The legendary AB battery has arrived!

At 2 PM today, NIO officially released a 75 kWh ternary lithium iron battery, which came quite unexpectedly.

According to official information, new customers can now choose either the ternary lithium standard range battery pack (75 kWh) or the ternary lithium extended range battery pack (100 kWh). The price and BaaS price of the model with a 75 kWh battery pack are the same as those of the original ternary lithium 70 kWh battery pack model.

This essentially means that the production of the 70 kWh ternary lithium battery pack has been discontinued, but it will continue to serve as a “standard range battery pack” and remain in service at battery swapping stations.

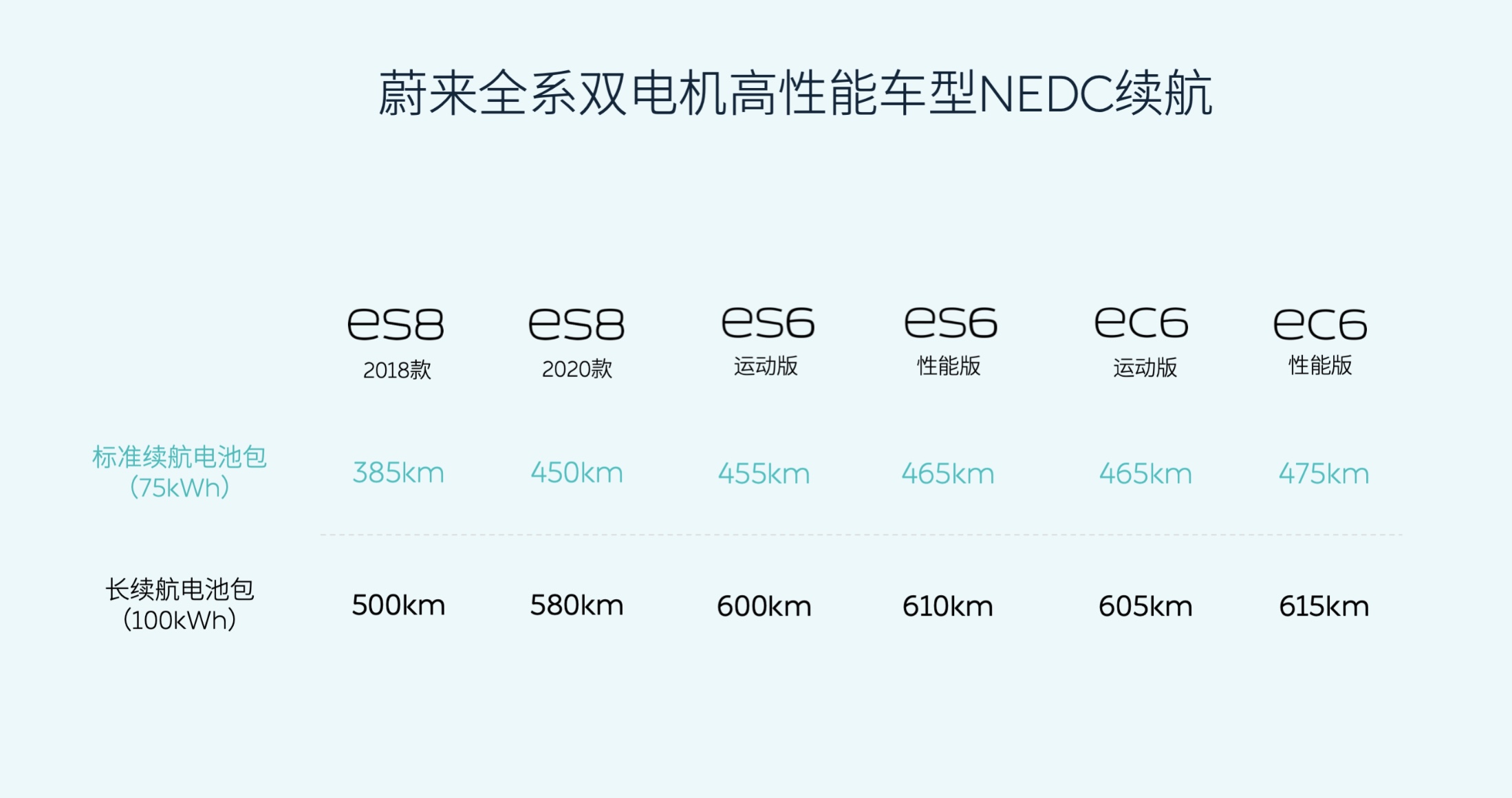

What? What is ternary lithium iron, and is it a joke that only adds 5 kWh capacity? Before understanding this new term, let’s first take a look at how much range increase this new battery brings:

You may think that a range increase of only 30-35 km is not that impressive. However, it is actually the first ternary lithium iron battery pack on the market.

In fact, ternary lithium iron is not a new battery chemistry material, but a technology that mixes two types of cells: ternary lithium and lithium iron phosphate, in one battery pack. It may seem simple, but it is actually quite challenging.

BYD’s main blade batteries are also lithium iron phosphate; Tesla and XPeng have successively adopted lithium iron phosphate batteries in their entry-level models of main vehicle types. However, NIO did not want to use a simple lithium iron phosphate battery. And in fact, a previous lithium iron phosphate battery with an actual capacity of 68 kWh was rejected by “honest” Bin brother due to reasons such as winter range.

Perhaps because of this insistence on user experience, NIO has become the first car manufacturer in the world to mass-produce the technology of using a mixed cell battery pack of ternary lithium and lithium iron phosphate. Today, let’s take a closer look at this new battery pack, what makes it powerful, what challenges it faced, and how it will move towards mass production.

Understanding the cell materials

Before discussing why NIO chose a hybrid cell battery pack, let’s first talk about the differences between two different cell materials.

Among them, the positive electrode material, as the core material, directly determines the nomenclature and charge-discharge performance of the cell. Ternary lithium and lithium iron phosphate batteries are the two most mainstream routes. The “ternary” in the former refers to nickel, cobalt, manganese (or aluminum), abbreviated as NCM or NCA.

Ternary LithiumThe biggest advantage of ternary lithium lies in the higher energy density in both volume and mass than that of lithium iron phosphate. In other words, for the same range, ternary lithium batteries are lighter and smaller. Pursuing higher energy density is an ongoing effort as long as range anxiety exists. Increasing the proportion of nickel is key to achieving higher energy density, but doing so will make the battery’s chemical properties unstable, affecting its lifespan and potentially leading to thermal runaway and fire or explosion due to oxygen release in the battery core. Additionally, the cost of ternary lithium batteries is higher, which is a critical factor for mass production vehicles.

Lithium iron phosphate’s biggest advantages are safety and low cost. The P-O bond strength in lithium iron phosphate crystals is higher, and can withstand about twice the temperature that ternary lithium can. Even if it decomposes, it will not release oxygen, resulting in lower risk of spontaneous combustion. Its superior chemical stability also allows for more cycles. Moreover, lithium iron phosphate does not contain the expensive cobalt element that has seen a sharp increase in price in recent years, which is the main reason for the cost difference. Its disadvantages, however, are also prominent, namely its lower energy density, only about 3/4 of that of ternary lithium, and significant capacity decline at low temperatures. Moreover, due to the little change in voltage during the charging and discharging processes of lithium iron phosphate, it is very difficult to estimate its state of charge (SoC).

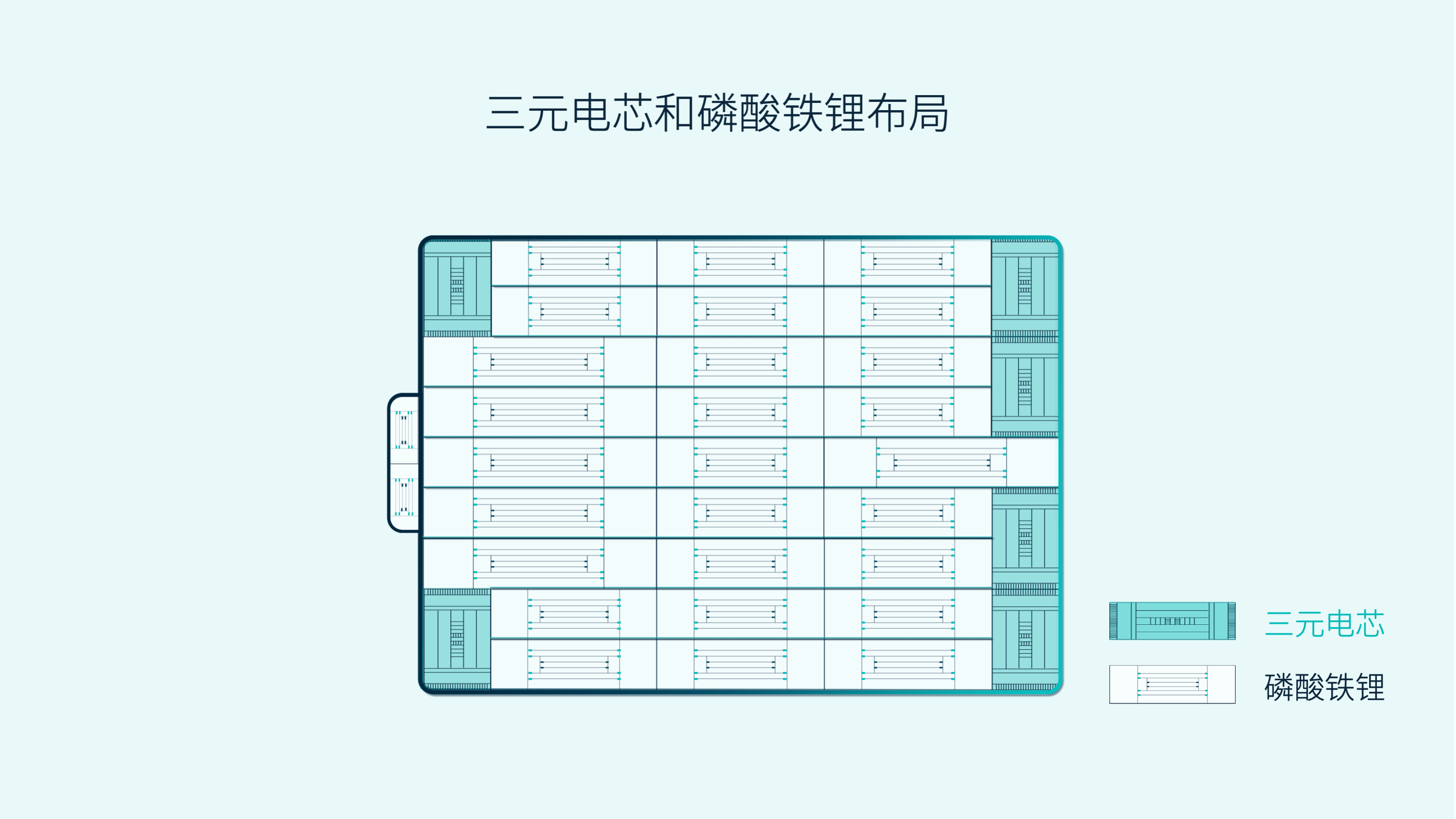

For NIO, using more lithium iron phosphate in their ternary lithium battery pack clearly reduces the cost. Data shows that the 75 kWh battery replaces the 70 kWh battery, with additional capacity and no extra cost. If saving money is the only goal, fitting lithium iron phosphate cells that approximate 75 kWh in NIO’s existing pack is not difficult. The real challenge lies in how NIO can ensure user experience with lithium iron phosphate batteries. Replacing the 70 kWh ternary lithium battery with a 75 kWh pack equivalent using 5 kWh increments is reasonable based on data, but as someone pointed out in the NIO app, it’s like replacing 70 g of crabmeat with 75 g of crab stick at the same price, which is not the optimal choice because, as everyone knows, crab sticks are made of fish meat. However, this analogy is not very applicable since there is still “crab meat” (ternary lithium) in this battery pack, plus NIO has used various tactics to make this “crab stick” better than crab meat. Nevertheless, ternary lithium in this battery pack plays a supplementary role, like a golden liner.

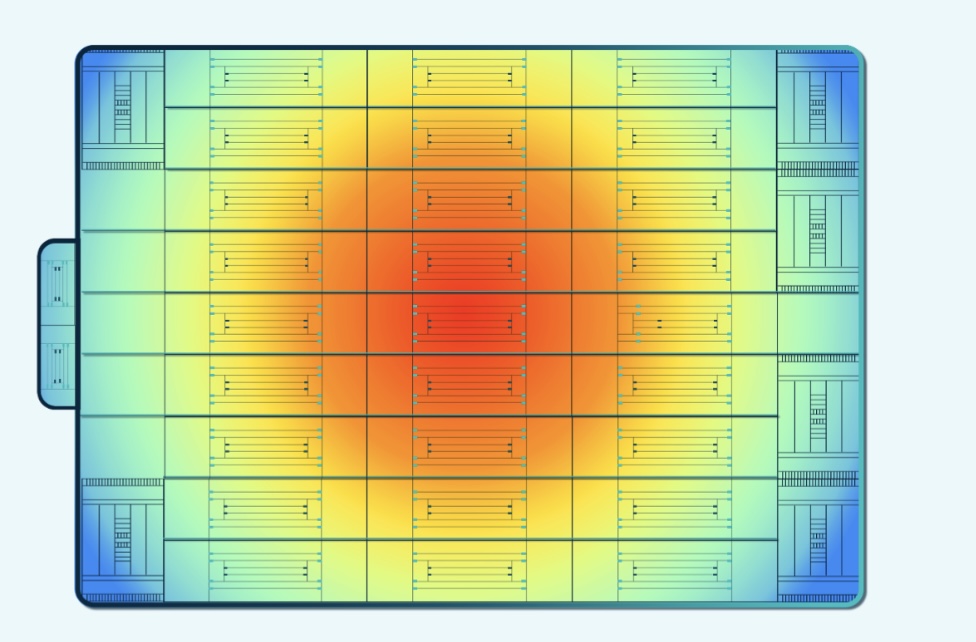

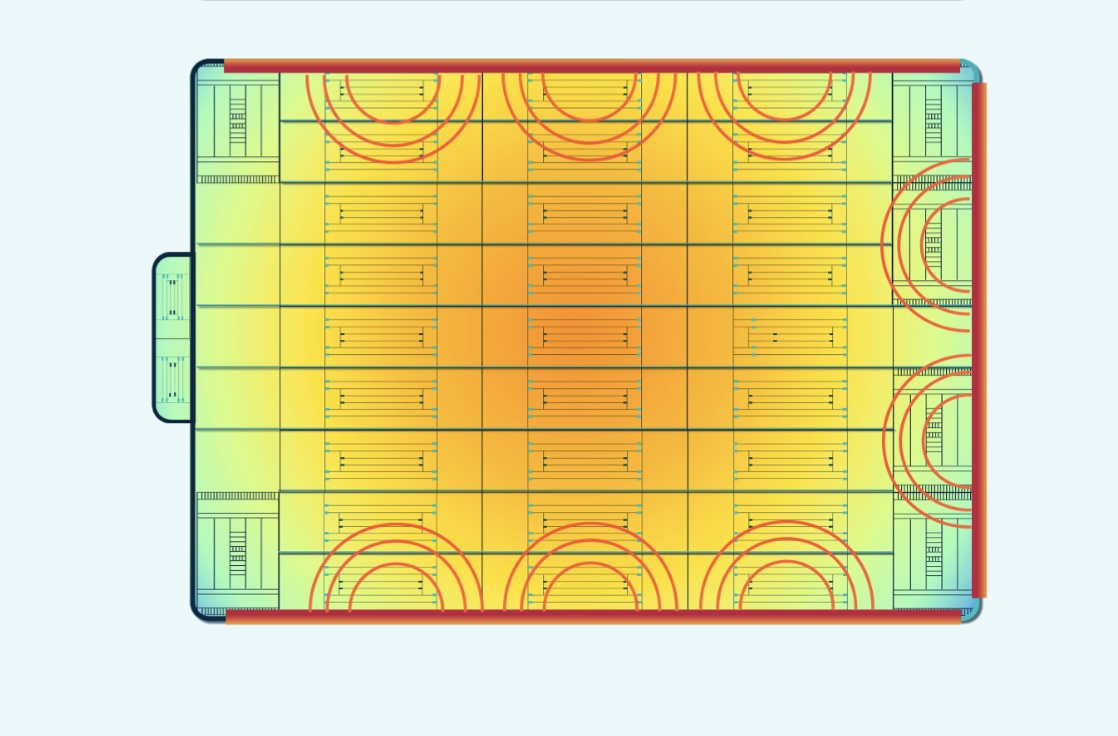

The edge of the battery pack, especially the four corners of the two-sided surface, has a significantly better heat dissipation effect than the middle part of the battery pack with cells on all sides. Combined with the fact that the battery pack shell is made of aluminum alloy material and that NIO models have gaps for battery swapping, the heat around it is more easily deprived in winter.

This is a fatal blow to weak low-temperature performance of lithium iron phosphate battery, making the increase of only 5 kWh less impressive under such circumstances.

In fact, NIO had considered adding thermal insulation material at the corners of the lithium iron phosphate scheme to increase winter mileage. However, this would have resulted in wasted space and weight.

After seeing this chart, it feels like NIO’s battery engineers thought:

Isn’t ternary lithium better for low-temperature performance? Then why not stack it in the coldest place? It can also act as insulation!

The minimum amount of ternary lithium cells effectively insulated the lithium iron phosphate cells. In combination with radiation-type active heat compensation, the new 75 kWh battery pack improved temperature uniformity by 60% and the minimum temperature of the battery by 40% compared with previous products in 12-hour extremely cold environments.

Interestingly, William Li also revealed that by radiation-type heat compensation, the idle temperature of the battery pack can be controlled to around -5 degrees Celsius. As for why this number was chosen, it’s because energy consumption would be too high if it was higher, and losses would be too great if it were lower.

As a result, compared to pure lithium iron phosphate batteries, the low-temperature mileage loss decreased by 25%.

Ternary lithium can also be a ruler

However, lithium iron phosphate still accounts for the majority of the battery, and it still faces a very serious problem, which is the SoC estimation of the lithium iron phosphate battery section (i.e. how much charge is left in the battery).Here is the translated English markdown text with HTML tags preserved:

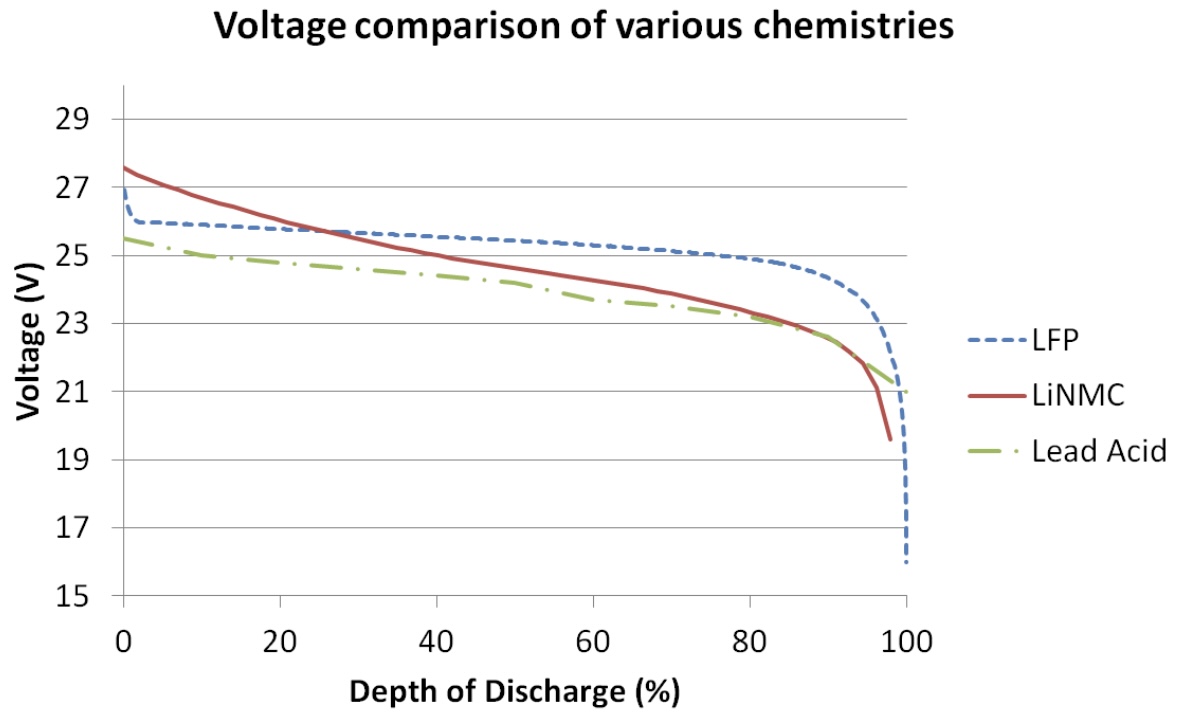

The figure above shows the discharge curves of three different types of batteries: lithium iron phosphate (blue), ternary lithium (red), and lead-acid (green).

The reason why it is difficult to calculate SoC for lithium iron phosphate batteries is that their discharge curve is too gentle. In other words, as the energy in the battery decreases, the voltage drop is not significant enough to judge the remaining power solely based on the battery voltage, until it suddenly runs out of power.

Lithium iron phosphate is like a new colleague who cannot hold his liquor, unable to refuse being heavily drunk by the supervisor and eventually getting drunk and vomiting all over the floor (of course, I do not recommend such a drinking culture).

However, ternary lithium is different. It is like a straightforward boy who easily gets angry and explodes (it is better not to do so).

Except for the first and last sections, the linearly decreasing voltage of ternary lithium with decreasing power is more favorable for estimating the SoC of the battery pack. Compared with the eccentric lithium iron phosphate, using the voltage of ternary lithium to estimate the remaining power is much simpler.

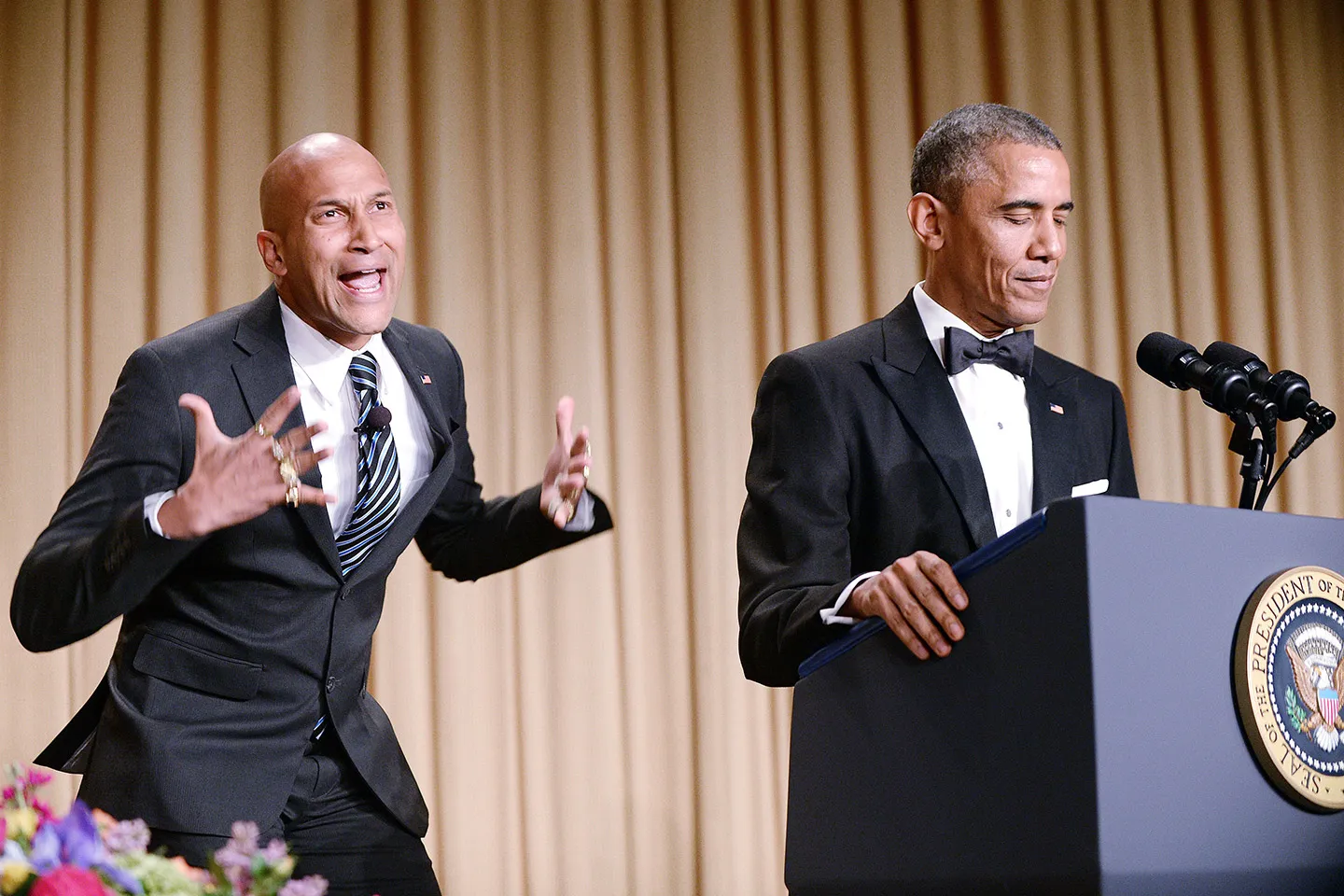

Therefore, lithium iron phosphate paired with ternary lithium is like Barack Obama, who can only express his true thoughts through his angry translator who shows his emotions explicitly.

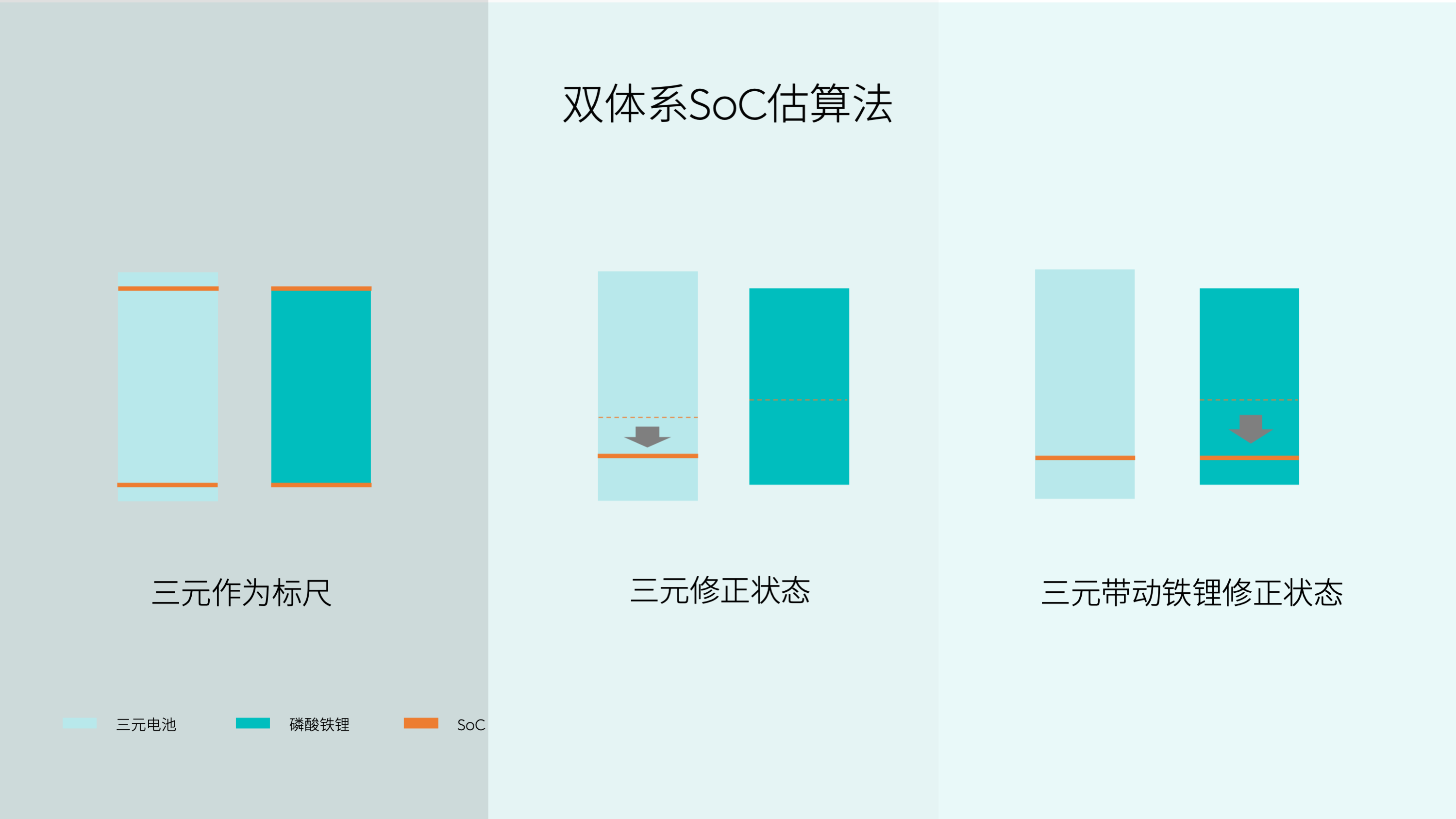

The principle of using ternary lithium as a ruler to estimate lithium iron phosphate is actually straightforward.

The actual capacity of the ternary lithium battery is larger than that of the lithium iron phosphate battery, so that it is possible to use the remaining power space of ternary lithium from 10% to 90% as a ruler, because as mentioned above, the accuracy of the first and last sections is not as high.

In simplified terms, 90% of the capacity of ternary lithium corresponds to 100% of lithium iron phosphate, and 10% of the former corresponds to 0% of the latter. The middle range is basically as simple as solving a linear equation, and then correspondingly proportional.

Regarding the accuracy of the final SoC estimation, NIO officials have stated that the ternary iron lithium battery pack can achieve the same accuracy as the ternary lithium battery, with an error of less than 3%.

Touching on the details

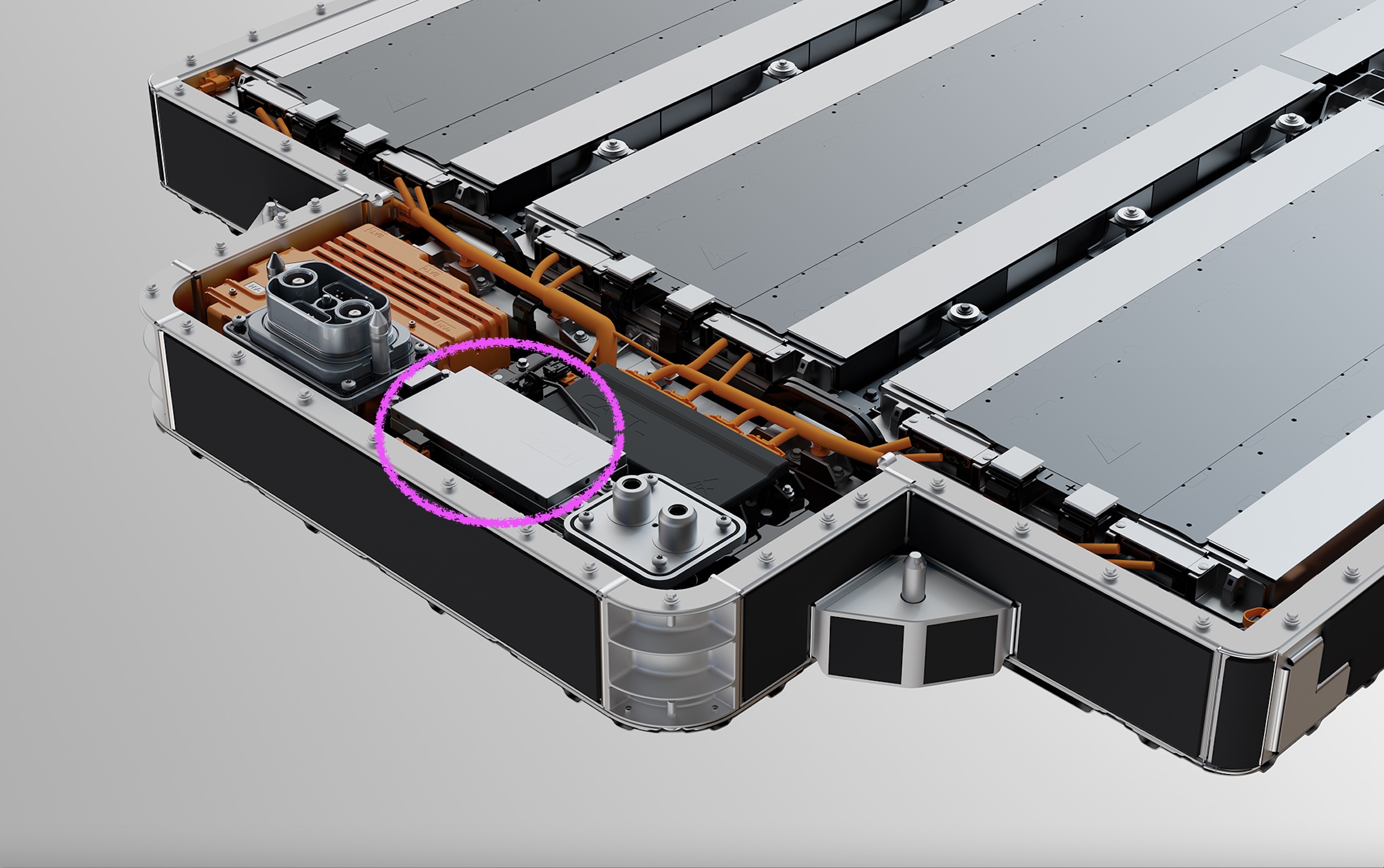

The marked part in the picture is the newly added DCDC, which can quickly and dynamically calibrate the power to ensure that the adverse factors brought by different battery cells in series are reduced to the minimum. At the same time, it also realizes self-checking when powered off without relying on a small battery. As DCDC further matures, it is not excluded to be installed on a 100 kWh battery pack in the future.

In terms of passive safety, in addition to the increase of the longitudinal beam in the battery pack area and the physical partition that acts as a waterproof function, the fuse in front of the battery pack has also been moved to the rear, further increasing reliability in the event of a collision.

If you look closely, you can also see two new incisions on both sides of the battery pack’s crushed area. This is also to reduce the side thermal conductivity and ensure winter cruising range. You can rest assured that the opening in this direction does not have any impact on energy absorption.

User experience speaks for all

After all these efforts, the 75 kWh battery pack manufactured and assembled using CTP technology has been simplified by 10%; volume utilization rate has been increased by 5%; energy density has been increased by 14%, reaching 142 Wh/kg.

As for weight, as the battery pack mainly consists of lithium iron phosphate, it has only increased by about 15 kg, and there is no need for suspension calibration. Similarly, according to Zeng Shizhe, there are 4 BMS solutions built into the vehicle, so there should be no compatibility issues when switching to the new 75 kWh battery pack at battery swapping stations.

Actually, this hybrid battery pack itself has many factors from CATL, and there is no guarantee that other companies will not use similar solutions. Or we can be more confident that other companies will definitely follow this fresh update strategy. After all, lithium iron phosphate batteries cost five cents, while ternary lithium batteries cost nine cents. The more you save, the more you earn.No matter what, it is a fact that the application range of lithium iron phosphate has been expanded. With the improvement of the energy supplement system, especially the replaceable battery of NIO, the battery size will also become more rational in the product evaluation as the understanding of usage scenarios improves.

Zeng Shizhe also pointed out that everyone can learn and imitate the hardware of this battery pack. However, algorithms and data are the key to making good products. From SOC estimation to dynamic adjustment of thermal management to optimize performance and power consumption, etc…

This self-research is not only NIO’s pursuit as a user enterprise, but also an important barrier for a leading new force to maintain competitiveness.

Of course, with more and more battery swapping stations, I am increasingly confident in conquering the cold winter. I hope to have the opportunity to personally verify the performance of this ternary lithium iron phosphate in Inner Mongolia or Northeast China during winter.

However, let me take this opportunity to express my admiration first:

It’s the ternary lithium that makes the lithium iron phosphate smell good…

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.