A few days ago, my colleagues and I were discussing Tesla’s “next car” and speculating about how much cheaper it would be when produced domestically.

The boss who already owned an imported Model 3 jokingly asked when he would be able to buy a 500,000 RMB Model S.

The hope of producing a domestically made Model S/X hinges on demand being the driving force. Assuming there is substantial demand in the market and the profit is high enough, then the biggest obstacle to domestic production will be eliminated.

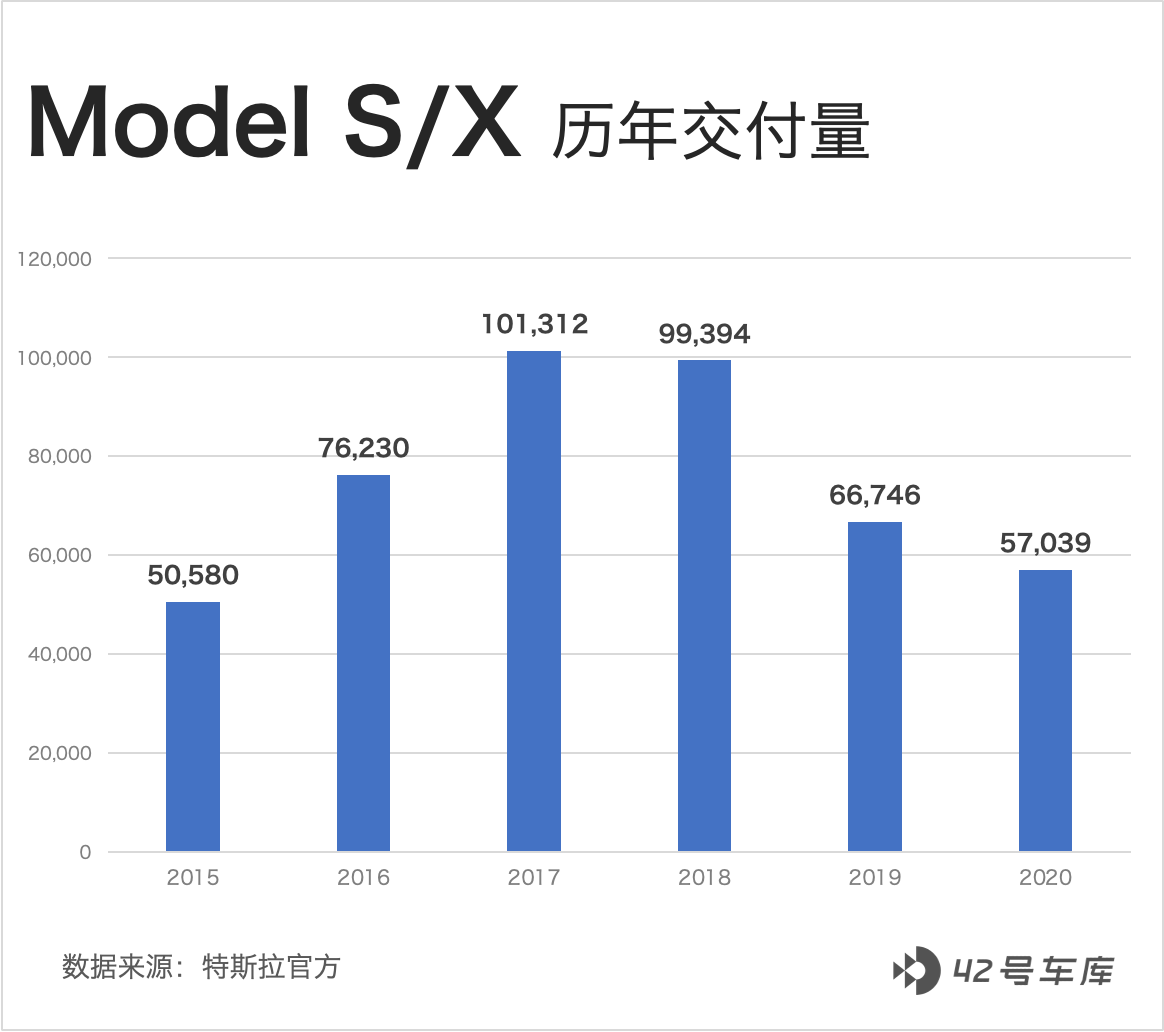

We can try to predict the market capacity and future sales trends of the Model S/X by analyzing past sales figures.

I have collected the historical global delivery volumes of the Model S/X from 2015 to last year, and the peak can be seen to be around 100,000 vehicles per year.

It’s worth noting that the Model S/X is only produced at Tesla’s Fremont factory in California, USA. In Tesla’s Q4 2020 financial report, the official capacity of the Fremont plant was reviewed and planned. The plan is to increase the production capacity of the Model 3/Y to 500,000 vehicles per year, while restoring the production capacity of the Model S/X to 100,000 vehicles per year. This capacity is basically in line with the peak delivery volume of the Model S/X, indicating that Tesla is preparing for the future sales of the Model S/X based on previous experience, but it seems to be somewhat conservative.

Although the planned production capacity is 100,000 vehicles per year, Tesla is clearly not going to meet this goal this year.

In the first quarter of this year, Tesla stopped production on the Model S/X production line at the Fremont factory for retooling, resulting in no new Model S/X being produced during the first quarter. After the second quarter, the production line for the Model S was retooled and the production preparations were completed, resulting in the production of 2,340 Model S/X vehicles and the delivery of 1,895 vehicles.On July 28th, Tesla postponed the delivery date of the Model S, with the delivery date of the Long Range version delayed from 9-10 months to 2-3 months next year, and the Plaid version delayed from August to 1-2 months next year. Even the Model X, which was originally expected to be delivered in January-February next year, was also delayed to February-March. New domestic orders will have a unified delivery time in the first quarter of next year.

Even in July, the Model S production line at the Fremont factory experienced a shutdown of about a week without official explanation, probably due to “chip shortage” issues. If the production of Model S/X is constrained by the chip issue, Tesla will not and cannot expand the production of Model S/X until the chip issue is resolved.

Combined with the previous sales performance of Model S/X reaching 100,000 units/year, plus the fact that the Fremont factory cannot reach a capacity of 100,000 units in a short period of time, and that Tesla has not disclosed the specific number of orders, it is difficult for me to determine whether the current incomplete capacity and future complete capacity of the Fremont factory can meet current and future orders with two of the three numbers missing in this question.

Therefore, judging the size of the market gap from the production and sales volume, and then judging whether there is a possibility of domestic production, this clue is broken. As we mentioned at the beginning, “seeking truth from facts”, so we continue to explore, assuming that domestic demand supports the production of Model S/X, what are the difficulties that need to be solved.

Difficulties in domestic production

Giga Shanghai

Domestic demand must land at Tesla’s Shanghai factory, so can a new Model S/X production line be built in Shanghai?

Many people may wonder why it is necessary to build a new production line instead of modifying the existing production line to adapt to the production of Model S/X. There are two main reasons:

- Tesla does not have experience in converting the Model 3/Y production line to the Model S/X production line.

In 2017, Tesla spent $1.6 billion to prepare for the conversion of the Model S/X production line at the Fremont factory to adapt to the production of Model 3. In fact, the Model S/X production line at the Fremont factory has only had a history of shutdowns for upgrades.

- The Model 3/Y production line at the Shanghai factory shoulders the global demand.Tesla’s Shanghai factory was initially designed with a production capacity of 500,000 vehicles per year, and it belongs to the Model 3/Y production line. While the Fremont factory mainly supplies the North American market, the Shanghai factory not only provides deliveries to the domestic market but also shoulders the responsibility of delivering to regions such as Europe and the Asia-Pacific. For example, in July, Tesla sold a total of 32,968 vehicles with domestic sales of 8,621 vehicles, and exports accounting for 2/3 of sales, totaling 24,347 vehicles.

As Tesla faces the strong demand in the European market, it is further boosting the production capacity of Model 3/Y in Shanghai’s plant and will not turn to the production of Model S/X.

Since it is not practical to retrofit the existing Model 3/Y production line, what about building a new one?

At present, the production capacity of the Shanghai factory has approached the designed 500,000 vehicles per year. According to Tesla’s Q1 2021 earnings report, the existing production capacity is 450,000 vehicles, mainly providing Model Y/3 models to the Chinese and European markets. Additionally, four projects at Tesla’s Shanghai factory, including the first-phase project of the Super Factory, the parts production process upgrade project, the Super Factory building project, and the new model early launch project, are still incomplete, with only the parts production process upgrade project remaining. It can be seen that Tesla did not reserve any plans for the construction of other production lines.

In March this year, the land opposite the Shanghai factory was put up for auction, and Tesla did not bid for it. If this land were to be expanded into a factory, it could increase annual production capacity by about 200,000 to 300,000 vehicles, or it could be used to build Model S/X production lines.

However, Tesla did not do this, indicating that it currently has no plans to expand production, although some speculate that it is due to US-China trade friction.

Priority

Compared to the domestic production of Model S/X, in fact, there are more urgent and important things for Ma Yilong to push forward. I can clearly see that Ma Yilong’s “to-do list” on hardware manufacturing is full.

For example, the production of Cybertruck. The Cybertruck was originally scheduled to be mass-produced at the Austin factory in Texas this year, but it has also given up the promise of delivery by the end of this year, with the displayed delivery time being next year. In the meantime, Ma Yilong will be closely monitoring the progress of Cybertruck’s production. The Austin factory in Texas is still under construction, although some areas have begun testing. Another current focus of the factory is on the one-piece pressing process test for the front and rear bodies of the Model Y production line.## Compact Car “Model 2” Hyped Recently

When the domestically-produced Model 3 was delivered at the beginning of last year, Ma Yilong announced that he would establish a vehicle design team in China and produce a car specially designed for the Chinese people. At Battery Day in September last year, Ma Yilong also stated that he would produce a cheaper car model priced at $25,000 (approximately RMB 160,000). Many people consider these two pieces of information to be describing the same car model, and the latest news is that this car model will debut at the end of this year at the earliest and will be put into mass production next year. Another “next year.”

In addition, we can even foresee that after the mass production of the 4680 “can” battery next year, the very precious output should make Ma Yilong perplexed: should it be allocated to the domestically-produced Model S/X or the American Model S/X? Or Cybertruck? Or should Model 3/Y be the first?

Can You Buy a Model S/X for RMB 500,000?

During a chat with colleagues, someone imagined using the domestically-produced BMW 5 Series, Mercedes-Benz E-Class, and Audi A6 as a reference to gain insight into the pricing and sales performance of the domestically-produced Model S/X. However, this is not very meaningful.

First of all, these cars were domestically produced in the early 2000s when the door to China’s automobile market was just opening. These earliest joint ventures benefited from the rapid growth of the market, with peak sales reaching around 20,000 units per month. After 2008, China’s auto market entered the stock era, and on top of that, with the impact of the global pandemic, the monthly sales of these cars have been only around 10,000 units, which is already quite gratifying. Now, in addition to the background of stock and the pandemic, people’s consumption concepts are also undergoing too many significant changes and differences.

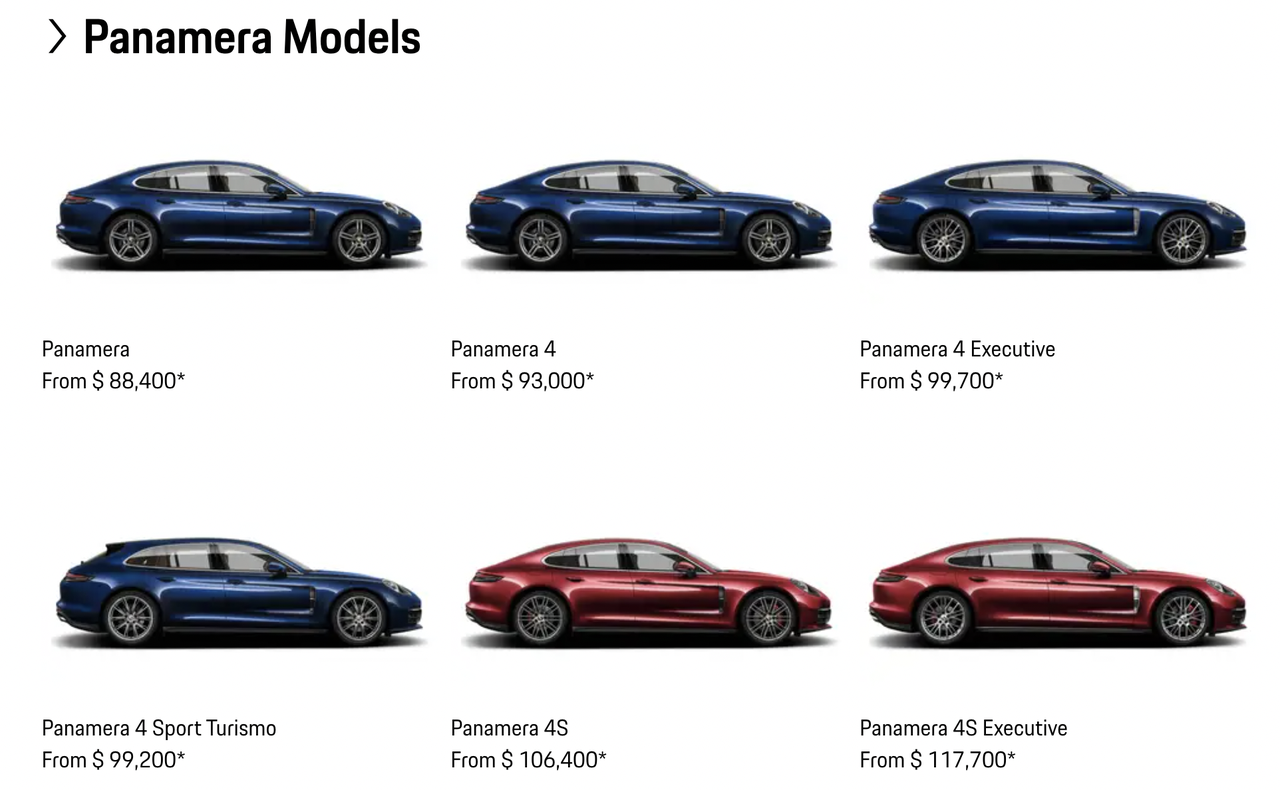

In addition, in the United States, the Model S is priced between $83,000 and $133,000 and competes with the BMW 7 Series, Mercedes’ S-Class, and even Porsche’s Panamera, not the C-Class mentioned above. In the United States, the Model S sold approximately 17,000 units last year, more than the total of the three mentioned above.

So someone asked, after the domestically-produced Model S/X, will it sell for RMB 500,000?

If we follow the cost and profit margin-oriented thinking, we will find that the localization rate determines these indicators, which has led me into a dead end.

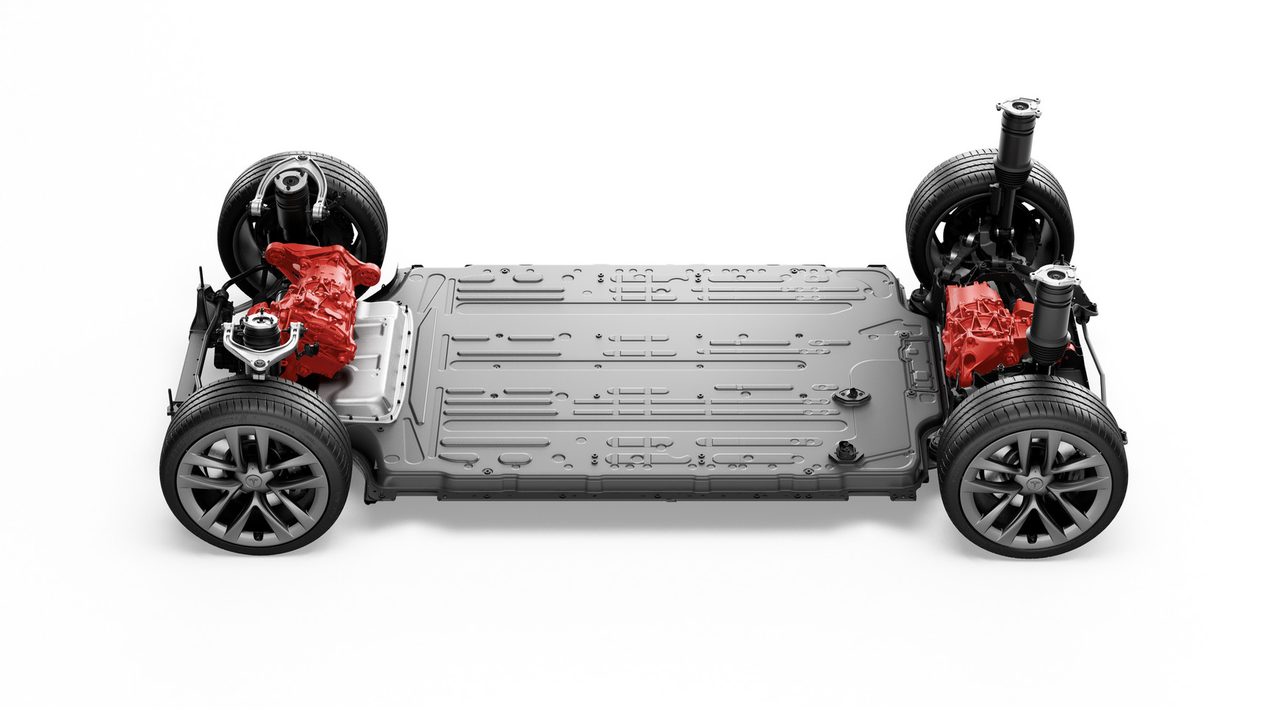

The most eye-catching feature of the Model S Plaid at present is its extreme acceleration, which is powered by a motor with a carbon fiber-wrapped rotor that can reach up to 20,000 rpm. The cost of this motor is currently unknown, but the difficulty of achieving domestic production is undoubtedly high.

The most eye-catching feature of the Model S Plaid at present is its extreme acceleration, which is powered by a motor with a carbon fiber-wrapped rotor that can reach up to 20,000 rpm. The cost of this motor is currently unknown, but the difficulty of achieving domestic production is undoubtedly high.

In addition to the motor, products and technologies such as the 4680 battery and CTC are gradually being introduced in the Model S/X, further increasing the difficulty of domestic production.

Although Tesla already has a mature supplier system in China, the lack of experience in transplanting the Model S/X production line is not the main issue. The crucial point is that, during the early stage of domestic production of the Model S/X, Tesla will need to select domestic suppliers based on the cost and performance of the components provided by them, then price the vehicle accordingly. Therefore, it is difficult to predict the price of the Model S/X based on cost alone.

The price of 500,000 yuan is cleverly positioned between the C-class and D-class cars. As Tesla’s flagship model, will Tesla choose to lower the price or positioning of the flagship model due to a significant reduction in manufacturing costs in China? This is hard to say, especially since the current Tesla models that carry the “affordable mission” are the Model 3/Y and the future “Model 2.”

To sum up, there are many reasons why the domestic production of the Model S/X may be rejected at this stage. Ma Yilong has always been cautious about things that can be done but don’t have to be done, as there are many other more important, certain, and urgent matters to address. Therefore, domestic production of the Model S/X may not appear as a topic in Tesla’s internal discussions in the near future.

In conclusion, at least in the short to medium term, Tesla will not introduce the Model S/X production line to China, which means that domestic production is not likely to happen in the next 2-3 years. However, if the Model S/X is indeed produced domestically and priced at around 500,000-800,000 yuan, or if the lower cost has been achieved, how will the domestic new energy vehicle brands respond?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.