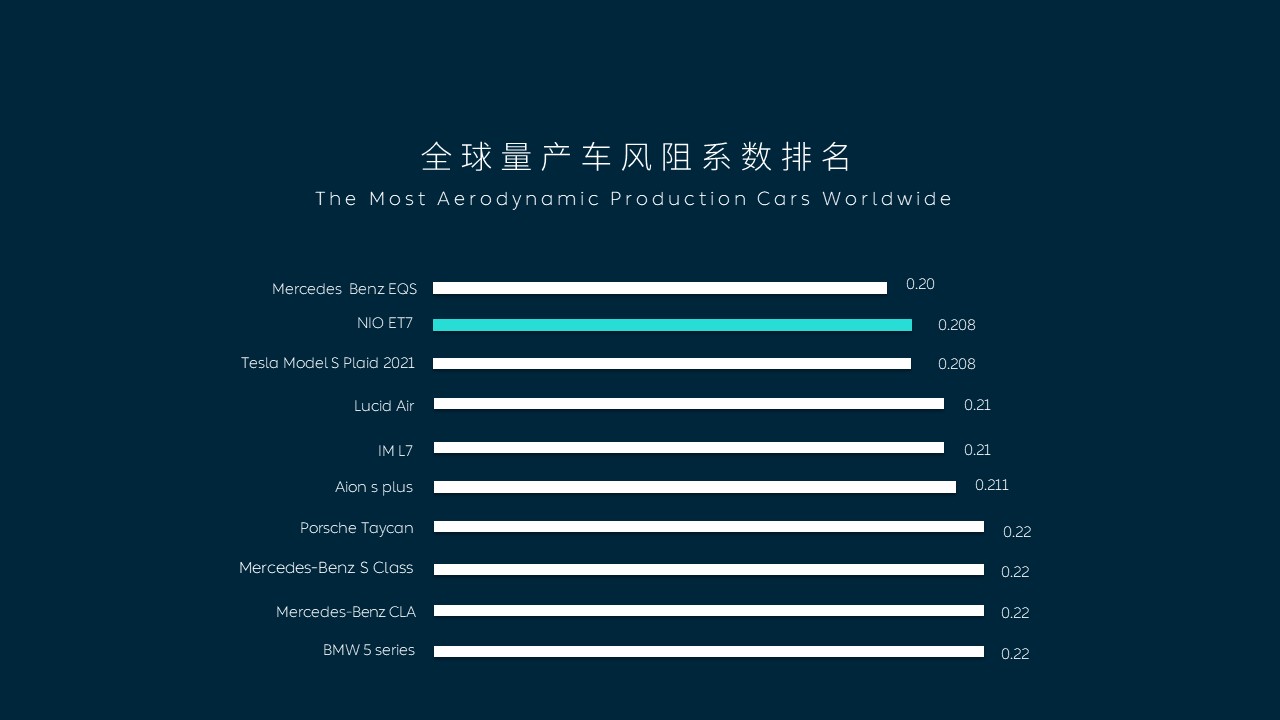

On the afternoon of September 24, 2021, in Chongqing, China, NIO announced the latest drag coefficient of its ET7 sedan:

0.208

Compared to the 0.23 advertised at the NIO Day in January this year, the drag coefficient has been further reduced by about 10%.

First of all, we need to correctly understand the drag coefficient: 🔗Source: Do You Really Understand the Drag Coefficient?

This data makes NIO ET7’s drag coefficient the second highest on the list, just behind the Mercedes EQS, and on par with the Tesla Model S Plaid. The IM L7, which was certified by Changan Institute of Technology just three weeks ago with a drag coefficient of 0.21, ranks second among domestic models with a difference of only 1%, and the third is Aion S Plus of GAC. The appearance of three Chinese brand models on the list also proves that the pursuit of aerodynamics and the technical strength in this regard of the self-owned models have already caught up with the world’s top level.

To ensure smooth battery swapping, NIO’s ET7 body strength needs to be higher than that of other electric vehicles to reduce twisting and deformation. In addition, due to the occupation of battery space caused by battery swapping, the ET7 is significantly heavier and more solid in appearance than other similar electric vehicles. Achieving a drag coefficient of 0.208 under such circumstances is not easy. A low drag coefficient is crucial for electric vehicles with lower energy recovery efficiency and higher high-speed energy consumption, as it has a decisive impact on driving range.

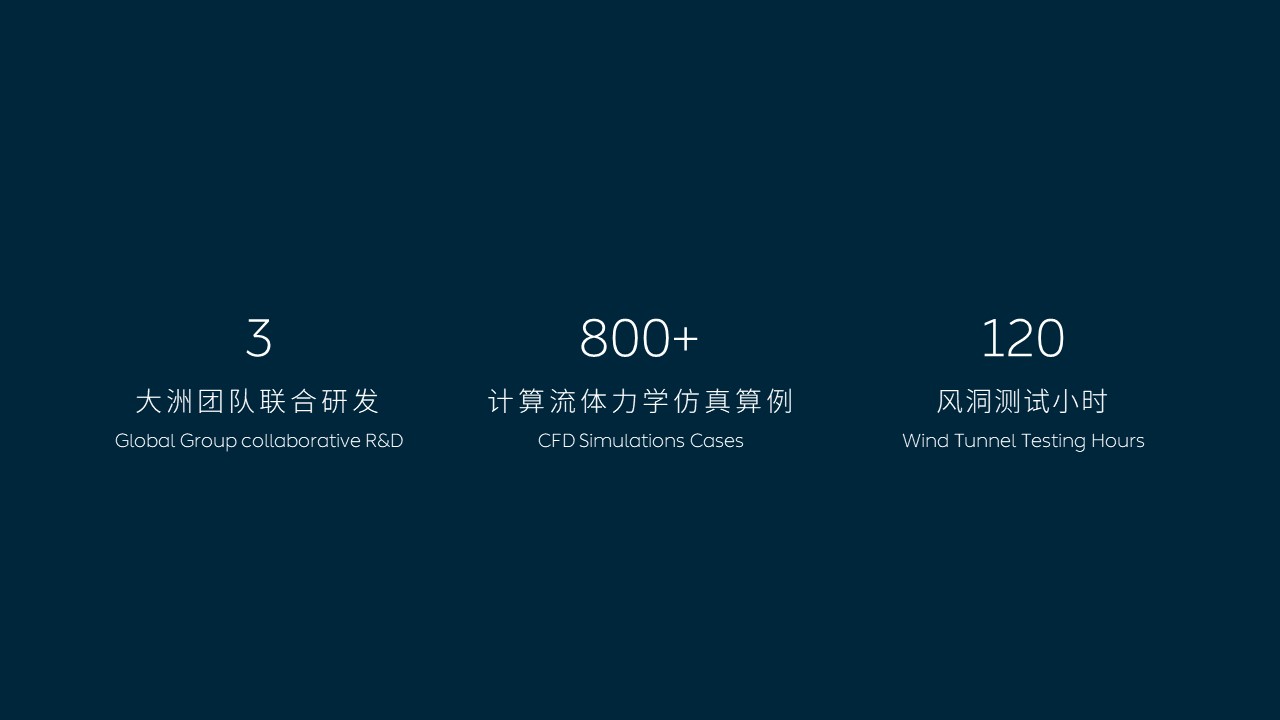

The NIO ET7 was jointly developed by NIO engineers from three continents, and NIO’s aerodynamics team spent two years on more than 800 aerodynamic simulation tests and 120 hours of wind tunnel testing.

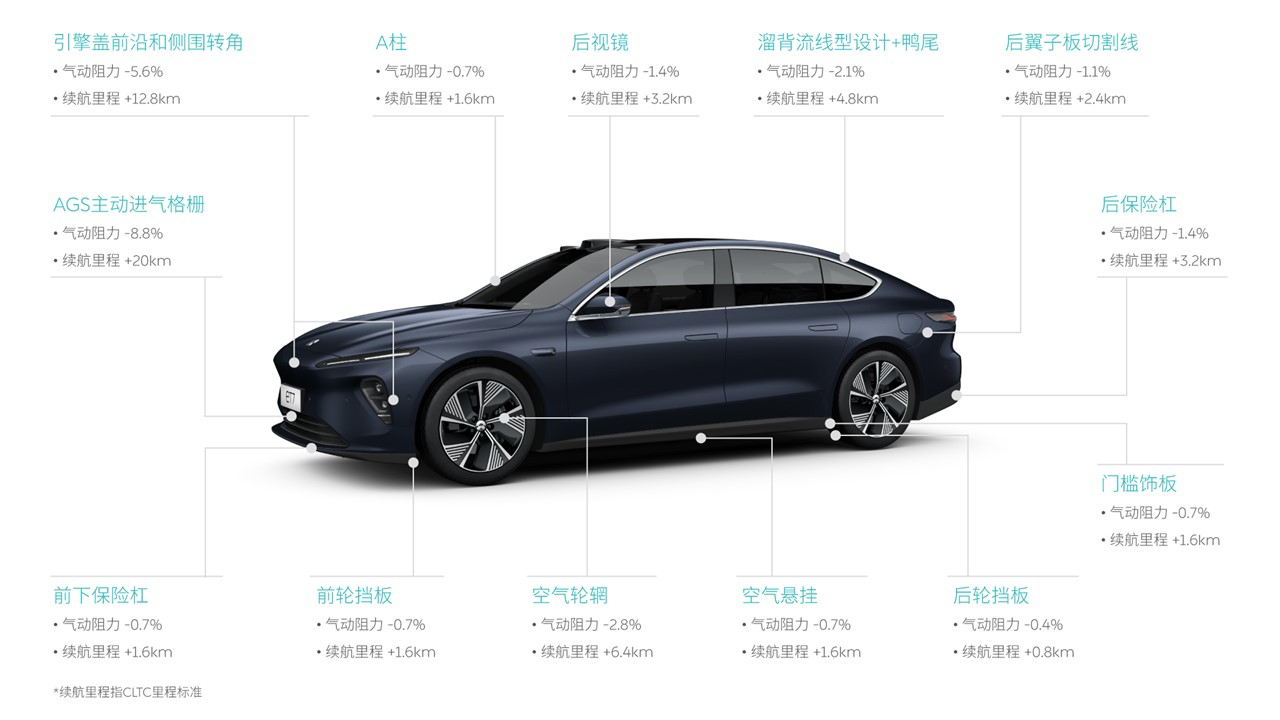

The aerodynamics team was involved in development at a very early stage, during product definition and early styling selection, as they optimized design details such as the windshield angle, headlamp side angle, spoiler streamline angle, C-pillar shoulder line feature, approach angle, departure angle, and wheel rim under the premise of meeting ergonomics and comfort.

The “lookout tower”-style layout of the roof’s ultra-long-range and high-precision lidar and two 8 million-pixel high-definition cameras has a superior detection range and is also a new trend in the exterior design of vehicles in the era of automatic driving. At the same time, such projections pose a huge challenge to aerodynamics. The aerodynamics team has done everything possible to optimize the lidar and camera angles, curvature on both sides, top curvature, and reduce the wind resistance coefficient to the limit.

In addition, the ET7 is also equipped with an active air intake grille as standard across the board, which can better balance the needs of heat dissipation and reduce resistance. It can reduce the air suspension’s ground clearance and also help to reduce wind resistance under high-speed conditions, thus reducing power consumption. The chassis is covered with lightweight protection plates for all-round coverage, which is also a pursuit of perfection in detail.

As for the number 0.208, according to NIO staff, it is obtained when equipped with the same type of hub shown in the figure and rotated. We also look forward to NIO’s early release of relevant certification from the China Automotive Technology and Research Center to confirm the ET7’s first place in China.

🔗 Source: NIO

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.