Translation in English Markdown

Recently, I have been quite busy, so I decided to use some of my saved materials.

I recently went to the Tianma Circuit and met with old friends. I also saw that Ford had showcased the battery system for the Mach-E in China, and overall, the localization was done very well.

Here, let’s do some organizing and discussion.

Battery Selection

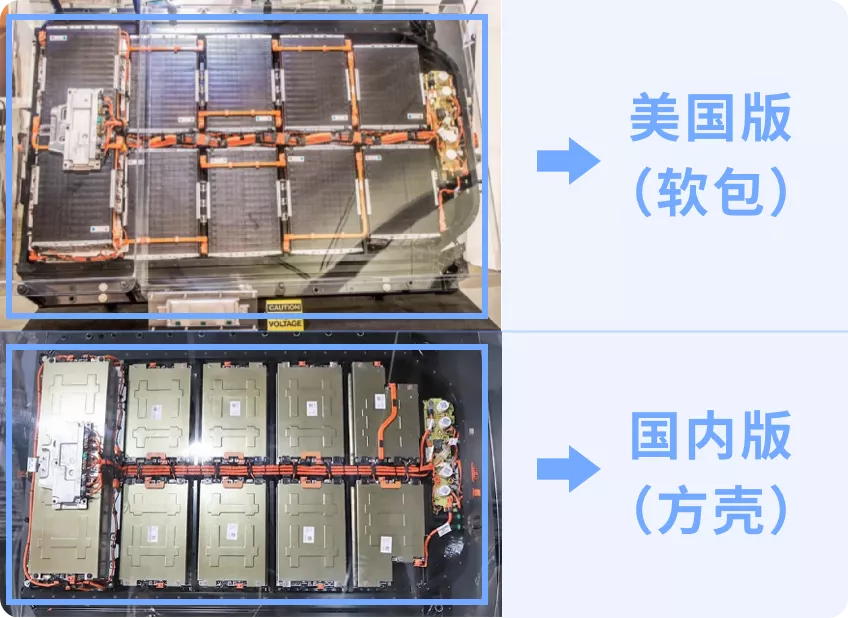

For the Mach-E battery system, LG batteries are used in foreign countries, while domestic ones are designed using a modular approach, and the cells utilize BYD’s 58.5Ah small-capacity ternary cell design.

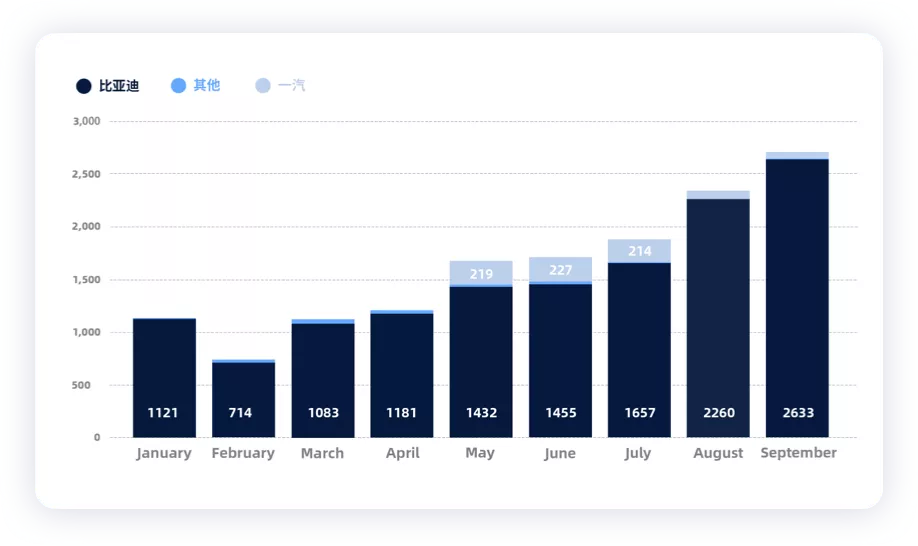

BYD has begun to separate its battery business. The main clients for ternary batteries are Changan and Ford, while blade batteries are used by FAW, as shown in the figure below. It can be seen that BYD’s battery client distribution is primarily self-owned.

Note: BYD’s external supply is also heavily dependent on foreign brands and has a relatively low percentage of domestic demand for independent brands in the short term.

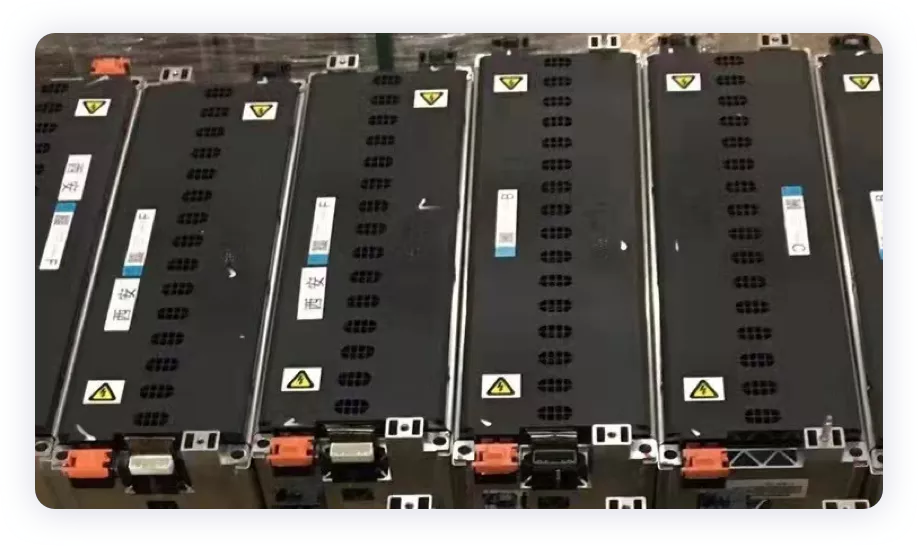

I’ve seen this module before at a friend’s place.

To ensure safety, BYD uses a high-strength ceramic-coated diaphragm and explosion-proof valve design inside the battery cell to avoid short-circuiting between the positive and negative poles as much as possible. The battery module reserves expansion space between the cells and is equipped with a gas gel to slow down or even prevent the chain reaction caused by the heat expansion during the battery’s heat spreading process.

Through various designs, the time it takes for the battery system’s thermal runaway propagation during thermal runaway testing is about tens of minutes, and a thermal runaway warning is issued to the user within 2 seconds.

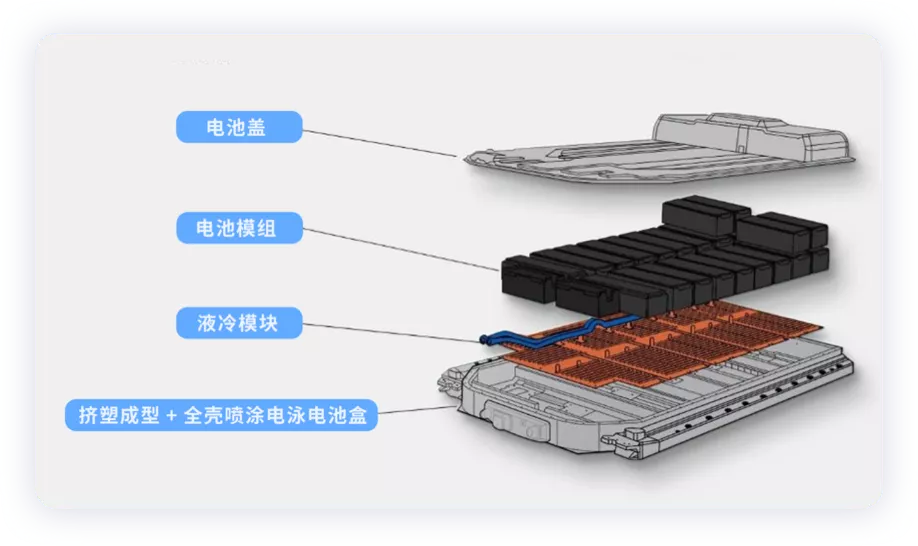

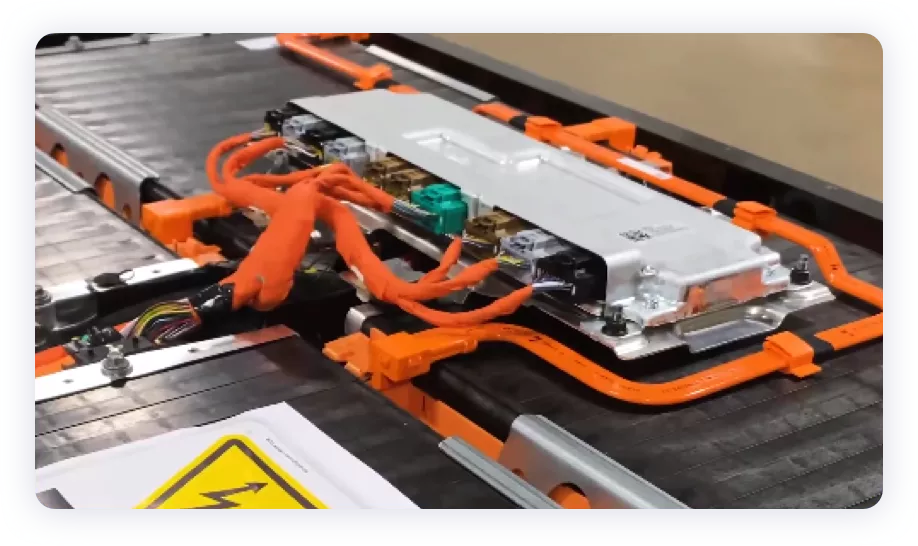

There are a total of 22 module designs, and the water-cooling system is primarily based on the original Mach-E version. Therefore, based on the comparison, the main difference between soft pack and square shell designs is as shown in Figure 4.

1. The module was designed as a whole, with 10 modules packaged together. In the domestic version, 22 modules were used in the early design, and two were combined and covered with mica sheets to appear as a double-spaced module, but the internal structure remains complete. It should be noted that due to the design of the battery box, there are two types of modules, long and short – with 2 specifically small ones.

1. The module was designed as a whole, with 10 modules packaged together. In the domestic version, 22 modules were used in the early design, and two were combined and covered with mica sheets to appear as a double-spaced module, but the internal structure remains complete. It should be noted that due to the design of the battery box, there are two types of modules, long and short – with 2 specifically small ones.

- As the modules are separate, the bus bar has been optimized for a better routing path from a total layout point of view.

The overall design of the battery management system, distribution box, and central routing is basically similar.

The next step for Ford: This generation of Mach-E is more like a start, and in my understanding, due to Ford’s deep cooperation with SK in the United States and adopting Volkswagen’s MEB platform in Europe, it is highly likely that they will continue to use a cooperative model in future small markets in China.

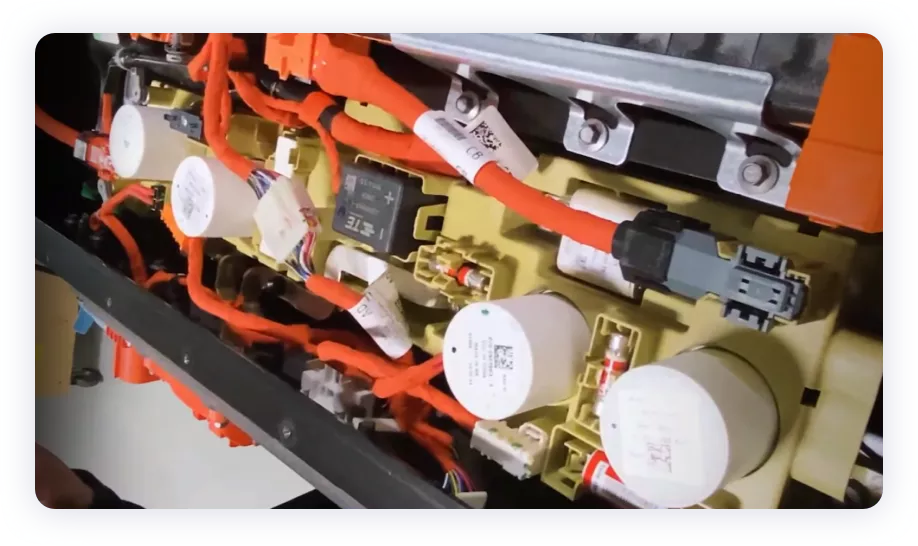

BDU Design

Here I will also talk about my previous job: BDU design.

My personal opinion is that I really don’t like the snake-like arrangement of this type, and the overall layout efficiency here is relatively low.

Looking at the contactor, four large high-voltage contactors and a small contactor from TE are used here, and a fuse is embedded. Overall, it is fortunate that Ford left some space in the length direction, so that there is room for the main fuse and contactor. From the overall insulation point of view, this type of insulation design with plastic seats, combined with the bus quick-insert design, is a more easy-to-assemble approach. If the design targets 800V, similar hanging arrangements combined with embedded busbars are actually more effective for insulation purposes.

Mach-E’s centralized collection is almost identical to iX3’s solution, so the cost of this collection cable and connector is not low. I have analyzed the collection board of iX3 and I plan to do a comparison of this part in the future.

Conclusion: With Tesla importing all lithium iron phosphate batteries, LG’s installation volume has plummeted.I believe that all foreign brands will definitely choose domestic batteries in China. By the second half of 2022, BYD’s installation volume is expected to further diversify, and we will also see more cars from other companies on the assembly line.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.