What attributes should BMW’s products possess?

In the eyes of most people, “in-line six-cylinder with rear-wheel drive” is the most essential power combination for BMW, which reflects the brand’s core attribute of sportiness. Will the excellent mechanical quality and sports performance still be widely respected in the upcoming new era of automotive industry? It is hard to say. However, traditional brands need to become more diversified.

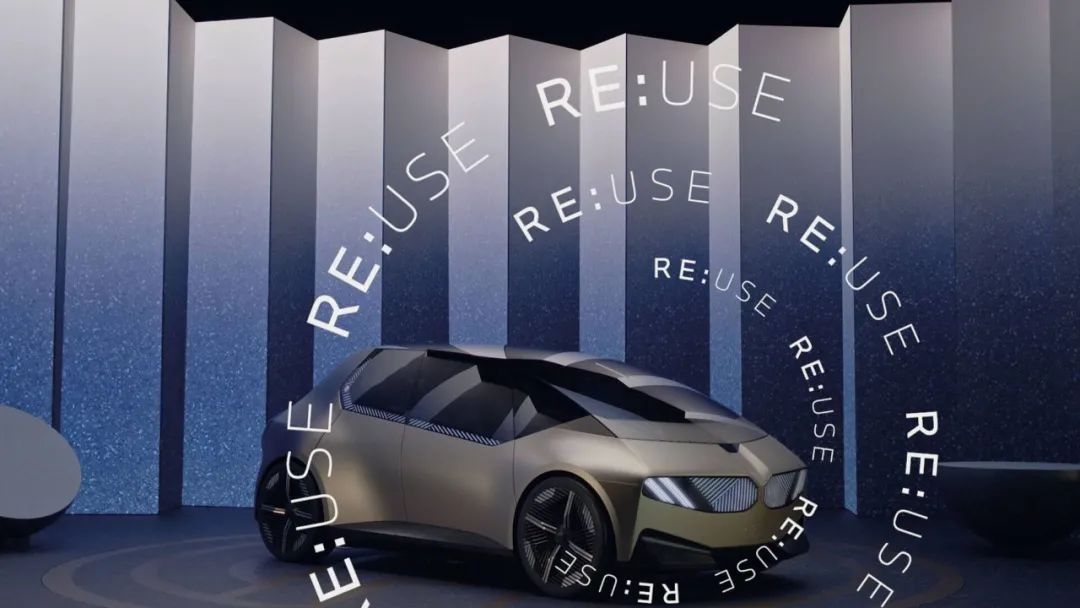

Therefore, at this year’s Munich Motor Show, we saw a different BMW – the BMW i Vision Circular, which translates to BMW Circular Concept Car.

In the face of the new wave of industrial revolution, traditional car companies need to face earth-shattering changes, and of course, they also have the opportunity to redefine their brand image.

BMW’s circular concept car is a product that BMW is trying to develop to break its brand’s inherent perception. In fact, from the all-new BMW iX and i4, we can see that BMW is exploring the road of sustainable development. In my opinion, the BMW i Vision Circular is the flag that BMW sets for themselves, and BMW calls it a compact sedan looking ahead to 2040.

A car made of 100% recyclable materials

BMW claims that they achieve 100% use of recycled materials on the BMW i Vision Circular. In terms of the application of materials in the entire vehicle, BMW adheres to the principle of using a single material.

In terms of appearance, we can hardly see any paint or chrome materials. The body structure is made of recycled aluminum and recycled steel. The body is not painted, and the golden color of the aluminum is derived from anodizing. The rear fender and tail section are made of recycled steel, and their blue-purple gradient effect is achieved through heat treatment.

We see that the position of the front bumper of the car uses parts with marble patterns. In fact, the material of this part is recyclable plastic. Because the chrome materials on the appearance are removed, we often see that the front grille and window frames that used chrome materials are replaced with digital animation to outline the details of the car body.

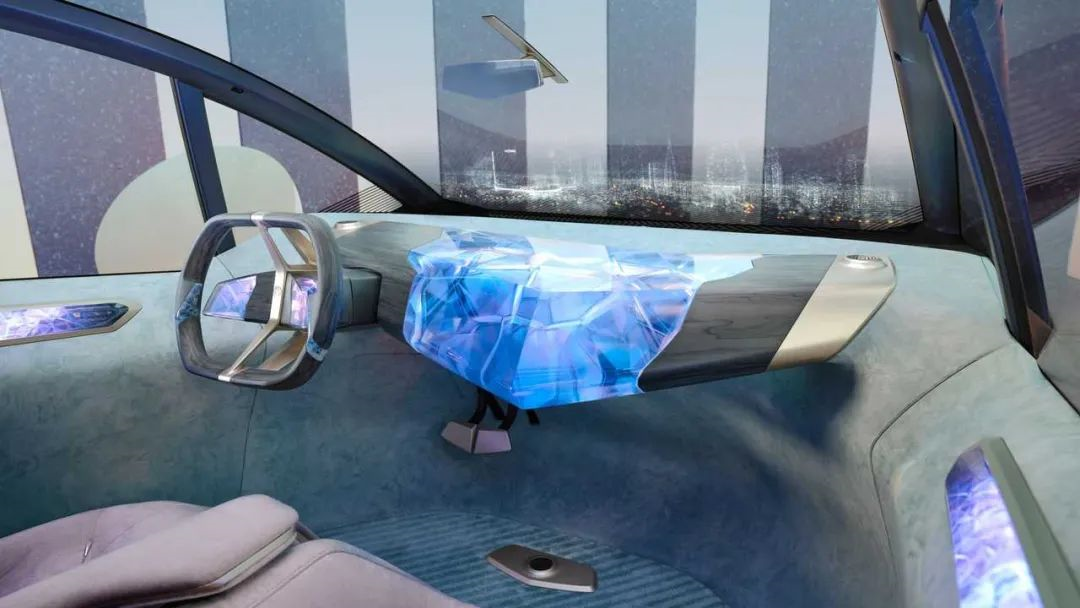

The tires of the BMW i Vision Circular are made of eco-certified natural rubber, and colored rubber particles are added to the material, presenting a terrazzo effect.The interior of BMW i Vision Circular is also made entirely of recyclable materials. BMW has applied intelligent and clever innovative technology to connect different materials and components together, making subsequent dismantling and recycling more convenient. To further reduce material waste, all components will use additive manufacturing and other techniques for precise matching, minimizing waste production, while excess material can be systematically returned to the material cycle.

The fabrics on the surface of the four independent seats are made of recycled plastics, providing a velvet-like texture. The seat frames are made of light-gold aluminum and the entire seat is cleverly connected by a rope, allowing metal and fabric to be easily separated for recycling. The seat base uses a single-column pedestal that can be adjusted back and forth, further increasing legroom for passengers in the car.

The steering wheel is made of recycled wood powder and manufactured using 3D printing technology, reducing materials and parts and making it a node that connects the past and the future.

The panoramic sunroof uses two thin and light panels, which can slide to adjust the shading effect. This innovative design achieves excellent effect without requiring new electronic components or technology.

The hidden reading lamp in the C-pillar of the car is an example of the “reuse” principle. The iDrive knob recycled from the BMW iX has found its “second life” here.

BMW has specially created the “joyful fusion” design – with just a sleeve wrench, the wheels, seats, and dashboard can be easily dismantled into various components, ensuring the ease of subsequent dismantling and recycling.

Before the advent of BMW i Vision Circular, what would a car made of recycled materials without any embellishment look like in our minds? It certainly wouldn’t look too sophisticated, and perhaps wouldn’t have anything to do with luxury. BMW i Vision Circular breaks this cognition, showing that recyclable materials can also exhibit very good quality and texture.

New Thinking, New Materials, New Texture, New DNA# BMW Group proposes the four guiding principles of “rethink, reduce, reuse, and recycle” based on circular economy, putting forward a new way of thinking for the company’s future direction and even the development of the automotive industry.

Rethink: Consider product technology, manufacturing processes, and the functionality of each component in a new way, and then streamline or redesign to achieve material recycling.

Reduce: Continuously implement the minimalism philosophy of the BMW i brand, reducing the number of parts, types of materials, and processes. The concept car completely abandons car paint, leather, and chrome, and introduces bio-based raw materials to reduce environmental impact and shrink carbon footprint.

Reuse: Sustainable products in the future will provide longer service life and always maintain a rich and enjoyable experience. The concept car uses “Yui” intelligent design, allowing users to easily renew the vehicle and keep a fresh feeling.

Recycle: Prioritize the use of recyclable materials in product design and optimize for recycling. Therefore, the vehicle uses a single material as much as possible and can be easily disassembled, avoiding adhesion or composite materials. The “Yui” intelligent design also makes vehicle renewal more convenient.

In terms of color and fabric, BMW will take the “decoration-free” route in the future. In the BMW iX model released earlier this year, BMW has already shown a plan to create an environmentally friendly high-end sense.

The control panel on the center console in the car uses FSC-certified sustainable production wood; the interior and fabrics are made with a large amount of recycled materials, such as 50% recycled polyester fiber materials used in fabric/microfiber interiors, and 100% recycled nylon materials used in carpet mats. The manufacturing process is more environmentally friendly, and the leather is treated with olive leaf extracts instead of traditional tanning agents. These extracts come from the leaves collected from olive groves trimmed annually in Europe.

Through the grille decoration panel on the BMW iX, the theme color of the early BMW i4 concept car, and the recently released BMW i Vision Circular, it is not difficult to see that gold is becoming BMW’s main tone. Perhaps from a traditional perspective, the luxurious and imposing gold color is not in line with the youthful and sporty style of BMW.

However, under the concept of circular economy, BMW may prefer to showcase the color and texture of the material itself to users, just like the natural metal finish formed by oxidation on the BMW i Vision Circular model; we can no longer see chrome or carbon fiber decorative panels in the interior of the BMW iX, only plant fiber leather and natural wood.

On the product side, the BMW brand has already started to plant a seed with sustainable development genes in the minds of users. Of course, this seed needs time to take root and sprout, and it will take generations of products to deeply embed the new brand genes in the minds of users.

Green Development Across the Entire Industry Chain

In fact, where users cannot see, BMW has already started to practice the concept of sustainable development. The BMW Group is committed to achieving full value chain carbon neutrality by 2050. They are also the first German automaker to join the “1.5°C target action” initiative. In short: net zero carbon emissions by 2050.

Promoting electrification will be key to achieving this goal. The NEUE KLASSE “new generation” models to be launched starting in 2025 will be a crucial step for the future. The “new generation” models are the focus of BMW’s future investment: a completely new car architecture, a completely new IT and software architecture, and pure electric drive.

The BMW Group plans to deliver 10 million pure electric vehicles in the next 10 years. By 2030, it is expected that half of the vehicles produced globally will be pure electric vehicles. At that time, the MINI brand will also be completely electrified. By 2030, the carbon emissions from BMW Group vehicle usage will be reduced by half compared to 2019. This means that BMW will fully comply with relevant EU regulations by 2030. By 2030, the single-bicycle carbon emissions throughout its lifecycle will also be reduced by 40%.

When BMW syncs its sustainable development concepts to its products and industry chains, we can easily envision that social responsibility will certainly be a key reference item in defining luxury brands in the future.

Conclusion

What will the future BMW look like? Perhaps it will still be sporty and intelligent, but above all product attributes, “sustainable development” will surely be engraved in the BMW brand genes.The reason why luxury brands are endowed with higher added value than other brands must be that one of their abilities is in a leading position in the relative field, and BMW of the future will definitely lead a sustainable development trend in the automotive industry.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.