Toyota’s Battery Development and Supply towards Carbon Neutrality

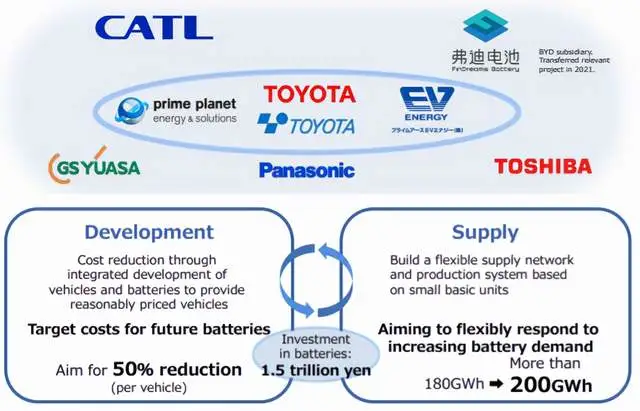

Toyota has been relatively slow in the pace of electrification, but is still constantly adjusting its pace. Recently, there have been signs that Toyota is accelerating its investment pace in power batteries, and it has announced that it will invest over $13.5 billion in battery development by 2030.

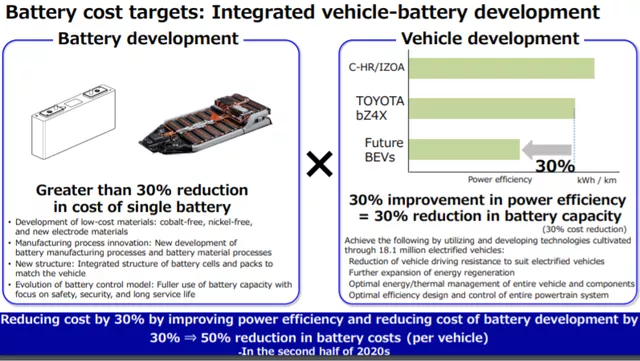

Toyota’s plan is to reduce battery costs by more than 30% by improving the materials and structure of the batteries. Masahiko Maeda, Toyota’s Chief Technology Officer, introduced the plan in “Toward Carbon Neutrality Toyota’s Battery Development and Supply”.

Note: There are rumors that the purchase price of Toyota’s self-developed battery is above 1.5 yuan / Wh, which is approximately twice the purchase price in China.

Toyota’s Battery Development Concept

In my understanding, Toyota’s requirements for power batteries are still very strict, and the reason for the high cost is not due to the unfulfilled commitment of battery suppliers to cost reduction.

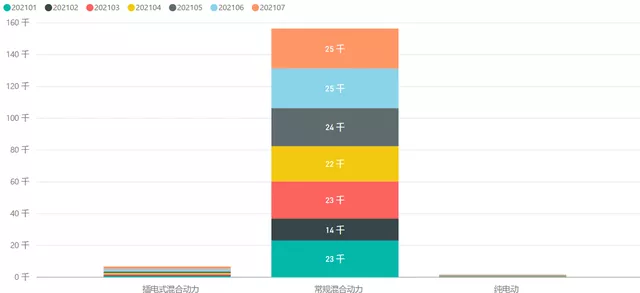

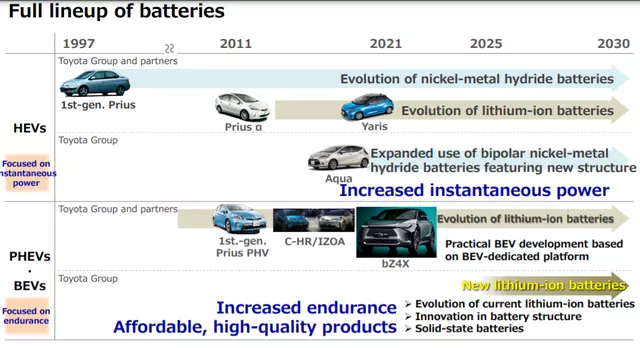

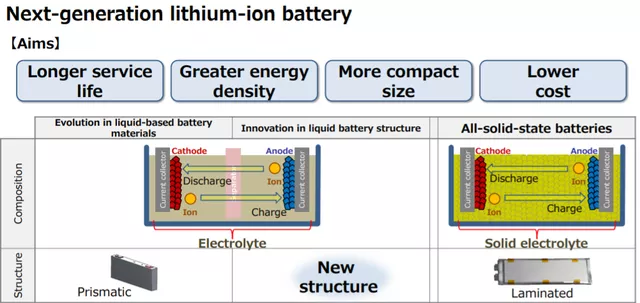

As shown in the figure below, Toyota’s focus is still on hybrid electric vehicles (HEV), so the overall development goal of HEV batteries is to increase the rate and improve HEV power. From the category of PHEV and BEV, Toyota divides them into traditional lithium development batteries and new lithium electronic batteries (which is Toyota’s desired black technology).

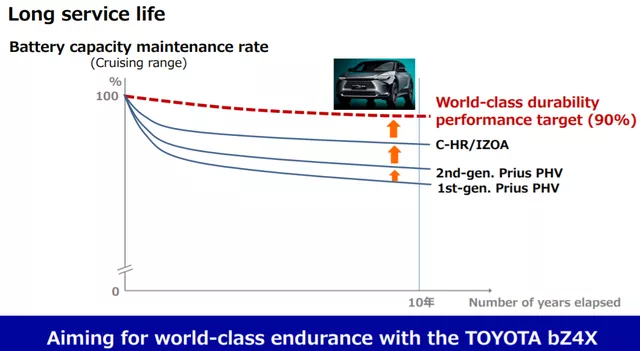

From the current requirements, Toyota’s requirements are quite high. That is, they aim to have long-life battery cells for bZ4X, with a degradation rate of 10% per 10 years (possibly accompanied by a mileage of 100-150 thousand).

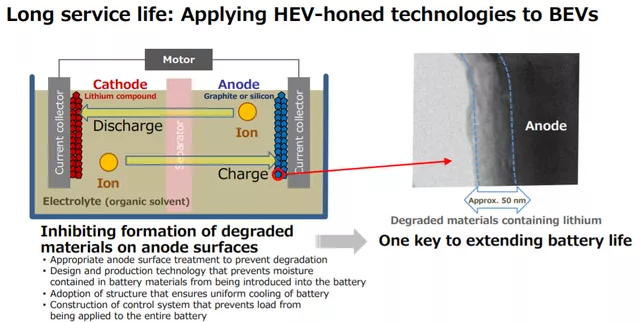

The main method to extend the battery life is through surface treatment of the negative electrode, humidity control at the battery material end, reasonable cooling structure of the battery, and proper control of the battery management system.

Translate the Chinese Markdown text below into English Markdown text, in a professional manner, while retaining the HTML tags inside Markdown, and only outputting the result.

Translate the Chinese Markdown text below into English Markdown text, in a professional manner, while retaining the HTML tags inside Markdown, and only outputting the result.

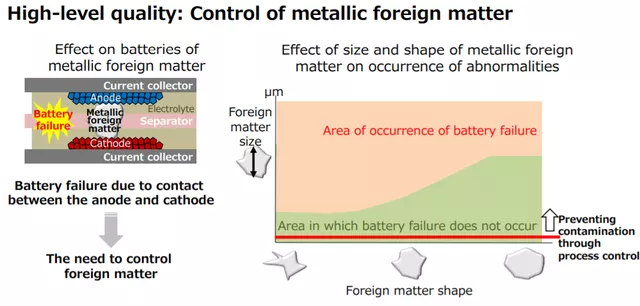

On the quality level, Toyota fully taps into the potential of quality control to control foreign matter by adopting a concomitant control method.

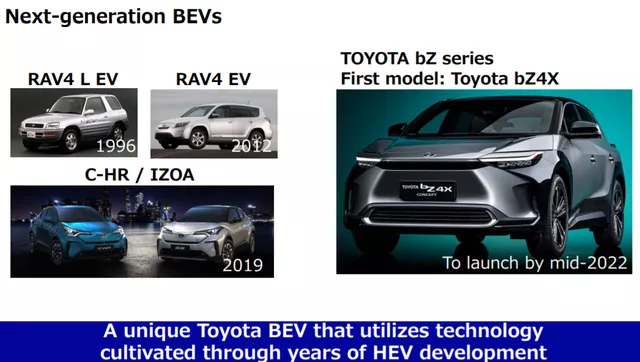

The key is still one sentence: Toyota wants to use its experience developed during the era of HEV to continue its development in the field of BEV. I am very curious whether this bZ4X will be similar to previous C-HR and IZOA.

If we estimate based on C-HR 1.5 yuan / Wh, the bZ4X still needs about 1.2 yuan / Wh. By the next generation of Toyota’s plan, it will probably be able to achieve 0.84 yuan / Wh. If the battery life can reach 10 years (150,000 kilometers) with a 10% attenuation, the cost-effectiveness of this battery will be good because it can be used for a long time.

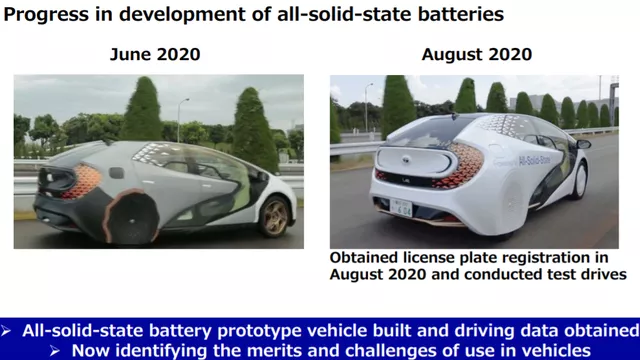

Progress in solid-state batteries

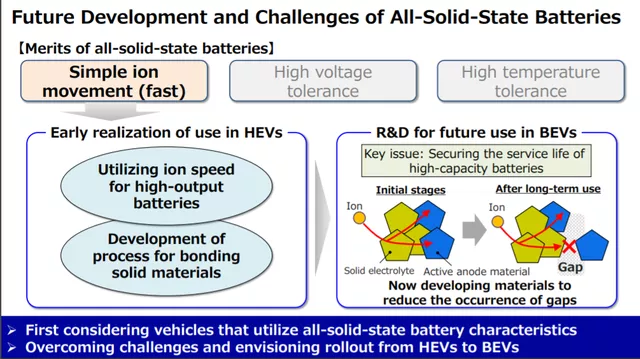

From this figure, it can be seen that Toyota is making changes to 30% of the battery structure, and the solid-state battery is carried in the form of a soft pack.

Note: The stage where soft-pack batteries might become a reality is likely to be when solid-state batteries are developed.

Here is an interesting thing that Toyota mentioned last year’s installation of solid-state batteries on cars. In June 2020, Toyota built a concept EV with a solid-state battery installed and began test driving it on a test route in August. In other words, Toyota specifically built some engineering cars to obtain vehicle driving data.

According to the material on the following page, Toyota’s vehicle may be an HEV solid-state battery, which means Toyota’s engineers’ top priority is to develop HEV cells to support HEV battery lithium electrification, which takes a relatively long time before it can be used in BEV. This is what I found most surprising.

Here, my opinion began to change. The high requirements are not easy for CATL and Freudenberg batteries to meet. Toyota’s demand for 200GWh by 2030 is a very interesting issue. But to be honest, it is difficult to join the game of BEV in the short term, and it is also difficult to come up with it by 2030.

Note: BEV currently appears to be lagging behind, but it can also catch up. The most important point is when Toyota can make efforts and come up with competitive models.

Conclusion: In 2019, we thought about many things based on Volkswagen’s MEB pure electric and Toyota’s PHEV demand. Currently, the reference is not correct in the world of pure electric vehicles. Looking to the future instead of looking back is the most important thing. After reading this material, I feel that Toyota cannot make electric cars in the 3-5 years because the ideas seem to be somewhat different from the current trend.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.