Author: Mr. Yu

The 2021 Munich Motor Show in Germany is here as scheduled. In addition to major manufacturers showcasing dazzling new products and technologies, we noticed that the “century-old shop” ZF Friedrichshafen AG (ZF) has brought multiple innovative achievements.

As a seasoned Tier 1 supplier located in Friedrichshafen, Germany, ZF’s pedigree needs no introduction. From automotive powertrain systems, chassis technology to assisted driving related technologies, even investing in Chinese start-ups specializing in low-speed automatic parking technology, all indicate ZF, as one green shoot among Tier 1, deeply understands the concept of “down-to-earth.”

Following the dazzling sales growth in the first half of 2021, ZF also brought a series of new landing and plans at this Munich Motor Show.

After the online press conference, Mr. Yu was invited to participate in a virtual group interview with ZF’s CEO, Wolf-Henning Scheider, together with multiple global industry media.

Mr. Yu @ GeekCar:

We noticed that in the financial report for the first half of 2021 released not long ago, ZF achieved a 43% year-on-year increase in sales compared with last year. At the same time, we also noticed that ZF is one of the European auto parts manufacturers with the fastest revenue growth, reaching 6.6 times that of 20 years ago.

During the global economic downturn caused by unfavorable factors such as the COVID-19 pandemic, how did ZF achieve rapid growth? What are the key areas of ZF’s business focus next?

ZF CEO Wolf-Henning Scheider:

Overall, as you just mentioned, our business is much better than last year. On the other hand, the logistics problems and chip shortage caused by the pandemic also brought challenges to ZF. Because it has slowed down the development speed of the global passenger car and truck markets, which are at the same level in China, the United States, and Europe. At the press conference for the financial report for the first half of the year held in July, we were very cautious. I still think that the second half of the year will be even more challenging than the first half. In any case, we will continue to maintain significant growth compared to last year.I also estimate that ZF’s growth rate is still higher than the industry average. So, what is our growth area? Specifically, it is electronic components. For example, we have received project orders from Dongfeng and other manufacturers in China. This is very encouraging for ADAS systems. At the same time, our new products are also firmly positioned in the entire vehicle plant, providing us with additional growth.

Schaeffler mentioned the Dongfeng project, which is the Dongfeng Fengshen Yixuan MAX that was launched just a few days ago. This model is equipped with the next-generation medium-range radar recently launched by ZF, and the ZF coASSIST semi-automatic driving system provides relevant empowerment for the model.

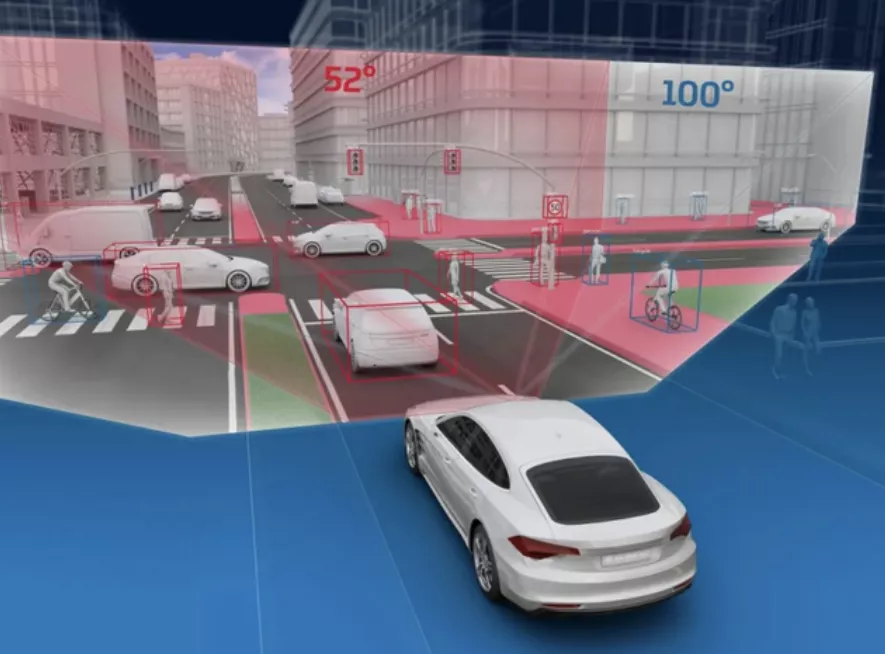

It is understood that ZF’s medium-range radar can provide three operating modes, and each mode can flexibly adjust the appropriate distance and resolution combination according to the actual driving situation:

At low speeds, it can provide a wider field of view required for close-range, optimize pedestrian detection functions, and provide support for automatic emergency braking (AEB) and other systems.

At high speeds, it can provide longer monitoring distances and enhance driving functions such as adaptive cruise control (ACC).

Built for the Automotive Industry: Inauguration of ZF’s Onboard Supercomputer “ProAI” in Europe

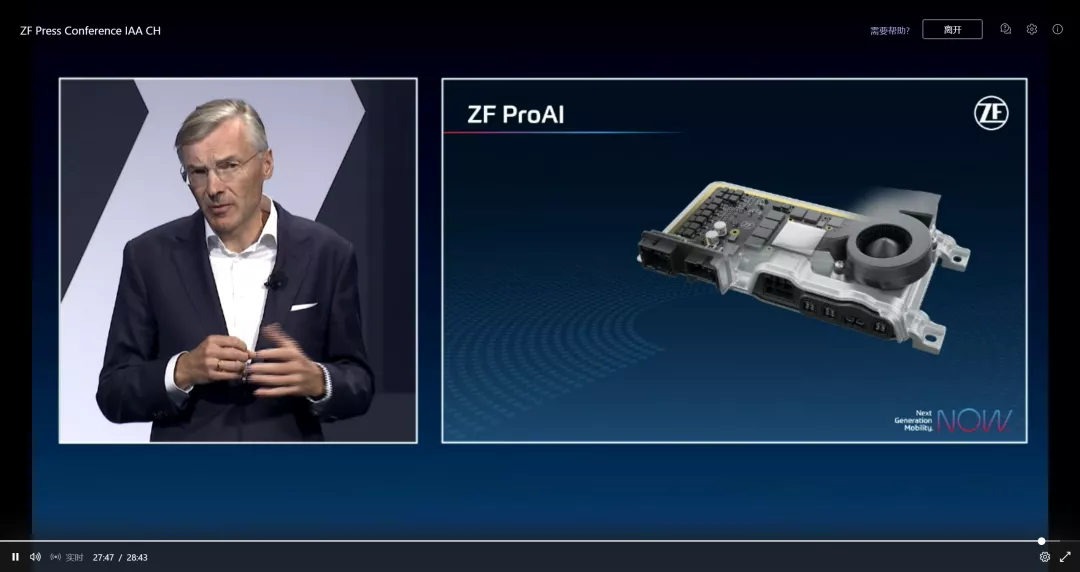

In recent years, the automotive industry has generally recognized the importance of supercomputers for assisted driving and autonomous driving vehicles. The “ProAI” unveiled at the Munich Auto Show is ZF’s onboard supercomputer built for the automotive industry.

When it comes to supercomputers, not all of them are large enough to be measured by the area they occupy. The “ProAI” supercomputer that ZF released this time is a scaled-down version that can be installed on a vehicle.

All different versions of the ZF “ProAI” are installed on a standard housing with a size of 24 x 14 x 5cm. This means that the area occupied by a single “ProAI” is smaller than that of an iPad and will be applicable to various types of vehicles, and support L2 to L5 levels of assisted and autonomous driving applications.

It is reported that “ProAI” has scalability performance levels ranging from 20 TOPS to 1000 TOPS. Compared with the previous version, the latest generation of “ProAI” has increased its performance by up to 66%, and reduced power consumption by 70%, ultimately achieving an average of 3 TOPS per watt of high-efficiency energy utilization.

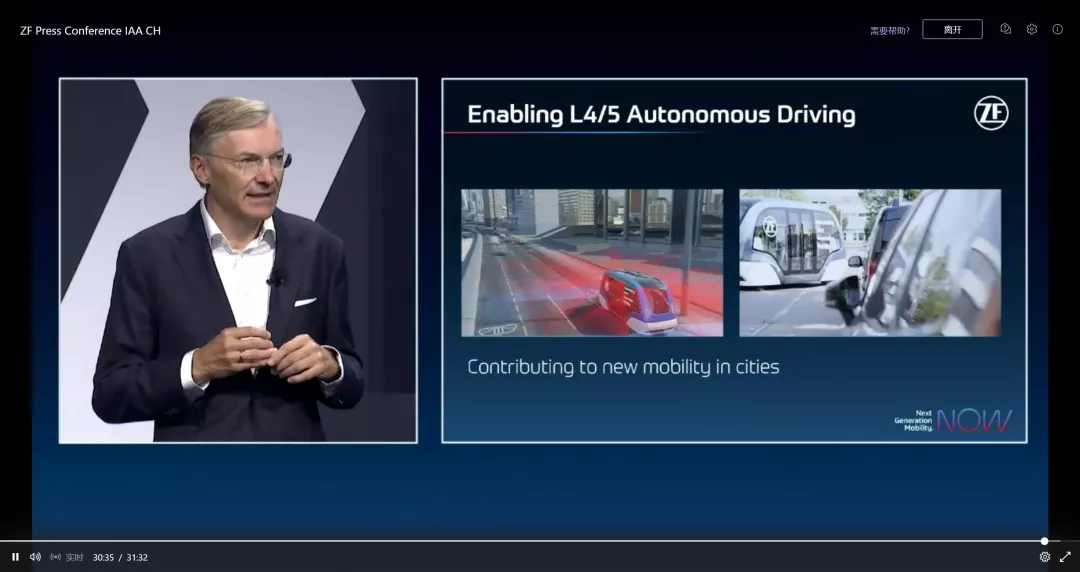

Schneider believes that Level 4 or Level 5 autonomous driving will be first deployed in the commercial vehicle sector and in urban passenger transport. Currently, ZF has actively participated in autonomous shuttle systems and other niche markets.

ZF: We will achieve carbon neutrality ten years ahead of schedule

In a green power roadmap, ZF has ensured that all its activities will achieve carbon neutrality by 2040, which is ten years ahead of the schedule planned in the Paris Climate Agreement.

Schneider states that ZF will achieve its goal of reducing carbon dioxide emissions by 80% below 2019 levels by 2030. ZF Group will expand its responsibilities to the supply chain and the use of its products. The goal is to achieve a 40% reduction in Scope 3 emissions from 2019 levels by 2030.

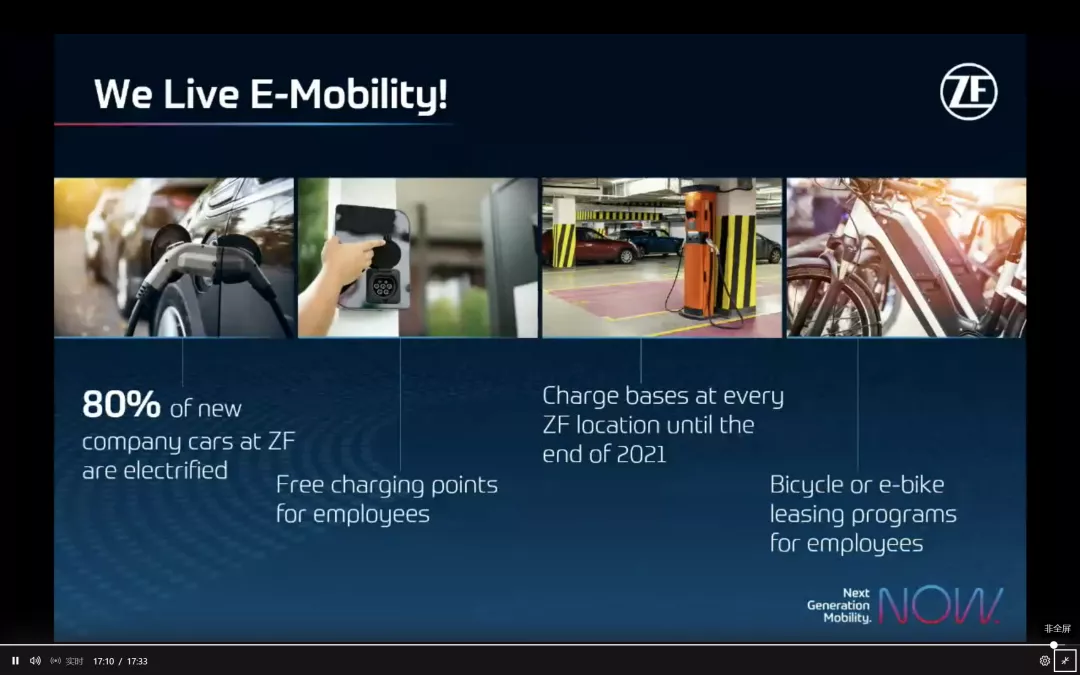

Moreover, ZF employees can also play an active role: currently, 80% of ZF’s newest business vehicles in Germany are electric. In addition, ZF provides subsidies for the installation of private charging facilities for official vehicles. As of the end of 2021, every ZF office worldwide will be equipped with charging facilities. In Germany, more than 50,000 employees can also rent bicycles or e-bikes from ZF.

Schneider said: “Our efforts are more than that. We also play an important role in renewable resource generation. Today, every fourth wind turbine in the world is equipped with a ZF transmission system. These existing wind turbines can already provide renewable energy needed by one hundred million households – and this number is increasing by one million per month.”

Schneider also stated that in recent years, ZF has always focused its strategic focus on technology that supports the next generation of travel. At the Munich Motor Show, ZF exhibited not only futuristic ideas, but also mass-producible solutions that customers can order, and they will soon be able to change the way people travel on the road.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.