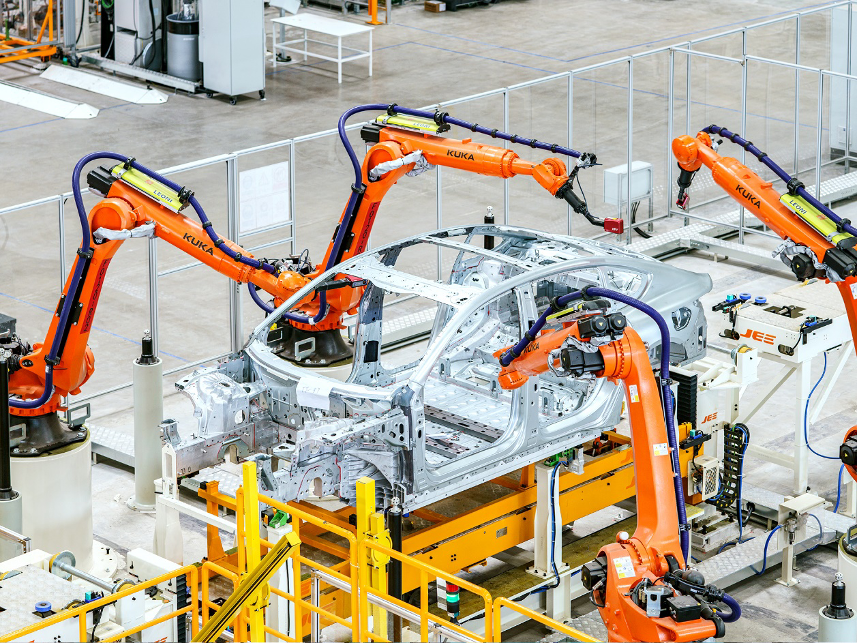

Earlier this year, the JAC-NIO plant in Hefei upgraded its production line and completed key renovations for the body, painting, and final assembly workshops during the National Day holiday period. After more than six months, a phased upgrade has finally been completed, and according to NIO’s plan, this upgrade will be fully completed in the first half of next year. The main improvements during this phase are as follows:

- The addition of 101 robots in the body workshop and upgrading and optimizing the programs of 408 robots, while installing a high-strength steel-aluminum hybrid technology body production line;

- Two new production lines were added to the final assembly workshop, and online tooling and equipment were upgraded;

- The new painting workshop under construction is also progressing as planned.

At present, JAC-NIO’s annual production capacity can reach 120,000 units per year. It is reported that after the factory upgrade is completed in the first half of next year, the estimated annual capacity for complete vehicles and parts can reach 240,000 units, with a peak of 300,000 units. In addition, the second factory in Neo Park will also start production in the third quarter of next year.

Previously, XPeng completed the co-line transformation of P5/P7 at its Zhaoqing factory, with an expected capacity of 300,000 units for the three factories in Zhaoqing, Guangzhou, and Wuhan. IDEAL also plans to use its new factory in Beijing.

From the next stage of capacity expansion plans announced by the three leading new players, people can see their expectations for the growth of China’s new energy vehicle market over the next few years. At the same time, the top new energy vehicle enterprises have gradually transformed their advantages into systems and scale, and the once-difficult-to-control supply chain will gradually rise in this process.

Source: NIO Official.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.