*This article is reproduced from the “autocarweekly” WeChat official account.

Author: Hookonws

“Sales Ranking of Pure Electric Cars Over 300,000 RMB”, “Sales Ranking of High-end Electric Cars Over 400,000 RMB”, “Sales Chart of Luxury Electric Cars Over 500,000 RMB” … There are more and more high-end electric cars, and rich people almost can’t use them up.

However, the increasing luxury of electric cars is of little constructive effect on the “big trend”. More than 75% of passenger cars sold in China each year are priced below 200,000 RMB, and more than 60% are less than 150,000 RMB – it’s the Corolla, Santana, Passat, not the “34C” or “56E” that we all dream of.

High-end users generally have more time and space freedom, which means they are less sensitive to charging issues. If the “big trend” satisfies only 30% of high net worth users, it can never become a “big trend”. The energy revolution is not driven by luxury cars that can go from zero to 100 km/h in four seconds with thousands of horsepower. History tells us that the revolution is “pushed out by the people with small cars.”

Volkswagen’s ambitious MEB plan has not achieved a great start in China. With over 10 billion RMB in investment, a new factory in North and South China respectively, and the accurate targeting of SUV sales with the ID.4 and ID.6 models, market response has been slow. The total sales of these two/four (depending on whether they are calculated separately for North and South) models in August just exceeded 7,000 units. As for the “electric era Golf” ID.3, the compact two-door car is nothing more than a failure. Normal people should not expect the “Golf” to support sales.

Of course, Volkswagen may have hoped that the ID.4 or ID.3 would be a smash hit, which is understandable, but failure to achieve this cannot be considered a disaster. Because the final sales redeemer of the MEB plan is not the ID.6 or ID.4 or ID.3, but the concept car ID.LIFE launched at the IAA Munich Auto Show in early September – oh no, it’s actually underneath it.Volkswagen and most media outlets love to tell you about the sci-fi and futuristic features of the ID.LIFE concept car, such as “splattered ink” paint, a removable roof, and in-car movie viewing, among other things. However, the most important significance of the debut of this concept car is unrelated to its exterior and interior, as Volkswagen has publicly announced the front-wheel drive configuration of the MEB platform for the first time, which indicates cheaper cost.

If you haven’t heard of it before, the MEB is Volkswagen’s brand new all-electric exclusive platform, equivalent to the MQB platform in the era of electric vehicles. The extremely wide platform can cover compact cars such as the ID.3 to three-row SUVs such as the ID.6. In addition to the Volkswagen brand, Skoda, Seat, and Audi’s entry-level pure electric models are also based on the MEB platform.

The current batch, also the earliest batch of MEB models, such as the Volkswagen ID.3, ID.4, ID.6, Audi Q4 e-tron, and so on, all use the rear-wheel drive configuration of the MEB platform (including its four-wheel drive version). This rear-wheel drive-based MEB configuration was once equivalent to the “MEB platform” itself until the ID.LIFE concept car brought out the front-wheel drive configuration of the MEB platform.

The initial release of the MEB platform, or what should now be called the rear-wheel drive configuration of the MEB platform, was in a state of trying to reduce costs while having surplus driving performance. Why does a small car like the ID.3, which is benchmarked against conventional gasoline Golf, use rear-wheel drive (and its four-wheel drive based on rear-wheel drive)?

In the era of electric vehicles, rear-wheel drive is indeed much easier than in gasoline vehicles: smaller electric motors can be easily arranged on the rear axle without the need for a drive shaft running through the body from front to back. However, even so, using a front-wheel drive layout in an electric vehicle will still have cost and space advantages over rear-wheel drive.

In other words, the rear-wheel drive configuration represented by the ID.3 is not the most “affordable” configuration of the MEB platform.The MEB platform with rear-wheel drive standard layout can be upgraded to all-wheel drive by adding a front motor. The front suspension is a vanilla MacPherson structure, while the rear suspension, due to the RWD, uses a five-link independent structure. This is the same setup as found in a host of new-generation electric vehicles including the Model 3.

The independent five-link suspension is one of the ultimate solutions for modern passenger car rear suspension, especially for electric cars. There are five large hardpoints on both the body and the steering knuckle of the five-link suspension, making it better suited for the instantaneous high torque of an electric motor. It also provides less pressure on weight and cost.

Tesla’s Model 3/Y, Hyundai’s E-GMP platform, VW’s higher-end PPE platform, the Mercedes-Benz EVA platform, Lucid Air, and a host of other high-performance, RWD-based electric vehicles all feature five-link rear suspension.

The original RWD configuration of the MEB platform has brought about two problems and two advantages.

The first problem is that the rear motor and five-link suspension take up space under the rear body of the car, making it difficult to arrange a low floor height for the cargo area and a spare tire. The ID.3 to ID.6 do not have spare tires, partly due to weight reduction, and partly due to space issues.

The second problem is that the five-link structure is not a low-cost option. The 20 bushings required for the five rods alone are enough to strain cost management.

The first advantage is that rear-wheel drive allows these MEB models to have a higher power output limit. Because the conventional front MacPherson suspension has limited tolerance for high power, adding a high-performance motor to the rear axle allows the front axle to be powered by a small electric motor, forming all-wheel drive. This maximizes the advantage of electric power over fuel, making it perfect for the initial focus on the European market.

The second advantage is that the electronic control system and the motor are concentrated in the rear of the car, making the charging port easier to arrange in a more convenient location on the rear fender, and requiring shorter high-voltage lines.

In fact, the RWD configuration of ID.3 and the MEB platform is the result of Volkswagen’s careful control of costs. Because electric vehicles have a considerable battery cost, in order to sell ID.3 at a price comparable to that of the same level of gasoline vehicle (Golf), Volkswagen has previously revealed that the whole vehicle cost of ID.3 excluding the three-electric part is only half of that of the electric Golf e-Golf. Yes, the pure electric platform is cheaper than oil-to-electric conversion.

The most illustrative example is the controversial rear drum brake. The prerequisite for MEB platform to use rear drum brakes is RWD and rear motor. Only with the help of energy recovery function of the rear axle motor, can the braking pressure of the relatively less important rear wheels be greatly reduced, and drum brakes as a cost-reducing measure will become a realistic consideration (you will see the magical reversal of FWD MEB later).

In short, the existing RWD configuration of MEB platform is a form that is difficult for us to understand: on the one hand, it makes great efforts to improve the basic driving performance, on the other hand, it strives to reduce costs to the utmost. The latter determines that it will face some questions in the initial stage; and the former determines that it is only suitable for the boutique small cars of European style and the medium and high-end market of over RMB 200,000.

However, Volkswagen’s ambition for MEB is not only that. In order to achieve breakthroughs in sales, Volkswagen needs not only an “electric (European version) Golf”, but also the “electric Lavida” and “electric Bora” armies.

“Make-do” for less than 150,000 yuan

Although the title “Electric Era Golf” sounds impressive, the era of Golf has long gone. As discussed in “Why is there such a big difference between buying electric cars in the east and the west?” in this huge market of China, driving performance is only the icing on the cake rather than essential, and space and affordability are the guarantee of sales, which is the real demand of the people.

I first learned about the fact that besides the existing RWD configuration, MEB platform also has a cheap FWD and rear torsion beam configuration a year ago. If you look at the sales ranking of pure electric vehicles in China, you will find that almost all 100,000-150,000 yuan electric vehicles on the list are of this configuration. This is the stage reality of the development of electric vehicles: the still considerable battery cost squeezes the budget of the whole vehicle.The difference of the MEB front-wheel-drive configuration lies in that it is still an MEB, a brand-new, next-generation platform developed entirely for pure electric drive.

In Europe, it will become a smaller model than the ID.3, such as the production version of the ID.LIFE; while in China, it will eventually evolve into the “MEB version” of the Lavida and Bora. Volkswagen said that the production version of the ID.LIFE concept car will start at around €20,000, or about RMB 150,000. The “MEB Lavida” can be seen as a larger version of the ID.LIFE, with a target price of RMB 150,000, or even lower.

Therefore, the appearance of the MEB platform front-wheel-drive configuration indicates that Volkswagen is ready to sell electric cars—the truly pure electric new platform electric cars—to the 70% economy-level users.

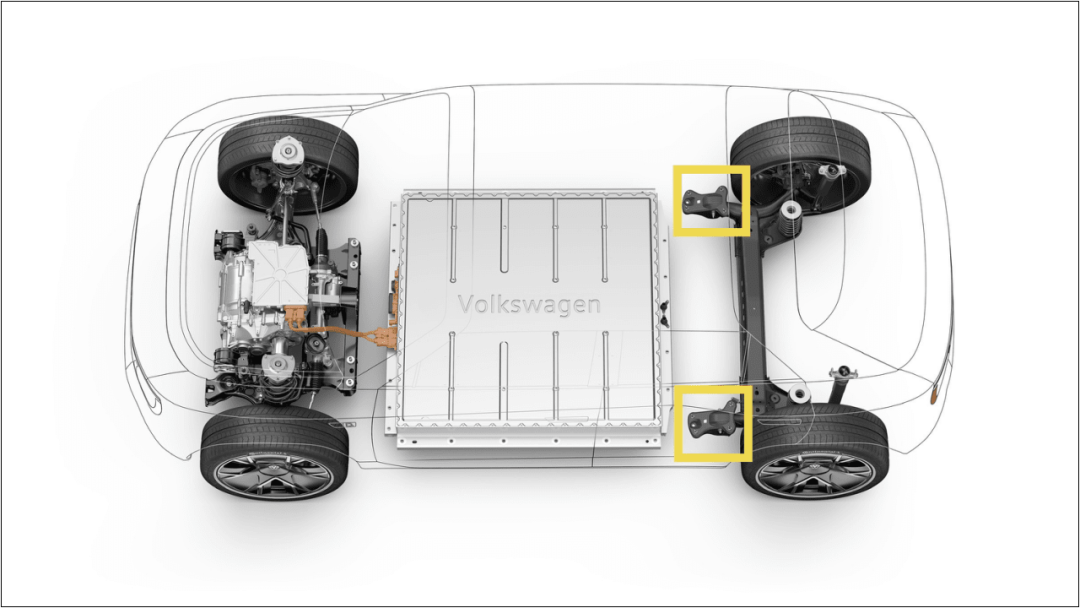

Compared with the rear-wheel-drive MEB configuration of the ID.3, the front-wheel-drive configuration exhibited by the ID.LIFE not only eliminates the rear electric motor, changes rear-wheel drive to front-wheel drive, and changes the rear five-link suspension to torsion beam.

First of all, if you observe carefully, you will be surprised to find that the ID.LIFE rear axle is equipped with disc brakes, instead of the rear drum brakes that are consistent with the ID.3 to ID.6.

Although the ID.LIFE is just a concept car, the “concept” mainly refers to the surface decoration inside and outside the car, and the core of the new MEB front-wheel-drive configuration is referential. Under the front-wheel-drive configuration, there is no motor on the rear axle to recover energy and reduce brake pressure, so the rear wheels should return to normal disc brakes.

With drum brakes for cars costing RMB 200,000 and disc brakes for cars costing RMB 150,000, electric cars are changing common sense in unexpected ways.

With the change from rear-wheel drive to front-wheel drive, and the lack of pressure from the driveshaft on the rear axle, the rear suspension is directly replaced with a cheaper torsion beam. On the one hand, this greatly reduces costs; on the other hand, it frees up space under the rear trunk, making it more convenient for expanding trunk capacity or arranging spare tires, as clearly seen in the space between the rear wheels in the above picture.However, the torsion beam suspension on the rear of the front-wheel drive (FWD) MEB also limits the battery range compared to the rear-wheel drive (RWD) MEB models of the same size. This is because the hinge point between the torsion beam rear suspension and the vehicle body extends forward, occupying a portion of the space that could have been used for the battery between the front and rear axles. However, FWD MEB models are primarily intended for entry-level, low-cost vehicles, so there is limited impact in reality since there are no conditions for stacking batteries on a cost basis.

The front MacPherson suspension has limited adaptation capability for high power, and since the threshold for choosing RWD over FWD has been significantly lowered for electric vehicles compared to traditional fuel vehicles, the FWD MEB configuration is inevitably limited in terms of power (the RWD configuration can have a larger rear motor and a smaller front motor as mentioned before). The ID.LIFE concept car, which has 234 horsepower and can go from 0 to 100km/h in 6.9 seconds, is a rough representation of the power ceiling for this MEB configuration.

In the RWD MEB configuration, the motor and electronic control system are concentrated on the rear axle, leaving more space for the front axle, even for the front motor in the four-wheel drive version. The steering gear in the four-wheel drive ID.3 can thus be placed at the bottom of the front motor, allowing the steering rod to be positioned in front of the drive shaft and the front brake caliper to be positioned at the rear of the brake disc. Rear calipers are beneficial for the ventilation and heat dissipation of the front brake system, as well as the weight distribution of the entire vehicle.

In contrast, in the FWD MEB configuration, the motor and electronic control system have been moved entirely from the rear axle to the front axle, resulting in a more congested front axle space. This makes it impossible to position the steering rod at the front and necessitates moving it to the rear of the front motor, which means the front wheel brake caliper is once again located in front of the brake disc.

This caliper placement method, which positions the brake caliper facing away from the front airflow, is relatively disadvantageous for brake system heat dissipation. This is very common in traditional fuel cars with transverse engines, where the space in front of the front axle is occupied by the internal combustion engine, necessitating the placement of the steering rod at the rear and, consequently, the brake caliper at the front. However, electric vehicles do not have this problem, since they are more easily able to achieve ideal layouts than fuel cars, unless cost reduction is necessary.The reason why the rear charging port, which is very convenient for ID.3 and other rear-wheel drive MEB models, has been moved to the front of the car on the ID.LIFE concept car is because the entire motor and motor control system has been moved to the front axle. This approach reduces the length of the high-voltage line, saving weight and cost, but at the cost of the convenience of reversing into the charging station. For models with the electric drive system located in the front, moving the charging port to the rear requires longer high-voltage lines. It is worth debating whether to pay these costs and weight for low-cost front-wheel drive electric cars.

In fact, any means of reducing costs and pursuing economic benefits, whether it is the two configurations of MEB platform, fuel platform, or pure electric platform, require compromises other than cost. Those practices that deviate from the ideal engineering approach are ultimately due to cost or indirect cost, and any ideal engineering approach will always pay more space or cost.

There is no free lunch in the world, and there is always a cause for every effect.

The “New” Value of the New Platform

Compared with the rear-wheel drive MEB configuration of ID.3 to ID.6, the front-wheel drive MEB configuration of ID.LIFE has made compromises directly or indirectly for cost in all aspects. But don’t think that this means the front-wheel drive MEB is not good. It is still a brand new pure electric platform that even in its inexpensive version has significant advantages over the oil-to-electric conversion products in the low-cost market.

The ID.LIFE concept car is only a small SUV about 4.1 meters long with a wheelbase of 2.65 meters (smaller than the MINI COUNTRYMAN). Yet it is equipped with a 57kWh battery pack, even though the battery size is constrained by the rear suspension structure. It can be imagined that if it were extended to the size of a mid-size car, the upper limit of battery capacity would be even higher.The reason is simple: the collision-resistant body structure of the gasoline-powered car platform often conflicts with the flat battery pack required for pure electric vehicles. The result is either a peculiar-shaped battery pack inserted wherever possible (such as the e-Golf and Volvo CMA platform electric vehicles in the figure above), or an elevated body “hanging” below the chassis, sacrificing weight, space, ground clearance, battery capacity, and other features. And redesigning these most basic body structures is basically equivalent to developing a brand new platform for pure electric vehicles.

So even the inexpensive configuration of the MEB platform, the advantage of a pure electric platform still exists.

The ambition of the MEB platform is so great that it not only targets the critical 150-250 thousand yuan market but also has made serious and sufficient preparations for the inexpensive market below 150 thousand yuan. Covering the brand-new pure electric platform to the lowest point of the company’s product line is the sign of judging whether a car company is genuinely all-in on pure electric (regardless of whether it is too early to be all-in).

We always focus on the high-end, luxury, and “wow” aspects of the car industry but seldom realize that only when those who rely on cars as their only means of transportation choose pure electric vehicles, only when the user groups of models like Xuan Yi, Bao Lai, Lang Yi, and Ka Luo La have choices, can the so-called “big trend” escape from being merely a trend and become a reality.

A glance at the market for economical pure electric vehicles, you will find that there are only two options: conversion from gasoline to electric or repeated iterations of the conversion, with no real based on pure electric platforms. Domestic automakers are obsessed with “brand upgrading,” new manufacturers prefer to “shoot for the stars,” and luxury joint ventures emphasize “maintaining position.” As some people enjoy Tesla’s Supercharger and exclaim that gasoline-powered cars should be eliminated, I can’t help but feel sorry for the old beat-up electric cars charging by the power lines in the community.

To catch up with the “high difficulty,” the only possibility is to develop a new platform and sell it at a low price without losing money, which is much more challenging than stuffing a few motors into a car and selling it as a high-end vehicle.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.