Michelin

Since the goal of “3060 Carbon Peak and Carbon Neutrality” was proposed, carbon neutrality has become a frequent visitor in the automotive industry.

At various press conferences, we can see the decarbonization plans formulated by various car companies. Recyclable materials have gradually become the mainstream trend in car design. Zero-carbon factories have also been put on the agenda…

However, some people are still making plans, while others have quietly submitted their first-half answer sheets.

At this year’s Bosch Automotive and Intelligent Transportation Technology Innovation Day, carbon neutrality became the main thread throughout the whole event, connecting Bosch’s new technologies and strategies in response to smart and electrification.

Where does Bosch’s confidence come from when talking about carbon neutrality?

What are the innovative technologies in cars related to carbon neutrality?

How do the “study masters” achieve carbon neutrality?

“We have done a lot in terms of carbon neutrality, but few people know about it.” said Chen Yudong, President of Bosch China.

If it were not for the introduction at the scene, few people might have noticed that as early as February 2020, Bosch achieved carbon neutrality in more than 400 business locations worldwide and became the world’s first large-scale industrial enterprise to achieve carbon neutrality. If we compare carbon neutrality to a global exam, Bosch’s performance is undoubtedly that of a “study master.”

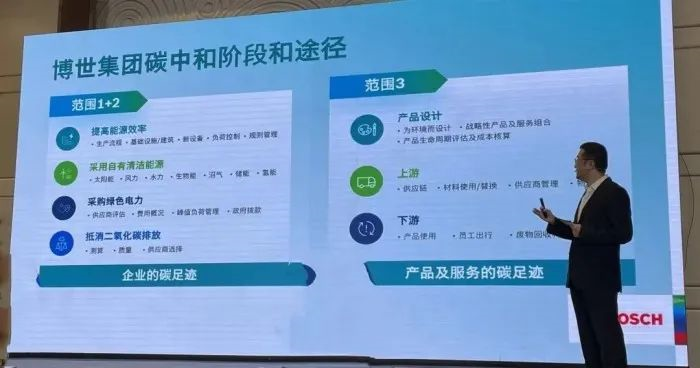

As a large and complex system engineering, Bosch’s method of dealing with carbon neutrality is to divide the goal into different scopes and tackle them separately.

Scope one is the carbon dioxide produced by Bosch’s own factories and offices;

Scope two is the carbon dioxide generated by the electricity purchased from the power grid during the factory and office production processes.

To solve this part of carbon emissions, it is necessary to improve energy efficiency to fundamentally reduce carbon emissions, and to create clean energy as much as possible, using its own clean energy. At Bosch China headquarters in Shanghai, you can see the geothermal heat pump buried a decade ago, regulating the temperature through geothermal energy to reduce air conditioning power consumption. In the Bosch factories in Nanjing, Changzhou, and Suzhou, photovoltaic systems have been established, with an annual output equivalent to the electricity consumption of 6,000 Chinese households.

In addition, the purchase of renewable green electricity during factory electricity consumption has greatly reduced the “big head” of carbon emissions.After the implementation of carbon neutrality in its own factories, the goal of carbon neutrality is extended to a larger scope, which is the carbon emissions generated throughout the full lifecycle of Scope 3 products, including the carbon emissions generated from upstream raw materials and downstream product uses in the automotive industry.

According to Bosch’s data, the carbon emissions generated in the indirect emission stage will be 200 times the carbon emissions of Scope 1 and Scope 2, and the carbon emissions generated during the use of cars, in particular, account for 76% of the total lifecycle emissions. Therefore, although the goal of reducing indirect emissions by 15% by 2030 proposed by Bosch seems conservative in terms of numbers, it is, in fact, a very challenging task when the total amount is taken into account.

Under the dual carbon goals, new demands for intelligent vehicles arise. When it comes to carbon neutrality and automobiles, the first thing that comes to mind is usually new energy vehicles. On Bosch’s Innovation Day, four product lines were shown, including chassis control, hydrogen power systems, engineering technology, and intelligent driving and control business units, which attempted to demonstrate that the relationship between carbon neutrality and automobiles is not as simple as just electric vehicles but a thorough revolution of electrification, intelligence, and interconnection.

Up to now, Bosch’s investment in the field of electrification of powertrains has reached 5 billion euros, and its solutions cover from mild hybrid, plug-in hybrid to pure electric. For instance, the three-in-one electric bridge displayed in this Innovation Day integrates the driving motor, controller, and gearbox into a compact layout. When the three-in-one electric bridge integrates the electronic parking system, the control part will be integrated into the motor controller, and the executive mechanism will be integrated into the gearbox. OEMs can choose according to their needs.

In the fuel cell area, Bosch has set up a dedicated fuel cell center in China, jointly established a fuel cell system joint venture with Qingling Motors, and developed a hydrogen fuel cell power module that can provide compact, efficient, reliable, and easy-to-integrate fuel cell system solutions for various vehicle types and performance requirements.

What is the relationship between intelligence and carbon neutrality? Zhao Shuyan, the Vice President of Bosch Intelligent Driving and Control China, gave the answer: to combine intelligent driving and braking to form a systemic decarbonization solution.During the second day of Innovation Day, we experienced the latest Intelligent Integrated Brake System (IPB) which eliminates the vacuum booster and relies on an internal electric motor for braking. Through the calculation control unit, this system achieves more precise pressure control. During the test ride, the system automatically releases the brakes slightly at the end of a quick stop, ensuring safety and avoiding brake “nodding”. Behind the improvement in comfort, this new technology also has an energy-saving effect. With the IPB system switched on, energy can be recovered better during a 180 km drive, saving nearly 9% of energy.

IVC, the Integrated Vehicle Dynamics Control, showcased on the HiPhi X model, controls braking and rear-wheel steering to reduce turning radius by turning in reverse at low speeds, and turning in the same direction at high speeds to improve stability and reliability. In the test drive, the turning radius was reduced by nearly half a car width when the system was turned on and off.

In addition to the innovation in the braking system, Bosch also showcased other innovative technologies in driver assistance, such as the upgraded Deep Learning Automated Parking (DLP) which uses camera perception to identify parking areas and accurately locate parking spots by recognizing the feature values of four points. The fifth-generation millimeter-wave radar, the Ultimate Version, uses 4D imaging technology to detect the longitudinal height of objects and people more accurately and quickly, with a denser point cloud image.

At the Innovation Day, Bosch announced the upgraded driver assistance system, which further expands the scene of highway driving assistance and the intelligent navigation function on up and down ramps. The launch of these mass-produced functions is thanks to the previous innovative technologies and products. They provide driving assistance, ensure safety, and also contribute to reducing traffic congestion, accidents, and carbon emissions on the road.

“Crypto-neutral is like being a model worker. If you do it, you’re solving the problem for all mankind. But if nobody else does it, we all ‘die’ together,” said Zhao Fuquan, dean of the Automotive Industry and Technology Strategy Research Institute of Tsinghua University, jokingly about carbon neutrality. Facing the severe challenge of climate change, carbon reduction requires not only faith but also investment of time, energy, and capital, which may not yield results in the short term.According to the data provided by Bosch, they invested 42 million yuan in China alone last year to achieve carbon neutrality, and plan to invest 1 billion euros in energy efficiency from 2020 to 2030, not to mention their investment in product development. Are these investments just for show? Absolutely not.

On the one hand, it was precisely the advance layout of Bosch in the low-carbon product line that allowed them to confidently respond to the sudden explosion of the new energy market and provide OEMs with energy-saving and environmentally friendly products and solutions in a timely manner.

On the other hand, the implementation of the dual-carbon policy, the opening of the carbon trading market and green electricity market in the past year have made carbon reduction tasks urgent for domestic enterprises. At this point, Bosch’s investment and successful experience in carbon neutrality enables them to provide more services and suggestions related to carbon emission reduction and energy efficiency solutions. Just last month, Bosch, Wuxi National High-tech Industrial Development Zone, and Weifu Group signed a strategic cooperation framework agreement. Bosch will help Wuxi National High-tech Industrial Development Zone and Weifu to conduct carbon footprint analysis and propose pathways and strategies for achieving carbon neutrality.

These investments in carbon neutrality are gradually transforming into products and experience, ultimately becoming the path for Bosch’s progress.

Final Thoughts

In the past year since the dual-carbon goals were proposed, the concept of “carbon neutrality” has gradually become familiar to everyone, and has evolved from an abstract concept to concrete measures.

What is the relationship between carbon neutrality and automobiles? I believe the Bosch Innovation Day is the best answer: it requires the incorporation of these new cross-border elements such as energy conservation and emissions reduction, green electricity, and carbon footprint analysis; while also constantly exploring the original fields of intelligent automotive technology such as electrification and smart innovation, braking systems, powertrain, driving assistance… All are the new potentials of intelligent automobiles.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.