In yesterday’s article, what I found interesting about BYD’s e-platform 3.0 is that, in addition to formally adopting blade batteries and 800V, it particularly emphasizes integration. This includes the integration of powertrain components, integrated design of thermal management, and the import of four domain controllers and BYD OS. Understanding these things requires time and cross-validation of subsequent dismantling information. Currently, among the materials available, two important pieces of information are the eight-in-one controller and the four domain controllers in the electronic and electrical architecture.

Eight-in-One Controller and Power Domain Controller

I think the key to the multi-in-one technology is speed. This technology has been attempted by BAIC and systematically developed on the General Motors’ BEV3 platform, which is also called an 8-in-1 electric drive + control system, including motor, inverter, reducer, vehicle control unit, integrated power distribution unit (PDU), on-board charger (OBC), and the two DC/DC units. Huawei also presented a highly integrated multi-in-one electric drive system at an auto show, which included a BCU, PDU, DCDC, MCU, OBC, motor, and reducer as the ultra-converged power domain solution.

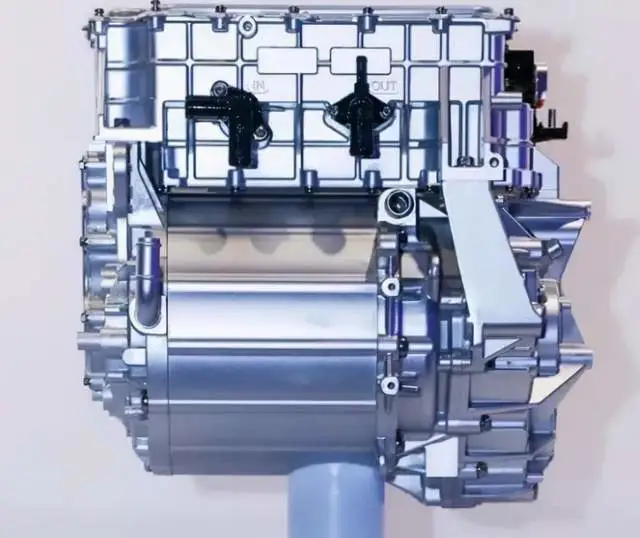

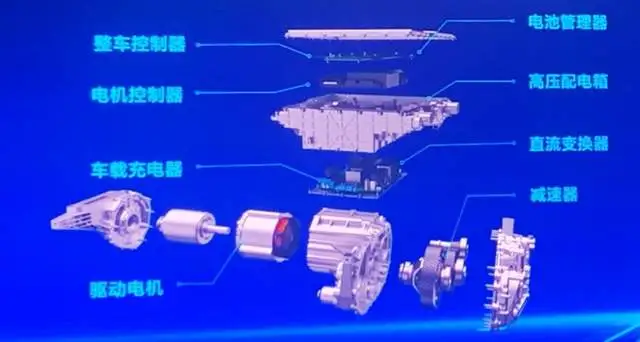

BYD’s system this time integrates the driving motor, reducer, driving motor controller, high-voltage power distribution box (PDU), DC-DC (high-to-low voltage DC converter), Bi-OBC (on-board charger), vehicle control unit (VCU), and BMS (battery management system).

I think one thing that needs to be confirmed here: due to the high integration of DCDC and ACDC, everyone has started using single-board fusion solutions. In BYD’s design, the VCU and BMS are single-board fused, while the motor controller is separated. It is possible that these three control parts have been integrated together. This is also the Intelligent Power Domain Controller mentioned by BYD before, which integrates the control parts of VCU, BMS, inverter, PDU, DCDC, and ACDC.

I think one thing that needs to be confirmed here: due to the high integration of DCDC and ACDC, everyone has started using single-board fusion solutions. In BYD’s design, the VCU and BMS are single-board fused, while the motor controller is separated. It is possible that these three control parts have been integrated together. This is also the Intelligent Power Domain Controller mentioned by BYD before, which integrates the control parts of VCU, BMS, inverter, PDU, DCDC, and ACDC.

Note: In the disassembly before the blade battery, we saw that the battery management system’s high and low voltage separation is meaningful here.

We can list a table for comparison. Judging from the mainstream trend, all companies have adopted an integrated solution for front-wheel drive systems. Everyone has the same idea and also considers the compatibility of the 400V and 800V approaches. Regarding motors, the common strategy is to transition from a cylindrical wire motor to a hairpin winding motor, making full use of the low loss, high efficiency, and high heat dissipation performance. The characteristic is to improve the slot fill factor, reduce the amount of copper used, and increase the rated power and maximum efficiency of the motor by reducing the resistance.

From this perspective, the integration degree of the rear-drive system may be slightly lower due to space limitations. This involves the ratio of front-drive and rear-drive planning platforms for different companies.

Temperature management and the other three domain controllers

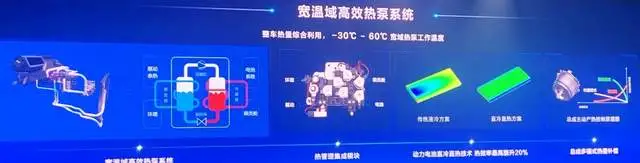

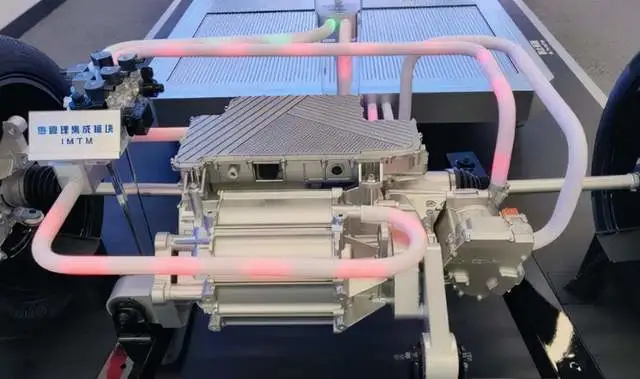

After Tesla innovated the integrated efficient thermal management, almost all automakers started to optimize their thermal management systems.

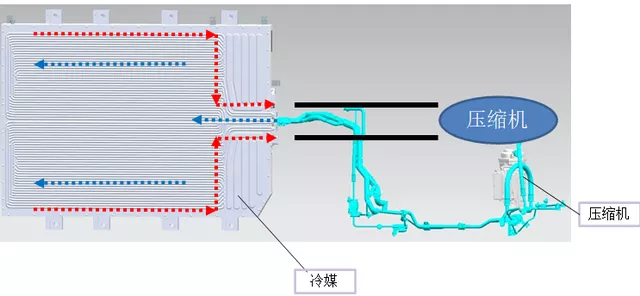

BYD’s e-platform 3.0 also uses a wide-temperature range and efficient heat pump system (-30~60℃, which is done according to a very high standard). By deeply integrating the passenger compartment, power battery, and electric powertrain, the waste heat of the electric powertrain is recovered to provide auxiliary heat source for the heat pump, covering passenger compartment temperature control and heating and cooling of the battery. According to BYD’s propaganda, there are 11 working modes, but there is no clear information at present.

Note: The on-site photos found through searching cannot be used. In the future, I will have to ask some media friends to take some photos for me to use. Due to the travel restrictions in Shanghai this year, I missed almost all the off-site activities, and I lost many opportunities to collect materials on-site.

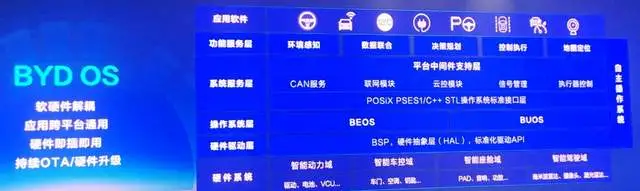

Lastly, BYD introduced the concept of its BYD OS system, which begins by constructing its own autonomous operating system from four domain controllers. BYD OS, which is decoupled from hardware and software, integrates control over various hardware devices in the car and allocates hardware functions according to application scenarios, and the networking features of these intelligent domain controllers may provide further information in the future, responsible for efficient signal transmission and efficient data processing within the domain controller.

In conclusion, I think that BYD has leveled up its technical capabilities in terms of integration and domain controllers, and has caught up with mainstream domestic and foreign automakers. Compared to the E2.0, the E3.0 shows a conceptual innovation in many aspects after three years. We should also timely reevaluate and analyze this innovation for reference.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.