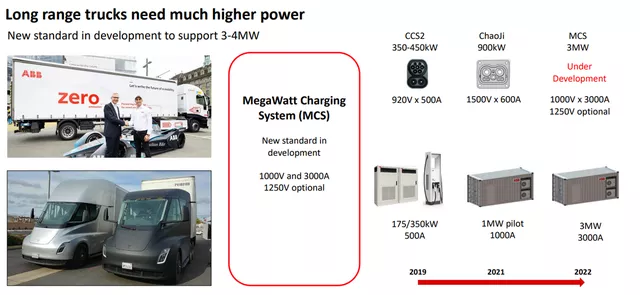

Yes, you read it right. Recently, Europe and the United States have respectively implemented the electrification of heavy-duty vehicles, and the top priority is the design of the super high-power charging standard, which is called the Megawatt Charging System (MCS) in the industry, with a maximum voltage of 1250V and a maximum current of 3000A – I did not add an extra zero.

The boundary between fast charging, ultra-fast charging and high power fast charging is 50kW, 100kW and 150kW, while the bottom line of MCS is 1000kW, that is, charging at the megawatt level.

Target of Megawatt Charging

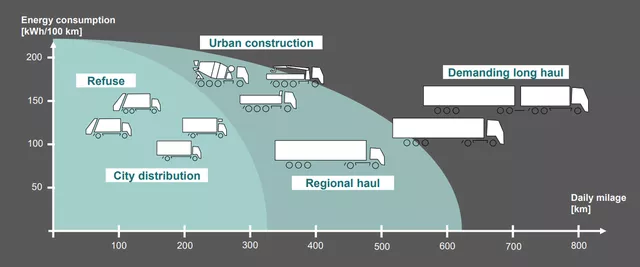

The application of this MCS is mainly for the logistics industry, such as trucks, ships or cargo planes. It is a future-oriented emission reduction solution for transporting goods. According to the European Heavy Duty Vehicle Initiative, user-friendly and fast high-power charging is the key to improving the electrification of this field. In order to meet the market demand for heavy-duty vehicle charging within a reasonable time for trucks and buses, MCS is a necessary high-power charging solution.

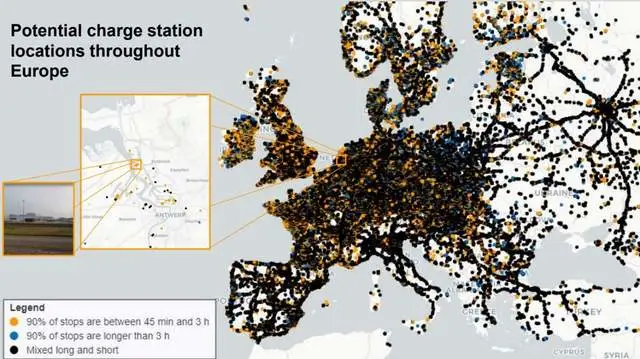

Investment in charging facilities in Europe is the next focus, which will support the penetration rate of electric heavy-duty vehicles in Europe.

This time point is actually very close. We have seen the development of ABB’s 3 MW MCS (1000V&3000A, 1250V is optional), which will be available in 2022.

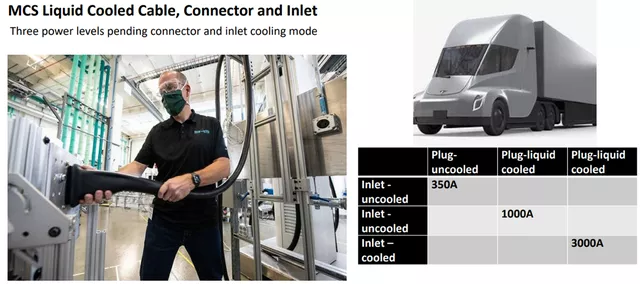

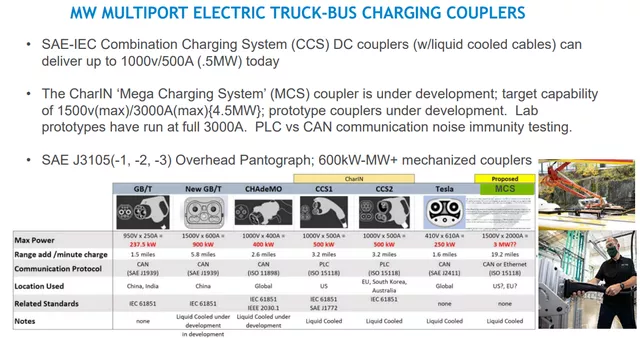

Many people may question what 3000A means. This requires cooling of both the plug and socket at the same time, as shown in the table below. If using plug cooling, the maximum current is 1000A. Looking back at the design, in 2018, CharIN initiated the “Megawatt Charging System (MCS)” working group, based on the previous CCS charging design methodology.On September 23, 2020, a milestone was reached in the testing, feedback, and evaluation of compatibility between MCS charger plugs and connectors by representatives from different industries at the National Renewable Energy Laboratory (NREL). The activity included compatibility testing of seven vehicle plugs and eleven charging sockets.

This means that 2021 is a critical juncture, as Tesla, Daimler, and Volvo’s models enter the final sprint, and the first batch of heavy-duty vehicles based on MCS will gradually land in 2022. I believe that China should support the supercharging standard. Delaying the existing GBT standard is not conducive to the overall technical evolution. Currently, the domestic trend is still leaning towards retaining the original GBT standard, which is not conducive to future domestic charging expansion. If a supercharging standard cannot be achieved, potential MCS cannot be achieved, and this is regrettable.

The Implementation of MCS

WattEV, a startup in the U.S., received $5 million in funding to build a 4 MW EV truck charging station in Bakersfield, California. The funds were provided by the California Energy Commission, and this is one of California’s first solar truck charging stations dedicated to heavy-duty electric trucks. The facility covers 110 acres, has 40 charging stations, and has a solar + energy storage capacity of 25 MW, with a charging capacity of 40 MW. The project will be equipped with light, medium, and heavy-duty charging piles with capacities of 250 kW, 350 kW, and 1 MW. The 1 MW charging pile can charge a pure electric truck to a range of 320 miles in 30 minutes.

In conclusion, I think we can try battery swapping. With the overall layout, the improvement of fast charging globally presents a significant challenge to the design of high-voltage connectors. The upcoming electrification has more technical content than the current internal tangle within the passenger car electrification field. We need to embark on the journey to the stars and explore the unknown.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.