Author: LYNX

The K-cars 001 is undoubtedly the most talked-about pure electric vehicle in China this year.

On the one hand, since its debut in April, the K-cars brand has attracted extensive attention. In the subsequent small-scale test drive activities, this new car has received almost “zero negative reviews.” Reflected in the sales level, even though it has not been officially delivered, the order quantity of the K-cars 001 has sold out in 2021 with an average transaction price of 335,000 yuan.

On the other hand, the supply chain and delivery speed could not keep up with the topic’s popularity, which brought “sweet troubles” to Geely Group. In mid-June, due to the inability of the products to be delivered next year to enjoy the 2021 national new energy subsidy standards, the K-cars 001 was caught in a “price increase” puzzle. Subsequently, configurations such as EC light-sensing sky curtains and air suspension that affected delivery speed caused another public opinion storm. Recently, doubts from many users who placed orders have been raised due to the problem of mixing imported and domestic motors.

The only way to dispel misunderstandings is to explain them in a timely manner. Fortunately, the K-cars official website is also “responsive” and has continuously released new policies to actively respond and solve doubts.

To deal with the delivery delay caused by parts shortages and production reasons, K-cars has promised to bear the difference in national subsidies, compensate waiting points, and other commitments.

As for the impact of domestic and imported motors on product performance, K-cars recently invited two large-scale vehicle owners to visit the production base and conduct an “electric triple tour” online, demonstrating their comprehensive strength in “three-electric” technology.

Without mentioning all kinds of technical parameters, the core part of the entire live broadcast is actually the last half-hour when two owners test drove two K-cars 001 on-site.

The host then asked, “Did you feel any difference between the two cars during the test drive?” After the owners answered “no difference,” the host revealed the answer to them and all the audience who watched the live broadcast. One test car was equipped with imported Japanese Denso motor, and the other was equipped with domestic Wairui motor – to prove that different suppliers’ motors would not cause substantial impacts on the K-cars 001’s driving experience.

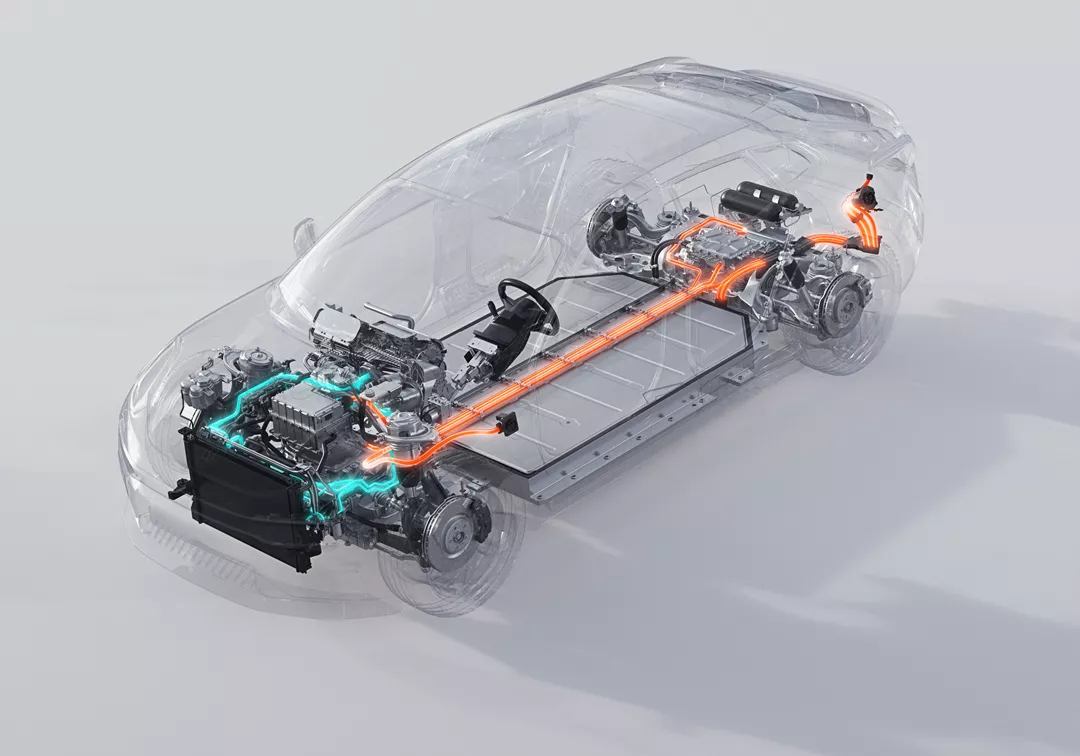

Of course, everyone knows that the electric vehicle “Three Electric” covers the whole complex system of battery, motor, and electric control. In addition to explaining the impact of different motor suppliers that has received the most attention recently, this online live streaming also demonstrated the efforts of Zeekr to improve the overall performance of the “Three Electric” system. To put it simply, the battery is safe enough, the charging is fast enough, and the motor is strong enough.

“Show Again” Battery Safety

Safety is still the focus of attention for consumers when purchasing electric vehicles today. After last year’s BYD blade battery became popular, now electric vehicle manufacturers always first take out the new car battery pack and make some tests to prove that the battery is safe and will not catch fire when talking about the “Three Electric” system.

Zeekr’s online live streaming this time also used four tests, “stabbing”, “soaking”, “heating”, and “falling”, to emphasize the all-round safety of the “Ji Xin” battery pack.

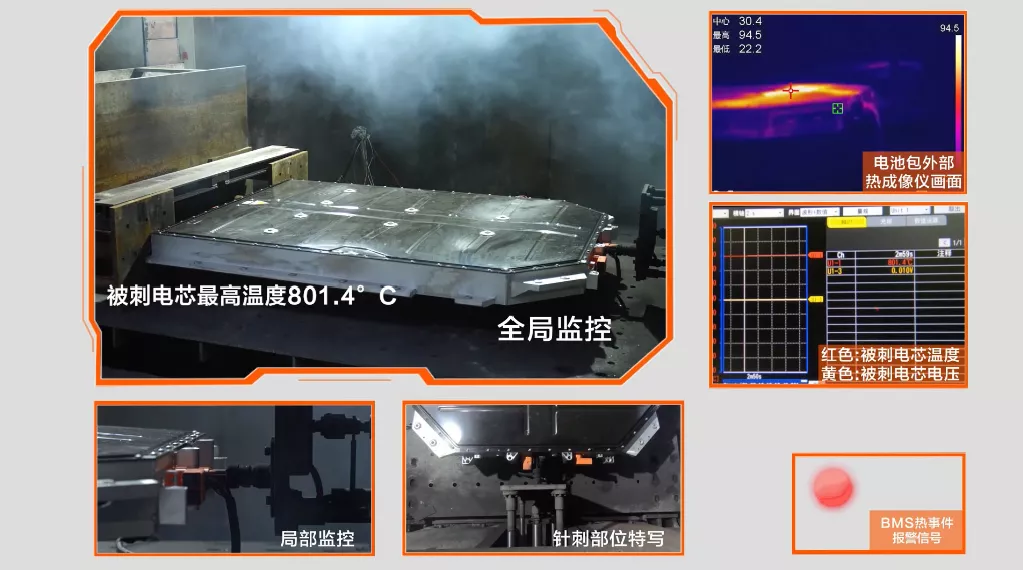

- Stabbing: Video of Zeekr 001 battery pack needle puncture test

In the video, when the steel needle is inserted into the battery pack and triggers thermal runaway, the BMS battery management system immediately triggers an overheating event alarm signal. At the same time, the pierced battery pack began to smoke, and the highest temperature of the pierced cell reached 801.4℃, but it did not catch fire or explode.

After being placed for 24 hours, the voltage of the pierced cell dropped to 0 V, and the temperature dropped to room temperature. The thermal insulation and barrier structure of the battery pack remained intact without significant deformation, and the internal structure and high-voltage connection of the battery pack were intact. The battery shell was not electrified, and the design was not affected by heat propagation.

However, the fact that the needle puncture test did not cause a fire does not mean that the battery will never catch fire. This was demonstrated in the collision test of a BYD Han EV carried out by some media earlier. The electrolyte in lithium batteries is a flammable substance, so there is still a risk of fire in case of electrolyte leakage, overheating, and other situations.

The purpose of the needle puncture test is still to use an easily understandable form to tell everyone that the protective measures of the battery pack have reached a relatively high level of safety.

- Soaking: The battery pack is immersed in water for 48 hours without leakage, and the pool can raise fish.When the battery meets water, people easily think of electric leakage. Therefore, JiKe submerged a fully charged battery pack in water for 48 hours, and then put a small group of goldfish into the pool. These lively and leisurely swimming fish can tell everyone that the battery pack has met the airtightness requirements and there is no electric leakage.

In fact, nowadays many car companies have higher experimental requirements for their own batteries than the national standards. The soaking time of JiKe’s battery pack in water experiment also far exceeds the national standards.

However, it should be noted that the requirements for battery soaking experiments in the “Safety requirements and test methods for power batteries for electric vehicles” of the country is to submerge them in a solution containing 3.5% NaCl (sodium chloride, simulating more corrosive seawater) for 2 hours in a fully charged state, without any phenomenon of fire and explosion.

Although the soaking time of JiKe’s battery pack exceeds the national standard by a lot, goldfish…Next, let us look forward to which car company will be the first to use turtles in a similar experiment.

- Heat test: Single cell heated to 800℃, the battery pack does not smoke or catch fire

More important than the needle puncture and soaking experiments may be this thermal runaway test. JiKe’s technical staff simulated the thermal runaway inside the battery pack and heated the single cell to above 800 ℃.

Subsequently, the technician’s computer received the thermal runaway warning in time, and the battery pack did not catch fire.

The thermal runaway warning is of great significance for safety, and the driver and passengers will receive warning before obvious signs such as smoke and fire. This gives valuable time for evacuation.

At the same time, JiKe’s technical staff also emphasized that the system will not wait until it is too late to issue a warning. In the JiKe 001 battery pack, the system transmits the status of each cell to the cloud every 10 seconds to give the car owner an earlier warning.

- Drop test: Battery pack falls 4.9 meters, without explosion or fire

This test is more simple and rude, it simulates the impact of external forces on battery safety when the vehicle falls on a high bridge or other road conditions.

From the test results, JiKe’s battery pack also passed this test smoothly.The live test showed a whole body downward impact may not be the typical real-life scenario for high altitude falls, where an angle may exist, causing larger damage to the battery pack when a certain corner is hit. Furthermore, why was it 4.9 meters rather than 5 meters remains unknown.

In short, Extreme-E for “ExtremeCore” has confirmed the safety of their battery pack through the aforementioned four obvious test items. The company claims that these are just the tip of the iceberg of their rigorous battery pack tests.

In reality, the safety testing of the entire battery pack involves up to 472 tests, surpassing the national standard by 122%. Overall safety of the battery pack was achieved through the engineers’ systemic efforts, including material selection (high voltage single crystal Ni55 and battery cell NiCoMn ratio of 5:2:3), structural protection (NTP non-thermal propagation technology), and the BMS thermal management system (three-terminal coordination of cloud, car, and charging pole with 7×24 hour real-time warning).

Charging for 5 minutes can extend the driving range up to 120 kilometers.

Previously, Extreme-E 001 had raised controversy for promoting support for the SEA architecture that could sustain 800 V electrical platform at the press conference but ended up using a 400 V platform in the vehicle.

During the test, however, the company attempted to reassure users that 400V would be sufficient to dispel the commonly known “range anxiety,” and users who paid over 300,000 RMB for an Extreme-E 001 can rest assured that they made the right decision.

During the live demo, the vehicle was parked at the Extreme-E charging station equipped with “ExtremeCharge,” where the car’s NEDC (New European Driving Cycle) driving range went from 21 kilometers to 144 kilometers in just five minutes of charging time, achieving the promised “5-minute charging for 120 kilometers of range”. The high-current charging demo exceeded 500A, with the highest charging rate of 2.2C.According to reports, under the 400V voltage platform, the JIK-001 SoC can reach an 80% charge from 10% in just 30 minutes. However, to achieve such efficient charging results, it must be done at JIK’s self-built “JiChong” charging station. It requires a 360 kW charging pile (Tesla’s V3 supercharging pile’s maximum is 240 kW), and the charging cable also needs to be equipped with an exclusive liquid cooling system to solve the heat dissipation problem caused by high current.

This also illustrates that in addition to the need for high-quality vehicles, the self-built energy supplement network is also a common issue facing all car companies today.

In addition to fast charging, solving “range anxiety” also requires “accurate display.” In response to this, JIK’s answer is the first domestically produced three-in-one flat wire technology, with the highest motor efficiency of 97.86% and the leading electric drive power density of Weirui, which can maximize the reduction of energy loss, recycle excess output energy, efficiently convert it into battery energy storage, achieve accurate display range, and an average accuracy of SOC can reach 3%.

Different motor suppliers, same experience.

Currently, JIK-001’s motors come from two suppliers, Japan Electric Corporation and Weirui. The controversy this raised is the slight difference in parameter between the two suppliers’ motors, making the ordering customers raise concerns about “downgrading.”

For this reason, JIK officials previously stated that they would leave the motor selection option to the user to choose, and there will be a motor selection pop-up window when placing an order in the APP.

However, in fact, Weirui’s motor is Geely Group’s “progeny”—established as a subsidiary of Geely Holdings specializing in electric vehicle drive systems as early as 2013. In 2017, Geely set up Weirui Electric Vehicle Technology (Ningbo) Co., Ltd., together with its previous Suzhou company, specifically to supply battery packs to Geely’s brand.

Therefore, in this live broadcast, JIK obviously wants to endorse its own brother. First, they took everyone to visit Weirui’s fully automatic factory and demonstrated the mass production process of the three-in-one flat wire motor.

This flat-wire motor adopts a complex eight-layer hairpin stator winding technology and a square flat wire, which can increase slot fullness and improve power, enhance heat dissipation, and enable JIK-001’s motor to achieve excellent peak efficiency of 97.86%.Translated English Markdown Text:

Later, Zeekr reiterated that the torque of the wheel end for the two motors from Nidec and Weirui is 3840 Nm.

Finally, there is the section where car owners “blindly test” two types of electric vehicle motors, which was mentioned at the beginning of this article. Judging from the car owners’ feedback, the two motors perform identically based on the requirements of the whole vehicle, in terms of whole vehicle acceleration, whole vehicle power consumption and NVH noise control. The acceleration time of the four-wheel-drive version of Zeekr 001 is also consistent at 3.9 seconds.

However, the question remains worth considering: in this era where electric vehicles generally have “excessive performance,” is it really that important for consumers to simply pursue performance when making purchasing decisions?

Conclusion

With the advent of the era of electric cars, the three electric technologies of batteries, motors, and electronic control, which are core values, undoubtedly test the basic skills of car manufacturers in terms of competitiveness.

And Zeekr’s display of its three electric technologies once again proves that, when it comes to the most fundamental “car-making” level, Geely is serious. Zeekr 001, the first car model based on the SEA architecture, has enough mechanical quality, so we need not worry too much about it.

However, what is worth more careful consideration is why Zeekr 001 still faced various controversies despite having excellent vehicle performance?

In addition, as the three electric systems are an integrated whole, for the new Zeekr brand, subsequent channels, marketing, intelligentization, charging networks, and other areas are a comprehensive system engineering project. Fortunately, the first batch of Zeekr 001 will start delivery as planned in more than a month.

As for these tasks, what kind of answers will Zeekr present in the future? Perhaps we can let the bullets fly a little longer.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.