Author: Unknown LYNX

There have been new developments in the recent “lock battery door” incident involving GAC Toyota iA5, which once sparked heated discussions.

Recently, the Guangzhou market supervision department responded to consumer feedback that “GAC Toyota upgraded the vehicle battery management system without the owner’s consent, leading to a decrease in the battery’s power” and stated that they have repeatedly talked to GAC Toyota, collected information and launched an investigation. Based on the investigation results, they will take action and require GAC Toyota to properly solve the problem.

In fact, the issue of electric vehicle “lock battery” and power reduction is not particularly new news. If we only watch the dispute between the rights defenders and car companies without thinking, we may end up in a situation similar to the Tesla “brake failure” incident.

Today, we will discuss the reasons behind the “lock battery” issue and hope to encourage everyone to come up with their own thoughts and answers.

Review of iA5 “Lock Battery Door”

The “lock battery door” of GAC Toyota iA5 broke out on a large scale in July and August of this year. At that time, many car owners found that after the OTA upgrade in July, the vehicle had problems such as reduced charging speed, power attenuation, and reduced cruising range.

The cause of the problem is closely related to this OTA upgrade.

Many affected users found that the originally stated battery capacity of the iA5 at 58.8 kWh was actually limited to around 40-51 kWh after being sent to the 4S store for inspection.

The consequence is naturally a substantial decrease in actual cruising range. In the most extreme case, a user stated that the actual cruising range of the vehicle had dropped by nearly 100 km.

At the same time, not only has the battery power decreased, but the motor output power has also been forcibly locked at around 60%, which means that the power output is far less powerful than before, even if the same amount of gas pedal pressure is applied.

Regarding this, there is a vivid analogy on the Internet: you originally bought a 2.0T gasoline car, but after the upgrade, it turned into a 1.2 naturally aspirated car for shopping, and at the same time, the fuel tank capacity also shrank – no matter who it is, they will be angry, right?

This is the English Markdown text:

In addition, by chance or by design, the most severe OTA version of “Lock Power” is 2510015ARD0000S.B, which has angered iA5 car owners to self-organize a rights protection group and have complained to multiple channels such as 12315, the State Administration for Market Regulation, etc.

The most widely circulated report on the internet is the following report letter, which specifically points out the problems and suspects that Guangqi Toyota’s OTA after the July Xiamen spontaneous combustion accident was intended to conceal vehicle defects and avoid recall responsibilities.

“Lock Power” is a game of safety

Before the official investigation results of the relevant departments are announced, we cannot assert that the “Lock Power” of iA5 is really related to vehicle defects. However, it can be clearly stated that the purpose of “Lock Power” is ultimately for safety.

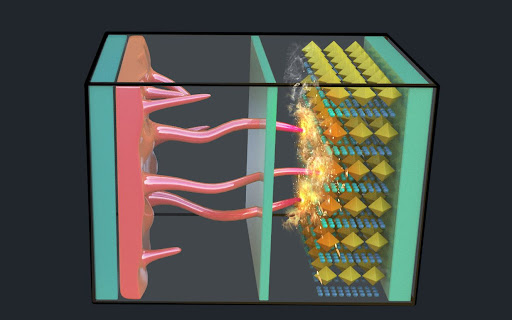

Here we can first popularize the basic principle of lithium-ion batteries. The charge and discharge process is realized by the lithium ions carrying energy through the “insertion-extraction” process between the positive and negative electrodes. We can imagine it as a “lithium-ion swimming pool”:

During charging, lithium ions carry electrons and swim through the electrolyte and into the graphite material of the negative electrode.

During discharging, the lithium ions holding electrons swim back to the positive electrode and transfer the energy to provide power to the vehicle.

The problem is that the bonding ability between the layers of the negative graphite material is relatively weak, and it is easy to peel layer by layer during the charging and discharging process. Its consequences are not hard to imagine, which is to trigger thermal runaway and even cause spontaneous combustion. Luckily, on the side where the graphite is in close contact with the electrolyte, a protective film called the “Solid Electrolyte Interphase” (SEI) layer will be formed during the first few cycles of the battery life. The SEI layer can lock the graphite and prevent the danger of peeling.

However, in the actual use of batteries, if overdischarge occurs, that is, if lithium ions in the graphite layer have been depleted and continue to demand lithium ions from the graphite layer, the lithium ions in the SEI layer have to leave the electrode, causing the SEI layer to be damaged.If the battery is excessively charged, the remaining lithium ions cannot be embedded because the negative graphite layer positions are already filled, which can only precipitate lithium metal on the graphite surface, eventually accumulating lithium dendrites that puncture the SEI layer and cause SEI layer destruction.

In other words, overcharging or over-discharging the battery can cause safety hazards. Of course, automakers understand this and reserve a certain battery capacity in the design of electric vehicles, which is not involved in daily charging and discharging. In more trendy terms, they use “hidden power” to leave enough safety redundancy.

The problem is that the industry currently lacks relevant standards. Naturally, automakers and battery manufacturers will have conflicts and games over the reserved battery capacity. Battery manufacturers naturally want to keep more power for safety and life, while automakers want to minimize the reserved power for cost and better performance parameters.

It is understood that generally conservative companies will control the discharge depth of vehicle batteries at around 85%. However, more aggressive manufacturers for pursuing a more beautiful endurance mileage data may choose to control this value at 90% or even higher.

As for which category GAC belongs to, it is not convenient to assert here. However, judging from its once radical use of 811 batteries and other measures, we can still imagine…

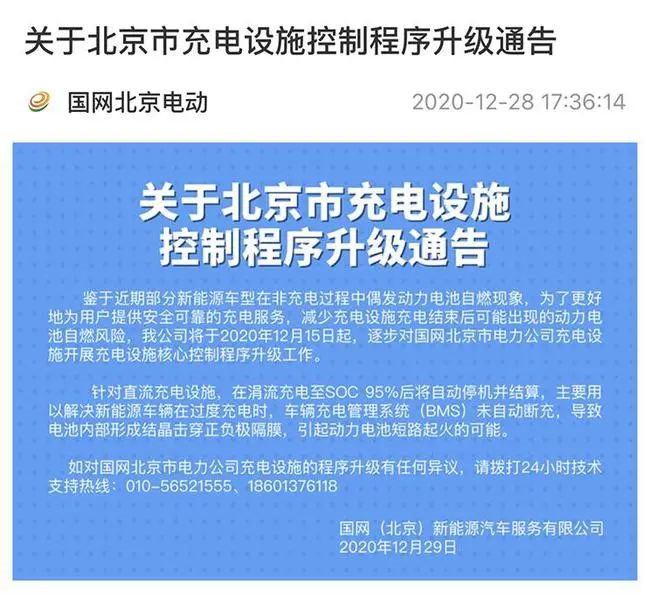

In this process, we should not forget a third party role, the charging operator. No one wants to bear the responsibility for electric vehicle fires. The charging operator will also adjust the charging strategy according to the actual situation to reduce risks.

The most famous example is that State Grid has set a hard threshold that the charging stations in Beijing can only be charged up to 95%.

In addition, with the passage of time, electric vehicle batteries will face aging and decay issues. In order to ensure safety, “locking power” has become the choice of some manufacturers through OTA adjustment of battery management strategies.

In specific operations, the manufacturers limit the voltage of single battery cells, the charging and discharging currents of the battery through updating the BMS battery management system software to achieve the so-called “locking power”.The electric vehicle (EV) battery consists of multiple battery cells that form a single battery pack. Each battery cell follows the formula Energy = Capacity × Voltage (W = E × Q). The battery’s capacity is determined by its electrochemical properties and is an unchangeable “hardware” attribute after production. However, the maximum allowable single-cell voltage during charging can be adjusted via software updates, known as the OTA “battery lock,” which reduces the risk of overcharging and thermal runaway.

The vast majority of EV fires occur during high-state-of-charge (SoC) conditions of 90% or more. Thus, limiting the voltage and reducing the available energy aims to decrease the occurrence of high-SoC conditions and, in turn, reduce the probability of overcharging and thermal runaway.

“Unfortunately, this can lower the vehicle’s available energy and reduce its driving range,” as car owners have experienced slower charging speeds and weaker acceleration.

Limiting the current is achieved by lowering the charging/discharging current, reducing the heat produced during charging and discharging and mitigating the risk of thermal runaway. However, this can result in slower charging speeds and lower acceleration due to the lower available capacity of the battery.

Automakers are not new to the use of OTA battery locks. For example, Tesla Model S experienced several fires globally in 2019, and Tesla responded with OTA software updates that limited the available energy, reduced charging speed, increased hidden energy capacity, and strengthened parking thermal control.

Despite guaranteeing safety, this measure has generated consumer complaints. In May 2021, Tesla was fined in Norway and ordered to pay $16000 to each of the 30 affected owners for its OTA software updates.

In China, the “battery lock door” controversy surrounding the GAC Toyota iA5 is not the first consumer complaint against EV charging limits. Other brands like Roewe and BAIC New Energy have faced similar complaints.

We still need to wait for national standards to be implemented.After reviewing the events and reasons for the issue, we can speculate that the fundamental reason for the “locked battery door” in the OTA update for the GAC Toyota iA5 was to guarantee safety. From this perspective, the manufacturer’s intentions are understandable.

As for the many dissatisfied consumers, the root cause lies with GAC Toyota’s failure to change its traditional business strategy by not providing timely, public, and transparent explanations to consumers, and not offering necessary compensatory measures.

The most unacceptable aspect for car owners in this event was that there was no notification before or after the OTA update, nor was there an option for car owners to decide whether to upgrade or not. The car was automatically and silently OTA updated.

In the past, when people described the convenience brought by electric car OTA upgrades, they often used “wake up, and the vehicle’s functions become stronger” to describe it. But for iA5 car owners affected, they unknowingly “updated” to an electric car with shorter endurance, slower charging, and weaker power.

Therefore, the car owners’ actions to safeguard their rights are undoubtedly reasonable.

As for whether similar events such as the OTA “locked battery door” will occur in the future, we cannot say for certain. We can only call on manufacturers, car owners, and regulatory departments to take active actions to promote standardized behavior.

From the manufacturer’s perspective, the first thing that needs to be done is to improve the product by fully considering the safety redundancy of the relevant battery during the design phase and to clearly disclose the relevant information.

On this point, traditional car giants still seem to be more stable. Take the Audi e-tron GT under the Volkswagen Group, for example. Not only does it retain enough “safety capacity”, but also when disclosing model information, it fully discloses the overall battery capacity and actual available electricity, letting consumers know at a glance how much electricity can be used.

In addition, manufacturers should also timely disclose relevant information during subsequent OTA upgrades, fully protecting car owners’ right to know. In case of any necessity to “lock the battery,” it is necessary to introduce supporting compensatory policies to make up for consumer losses instead of using a “one-size-fits-all” approach to deceive others.

At the consumer level, good driving habits should be developed during daily car use, with an understanding of battery principles and knowledge to avoid damage caused by overcharging or overuse.Translated English Markdown text:

If you encounter events that harm your rights and interests like “Locking the ECU,” you must have a sense of rights protection, actively report the problems to the automakers, and strive for compensation to safeguard your own rights and interests.

However, as mentioned earlier, the root cause of the negative events such as “Locking the ECU” produced by OTA is still due to the imperfect policies and regulations regarding electric vehicles as a new thing. This requires the national regulatory department to strengthen supervision and specify norms for similar behaviors of automakers from the bottom-up rule formulation.

Fortunately, there may be a lag in the establishment of rules compared to the development of new things, but it will eventually be established.

On August 12th, the Ministry of Industry and Information Technology issued the opinion on strengthening the production enterprise and product access management of intelligent connected vehicles, requiring manufacturers to:

-

Ensure that their vehicle products comply with national laws, regulations, technical standards, technical specifications, and other relevant requirements and file them with the Ministry of Industry and Information Technology before implementing online upgrade activities.

-

Declare changes in technical parameters related to safety, energy conservation, environmental protection, theft prevention, and guarantee the production consistency of automotive products.

-

Without approval, new or updated car autopilot functions cannot be added or updated through online or other software upgrades.

The handling of the Guangqi Toyota iA5 “Locking the ECU” incident by relevant departments may be a landmark judgment, worthy of our continued attention.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.