Author: Wang Lingfang

SAIC-GM-Wuling is also entering the field of battery swap and chips.

On September 15th, SAIC-GM-Wuling held the “China Wuling, Global New Energy Pioneer” brand conference, announcing that the cumulative sales of GSEV (Global Small Electric Vehicle Platform) products exceeded 500,000 vehicles, and releasing the GSEV big data report and technology research and development plan, as well as the smart micro swapping station and “Strong Chip” strategy.

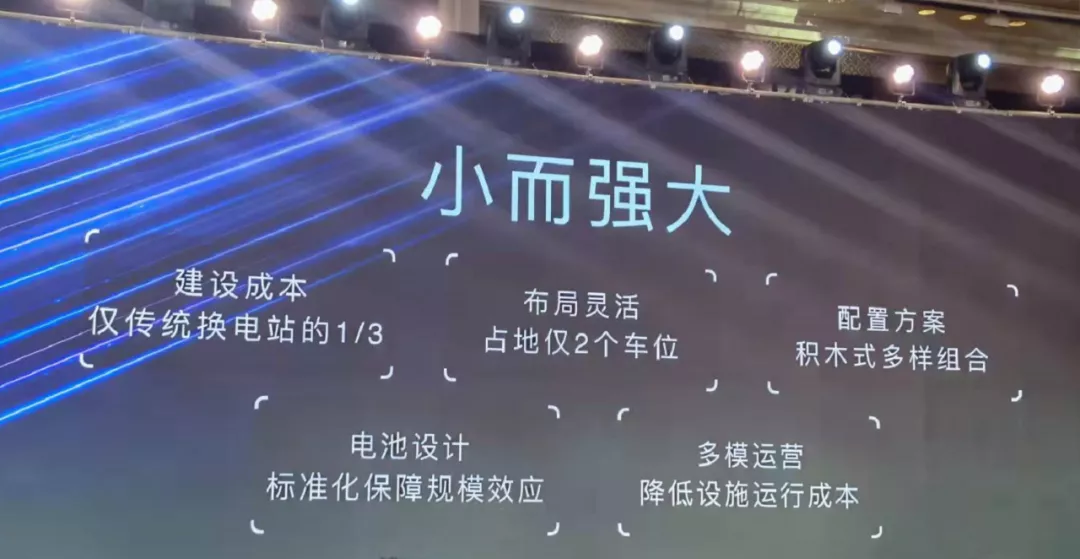

Regarding battery swaps, SAIC-GM-Wuling’s smart micro swapping station only occupies two parking spaces, with a construction cost that is 1/3 of the conventional swapping station in the industry. They hope that this swapping mode can surpass the early pioneers.

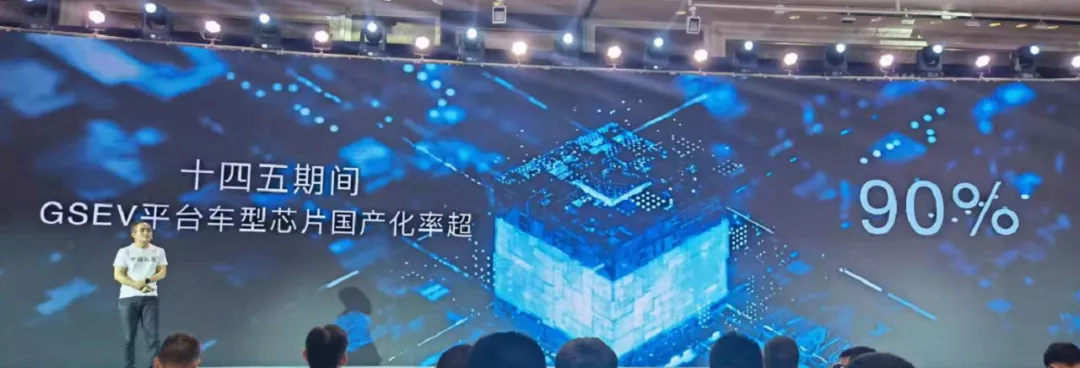

Regarding chips, SAIC-GM-Wuling hopes that the domestication rate of GSEV platform vehicle chips will exceed 90% during the “14th Five-Year Plan” period.

Develop Smart Micro Swapping Stations.

Since last year, the country’s support for battery swapping has become greater and greater, with related policy measures being introduced quickly, which has made SAIC-GM-Wuling realize that the time is ripe for developing battery swapping.

SAIC-GM-Wuling quickly launched the smart micro swapping station, which is a targeted solution to improve small new energy vehicles.

The swapping system of the transformed swapping station includes a battery compartment (for storing and charging batteries) and an AGV swapping robot hand (for automatic positioning, loading and unloading batteries between the vehicles and equipment). It can be powered by a 220V household power supply.

The swapping principle is a standardized thin-layer battery design. The AGV swapping hand shuttles between the swapping equipment and the vehicle chassis, performing intelligent battery pack position recognition and swapping operations. The AGV does not need to drill into the ground, and the vehicle does not need to go up a bridge and park accurately, making the construction of the swapping station very simple, occupying a small area, and with mobile and strong features. Its technical highlights include the combination of wireless BMS technology to achieve a battery structure that uses a horizontally spanning battery box frame, without altering the original vehicle structure and installation method.

Different from the battery swapping stations of domestic car companies, SAIC-GM-Wuling’s fully automatic micro swapping station only occupies an area of two small E-parking spaces, increasing the utilization rate of the area by 50%. It is flexible and movable, and the entire construction does not require infrastructure or support, and is quickly fixed. At the same time, the swapping station is highly intelligent, requiring no vehicles to go up a bridge and park accurately. The swapping robot can perform precise recognition using visual recognition and laser positioning technology, quickly swapping batteries.

The fastest swapping speed of this smart micro swapping technology is equivalent to the speed of filling up a fuel tank. The user experience is comparable to that of traditional refueling. At the same time, the construction cost of this smart micro swapping station is only 1/3 of the conventional swapping station in the industry. It can also be expanded like building blocks, with flexible configuration of multiple energy storage compartments. It can also be combined with energy storage, V2X, V2G and other energy interactive technologies for multi-mode operation, reducing operating costs and accelerating investment recovery.

The technology has been implemented on unmanned logistics vehicles at SAIC-GM-Wuling Baojun Plant since October 2020, completing over 2000 battery swaps and saving nearly 20,000 hours of charging time.

In terms of versatility, according to Shao Jie, the Director of Electrification at SAIC-GM-Wuling Technology Center, many automakers are developing mini electric cars that can travel 150-170 kilometers, which are compatible with battery swap technology. Additionally, the battery packs they’ve developed can be expanded horizontally and vertically, and larger passenger vehicles can use 2-3 standard battery packs for battery swaps.

Implementing the “Strong Core” Strategy

In addition to developing mini battery swap stations, SAIC-GM-Wuling also participates in chip development.

Currently, SAIC-GM-Wuling’s Hong Guang Mini EV uses Coretronic Microtech’s MCU chip. Shao Jie explained that this chip meets automotive-grade requirements and is mainly used in communication modules and vehicle control modules.

Shao Jie stated that in 2018, SAIC-GM-Wuling’s new energy vehicles were already considering moderately domesticating chips, with domestication rates then around 3%. In 2020, this number reached 7%, and as of this year, it has increased to 30%. However, they still have a bigger vision: they aim to domestically produce over 90% of the chips for GSEV platform models during China’s 14th Five-Year Plan period.

To achieve this goal, SAIC-GM-Wuling will cooperate with domestic manufacturers to develop chips for all vehicle categories, including calculation, storage, communication, power, and self-driving related chips.

SAIC-GM-Wuling will also create an open and shared domestic chip testing, validation, and application platform and partner with excellent domestic companies to jointly research and develop.

GSEV cumulative sales exceeded 500,000 units

The confidence to develop battery swap stations and chips comes from the market’s scale. Currently, the total number of new energy vehicles in China has exceeded 5 million, and SAIC-GM-Wuling’s cumulative sales of GSEV have exceeded 500,000 units, meaning that their market share is roughly 10%.Since its launch at the Chengdu Auto Show in July last year, the cumulative sales of the Hongguang MINIEV have exceeded 370,000 units, and it has been the best-selling new energy vehicle in China for 12 consecutive months. It also successfully won the global sales champion twice in January and April of this year. Since its launch, the Hongguang MINIEV has driven a year-on-year growth of 410% in small new energy vehicle sales nationwide.

Therefore, SAIC-GM-Wuling has defined itself as the “global promoter of new energy vehicles”.

Currently, GSEV series products have covered 33 provinces and 333 cities nationwide, with a proportion as high as 14% even in first- and second-tier cities.

In the past year, SAIC-GM-Wuling has received new energy vehicle demand inquiries from more than 200 institutions in more than 70 countries and regions in Asia, Europe, America, Africa, and others.

As of now, GSEV has provided car owners with over 140 million convenient trips, of which 95% are short trips within 20 kilometers due to its convenience and low usage cost. GSEV users have accumulated a driving distance of over 3.9 billion kilometers, which is equivalent to a Hongguang MINIEV circling the equator of the earth for 90,000 times.

In addition, the daily average travel times of SAIC-GM-Wuling’s new energy vehicle owners are also very high. GSEV owners have an average of four daily trips, while the daily launch rate, namely the daily active user rate, is as high as 94.7%. Among our 500,000 GSEV users, there is one user with particularly outstanding travel data, who has driven more than 120,000 kilometers, even exceeding five times the length of China’s border.

The sales of micro-cars have further strengthened SAIC-GM-Wuling’s determination to deepen its roots in this field. In the view of Shao Jie, the future of China’s automobile market will move towards a phase of more functional vehicles, and people will consider what scenarios the car will be used in when buying a car. Some of these functional vehicles are actually completely the second or third car of a family. Therefore, we believe that the market space for (new energy) micro-cars is very broad, at least the level of ten million units.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.