Author: Chang Yan

From childhood to adulthood, there is a game genre that has stood the test of time, called “spot the difference”.

In this game, the source of fun is roughly like this: the more subtle the differences between two pictures, the more difficult it is for people to notice, the more fun the game is.

From this perspective, the NIO ET7 has presented a marvelous game today.

You see, this is the ET7 that debuted today.

Compared to the ET7 that appeared at NIO DAY earlier this year, even if you enlarge the details for me to see, I cannot tell the difference.

But these two cars are different.

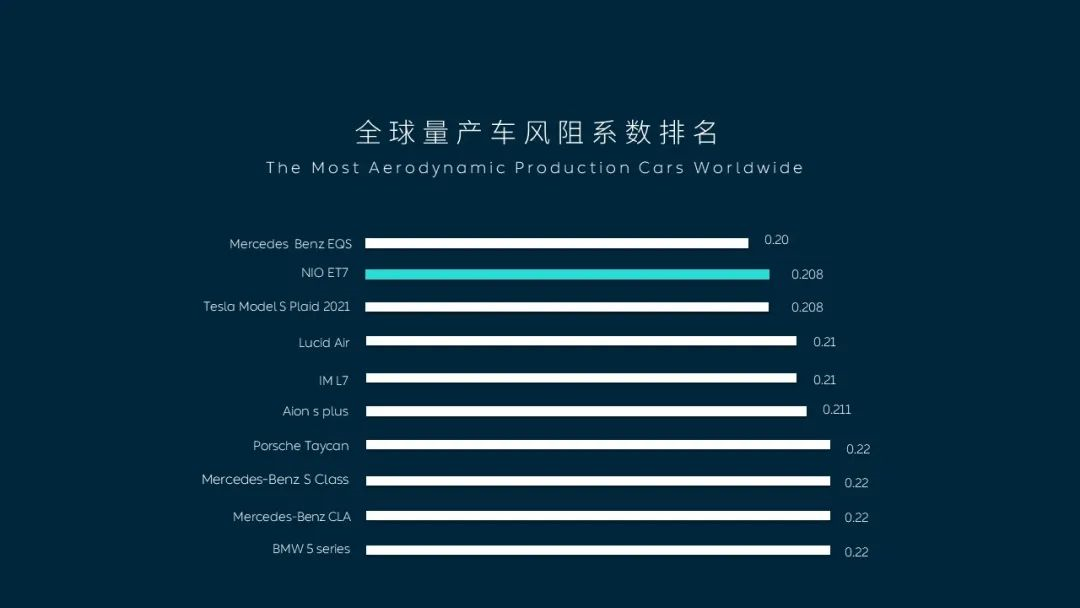

The aerodynamic coefficient of this car has been optimized from 0.23 of the one earlier this year to 0.208.

This result is second only to the Mercedes-Benz pure electric flagship EQS and is tied with the Tesla Model S Plaid, achieving second place in the world.

Mobilization of All Forces

From the positioning of the ET7, it is not easy to achieve this result.

On the one hand, the ET7 is the first sedan of the NIO brand, and the design needs to have a high degree of recognition of the NIO family characteristics while adapting to the new body shape and then doing detailed optimization.

On the other hand, the price and size positioning of the ET7 determine that its design cannot be too bizarre, it needs to have the space size and stable and dignified feeling that this level of car model should have, and then consider the issue of air resistance.

If you calculate more, the ET7 is also NIO’s first vehicle to adopt a lidar and a tower-type sensor layout design, and many optimizations of its shape cannot be easily done with just a designer’s brushstroke. It also requires close cooperation between the product department and the factory team.

In addition to organizational structure, it also means multi-site cooperation in geography.

# Maximilian Ludwig Ganis, Deputy Director of NIO’s Aerodynamics and Thermal Management Team, told us that the aerodynamic drag optimization of ET7 involved personnel from departments in China, North America, and Europe. To achieve the best results in a limited time, they adopted a flatter and more efficient mechanism, making rapid product iteration possible.

# Maximilian Ludwig Ganis, Deputy Director of NIO’s Aerodynamics and Thermal Management Team, told us that the aerodynamic drag optimization of ET7 involved personnel from departments in China, North America, and Europe. To achieve the best results in a limited time, they adopted a flatter and more efficient mechanism, making rapid product iteration possible.

In the end, NIO completed more than 800 aerodynamic simulations and 120 hours of wind tunnel testing in two years.

The car owner may be the biggest winner

Let’s return to the “game” illustrated below for a moment.

There are already as many as 13 subtle differences between the two cars.

In the overall technical explanation, Maximilian Ludwig Ganis paid close attention to every edge and corner of the car. It can be said that any slight adjustment from any angle would affect the smoothness of the airflow through the car and consequently change the overall effect.

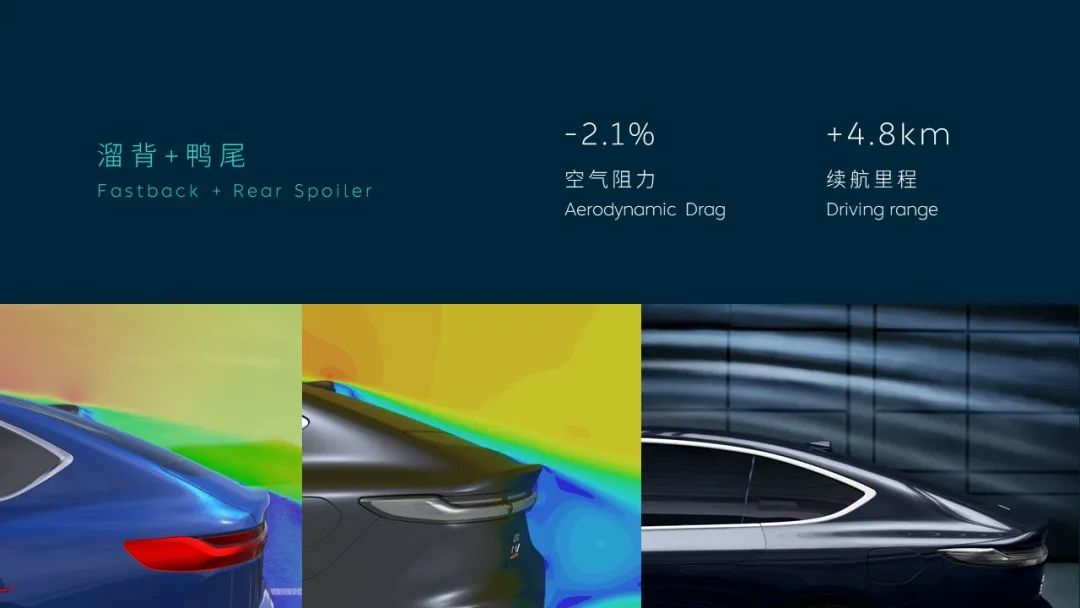

Finally, there are 13 subtle adjustments made on the car body, including the front windshield angle, headlight bezels, streamlined roof angle, C-pillar characteristics, approach angles, departure angles, wheel rims, front bumper hood transition angle rounding, rounding of the lower front bumper, corner rounding of the headlights and fenders, the curvature of the lower and upper mirror housing, the thickness of the mirror handle, the curvature and height of the trunk lid, door sill trim, front and rear wheel guards, etc.

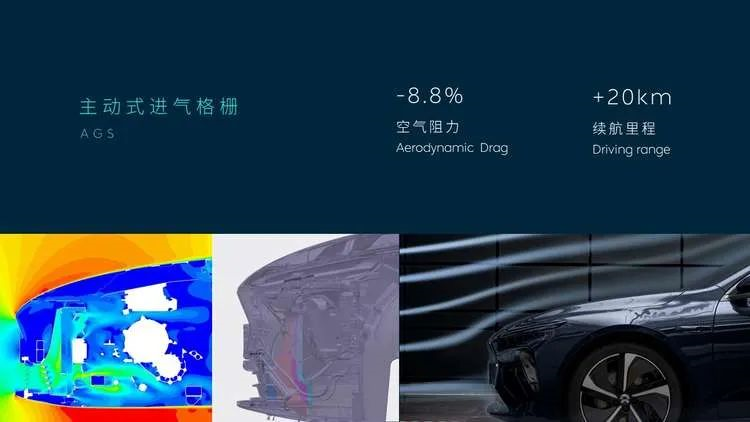

It is worth noting that the AGS active air intake grille, air suspension, and lightweight underbody armor plate, which are standard on the ET7, also played a significant role in reducing the drag coefficient.

You can find the effect of each improvement and how it impacts the crucial dimension of range from the chart below, which is similar to “dissecting the ox.”

It can be seen that the vast majority of the top ten vehicles in global aerodynamic performance optimization are pure electric, especially high-end pure electric vehicles.

Apart from the reason that electric cars have triggered a new round of design changes, what is more important is that low wind resistance has a significant practical effect on pure electric car users.

Firstly, it helps to increase the range. When calculating the actual resistance, the impact of wind resistance on the results should be squared. Therefore, for electric cars, under the same conditions, reducing the drag coefficient by 0.01 can increase the pure electric car range by about 5-8 km.

Secondly, it helps to improve visibility. By adjusting the direction of airflow in different dimensions of the car body, the effect of cleaning the car body can be achieved by guiding the airflow, such as the ET7, which can improve the cleanliness of the external rearview mirror by 80% after the styling adjustment, showing better availability and visibility.

Thirdly, it helps with autonomous driving. Maximilian Ludwig Ganis mentioned that the current final solution for the direction of airflow can also help to keep the ET7 roof lookout tower cleaner and achieve the best use effect.

The consecutive convening of two recent NIO press conferences not only awakened more interest in the ET7 but also may have new impacts on everyone’s configuration choices. For example, please remember that the drag coefficient test of 0.208 was achieved when using low-drag wheels. At the same time, when the base range optimization is better, the 75kWh battery solution also reflects a higher cost-effective choice, which helps ET7 attract more budget plan users.

Since I posted this news on Weibo today, it has also sparked a lot of discussion. Someone asked directly: Does a low drag coefficient always mean a good car?

I said, no, but at least it shows that their technology and attitude are unique.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.