On June 7th, Ma Yilong announced on Twitter that he was canceling the Plaid+ version of the Model S, and said that the Plaid version was already good enough. However, during the delivery livestream on the 11th, he didn’t mention anything about the cancellation. This “best in production” model disappeared just like that with only a few tweets from Ma Yilong, which of course didn’t satisfy the masses who were curious about the reasons behind the cancellation.

Tesla has not given any explanation for the cancellation of the model, nor has it offered any compensation to those who had placed orders for the Model S Plaid+ version, or even given them any advance notice. This has likely disappointed many Tesla fans.

Just after canceling the Model S Plaid+ version, Ma Yilong raised the price of the North American Model S Plaid model from $119,990 to $129,990 on June 10th. Was this a move to make those with Model S Plaid+ orders feel like the Model S Plaid was worth it?

The biggest difference between the Model S Plaid+ and the Model S Plaid is not the difference in total power between the three electric motors, but in the batteries used, with a “generation gap” between them: The Plaid+ has the “next generation” 4680 battery, while the Plaid has the old-fashioned “previous generation” 18650 battery.

The difference is that the EPA range of the Model S Plaid+ is up to 840 km, while the Model S Plaid is only 628 km. This is quite a big difference. However, Ma Yilong further explained that:> “What we are seeing is that once you have a range above 400 miles, more range doesn’t really matter. There are essentially zero trips above 400 miles where the driver doesn’t need to stop for restroom, food, coffee, etc. anyway.”

So, drivers don’t need a range above 400 miles (about 640 kilometers)?

This is clearly Ma Yilong’s sophistry, shifting the focus with a false premise. Because under the current charging infrastructure, longer range means less range anxiety. Numerous domestic manufacturers have exceeded 700 or even 800 kilometers under the NEDC standard, and even NIO ET7 and Zhi Ji L7 are heading towards a range of 1,000 kilometers. More importantly, the main competitor to Model S, Lucid Air, already has a maximum range of over 500 miles (about 800 kilometers). This comment has humiliated Ma Yilong.

However, this comment successfully redirected the attention to the issue of range. This has caused speculation that there might be issues with the production of the 4680 battery cells.

What is 4680?

At the Battery Day in September last year, Tesla unveiled a new battery cell called the “4680”, which has a diameter of 46mm and a length of 80mm.

_20210611112957.png)

Compared to the previous 21700 and 18650 cells, this cylindrical can-shaped cell is larger, enabling the elimination of the middle layer, which is beneficial for both range and cost.

_20210611113006.png)

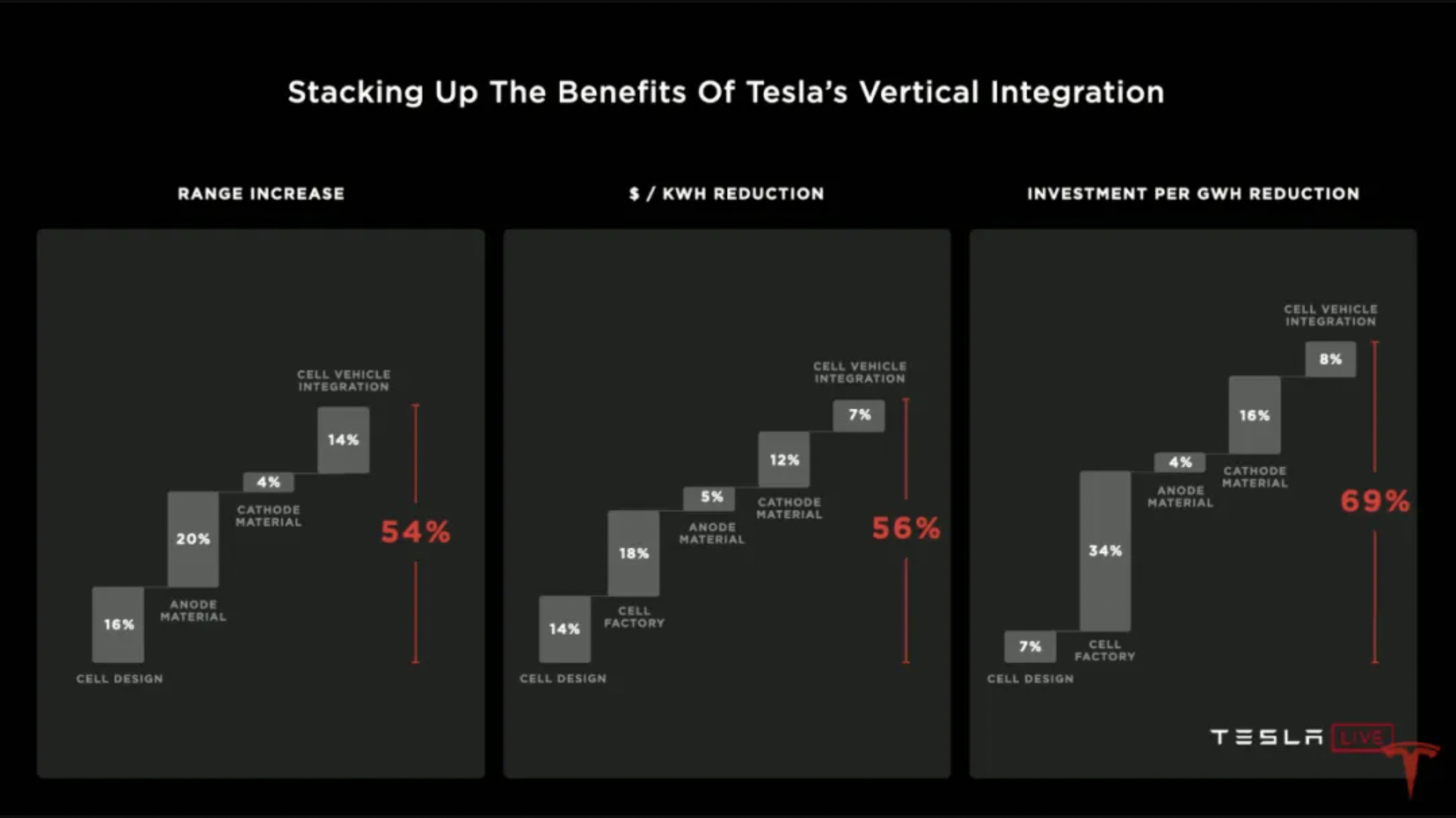

Tesla has developed many constructive design and manufacturing ideas for the 4680, but has not released specific details on when and to what extent such technologies will be implemented, including:

-

A “tabless” electrode design, which places the positive and negative electrodes directly on the cylinder side, reducing internal resistance and heat generation.

-

A high-nickel, cobalt-free cathode design, reducing the reliance on cobalt and lowering raw material costs, further increasing battery energy density.

-

A 20% silicon-doped anode, further reducing costs and increasing energy density.- CTC (Cell to Chassis) packaging technology means that the battery pack, with batteries arranged in a honeycomb-like structure, becomes an integral structural component with the chassis, bearing the load.

After implementing all of the above technologies, Tesla’s battery costs can be reduced by 56% and their range can be increased by 54%! However, Tesla did not specify whether all of these technologies will be applied to the 4680 cells of the Model S Plaid+; they only indicated that it will take several years to achieve.

Difficulty of 4680 Mass Production?

The outside world has always thought that Panasonic’s difficulty in producing the 4680 cells was the “culprit” behind Tesla canceling the Model S Plaid+ version. But at the moment, I haven’t seen any specific issues that will delay the delivery of the 4680 cells.

And basically, this is just a guess because we don’t know for sure, but it appears as though we are about 12, probably, not more than 18 months away from volume production of the 4680. Now at the same time, we are actually trying to have our cell supply partners ramp up their supply as much as possible. So this is not something that is to the exclusion of suppliers. It is in conjunction with suppliers.

Since Battery Day in September of last year, people outside have been concerned about the progress of the 4680 cell production. In late April of this year, Ma Yilong said that “Tesla is about 12 to 18 months away from volume production of the 4680 cells,” while “urging suppliers to accelerate supply.” Here, the battery supply partner mainly refers to Panasonic, which has a love-hate relationship with Tesla.Currently, Panasonic is setting up a testing production line for the 4680 battery in order to proceed with production as planned. Yasuaki Takamoto, the head of Panasonic’s power battery department, stated in an interview that “producing these larger batteries requires improving the technology by one or two levels, otherwise safety issues may arise”. However, Panasonic’s well-tested safety management system “has an advantage in this regard”. No mention was made of “production difficulties” or “delayed delivery” issues.

On one hand, the production and delivery of the Model S Plaid+ has not yet arrived; on the other hand, there is currently no indication that Panasonic is having any difficulty with producing the 4680 battery, so Panasonic cannot be blamed for cancelling the Model S Plaid+ for Tesla.

Ram Chandrasekaran, Chief Analyst of Transportation & Mobility at Wood Mackenzie, stated in an interview with Bloomberg in early April that there are “significant technological issues” that need to be resolved for 4680 battery production, and it is not yet certain whether 4680 can be produced smoothly. This not only applies to Panasonic, but also implies that Tesla’s self-built 4680 production line is facing production challenges.

At a European Battery Conference in November 2020, Ma Junlong admitted the challenges of large-scale production of the 4680 battery. At that time, Tesla was already at the “bench-top level” (experimental stage), and planned to soon achieve “pilot-plant level” (test production stage), but “the process of scaling up production would be much more challenging”.

Image: The image is from Wood Mackenzie, Ram Chandrasekaran.At the beginning of this year, Tesla announced its self-built 4680 production line called “Roadrunner” in Fremont. Although it is only a prototype testing line, Tesla expects to reach a production scale of 10 GWh this year! During the year of production at Roadrunner, Tesla aims to solve the problems they face, so as to achieve large-scale production one year later while carrying the tag of a “test line”.

“We are not quite yet at the point where we think the cells are reliable enough to be shipped in cars, but we are getting close to that point. And then we have already ordered most of the equipment for battery production in Berlin and then electric for Austin, as well. So we are really down to the nitty-gritty on this. But overall, I think, we are still quite optimistic about achieving volume production of the 4680 next year.”

At the end of April, although Ma Yilong (Tesla China’s Vice President) stated that the current 4680 had not yet met the standard for installation in vehicles, he still directly ordered a large batch of battery production equipment for the Berlin super factory, which will produce Model Y powered by the 4680 battery in the future. Ma Yilong also expressed optimism that the volume production of the 4680 will begin in 2022 as planned.

Whether for Tesla or Panasonic, there is no indication of any delay in the originally scheduled delivery of the 4680 for Model S Plaid+ in mid-2022. Therefore, it is not true to say “4680 has delayed the Model S Plaid+”. Even if the delivery of the 4680 is delayed, Tesla is unlikely to cancel the Model S Plaid+ version.## What’s the Reason?

If it’s not 4680 related, what caused the cancellation of the Model S Plaid+ version?

Personnel Changes?

Victor Prajapati, who was in charge of Tesla’s 4680 battery production, left the company in January this year and joined Rivian as Director of Manufacturing Engineering. During the Model 3 “Production Hell” period, Victor was responsible for coordinating with Panasonic to accelerate battery supply. He also helped Tesla establish the battery manufacturing engineering department and led the acquisition of Canadian battery company Hibar.

The “Roadrunner” 4680 prototype test production line project in Fremont mentioned earlier is closely related to Victor. His departure early this year may have impacted the progress of Tesla’s own 4680 cell production project.

Giga Press Not to Blame Either

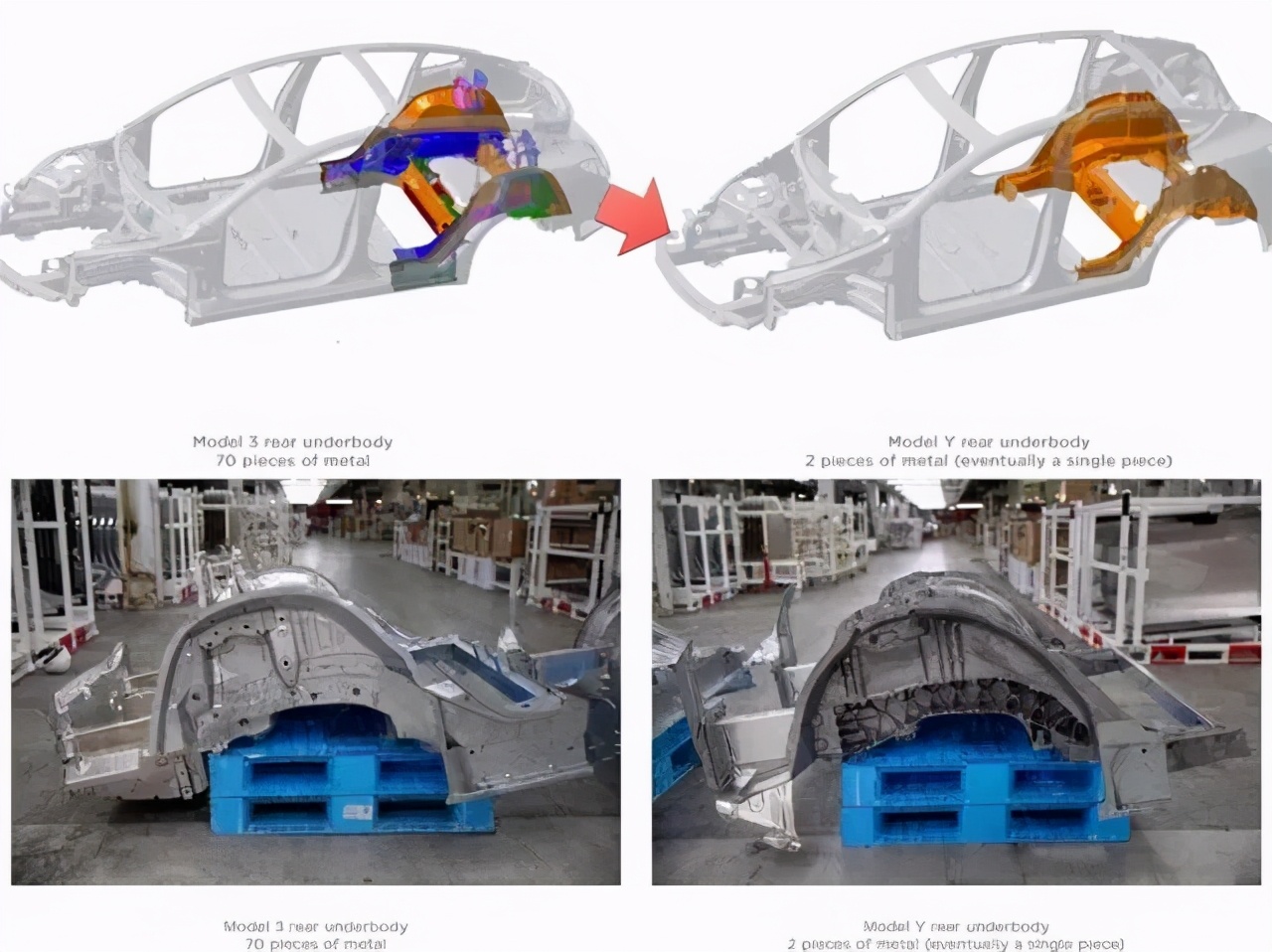

As we all know, Tesla wants to use the world’s largest die-casting machine “Giga Press” for its vehicles. Ma Yilong’s goal is to divide the entire vehicle body into three parts: front, middle (chassis), and rear, and directly perform one-piece die-casting, saving time, effort, and money.

Foreign netizens have revealed that the new S/X version will adopt an integrated die-casting process, and the flagship will use new technology. This is actually very normal. However, many foreign netizens speculated that the cancellation of the Model S Plaid+ version may be due to the low production efficiency of “Giga Press”.

Currently, the Fremont factory in California has two Giga Presses, the first of which began to be used last year, and the second one is also basically assembled. However, the die-casting workshop had an unexpected fire in March this year, which caused a stoppage for some time.

The first Giga Press at the Austin factory in Texas has been almost assembled, with two more still in the process of being installed. The Austin factory plans to finish by the end of this year, and according to the plan, they will produce Cybertruck, Semi, Model 3 and Model Y.

The first Giga Press at the Austin factory in Texas has been almost assembled, with two more still in the process of being installed. The Austin factory plans to finish by the end of this year, and according to the plan, they will produce Cybertruck, Semi, Model 3 and Model Y.

Currently, neither the Shanghai nor the German factory is responsible for the production of the S/X series, let alone any impact. The key point is that the delivery time for the Model S Plaid+ is the middle of next year, and it seems that these two factories in North America have not affected the significant “bugs” that may appear after a year.

Under the “oppression” of the “monster” Giga Press, a special proportion of aluminum alloy material is required, which can meet both the production process and the strength requirements after forming. As early as 2016, Ma Yilong dug up the aluminum alloy material master, Charles Kuehmann. In February last year, he invented a new aluminum alloy for Tesla and applied for a patent. This new aluminum alloy can maintain high yield strength and high conductivity, and can still be used for die-casting electric vehicle parts.

Does this new alloy have insufficient strength after casting?

In fact, at the beginning of this year, the Fremont factory started quietly delivering the Model Y with a one-piece cast body, and in May, the Austin factory successfully cast an entire front body. This indicates that this unnamed new aluminum alloy basically meets various requirements for body manufacturing and still has more than a year to be fine-tuned.

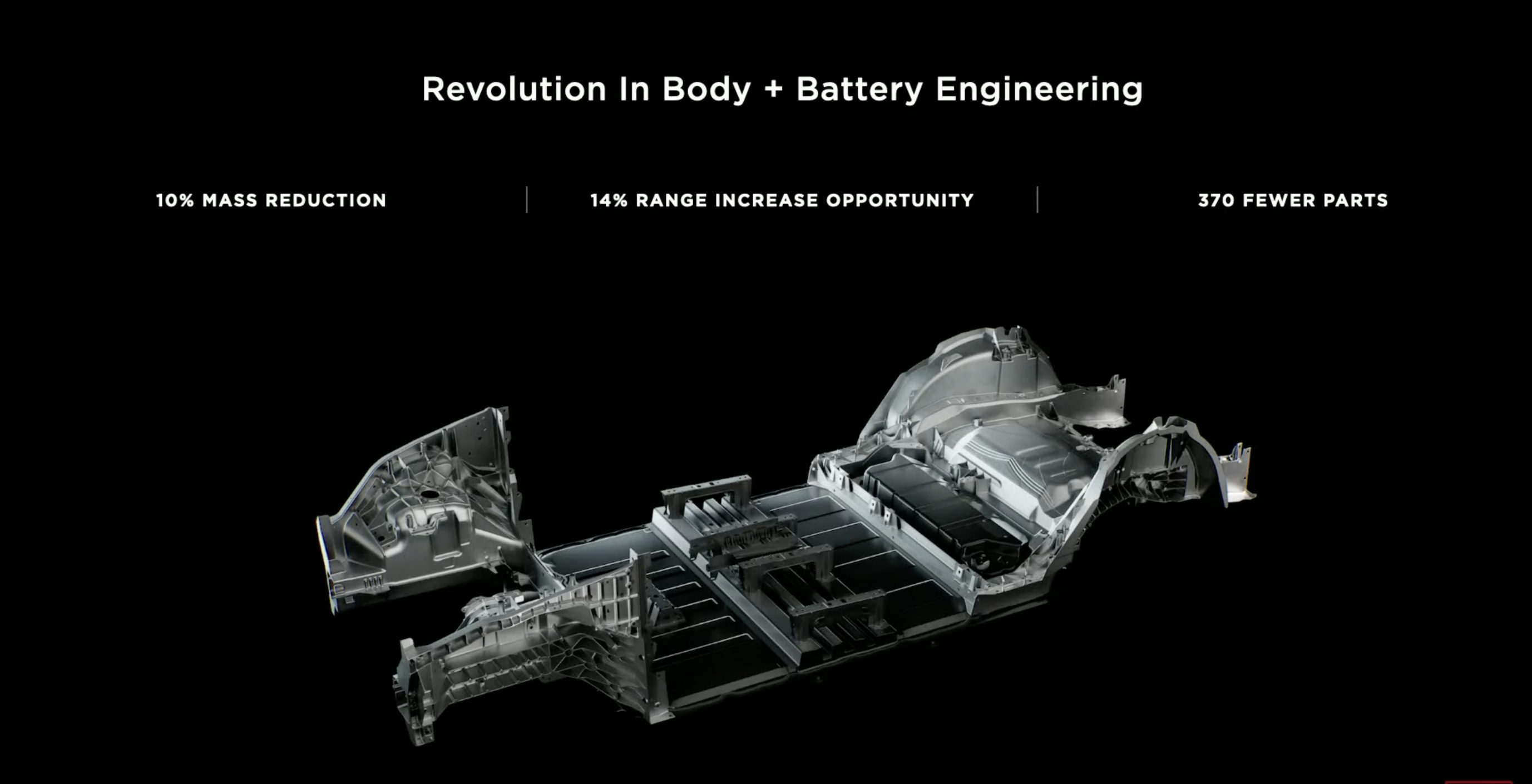

Did CTC’s new packaging technology get hit?Last year, in addition to the 4680 battery, Tesla’s Battery Day also introduced the CTC (Cell to Chassis) battery packaging technology. Therefore, it is assumed that CTC technology and the 4680 battery will be mass-produced in the Model S Plaid+ scheduled to be delivered next year. Simply put, CTC technology arranges the batteries in a cell-like vertical structure that integrates with the chassis to bear the load.

_20210611113732.png)

However, there is currently no successful example of mass-producing CTC technology. Thus, it’s suspected that CTC technology could pose difficulties for the production of Model S Plaid+. Due to the 4680 cell’s larger demand for heat dissipation, the CTC packaging could restrict the battery’s heat dissipation, thus requiring advanced cooling systems. However, we still do not know how this cooling technology will be implemented.

If Tesla plans to adopt several major innovative technologies, including integrated casting, new aluminum alloys, CTC, and the 4680 cell on the Model S Plaid+ chassis, any problem encountered could cause a delay in the delivery of Model S Plaid+. Nonetheless, it’s still uncertain to pronounce the Model S Plaid+’s verdict.

Is it because of the chip shortage?

As everyone knows, the semiconductor supply chain has been weak this year, causing global chip shortages, which have affected almost all OEMs.

The central control of Tesla’s redesigned Model S/X is powered by an AMD Ryzen series processor and an AMD Navi 23 RDNA 2 GPU. Some people speculate that this may be the reason for canceling the Model S Plaid+ version. However, these semiconductor chips are not only installed in the Model S Plaid+, but also in the regular version, so it is not feasible.

SpeculationWe can see that the Model S Plaid+ version, originally priced at about $140,000, had an acceleration time of less than 1.99 seconds for 0-60 mph (although I mentioned earlier that this data was exaggerated); and as Tesla’s top-of-the-line sports car, the $200,000 Roadster 2 had a legitimate acceleration time of 1.9 seconds for 0-60 mph.

A awkward situation arises, as the Roadster 2’s acceleration and even range performance is not significantly different from the Model S Plaid+, especially after it reaches above 2 seconds, where improvement becomes more difficult. The cancellation of the Model S Plaid+ may be to make way for the Roadster 2.

Of course, we also have to mention Tesla’s upcoming competitor, Lucid. Last year, in order to compete with the Lucid Air, Ma Yilong lowered the prices of old products, such as the Model S Plaid+, even surpassing the Lucid Air Dream Edition in PPT parameters. After the competition, Ma Yilong may have found it a bit too much, considering that the Roadster 2 would also need to be sold, and the acceleration of the next generation S series would still need to be refreshed, which would require him to lower the difficulty. But now it is clear that the Lucid Air will lead the Model S Plaid in terms of range.

Finally

Actually, by this point, I’m almost “out of my mind”.

Ma Yilong forcefully explained that the Plaid version is good enough and that a range of over 400 miles (about 640 kilometers) is “unnecessary”, which is obviously unsatisfactory.

But after observing the technologies that Tesla is currently using or will soon use, and even the personnel changes, I’ve come to the conclusion that these things are far from killing a car model that won’t even be delivered until next year.

As for why Ma Yilong suddenly cancelled the Model S Plaid+, I really want to ask him in person and get a clear and straightforward answer.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.