a generation of vehicle models. Not only have most of the vehicles on the market been iterated at least once, but also many of the platforms and architectures in the hands of automakers have changed hands.

The first batch of oil-to-electric vehicles that were criticized as “industrial waste” have now almost reached the end of their lifecycle as a generation of vehicle models. Not only have most of the vehicles on the market been iterated at least once, but also many of the platforms and architectures in the hands of automakers have changed hands.

This means that although they are all called “oil-to-electric,” there are also differences between one “oil-to-electric” and another.

The Compulsion of the Old World

Why can’t a fully comprehensive electric vehicle be born out of the platform designed for gasoline-powered cars? It’s simple because there is a natural conflict between the basic structures required for gasoline and electric cars.

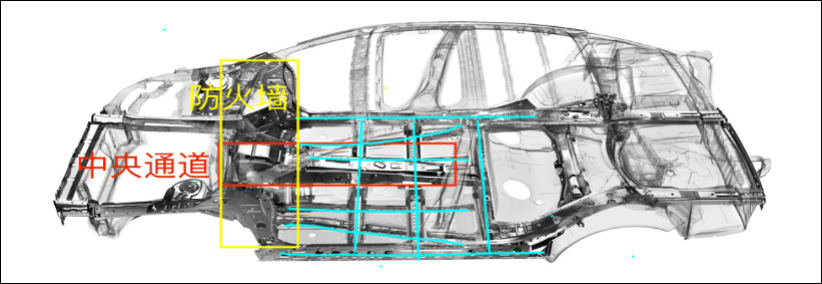

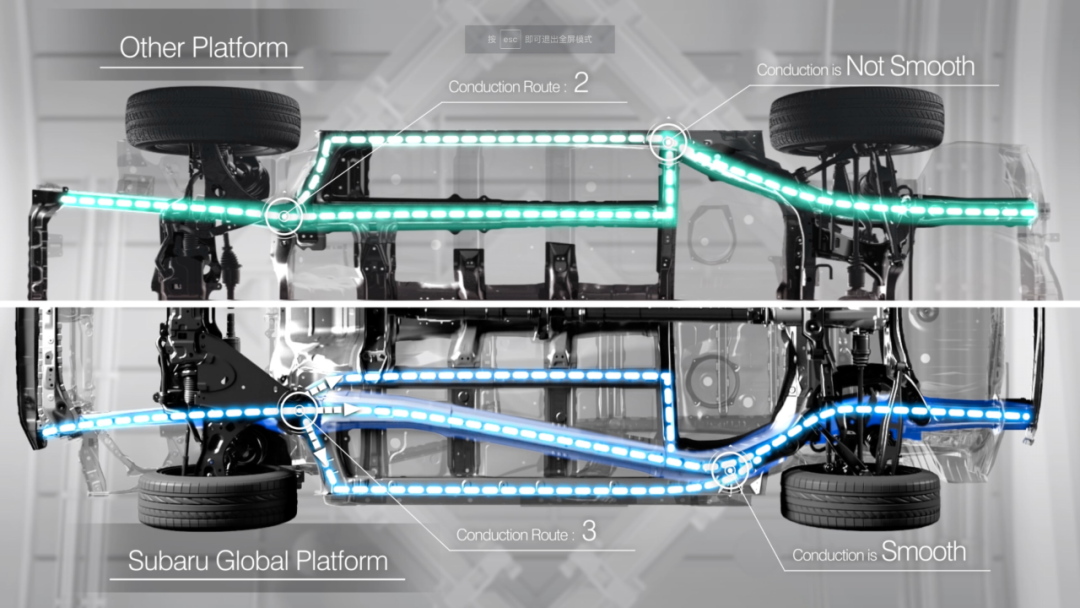

The biggest change required for an electric car is to arrange the battery pack under the car. Unfortunately, the lower half of the body is the most basic and important part of the car body (the upper half is usually variable, like hatchbacks, sedans, station wagons, SUVs, etc.). The various structures densely arranged in the lower body participate in and determine the stiffness and collision energy absorption of the car body, among other factors. This is also why automakers often display the lower body of the platform or structure when showcasing vehicles.

The typical body structure of a gasoline-powered car is highly complex and irregular. On the one hand, functional structures such as central channels (for arranging drivetrain and exhaust) and fuel tanks need to be arranged.

On the other hand, reinforcing structures such as the longitudinal and transverse beams need to be arranged on the bottom of the car. The position of the central channel is naturally fixed, and the fuel tank is usually only arranged beneath the rear seat. The beam on the bottom of the car, which withstands side impact, usually needs to occupy the area directly beneath the seat to leave legroom for passengers in front and back.

As a result, without significantly changing the bottom structure of the car, converting it to an electric vehicle is like finding needle in a haystack: avoiding the strong structures that cannot be touched or moved, and only cutting into the “soft spots.” For example, the fuel tank under the rear seat, or the empty central channel, can now be used to hold batteries.The first batch of pure electric vehicles Volkswagen launched in China in 2018, including pure electric Lavida, pure electric Bora, and pure electric Golf, were all achieved by “stuffing batteries” based on the MQB platform. The “clay” shaped battery pack is just under the front and rear seats with a central aisle. However, the simple stuffing method only allowed the e-Golf to have a battery capacity of 35.8 kWh and a nominal cruising range of only a poor 255 km – this is the original sin of “oil-to-electricity” transformation.

To make the battery capacity and cruising range reasonable, the irregularly shaped battery pack must be expanded into a flat shape by force. There are only two solutions to oil-to-electricity transformation: expanding upwards, invading passenger compartment space; expanding downwards, seeking space from the ground clearance.

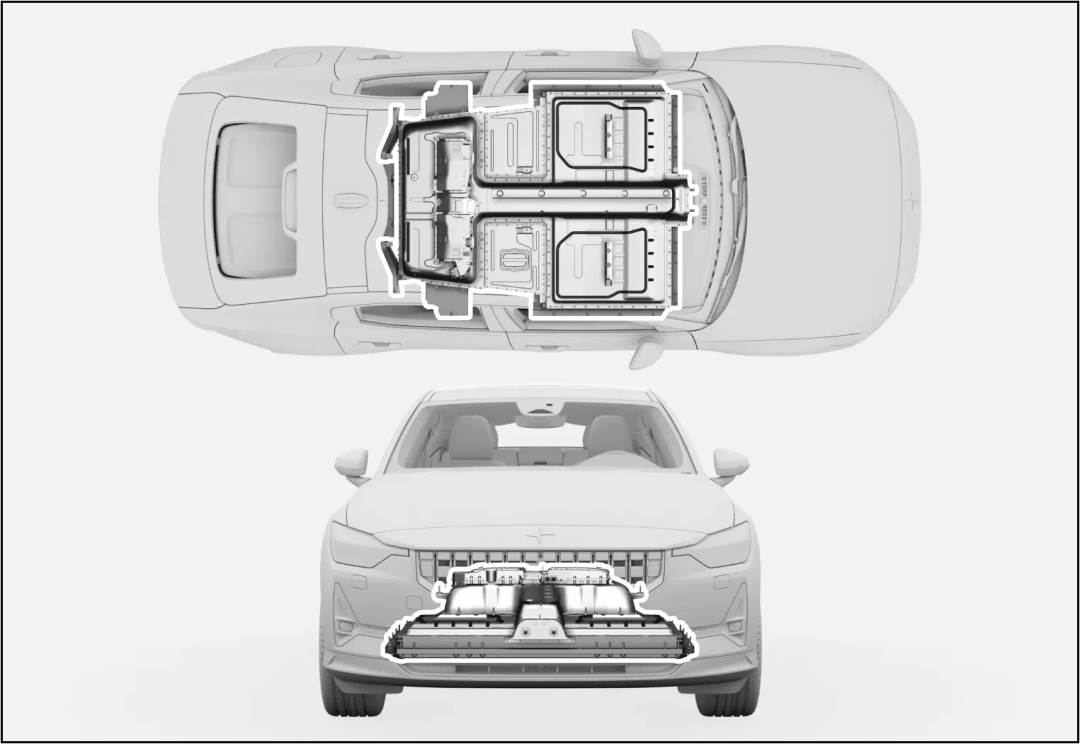

Stuffing batteries into gaps, raising the floor, and reducing the ground clearance are usually not used separately. For example, the Polestar 2 also raised the front floor to gain additional battery space while fitting in a T-shaped battery pack.

If you have taken a ride-hail car from brands such as BAIC and Geely, you may have felt the significantly higher rear floor. Toyota’s electric vehicles based on the GA-C platform reduced the ground clearance and raised the rear seat cushions at the same time.

As for a new strategy for oil-to-electricity transformation, no one understands better than BMW. Although they were the first to invest heavily in pure electric vehicles (i3), they did not have a happy ending, and were often mocked for waking up early and “arriving late for the party.” Nowadays, BMW is the most cautious one among BBA in terms of pure electric platform.

Meanwhile, the EVA platform by the next-door Mercedes-Benz already has two pure electric vehicles, EQS and EQE. Porsche, backed by the Volkswagen Group, and Audi cooperated to create the PPE platform (to be mass-produced in 2023). However, BMW has been silent for seven years since i3 until earlier this year. They decided to launch New Class, a pure electric platform, in 2025 to return to the native pure electric vehicle competition.

In the meantime, BMW can only rely on “general platforms” in the electric vehicle market.

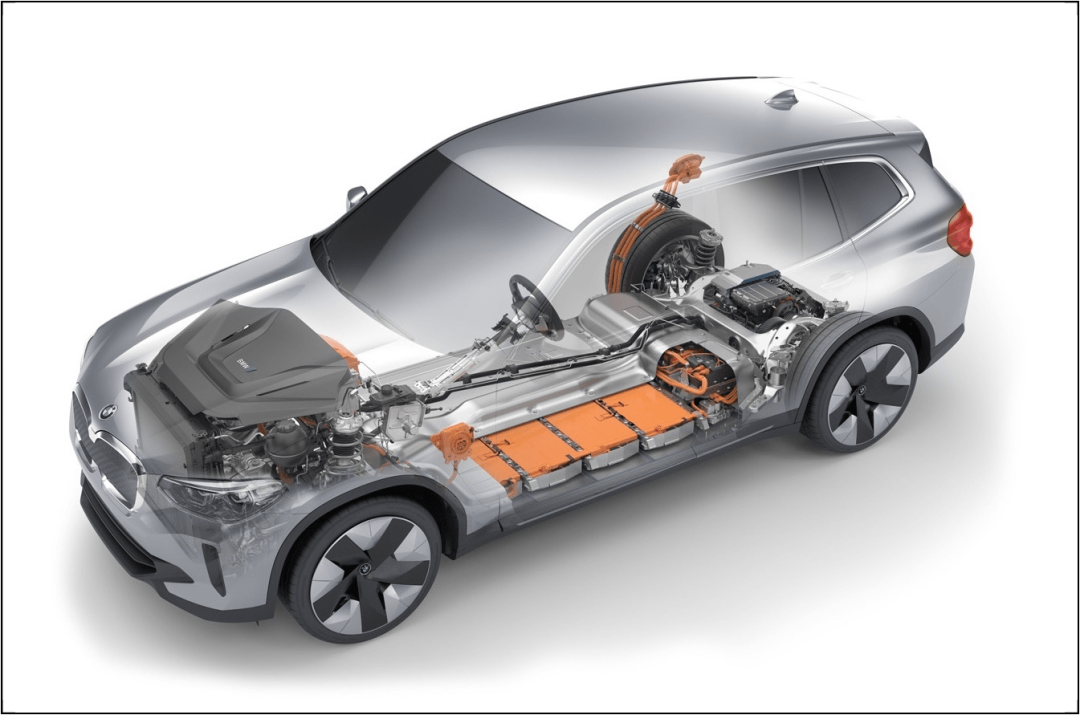

[iX3 image]Starting from iX3. The iX3 is based on the CLAR platform, which is a rear-wheel-drive platform used in BMW’s gasoline-powered cars, and has been applied to all the longitudinal engine models of BMW since 2015. Similar to other “universal platforms”, CLAR also claims to support various power systems such as fuel, hybrid, plug-in hybrid, pure electric, and hydrogen fuel.

However, because of the later development time and more consideration for pure electric power, CLAR allows the battery pack to be arranged between a small raised floor height and a lowered ground clearance. As a result, the iX3’s ground clearance of 179mm is nearly 30mm lower than that of the gasoline-powered X3, but it has the same basic floor height as the X3.

While the battery placement issue is solved, BMW did not allow the iX3 to have the full capacity of the battery pack. The battery pack is surrounded by an empty space, and the battery cells shrink to a relatively regular core area. The total capacity is only increased by the high energy density of the battery cells (811), and the space around the periphery is left for highly redundant protection structures to counter the risk of increased energy density of the battery cells.

Even though all electric vehicles strictly protect the battery, rarely do you see such a layered safety redundancy like the iX3. On either side of iX3’s battery pack, there is first a hollow aluminum buffer structure (blue circle in the figure below), then a blank area (yellow shadow in the figure below), and then a tile-shaped buffer piece outside the battery cell module (green circle in the figure below), before the battery cell module/battery pack core area.

It’s like squeezing eggs in the middle of a basket and then reinforcing the basket with the space around it, which means the basket is not full.

In the later i4, this multi-layered safety protection structure is no longer seen, and instead, there is a completely flat, larger battery cell module. This approach allows the i4 to have a lower vehicle height (sedan, relative to iX3) and a larger battery capacity (84kWh compared to 74kWh), which is the ultimate form of CLAR’s transition from fuel to electric.

On the Porsche side, the Taycan and e-tron GT are based on the J1 platform, which stems from Volkswagen Group’s high-end exclusive platform MSB developed for Porsche Panamera and Bentley brands. Like the Panamera, the Taycan has front-wheel brake calipers that are not commonly found in this class, and this is the optimization result of the MSB platform for the fuel four-wheel drive system.MSB is already a high-performance platform for sedans and coupes. To accommodate a sufficiently large battery pack, Taycan and J1 platforms had to look up for space. However, Taycan’s low roof design cannot be changed. To make space for the battery, the floor height was raised in the front, raising the feet and making the front row seats closer to a lying position.

The rear row, constrained by limited longitudinal space and the low roofline, has no extra room to move. Therefore, Taycan came up with the famous “footwell” design in the rear row. This reflects Taycan’s design priorities: exterior design > basic rear space > absolute range.

Comparing the body structures of Taycan and Panamera, you can notice that the floor of Taycan is higher than the latter under the B-pillar. The raised battery system below the rear of Taycan exceeds the height of the rear door sill. In contrast, Panamera has a flat bottom beam that is flush with the rear door sill.

CLAR and MSB are both new platforms launched after pure electric trends emerged. They are primarily fuel-based platforms but still take serious account of and reserve designs for pure electric power. This is at least the foundation for a car that is converted from fuel to electric and can be accepted and chosen by some people.

Before the arrival of BMW’s New Class and Porsche’s PPE, it was the only real choice to convert a fuel-based platform into an electric vehicle. BMW chose to make the conversion as practical and cost-effective as possible, while Porsche chose to give up the range battle for the design. BMW will not expect iX3 to compete head-to-head with Model Y, and Porsche will not expect Taycan to dominate the market like Model S.

Although the return on investment for both may not be as sensational as launching a brand new pure electric platform, they have still achieved certain accomplishments. Conversion from fuel to electric is not scary, but not knowing why and how much investment to expect for what outcome is. In the automobile market, finding the right positioning is always more important than product quality.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.