On August 26th, 2021, as the second part of Aiways U6 AI-TECH Technology Day, Garage 42 participated in visiting the Saint-Gobain factory located in Minhang district, Shanghai to learn about the research and development background of their panoramic sunroof, which is also 2.1 square meters in size like the NIO EC6.

Saint-Gobain Group is a multinational corporation with a history of over 300 years, and is renowned for its automotive glass civilization, but their business scope covers a wide range of industries including building materials, pipeline systems, and abrasives and molds.

There are several special designs for the U6’s panoramic sunroof. Unlike most vehicles that use panoramic sunroofs, which are only linked to the car body by adhesive, including NIO and other models, this design poses the risk of detachment during driving, and is more difficult to ensure structural integrity after secondary gluing.

Aiways and Saint-Gobain’s solution for the panoramic sunroof is to add metal clasps in the front and rear for mechanical connection and fixation to the car body, to provide double protection and enhance passenger safety.

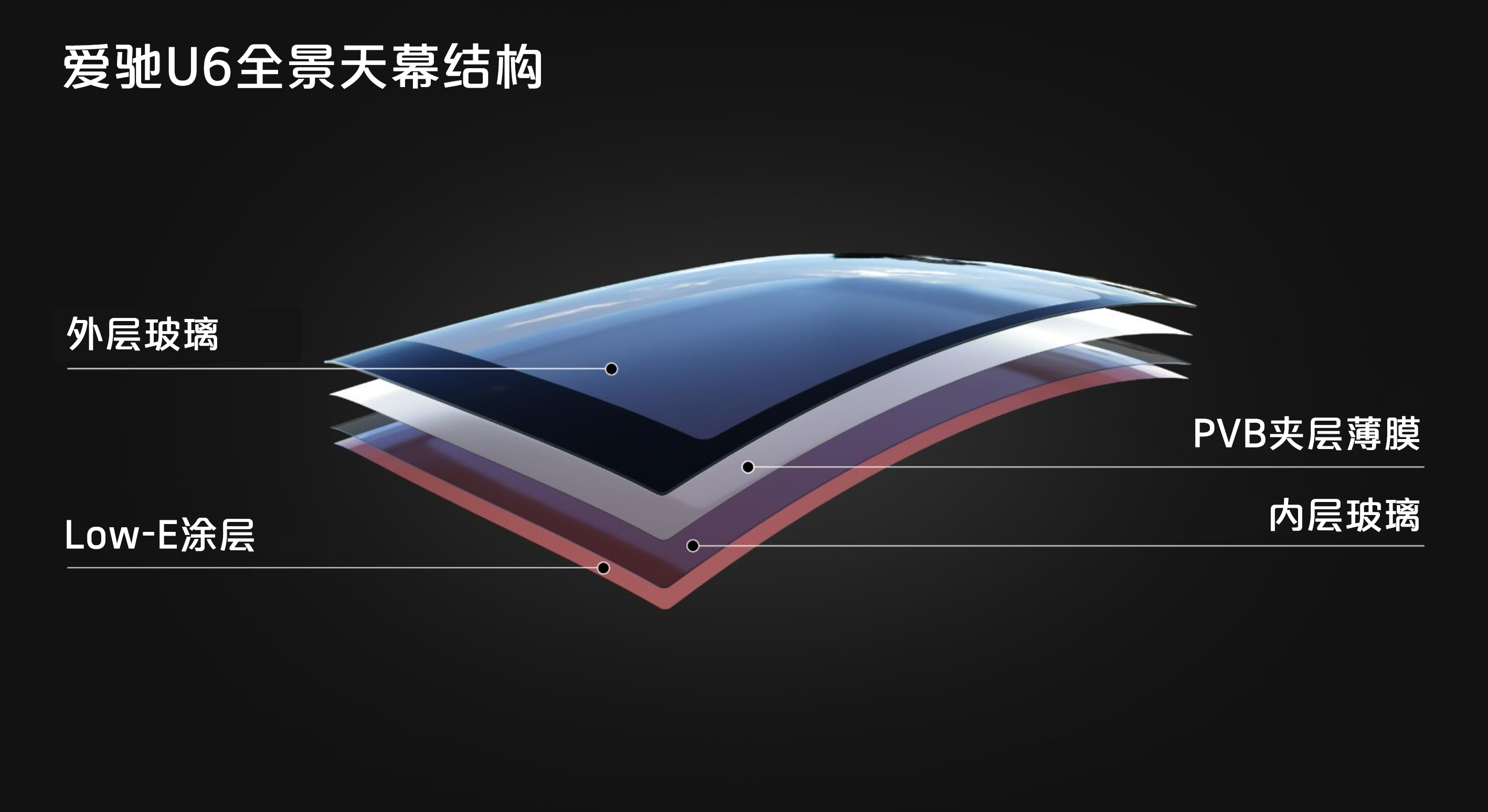

The Aiways U6 panoramic sunroof uses double-layered laminated glass with Low-E heat-insulating coating attached to the inner surface. This coating is different from silver or other coatings, and achieves a 78% reduction in heat conduction from outside the vehicle, similar to the function of a down jacket. This means that it can ensure less energy loss from the car’s air conditioning system all year round, providing an auxiliary function similar to that of warm winters and cool summers.

As for the question of whether the absence of the B-pillar crossbeam would reduce the vehicle’s rigidity, there is actually no need to worry. This is because the U6 has a torsional stiffness of 30,000 Nm/deg, which is at a mainstream level. Developed according to the E-NCAP 5-star safety standards, the entire vehicle of U6 is produced using aviation production processes such as SPR (self-piercing riveting), FDS (hot-melt self-tapping screw fastening), and CMT (cold metal transition welding), bolt fastening, and others. In addition, it is equipped with front and rear independent suspension settings. The combination of such a body and suspension foundation gives the U6 a relatively high cost-performance ratio among similar positioned pure electric SUVs.

🔗Source: Aiways, Saint-Gobain

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.