Author: Chang Yan

“Can’t beat them? Join them” has gone to the next level: “Can’t beat them? Partner with them.”

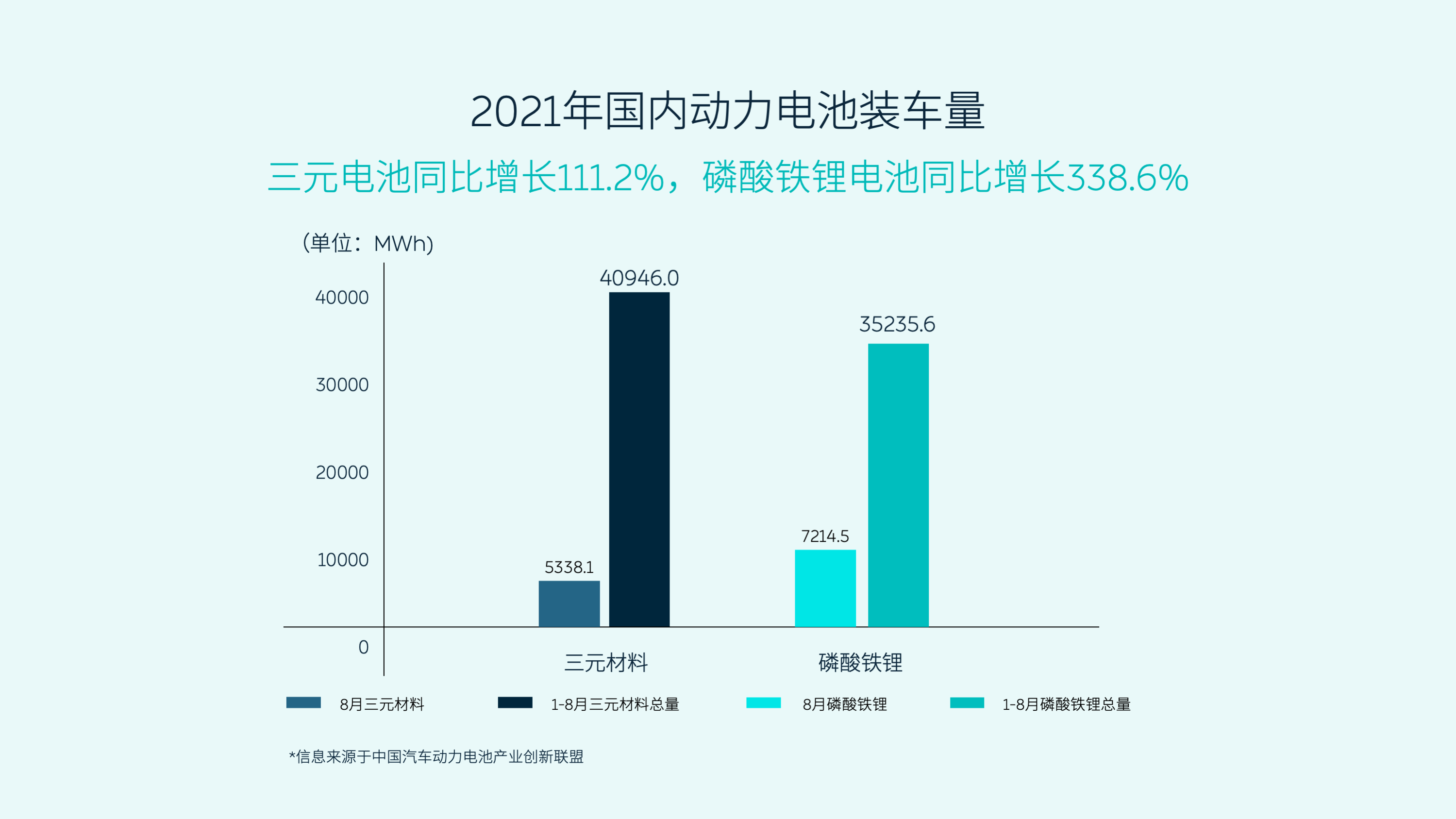

The relationship between ternary lithium batteries and lithium iron phosphate batteries, once considered as two distinct technical paths with obvious differences, has gradually become two excellent and competitive choices with distinct advantages.

The optimization of the battery pack structure greatly increases the overall density of the lithium iron phosphate battery. The characteristic of being able to be fully charged and discharged at will makes the commonly used capacity of the lithium iron phosphate battery much larger than that of the ternary lithium battery. Coupled with the traditional advantage of being “inexpensive”, it is undoubtedly the spokesperson for cost-effectiveness.

However, as many companies with super-strong three-electric capabilities have entered the lithium iron phosphate market, it is still frustratingly discovered that the two problems of poor low-temperature performance and inaccurate SoC estimation seem difficult to solve for the time being.

Perhaps inspired by the double-shell rice in the cafeteria at night, NIO came up with a solution: since each has its own advantages, why not combine ternary lithium and lithium iron phosphate?

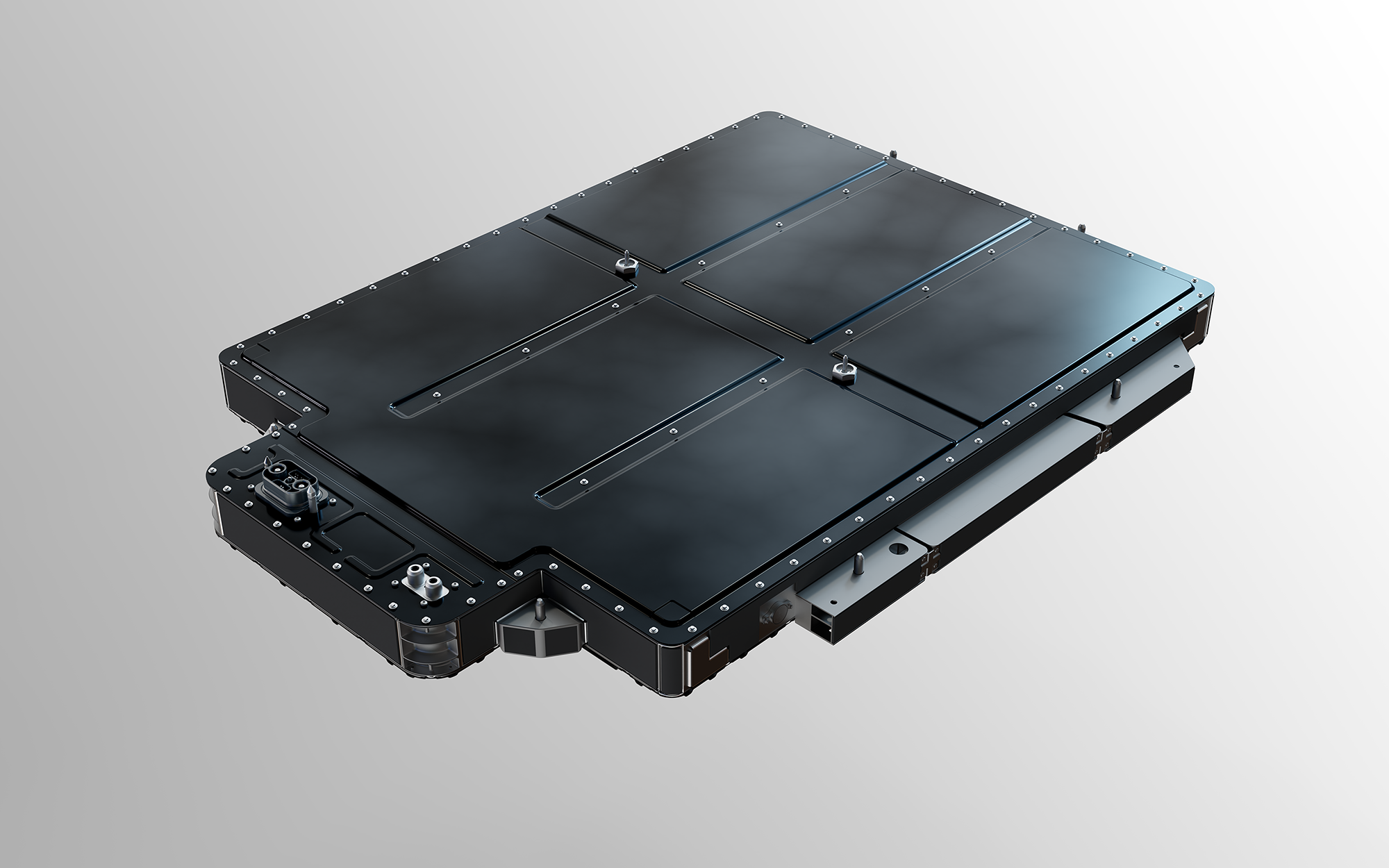

This gave birth to the NIO ternary lithium iron phosphate standard range battery pack (75 kWh) that we see today.

A project delayed by one year

NIO Battery System Vice President Zeng Shizhe told us at the beginning that this battery pack was delayed by one year from the plan.

The reason is simple: Li Bin is not satisfied.

At the beginning of the project, NIO only wanted to make a lithium iron phosphate battery pack. After a series of technological optimizations, the battery team developed a complete solution with a total capacity of 68 kWh.

Although it has undergone various verification and calibration, the overall capacity is also basically the same as the previous 70 kWh ternary lithium battery pack, but this still did not satisfy Li Bin, who thinks from a user perspective. On the one hand, the basic capacity is still 2 kWh smaller; on the other hand, if used in cold northern regions, the obvious impact of low temperature on range will be greater.

Without solving these two problems, the lithium iron phosphate battery pack cannot be delivered to users. This is the source of the redesign of the 75 kWh battery pack this time.# How to mix, it’s a good question

If we rely on intuition, many people might think that the structure of a ternary lithium battery will be evenly split between ternary and iron-lithium components, just like its name suggests.

But reality is not that simple. If they were arranged half and half, then the extensively used ternary batteries would lose their cost advantage, as the physical expansion coefficients of the two types of cells are different and it is difficult to ensure stability when densely packed together.

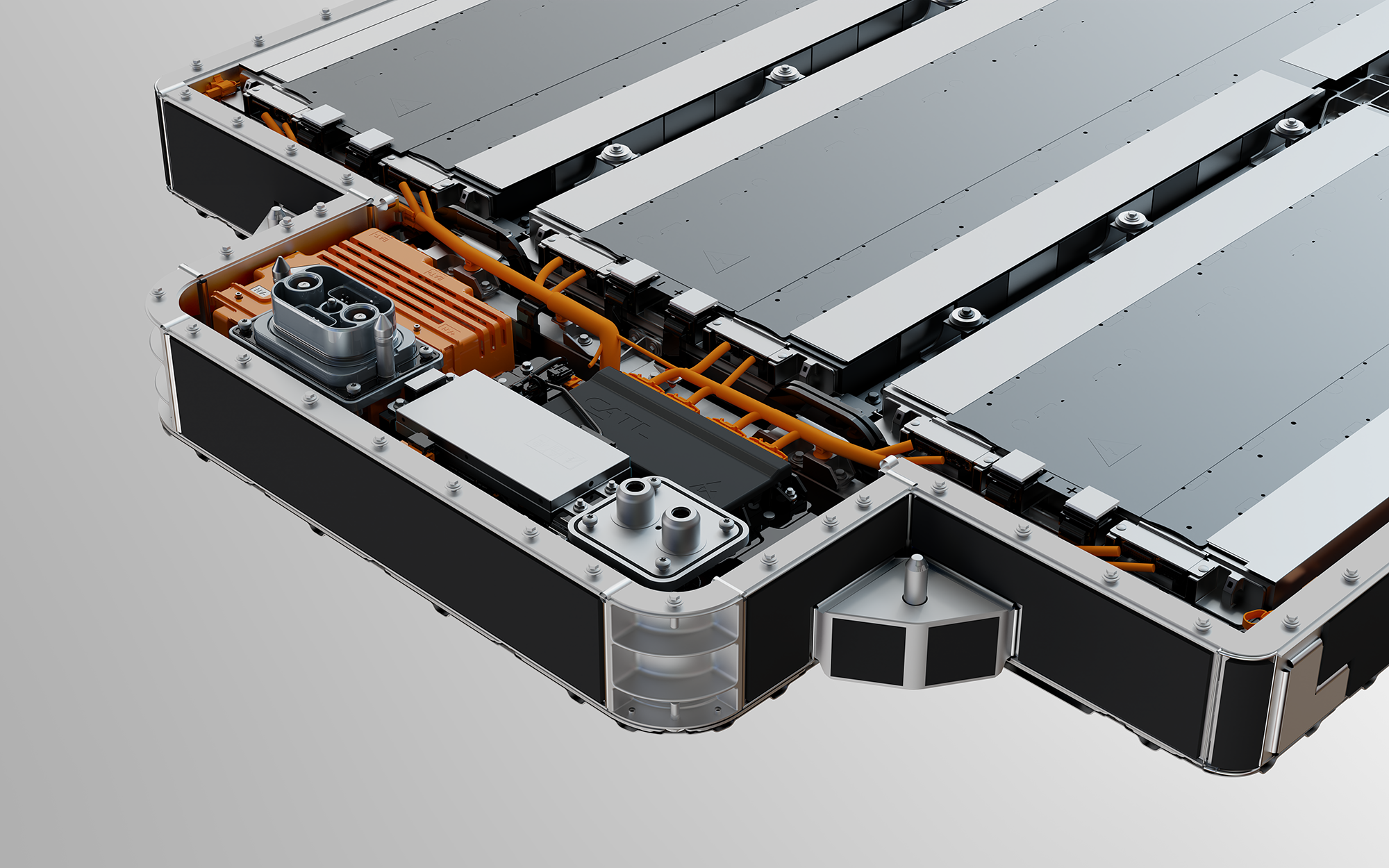

Therefore, we see NIO’s final solution: the majority of the battery pack is composed of iron-phosphate lithium cells, while ternary lithium cells are installed in the four corners of the battery.

The reason is simple: if iron-phosphate lithium is prone to low temperatures, then replace the prone-to-cold areas with ternary lithium, which has better temperature stability.

NIO conducted a temperature analysis of the battery pack as a whole. The four corners of the battery are far from the temperature center of the battery, and the modularized battery pack may create a vortex at the front and back edges, which speeds up heat loss. Therefore, it is more reasonable to install ternary lithium cells in these corners.

Another problem that needs to be solved is the insulation of the battery pack. NIO’s goal is to maintain the internal temperature of the battery pack above -5 degrees Celsius, regardless of external temperature. This enables the battery pack to warm up to the appropriate level for battery performance release within about 10 minutes of vehicle operation. Therefore, the entire 75 kWh battery pack includes a physical barrier on the entire heat dissipation path. After big data analysis, NIO installed a large number of thermal isolation materials at critical junctions inside and outside the battery pack. At the same time, it enhanced intelligent heat management of the battery’s heat production. Under low temperature conditions, the radiation heating system can actively increase the battery’s temperature uniformity without significantly increasing energy consumption.

In other words, NIO has made it possible for iron-phosphate lithium electrodes to say goodbye to low temperatures as much as possible during times when their performance is affected.

It’s time to show real technological capabilities

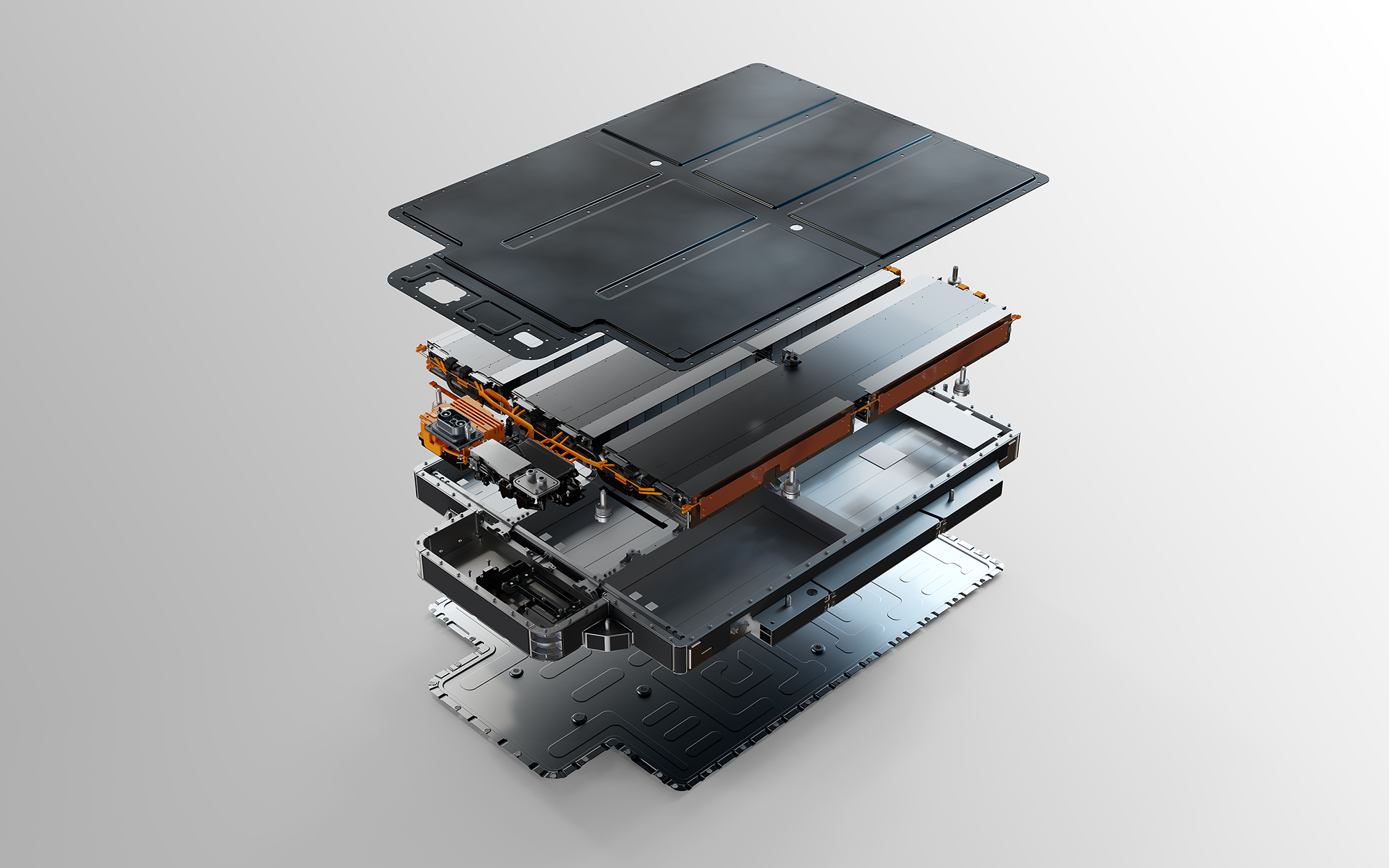

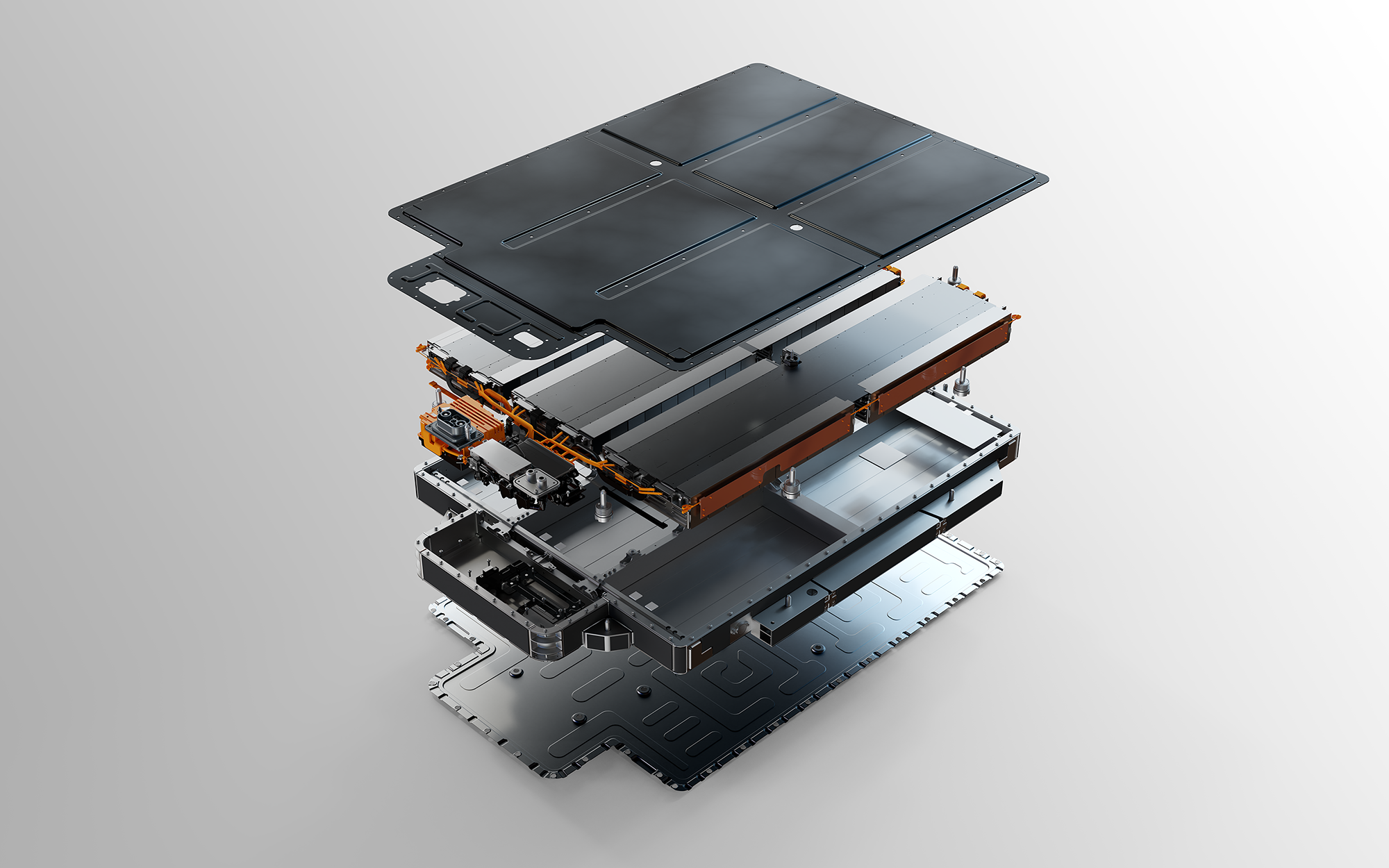

NIO does not hide the enormous help that CATL has provided in the development of this battery pack.After NIO adopted the CTP-0 structure from CATL in its 100 kWh battery pack, the 75 kWh battery pack once again uses a brand-new design, namely CTP-S.

This simplified assembly by 10%, improved volume utilization by 5%, and increased the energy density by 14% to 142 Wh/kg. The pack density also ensures that the battery pack is eligible for national subsidies.

Thus, we are also curious as to whether NIO’s display of this structure means that all manufacturers can adopt this approach.

Analyzing the hardware structure, this appears to be the case. However, there is still a high threshold for complete implementation, namely software calibration.

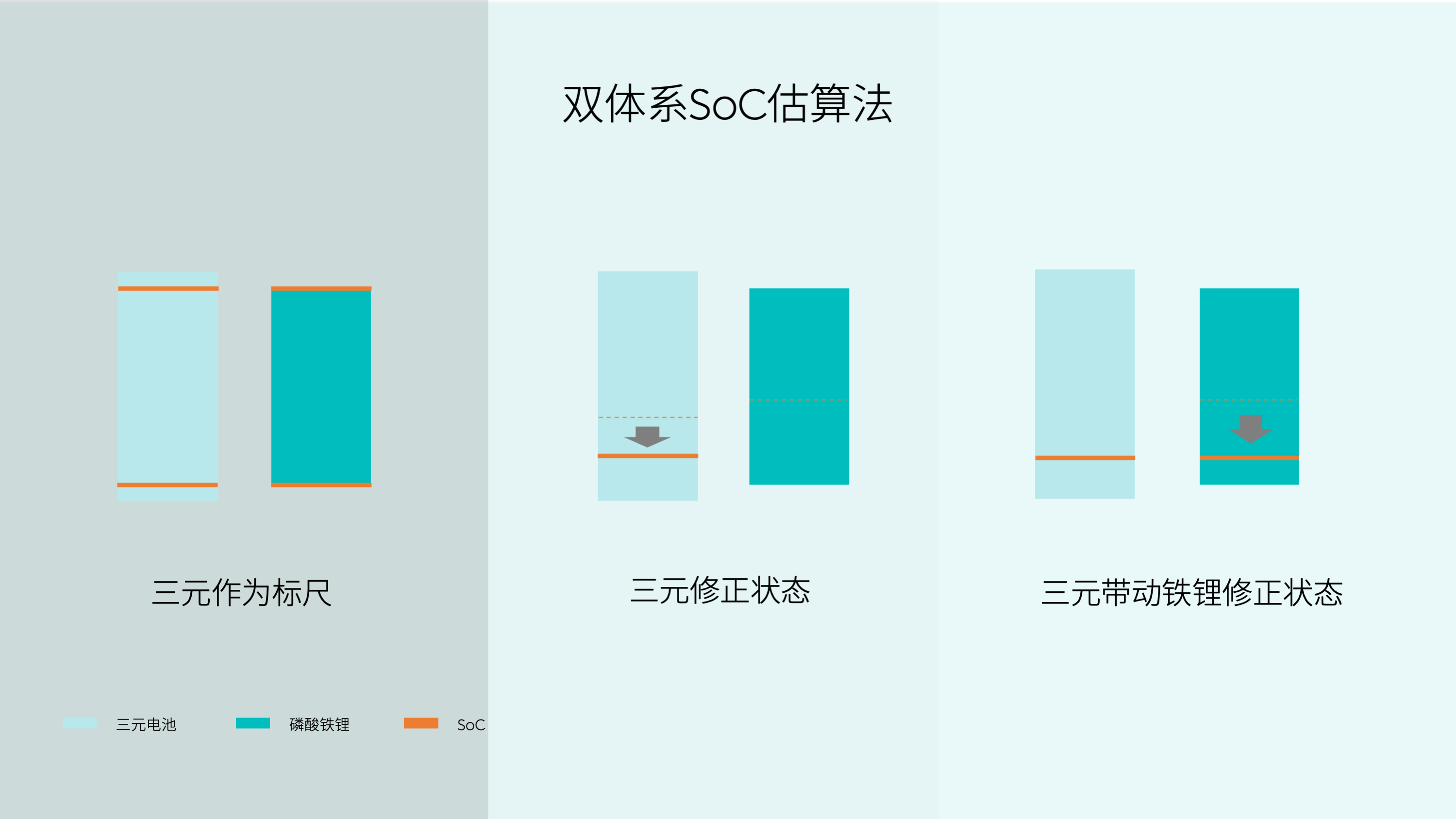

In this battery pack solution, ternary lithium batteries play an important role as a “ruler.” The basic idea is that the SOC of ternary lithium can be used as calibration in the imprecise phase of lithium iron phosphate. This SOC algorithm with a dual system eventually reduces the SOC calculation error of traditional iron-lithium batteries from10% to 3%.

In introducing the relevant components, NIO emphasized two innovations. They utilized high-power DCDC for fast, real-time, and balanced power calibration. The exact words were “we want to add this to all battery packs”. Furthermore, regarding the ongoing chip shortage, NIO also prepared several sets of inter-changeable solutions for critical components to avoid any impacts on overall production due to supply chain interruptions.

Not cheap, but a good choice

To be honest, when the PPT reached the end and “volume increase without price increase” appeared, I was a bit stunned. After all, don’t automakers use lithium iron phosphate batteries to cut costs? When did it become necessary to increase the price?

In the long run, the 75 kWh battery pack must have greater cost advantages over the previous 70 kWh battery pack, especially if the rare elements in ternary lithium batteries become more expensive.

However, besides the reason of high R&D costs claimed by NIO, there are also reasons why the price of the 75 kWh battery pack does not decrease. After all, in terms of core experience, it may even be better.

For example, the problem of reduced charging power after replacing lithium iron phosphate batteries appeared in NIO’s competitors before. However, NIO stated that the maximum C-Rate of the 75 kWh battery pack can reach 1.6, which is equivalent to 120 kW. This even leads to a saving of about ten minutes in overall charging time.

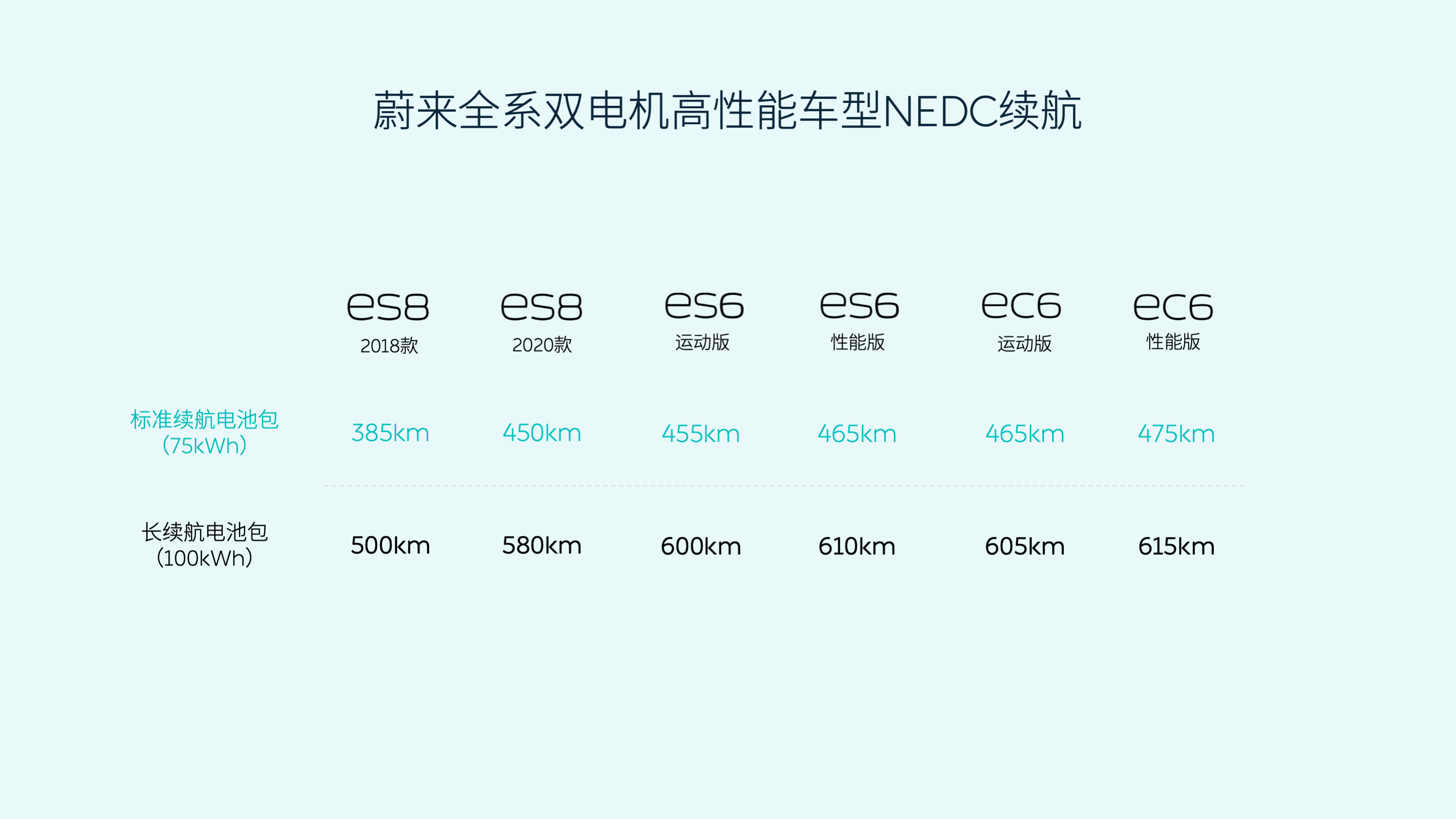

An even greater advantage is the help in endurance brought by the increase in capacity. The capacity has been increased by 5 kWh, and ternary lithium can also provide a larger usage percentage compared to pure ternary batteries. For cases where the current battery swapping station only charges to 93%, the increase in practicality is still obvious.

The significance of the 75 kWh battery pack for NIO is not only the guarantee provided by an additional battery formula and technical route, but also its own long lifespan. It can achieve a usage lifespan of over one million kilometers per single battery cell. This is an important basic feature for NIO’s battery swapping system and its possible Robotaxi service.

A few years ago, when we talked about NIO, we often used a term, “hardware upgrade.” However, perhaps with more research on the battery system, this term is used less frequently now. But in my opinion, this is indeed a major upgrade of NIO’s vehicle system.

Moreover, it’s coming in November.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.